Of all the known construction options, the most inexpensive and reliable is the construction of a wooden house, bathhouse or utility structure, the basis of which will be a wooden frame erected on a columnar foundation made of blocks. It should be noted that this type of foundation does not imply the use of blocks or other reinforced concrete analogues that differ in significant mass. Let's talk about how to make your own block foundation from elements whose mass does not exceed thirty kilograms.

2. Site preparation: marking and excavation work.

Clear the area from outsiders, uproot trees and bushes.

If the soil is loamy, you should also take care of a drainage system that drains melt and rainwater from the foundation. Make markings using a cord and pegs. But before excavating the soil, you need to decide what kind of foundation will be made: strip or columnar. It all depends on the type of structure. A heavy structure requires a strip structure, but a lightweight structure, such as a frame house or a summer cottage, will need a columnar base. Let's consider the construction technology of both options.

3. Columnar foundation made of blocks.

The principle of such a structure is that pillars are made along the perimeter of the marking at a distance of no more than 1.5 m from each other; by the way, they are easiest to make from Besser blocks. To do this, a hole is dug at each marked point.

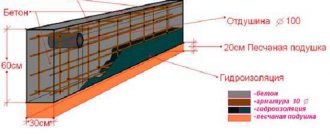

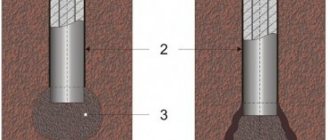

In the recessed version, it resembles a truncated cone, 1.5 - 2 m deep. A cushion of crushed stone and sand at least 15 cm thick is poured onto the bottom, compacted, then blocks are laid on the cement mortar, 2 in one row and each subsequent one placed perpendicular to the previous one . Then the excavated soil is poured back into the funnel, the block bordering the ground is waterproofed (treated with bitumen, roofing material is laid on top). Then the ground part of the pillar is erected, usually 2 more rows, and a concrete blind area on a slope so that water does not collect.

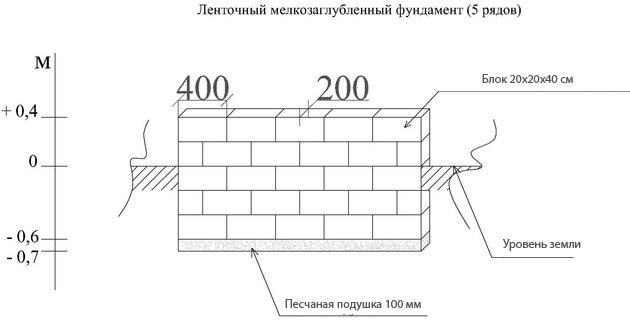

In the shallow-depth version, the pit looks like a square, 50-60 cm deep, and is completely covered with a sand cushion, on which the first row of blocks is installed, deepening almost flush with the surface. All other steps are repeated. It is worth noting that if in the case of a deep pillar the blind area can be lowered (although it is still better to do so), then here it is absolutely necessary. Next, a timber frame, the so-called grillage, is erected on the resulting pillars. It is connected to each other by stiffening ribs and resembles a lattice.

4. Strip foundation made of blocks.

Excavation is carried out along the entire perimeter of the marking, under all load-bearing walls. The depth will depend on the presence or absence of a basement, the soil, and groundwater.

If there is no need for a basement, then on sandstones it is enough to go 50-60 cm deep. If a basement is needed and the house is massive, it is better to make a trench 20 cm below the freezing level and thoroughly waterproof the foundation. Then suitable melt waters will not be dangerous. In general, drainage systems should be considered on sandy soils. It is worth saying that on unstable heaving soils, such as clay and loamy soils, it is better to build a monolithic concrete slab foundation, but if the soil is stable, then a less expensive and simpler option is a strip of blocks. A drainage cushion of sand and crushed stone or simply sand is poured into the finished trench, compacted and a foundation is erected. Masonry work is carried out in the same way as with conventional brickwork. The cement mortar is applied to the base and side edges of the block so that there are no gaps or voids left. First of all, the blocks are laid in corners and intersections; a building level is always used for control, and only after making sure that everything is correct can you pull the cord and continue along it. After the cement “sets,” it is necessary to joint the joints in order to protect them from moisture and destruction. You can make a monolithic belt at the base of the foundation; it will help distribute the load evenly and give more strength. To do this, you need to build formwork about 30 cm high (from boards or plywood), fill it with concrete mixture, and smooth the surface. Since the layer thickness is small, you should try to complete the work in one day so that the hardening time is the same, in order to avoid uneven adhesion. After a couple of weeks, lay sheets of roofing felt overlapping and you can lay the blocks.

Installation of blocks

No different from laying ordinary bricks. However, installation of reinforced concrete products requires compliance with certain rules.

- During installation, a seam is created for applying the solution. Its dimensions range from 10 to 12 cm.

- To increase the strength of the walls, the structure is reinforced with reinforcement.

- The laying of blocks begins from the corners to achieve maximum accuracy of the parameters specified in the design documentation.

- If it is necessary to leave voids, then leave a board in their place. This way the solution will not get into them. The board necessarily moves with the appearance of a new block layer.

- The creation of basement walls uses a similar technology. But the top row is tied to the base of the building or the floor.

Reference. To work with concrete products, a specific set of tools and solution are prepared. The mixture is made from the components specified by the manufacturer.

5.Waterproofing.

The finished foundation is covered with waterproofing from the inside, this is especially true if a basement is planned. First of all, seams need protection from water and moisture. For these purposes you can use

- bitumen compounds;

- rubber compounds;

- special impregnations;

- water-repellent plaster.

If necessary, it is possible to perform thermal insulation by installing insulation sheets on the outside (penoplex, technoplex, etc.).

In conclusion, I would like to note that building a foundation from blocks with your own hands is a completely feasible task. The main thing is careful preparation, adherence to the sequence of work and high-quality material.

Construction of houses

A block foundation has all the advantages of reinforced concrete, but is built much faster than a monolithic strip foundation. After its construction, you can immediately begin the next stages of construction without waiting for it to harden. The slabs are produced in different sizes, including those specifically for private construction, the installation of which does not require the use of equipment.

What are foundation blocks?

These are the building elements that form the prefabricated foundation of a building. The most popular are FBS concrete blocks produced at a reinforced concrete plant, which ensures compliance with the requirements for high quality products: precise proportions of mixture ingredients, reinforcement, pouring high-quality concrete and further vibrocompression for maximum density, steaming in special chambers and final hardening of the concrete.

It is theoretically possible to make them yourself, but in practice this results in a large expenditure of time and money, as a result of which the price of the blocks will be higher than the factory price. But the cost of a prefabricated foundation is already higher than the cost of a monolithic one. Today, they are produced by a large number of factories; due to high competition, the price of foundation blocks is not too high, and if you purchase a large volume, you can reduce it even further.

But when choosing blocks, you need to focus not on the price, but, first of all, on the load that they can withstand. For each type of FBS, standards are prescribed in GOST, and blocks manufactured in factories must undergo quality checks. In addition, additional additives are added to the concrete mixture to improve their quality.

- Frost resistance is achieved with special additives. Such blocks can withstand significant temperature changes. They should be chosen for regions with harsh winters.

- Resistance to acidic environments increases with the addition of granite crushed stone to concrete. As can be seen from the characteristics, they are adapted for use on acidic soils.

- Variety of sizes of products produced at the plant. For construction by large developers who have special equipment, large-sized blocks are produced, and small-sized ones are provided for private builders.

But, despite all the improvements, foundation blocks have disadvantages:

- high price. The foundation made from them is at least 30% more expensive than a monolithic one;

- the need for a double layer of waterproofing;

- The seams that the masonry has are very susceptible to external factors, and therefore require insulation.

Features and Specifications

If you decide to use blocks and make a foundation out of them, then try to carefully study all the characteristics of the material, and then analyze all the advantages and disadvantages.

Let's look at the performance characteristics of block building material:

- Its length is 40 cm.

- The width is 20 cm.

- The height does not exceed 20 cm.

- One block weighs from 33 to 38 kg.

- The specific gravity ranges from 1.66 to 2.21 t/m3.

- Thermal conductivity coefficient reading is no more than 1.14 W/mK.

- Frost resistance is 50 cycles and has an index of F50.

Please note that foundation blocks of size 20x20x40, which are offered by manufacturers, actually have slightly different dimensions of 395x195x190 mm. To speed up calculation operations, manufacturers use larger dimensions.

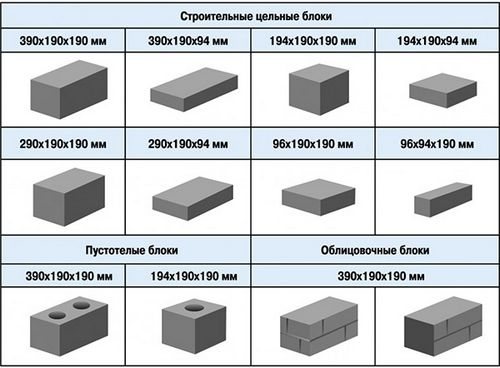

The presence of a cavity in the block is an important design feature of manufactured products in different variations:

- Monolithic blocks are used for foundations, as well as for the construction of basements and basements.

- Products with voids are perfect for constructing partitions between rooms, as well as for lintels and walls.

Block products have many advantages:

There is no need to use specialized construction equipment to lift the blocks.- There is no need to hire a large team of builders; a few assistants will suffice.

- There is no need to assemble formwork when constructing a columnar or strip base.

- Masonry can be accelerated by reducing the duration of the construction cycle.

- You can build at any time of the year, and there is no connection to temperature or weather conditions.

- The load capacity is acceptable and makes it possible to bear the weight of the structure.

- Moderate cost, which reduces the overall cost of the construction operation.

And there are a few minor drawbacks:

- The consumption of cement mixture has been increased.

- Additional insulation is required, which is associated with reduced thermal insulation characteristics.

- The material is susceptible to moisture, so you will have to spend money on good waterproofing.

Please note that the operational properties and technical characteristics of these blocks make it possible to use them for the construction of foundations for low-rise buildings, as well as for creating a basement.

How to make your own foundation from blocks measuring 20x20x40 cm

Using blocks to build a foundation allows you to carry out work quickly and efficiently. In private construction, for this purpose, products with dimensions of 20x20x40 cm, smooth walls and a weight of no more than 32 kg are purchased. The easiest way to lay masonry from such blocks is to do it yourself; there is no need to use special lifting equipment. The construction technology is simple at all stages: from drawing up a drawing to assembly, it is enough to follow simple rules. The reliability of the foundation directly depends on the quality of building materials.

Features and advantages of 20x20x40 blocks

A distinctive characteristic of these masonry products is their size: the length is twice the width and height. For foundation work, exclusively solid concrete blocks with a density of at least 1500 kg/m3 are used. The material plays an important role: options with solid fractional filler can withstand increased loads; hollow core, expanded clay or cellular are not suitable for the construction of a load-bearing base, but can be used as insulation for internal basement or basement walls. If it is necessary to lay complex communications, it is advisable to make a foundation from FBV (with a cutout).

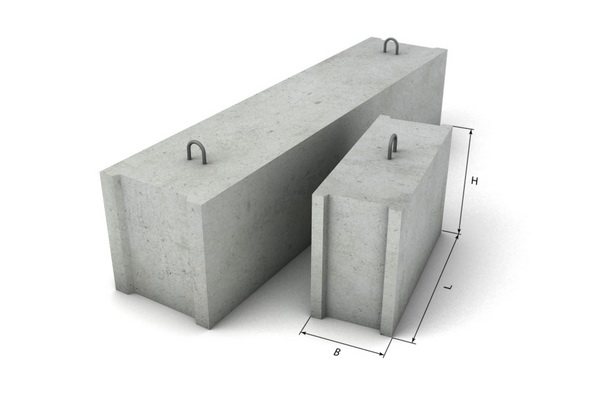

Blocks used

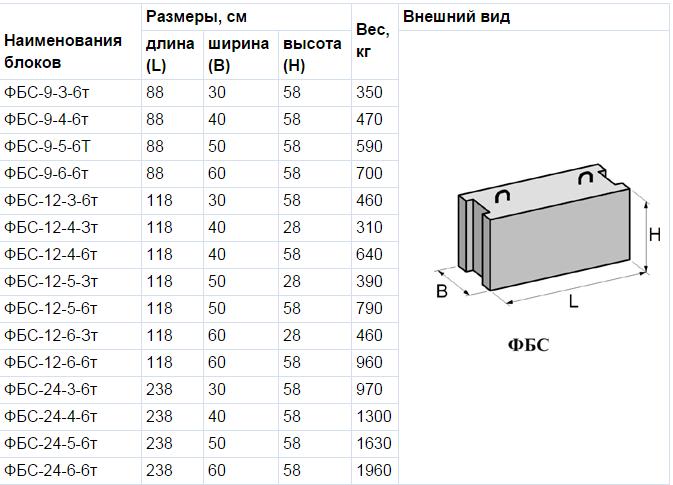

Block structures used to create foundations are marked FBS (foundation building blocks). Their manufacturing technology is regulated by the provisions of GOST No. 13579-58. According to GOST standards, concrete of a grade not lower than M-100 must be used to create blocks. The FBS grid of standard sizes is quite wide.

There are large-sized reinforced concrete structures designed for mechanized installation using a construction crane (their weight can reach two tons). Such blocks must be reinforced with a reinforcement cage made of hot-rolled A3 reinforcement. The diameter of the reinforcement used depends on the size of the FBS; it can vary between 9-15 mm.

Expert advice! Large-sized reinforced concrete FBS can be used for arranging slab and strip foundations for massive brick structures.

You can see the dimensional grid of reinforced concrete FBS in Table 1.1

Large-sized FBS are used extremely rarely in small-scale construction, since their weight does not allow manual laying of the foundation - for this you need to rent a construction crane, which negates the main advantage of a columnar foundation made of blocks - its low cost.

For manual masonry, FBS is produced from expanded clay concrete, a lightweight material with high heat-resistant characteristics.

The most common in private construction is FBS 20*20*40 cm, which weighs only 32 kilograms.

Technical characteristics of the FBS 20*20*40 block:

- Nominal strength - 150 kg/sq.cm;

- Dimensions - 200*200*400 millimeters;

- Frost resistance - at least 15 cycles;

- Moisture absorption up to 15% of volume;

- Maximum thermal conductivity is 1.16 W/mK.

Among the advantages of using FBS of this size, one can highlight the high speed of foundation construction - the laying of blocks is carried out using a special adhesive composition or sand-cement mortar, and all work is done with your own hands, without the use of special construction equipment.

The key disadvantage is the low hydrophobicity of the material - expanded clay concrete FBS has a porous structure, as a result of which it absorbs moisture from the soil like a sponge (up to 15% of its mass), which in the long term leads to the destruction of the block.

Expert advice! This disadvantage is eliminated by waterproofing FBS, which must be carried out without fail during the construction of the foundation.

Advantages of a block base

The advantages of concrete blocks 20x20x40 include:

- Simple masonry technology. There is no need for formwork, products with this size are easier to level, errors are practically eliminated.

- Less dependence on weather conditions: it is advisable to assemble a foundation from concrete blocks at above-zero temperatures, but there is no need to compact the solution, heat it up during a sudden cold snap, or constantly moisten the poured monolith in hot weather.

- Increased strength and durability of the base.

- Affordable cost of foundation blocks, low installation costs.

- High precision of geometric shapes, which in turn minimizes the consumption of masonry mortar and simplifies the process of waterproofing and finishing.

- Environmental friendliness and compliance with sanitary standards.

It should be noted that these advantages appear only when purchasing high-quality foundation blocks. Wall or hollow products are only suitable for temporary panel sheds; experts do not recommend buying them.

How to determine the weight of a concrete block

Foundation structure

To find out how much a concrete block weighs, you need to refer to the manufacturer’s documentation. The mass of the material also needs to be known to control its quality, because the density of concrete cannot be determined outside the laboratory, and weight is an indicator that indicates this value.

Example: passport for concrete products, item 9 - product weight

Concrete blocks are used for the construction of walls in low-rise construction, as a component of walls in monolithic high-rise buildings, for building foundations, and fences. Standards regulate the strength characteristics of concrete products, as well as dimensions and weight.

Concrete structures

They are classified:

- to size;

- in shape (with voids, with recesses and grooves);

- by composition (made of heavy or light concrete, reinforced concrete, wood-concrete and others).

Types of concrete products

Note: knowing the weight of a building element, you can calculate its density and compare it with that indicated in the accompanying documentation. Thus, the quality of the building material is checked at the site.

FBS

A guide to building a foundation out of blocks with your own hands

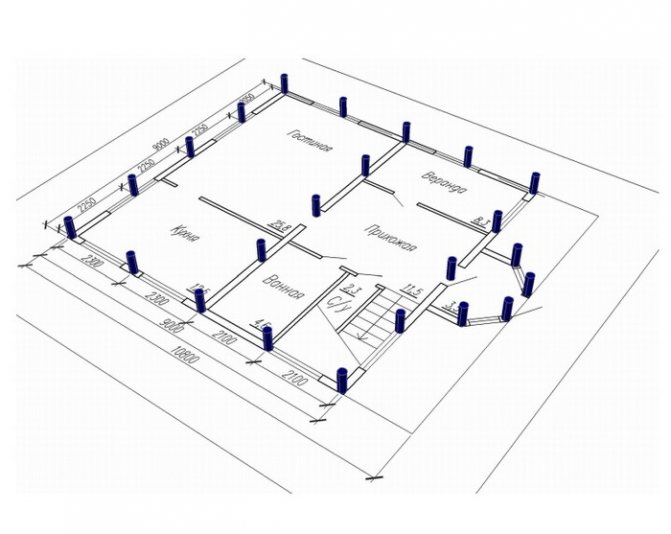

Step-by-step instructions for building a columnar foundation include the following steps:

- Drawing up a drawing taking into account the placement of square supports measuring 40x40 cm (two blocks laid side by side) at the corners and perimeter of load-bearing walls with a step of at least 2 m.

- Marking the site according to the diagram, excavation work. The depth of the filling is at least 30-40 cm higher than the calculated one (for filling the pillow).

- Filling and compacting 10 cm of gravel and at least 15 cm of sand; to simplify the process, it is recommended to water the pillow.

- Placement of support platforms (recommended step). To reduce the impact of groundwater on foundation blocks, many people place roofing felt, folded polyethylene or paving slabs underneath. But experienced builders advise making reinforced platforms from lean concrete 60x60 cm in size and about 50-70 in height. This complicates the process, but reduces the consumption of blocks and gives the building stability; when building walls from heavy materials, this stage becomes mandatory.

- Laying 20x20x40 blocks: two pieces per row with an overlap on the cement mortar. The proportions of the masonry mixture depend on the soil parameters; if there is a risk of flooding, the binder is mixed with sand in a ratio of 1:2, under normal conditions - 1:3. At this stage, it is extremely important to achieve the same location of all supports; the reliability of the columnar foundation depends on this. It's easier to do this with ropes and a water level.

- Waterproofing the upper section of the base.

- Organization of the grillage: tying with timber or channel. 20x20x40 blocks are not designed for heavy weight; for this reason, they are not suitable for pouring a concrete grillage.

It is important to remember that a prefabricated columnar foundation is only suitable for the construction of lightweight buildings on stable soils. For those that float heavily, it is better to choose a different type of base. The step-by-step instructions for the construction of prefabricated strip foundations largely coincide with those indicated above, the differences relate to excavation work (a continuous trench is dug, not rectangular sections), and the masonry technology also changes slightly. In particular:

- Installation of foundation blocks begins from the corner or intersection of adjacent load-bearing walls according to the diagram. Markings should be made in advance; deviations along the diagonal or perimeter should not exceed 20 mm. The level of the bottom row is checked with particular care.

- When building a foundation for heavy buildings, the rows are additionally reinforced: a metal mesh is placed in the masonry joints.

- The blocks are placed with a mandatory offset of 1/2, similar to brickwork. The formation of a continuous vertical seam between joints is unacceptable.

- The requirements for waterproofing protection are increasing; the block foundation is covered on top with at least two layers of rolled materials; in areas with a risk of flooding, it makes sense to coat the basement walls with bitumen.

- A blind area is organized around the perimeter of the base.

- In a strip foundation made of blocks, by analogy with monolithic structures, holes for laying water and sewer pipes and other communications are thought out and organized in advance. Drilling and punching through already laid walls is highly discouraged.

Nuances of technology, general recommendations

The main requirement is to tie the blocks correctly, which means changing the masonry pattern by 90° in each subsequent row when building a columnar foundation or shifting it by half when constructing a strip. Calculating the parameters of the foundation and the required amount of material will help you avoid many mistakes, which implies a preliminary analysis of the condition of the soil (and not in the process of digging trenches, as many summer residents do). Products from the same manufacturer are used, with the same characteristics.

The technology for constructing a foundation from such blocks is formless, which can significantly reduce the time required to complete the work. But if the columns are too high, it is advisable to use supports (supports similar to those supporting shields). This will eliminate the risk of arbitrary displacement of foundation structures during the hardening of the fresh mortar. Some developers claim that adhesion by masonry mixtures is optional, and that pillars or strips of blocks will stand securely under their own weight, but in practice this is only permissible when erecting temporary buildings.

To save money, you can make foundation blocks with your own hands. The solution is mixed from Portland cement, quartz sand and granite crushed stone in a ratio of 1:3.5:2.5, poured into molds measuring 20x20x40, where it is kept for at least 3 days. But this method takes a lot of time, and it is difficult to achieve factory quality. Blocks made on your own are suitable for laying no earlier than 3 weeks after removal from the molds.

DIY installation

To make a concrete base with your own hands, it is better to choose blocks 20 by 20 by 40 cm

A columnar foundation made of blocks is performed in the same way as for other materials. The first thing you need to do is make the calculations and put all the necessary marks. Worth considering. What should be located in all corners and intersections of the walls. The distance from one pillar to another should not exceed 3 meters. If this standard is not met, deformation of the structure may occur.

To make a concrete base with your own hands, it is better to choose blocks 20 by 20 by 40 cm. Plus, you can use solid or hollow types. All structural parts are fastened together with cement mortar.

Attention! If you are constructing a light building, then you can not use mortar, but simply lay the slabs one on top.

When installing concrete, fasten the block elements in a certain sequence. This base is resistant to high load volumes. This is due to the presence of a grillage in the structure, which distributes the pressure between the piles. You can make it with your own hands in the following ways:

- By combining the pile heads to form slabs;

- The base where the connection occurs between adjacent piles.

Attention! The best option is to create a monolithic grillage made of reinforced concrete. This type is highly practical and easily excitable.

The final stage is the installation of waterproofing and laying the timber. These are very necessary processes, so let's take a closer look at them.

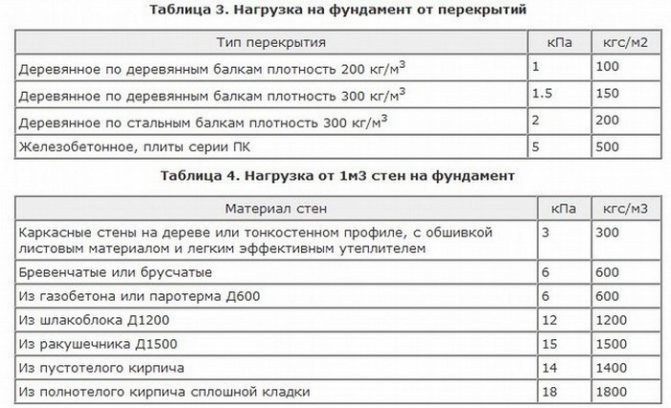

Calculating the load

A necessary step for doing the construction of a concrete foundation with your own hands is to carry out calculations of its load capacity

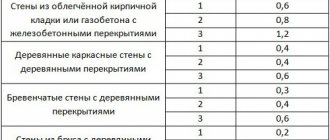

A necessary step for constructing a concrete foundation with your own hands is to carry out calculations of its load capacity at different seasons of the year. This need arises due to the possibility of destruction due to the large weight of buildings. So, if you are planning to install a small room, then a columnar base is ideal for you.

How to determine the magnitude of the load? To do this, you need to take into account the maximum load level per 1 cubic meter. cm, which is equal to 0.5 kg. It is worth considering that such indications are applicable to peat or dried areas. If calculations show that the pressure of your building is within the established framework, then you can safely install such a foundation with your own hands.

Attention! When performing such mathematical operations, you need to take into account the following indicators: all values of the masses of the building, furniture, foundation, snow and wind.

You will find most of these values in your project, which should have all the data about the peculiarities of the climatic characteristics in your region. In the case when you carry out all the installation work yourself, then the calculations must be done by yourself. It is worth considering that it is more comfortable and reliable to entrust all the work to specialists, since the stability and durability of the structure depends on the correct determination of the values.

Foundation for a house made of FBS blocks

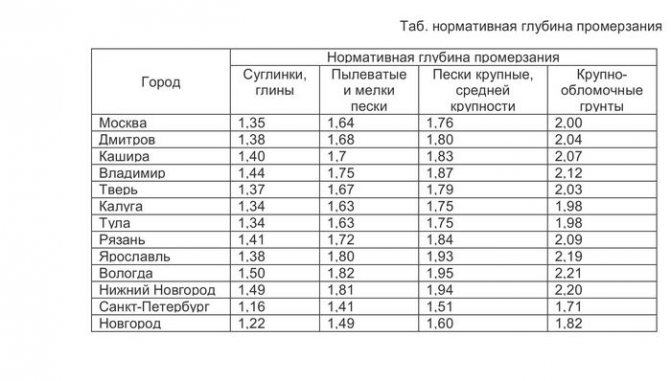

Determining the level of freezing of soil and surface water

This value is relevant for calculating the depth of foundation laying

This value is relevant for calculating the foundation laying depth. Such figures can be easily found in reference materials. Next, you should adhere to the basic rule that the concrete foundation should be located 0.4 meters lower than the freezing level of the ground.

Attention! If the level of soil freezing reaches half a meter, then the foundation of the building should be laid to a depth of 0.9 meters.

In addition to this factor, during construction work it is necessary to take into account where surface water flows. There is a requirement: the higher the water flow, the lower the structure should be laid. So, for example, if a piece of land is very saturated with surface water, then the foundation can sink two meters.

We carry out calculations of materials

In order to find out the number of pillars for building a foundation with your own hands, you should take into account some data

Having received the above data, you can begin to determine how much materials you will need for this work. This task should be performed based on the volume of loads. So, in order to find out the number of pillars to reproduce the base with your own hands, you should consider the following data:

- The post must be installed at all angles of the outer part of the building;

- At each connection of the internal partition;

- The distance between them should vary from 1.5 to 2 meters;

- The height should be 15 cm higher than the ground level. This standard is necessary for the future installation of a grillage on them.

Attention! You should take into account the sand cushion, the ingredients for the solution and materials for waterproofing.

Territory marking

We set the markings of the pillars, which must be identical to the project plan

When performing construction work on constructing a concrete foundation, you should follow the following step-by-step instructions:

- We clear the area from the top layer of soil, maintaining a depth of 15 cm. You can also rid the area under the house of flora.

- We level the area;

- Next, we set the markings of the pillars, which should be identical to the project plan. It is worth considering that you can use fittings or pipe scraps, which need to be hammered at the designated points.

- We check the compliance of all sizes and angles. When performing all actions, you should maintain a distance between objects of 1.5 - 2 meters.

hole drill

It is worth noting that this construction task is performed with a special apparatus - a drill

The next stage of work is the creation of holes for the blocks. It is worth noting that this construction task is performed with a special apparatus - a drill, and the dimensions of the recesses must be wider than the concrete slabs, since waterproofing will be performed. For shallow depths, the value must be increased by 15 cm on each side.

Attention! If the depth exceeds the meter mark, the hole needs to be made wider. So that plastering can be done easily. After completing this process, you need to compact the earth.

Laying blocks into pillars

The next step is to lay out the blocks on a viscous concrete solution. Please note that it is constantly necessary to monitor the construction of pillars vertically, because it will be difficult and very expensive to correct later. To perform this process correctly, you need to use tools such as a level, plumb line and thread.

Attention! If the height of the pillar is more than a meter, its installation must be done using formwork.

Waterproofing

To increase the strength of the future building, you need to perform sealing

To increase the strength of the future building, it is necessary to seal all joints in the structure. This action can be performed using mastic, film or membrane. When using mastic, you need to wait for it to dry completely and then continue working. This standard will ensure that the integrity of the building is not lost.

Attention! The void between the base and the walls of the well must be filled with earth, and then compacted.

Columnar foundation made of blocks - where to use them

Of all the known construction options, the most inexpensive and reliable is the construction of a wooden house, bathhouse or utility structure, the basis of which will be a wooden frame erected on a columnar foundation made of blocks. It should be noted that this type of foundation does not imply the use of blocks or other reinforced concrete analogues that differ in significant mass. Let's talk about how to make your own block foundation from elements whose mass does not exceed thirty kilograms.

Construction technology and important points when constructing the foundation

When constructing a columnar foundation, it is important to consider the following nuances:

- maintain a distance between block supports of 1.3 to 3 m;

- ensure a distance from the soil level to the upper plane of the support of 0.3-0.6 m;

- maintain the thickness of the damping sand and gravel bedding at a level of 15-20 cm;

- fill the space between the supports and the soil with sand and crushed stone.

- calculate the load capacity of the base, guaranteeing the stability of the structure.

The technology according to which a columnar foundation is erected or a strip foundation is constructed from 20x20x40 blocks involves the following steps:

To prevent mechanical damage and distortion of the structure, bricks or load-bearing wall blocks must not be installed on the pillars.

- Carrying out the necessary calculations.

- Determining the need for building materials.

- Preparatory activities.

- Construction site marking.

- Soil extraction.

- Filling the pillow.

- Laying blocks.

- Waterproofing works.

Let us dwell on the features of performing individual stages.

Blocks for columnar foundation

For this purpose, block material is used in the form of monolithic elements cast on a vibrating machine or press from a concrete mass of m100 - 150.

You should not try to make blocks yourself - purchasing them is much easier and cheaper. Moreover, you will need no more than five dozen pieces for the foundation.

To construct a columnar foundation made of blocks, elements with dimensions of 20 x 20 x 40 cm are used. And there are reasons for this:

- the parameters of the block indicate a small mass of material. Taking into account the filling component used in the manufacture, the weight of one stone can be 30 – 32 kg. This makes it possible to carry out installation work without the use of special equipment;

- A brick press and standard molds are used to make blocks. The result is a cast block, which is significantly stronger in strength than analogues produced by handicraft methods;

- the successful dimensions of the material create the opportunity for simple laying out of foundation columns and leveling the plane without trimming the supporting tops.

- Roughness is allowed on the block surface, but it must remain smooth and not have chipped areas, cracks, growths and potholes;

- void spaces in the block are not allowed;

- After manufacturing, the block must gain its design strength within four weeks.

To check the quality and strength, lightly hit the block with a hammer - it should bounce off. A high-quality block will not receive damage from a fall from a meter height.

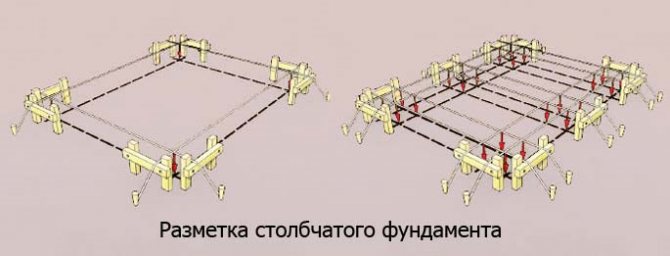

We build a columnar foundation from foundation blocks

Like any construction on a summer cottage, a block version of the foundation can be built several hours a day if you have free time and physical strength. The work is not hard and does not require a huge amount of digging of trenches or foundation pits. But there is one feature - the construction of a columnar foundation, first of all, will require very serious preparatory work. It is necessary to lay out the blocks, install beacons and landmarks along which the material will be laid on the cement mortar. The easiest way is to do this delicate part of the work right away, while the necessary details of how to mark the area are fresh in your memory. See how to seal and level a cushion under a columnar foundation of 20x20x40 blocks:

Two words about building blocks for a columnar foundation

For the construction of the foundation, in most cases, monolithic stones are used, cast on a vibrating machine or press from concrete grade M100-150. The easiest and cheapest way is to buy such material than to try to make it yourself. It is relatively inexpensive; during the construction of a summer house or utility room, you can buy leftover material from the owners, especially since you won’t need much of it, 40-50 pieces.

A 20x20 block with a length of 40 cm is most often used for the construction of columnar foundations for quite objective reasons:

- The size of the block determines its light weight. Depending on the filler used, the weight of one stone ranges from 30 to 32 kg, which makes it relatively easy to lift and lay out blocks without additional tools and devices;

- Most often, blocks are made on vibrating presses, in standard forms for foam concrete or cinder block. In this case, a cast stone is obtained with an initial strength that is significantly higher than an artisanal concrete casting;

- The successful proportions of the material make it relatively easy to fold the foundation column and level the plane, without using a grinder to trim the top of the support.

Advice! When purchasing material, check all the blocks with a prepared template in the form of a plywood frame with a calibrated hole. Often there are prefabricated batches made in different shapes and differing in size by up to 5 mm.

Marking the site and preparing the cushion for columnar supports

At the initial stage of preparation, you will need to correctly mark the installation points of the columnar foundation supports. For this purpose, the dimensions and shape of the frame of the dressing timber grillage, which will rest on the pillars, are used. Based on the project sketch, it is necessary to calculate the exact dimensions of the midline of the beam and transfer it to the ground using cords. In addition to observing the lengths of the sides of the future foundation with millimeter accuracy, you will need to check that a right angle is maintained between the adjacent sides.

The result should be four main installation points for corner column supports, between which a construction or marking cord will be stretched without sagging. In this case, the stakes on which the thread or cord is attached must be located outside the perimeter of the foundation.

In a similar way, you need to align the position of the marking cord in height so that the plane is perfectly aligned with the horizon.

Important! The intersection points of the midlines should become the centerline of the columnar support of the blocks.

The next step is to prepare the cushions for laying the blocks. It would be more reliable to bury the columnar supports into the ground by 20-25 cm, but in this case you will need to use an additional pair of blocks for each pillar, instead of laying three rows.

If you perform additional soil compaction within a radius of 50 cm around the support, you can get by with a non-buried version of a columnar foundation. In a pit dug to a depth of 30-35 cm, it is necessary to pour two layers of sand with the thickest layer of crushed stone in between. The poured material is carefully compacted layer by layer so that a small layer of spreading sand remains on the surface.

Installation of columnar foundation supports

Laying blocks at the base of a columnar support is carried out using the same technology as laying bricks. High mechanical strength is not required from the masonry mortar; the main thing is that it is plastic, but does not spread on the concrete. The sand base on which the block will be laid is moistened and immediately covered with a thin layer of mortar 1-1.5 cm thick. Blocks can be placed on the concreted layer.

The position of the block must be aligned with the stretched cords and the building level so that the supporting surface is well filled with the solution and there is no blockage along the horizon.

When laying the next pair of blocks, they are turned a quarter turn, thereby ensuring the ligation of the rows. If there is a third row, it also needs to be tied with the bottom pair.

In some cases, craftsmen make a cushion for laying blocks in the form of a concrete screed, which, after preliminary setting of the mortar, is cleaned with a lath and leveled horizontally. In this case, the top layer of sand is not poured onto the cushion, but the masonry mortar is laid directly on the crushed stone with liquid concrete poured over the gravel.

Finishing work and laying of strapping

After the masonry mortar has set, the base of the blocks in the columnar supports is cleaned, the cracks are filled with mortar, plastered and waterproofing is laid. If the pillars are installed correctly along the beacons, without blockages of the supporting surface, you can proceed to tying the foundation with timber.

The wooden frame of the grillage is made in carpentry in advance, most often in the form of two L-shaped elements. The lower part of the corner joint, which will rest on the columnar masonry of blocks, is reinforced with a metal plate. There will be an anchor pin running through a pair of metal flashings, embedded in the seam between the top two blocks.

The two halves of the frame are laid out on supports and centered along the axes of the columnar supports, after which they are connected by overhead plates. The timber is also attached to the intermediate supports with reinforcement, but without plates; the beams are simply tied with soft wire to the upper blocks, or as in the video:

Stage-by-stage execution of work

Step-by-step instructions for constructing a columnar foundation made of blocks are as follows:

Preparation

A plan for the future facility is being prepared, on which the locations for the pillars are marked. As a rule, they are located under each corner section and under the intersection points of the walls. In a straight line, the distance between two posts should not be more than two meters when the design solution includes a grillage made of metal or wood. For a reinforced concrete grillage, a distance between supporting elements of up to three meters is allowed. If this condition is not met, then manifestations of a deformation nature will occur.

What blocks can be used

Depending on the filler, concrete has different characteristics. To make structures lighter, they have voids and cracks. If you are planning a support-column foundation of 20x20x40 cm blocks, products with voids greater than 25% and fillers that reduce the strength of the structural material - sawdust, shell rock, expanded clay - are not recommended.

A hollow block cannot be used.

It is preferable to use posts made of cinder block or ready-mixed concrete without voids. Foam and aerated concrete are prohibited from being used in structures operated underground.

Solid blocks must be used.

The optimal format of concrete wall blocks is 20x20x40 cm. They are laid in the form of square columns 40x40 cm with ligation of each row, which is the minimum acceptable cross-section for prefabricated columnar type foundations.

What are the advantages of such a foundation?

Having certain skills and knowledge in the construction industry, you can build this type of foundation yourself within a few days.

Financial costs for the construction of a simplified foundation of a dozen pillars will not exceed three thousand rubles. But there is one condition here - blocks for a columnar foundation are purchased ready-made for fifty rubles per stone, and almost all work is carried out in-house.

For a small wooden building, you can’t think of a better way to arrange a foundation. The most difficult moment in such work is to maintain the geometry and horizontal levels of the supports.

Construction work is simplified if you have experience in masonry work using brick or cinder block material.

Scope of application of such a base

Such foundations are in most cases used in private construction. They do not have a high load-bearing capacity, which significantly limits their operational potential.

On soils that are not prone to heaving, one-story houses, bathhouses, and buildings for household purposes are erected on a columnar foundation.

If the construction is planned in an area with sandy, rocky or boulder soil, the load-bearing characteristics of the columnar foundation will be sufficient to build a full-fledged house from a log frame or a foam concrete block.

A columnar foundation does not imply the arrangement of a basement. If this criterion is important to you, you should consider the construction of other types of foundations.

You should not build such a foundation in the following cases:

- erecting a large house with heavy walls;

- on soils with a low level of bearing capacity, in areas with moving soils;

- on sites with a natural height difference of more than a meter. In this case, it is necessary to plan the site.