A veranda or terrace is a summer extension to a country or country house. The difference between a veranda and a terrace is that the veranda is a glazed room, and the terrace is open, although the terrace may have a roof. Both rooms are unheated and can be constructed from different materials - wood, brick, concrete, metal structures, etc. However, in any case, the veranda or terrace must be built on a reliable foundation.

If the extension is being built simultaneously with the main building, then there will be no problems if the builders build a foundation for the veranda of the same type as the main foundation and connected to it. Questions arise when the need to add a veranda arises some time after the construction of the main building.

When building a foundation for a terrace, the following circumstances must be taken into account:

- features of the properties of the soils from which the base of the extension is composed, and how they affect the design of the foundations;

- the depth of winter soil freezing in a given region;

- the presence or absence of groundwater, if present - the influence of a high groundwater level (GWL);

- variety of foundation types, the need to choose the most suitable one for specific conditions;

- the need to install a junction point between the new foundation and the existing one, as well as an expansion joint at the junction of the walls of the veranda and the walls of the house.

Selecting a location

It is not practical to arrange a terrace as a recreation area separately from the house. Only as an addition to an artificial pond or swimming pool. But there it is better to make it open (without a roof), and use umbrellas or awnings to protect from the sun.

Making it as a free-standing area with a wooden floor, roof and light fencing is also impractical. In this case, it is better to build a full-fledged gazebo.

Therefore, they make a terrace either in the form of a large porch, or as an open veranda without glazing.

Note! Regarding terminology. The difference between a veranda and an attached terrace is not so significant. Even experts consider a veranda as a special case of a terrace (or vice versa). By definition, an open veranda (without glazing) is exactly the same building as a closed terrace (with a roof).

You can call it whatever you like Source kak-peresadit.ru The attached terrace can be of any size. Short or long, along the entire wall near the main door or at the exit from the house to the backyard. You can even make a terrace surrounding the entire building. And the type of foundation depends on where it is located.

At the front porch, the terrace is built on the same base and with the same decorative finishing of the base as on the “main” facade. And for the backyard, you can choose a simpler foundation - for example, a columnar or light pile foundation.

Construction of a terrace on screw piles: advice from professionals

Every field has its own little tricks, and laying a pile foundation is no exception. Here are a few practical techniques that will help simplify the process of building a terrace with your own hands, as well as increase the reliability of the entire structure.

- Stock up on levers of different lengths.

As you go deeper, it will be more and more difficult to rotate the pile due to the increasing force of soil friction on the side surface of the support shaft. To simplify installation, use pipes of different lengths, gradually increasing the arms of the levers as you tighten them. - Pay special attention to the alignment of the piles when deepening.

Each of the screw piles must be positioned strictly vertically. An error of even 2 degrees can provoke deformation and destruction of the extension in the future. There is a simple but effective way to control the position of the supports. To do this, you will need two magnetic levels at once, which must be installed on the pile at an angle of 90 degrees relative to each other in the plane of the cross-section of the trunk. This technique will allow you to notice the slightest deviation of the support from the vertical axis. - Avoid direct contact of different metals

When constructing a pile foundation, a combination of a steel grillage and aluminum logs is often used. This approach is completely justified: steel is superior to timber in terms of strength characteristics, and aluminum is extremely resistant to environmental factors, while being lightweight, which is especially important when working on soft soils.

A typical mistake made by novice craftsmen is laying an aluminum profile directly on a steel grillage. The fact is that aluminum and steel have different redox potentials. Upon contact, these metals form a galvanic couple, which ultimately leads to their intense destruction under the influence of electrochemical corrosion processes. To avoid this, it is enough to place rubber gaskets, slightly wider than the aluminum beams, at the points of contact between steel and aluminum.

- Install the axle rod to secure the crown block.

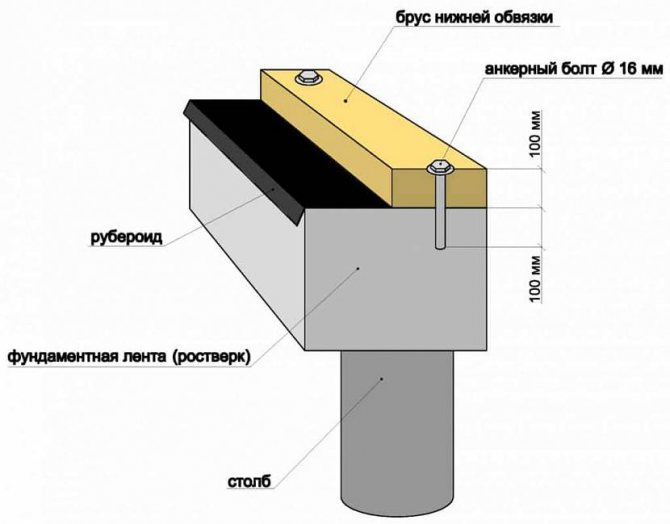

Planning to use a timber frame? Adopt the following technique: after deepening the piles, pour a metal rod positioned strictly vertically into the concrete. In the future, this will significantly simplify the installation of a wooden grillage: you just need to attach first the head to the metal axis, and then the crown block itself. To securely fix the latter, all that remains is to cut a thread on the rod for a nut of the appropriate diameter.

Type of foundation for a terrace

Depending on the location and bearing capacity of the soil, the type of foundation for the terrace is chosen. It can be strip, columnar, pile or slab.

For a terrace attached to a house, the height of the base is commensurate with the base. But if desired, the terrace can be made on pillars at the level of the second floor - this technique is especially often used for a house standing on a hillside. Although this is not a dogma.

If the first floor of the house is used as a technical floor (garage, storage rooms, equipment placement), then the terrace is made at the level of the living quarters Source pinterest.com

For a terrace not connected to the house, you can use a “floating” base (not fixed in the ground). The support for the logs of the wooden flooring are tiles laid on a bed of sand and crushed stone. And for a summer residence, such a terrace can be made temporary - from separate panels that are removed for the winter.

The base must be made so that the surface of the flooring has a slight slope for water drainage (about 1 cm per linear meter).

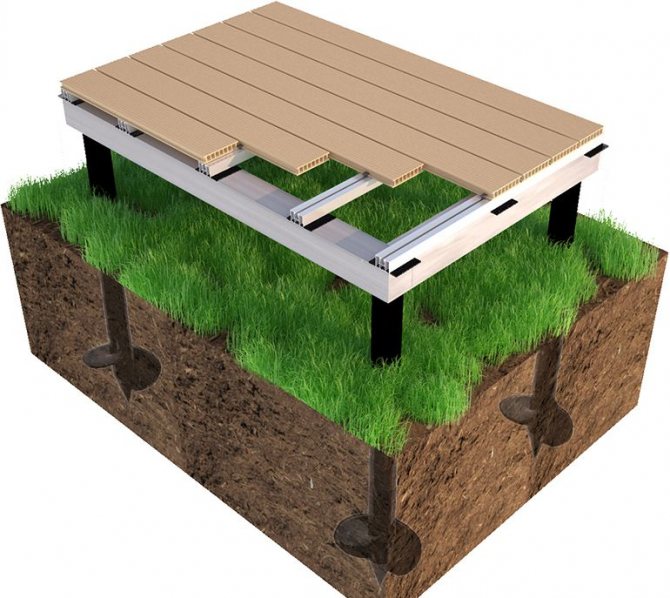

A strip, pile or column foundation for a terrace must have a top frame made of wooden beams. The flooring, like ordinary plank floors, is mounted on logs, the material for which is usually timber. But there are also ready-made systems that use aluminum or plastic profiles as lags.

Even plastic logs can withstand the load from the terrace if they have strong support Source nasha-besedka.ru

The layout of the logs depends on the thickness of the board and the installation method. The decking board can be installed traditionally or diagonally. And here the same rule as for floors - for perpendicular lags (relative to the board), the laying step is 10 cm larger than for diagonal installation.

Online foundation calculator

To find out the approximate cost of various types of foundations, use the following calculator:

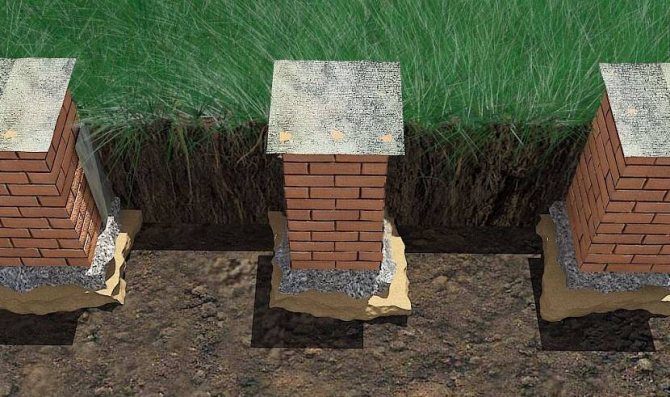

Columnar foundation

This is the least expensive type of foundation for a veranda in terms of materials and cost. The structure consists of a series of separate supports along the extension area - the perimeter serves as the basis for the piping, and the logs rest on the internal pillars.

The materials used are brick, solid cinder blocks, small foundation blocks (for example, one of the FBS 9 standard sizes), shallow pillars made of monolithic reinforced concrete.

This is what a diagram of brick columnar supports looks like Source jet-grouting.ru

See also: Catalog of companies that specialize in foundation repair and design.

The construction technology is simple:

- A hole is dug under each pillar. The depth depends on the nature of the soil. But if it is not very heaving, then the depth is in the range of 40-60 cm.

- Place a cushion of sand at least 10 cm thick at the bottom. If the bearing capacity of the soil is low, then it can be increased to 20 cm or another layer of crushed stone can be added. As an alternative to backfilling with crushed stone, a layer of footing concrete is sometimes made (this is concrete in which part of the cement is replaced with the same crushed stone).

- The pillars are laid out from bricks or blocks.

- Prime with a bitumen primer and wrap the underground part with a piece of roofing felt.

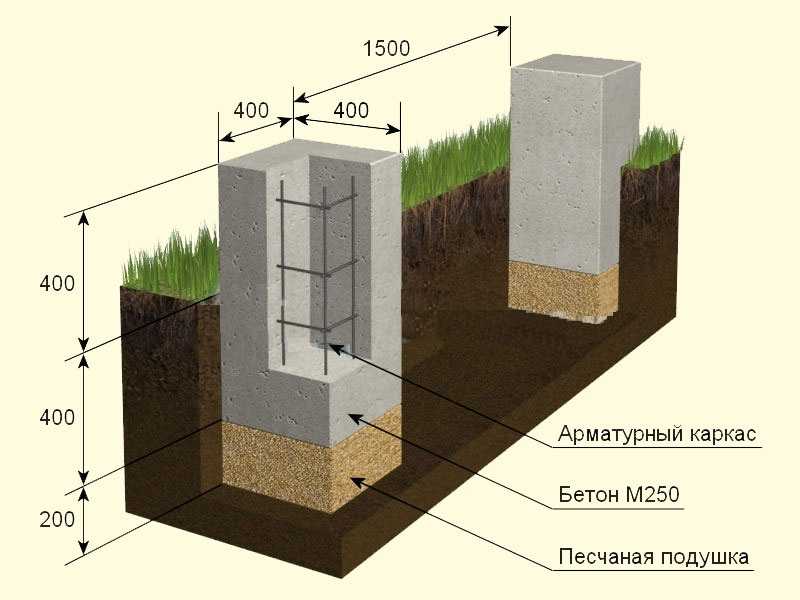

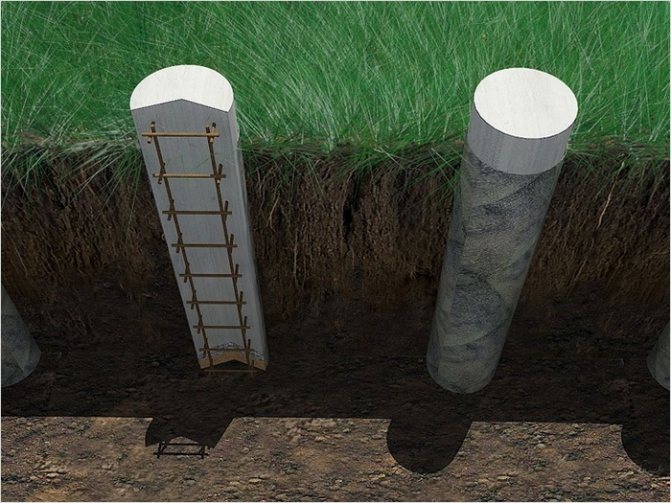

The construction of pillars made of monolithic reinforced concrete is a little more complicated. They already require the laying of formwork and reinforcing frame. But the load-bearing capacity of such a base is also higher - it is already possible to install a glazed veranda on it.

Scheme of a reinforced concrete pillar for a foundation Source isoler.su

There is also a purely “Russian” way to lay a columnar reinforced concrete foundation for a terrace. But if we draw analogies, then this is a monolithic concrete casting with permanent formwork made of asbestos-cement pipe. To do this, the following steps are taken:

- at the marked points, holes are made in the ground with an auger drill;

- pour sand to the bottom;

- asbestos-cement pipes are inserted into the pits;

- cut to height at the same level;

- lay reinforcement;

- concrete is poured.

In principle, this scheme is very close to a pile foundation. But no one will drive reinforced concrete piles for a light extension.

See also: Catalog of projects of houses with a terrace presented at the exhibition “Low-Rise Country”.

Screw foundation

In low-rise construction, this type of foundation is also used for houses. In its own way, it is a universal type that is suitable for most soils. And the bearing capacity of the foundation itself depends on the diameter of the pipe, the width of the blades and the number of piles.

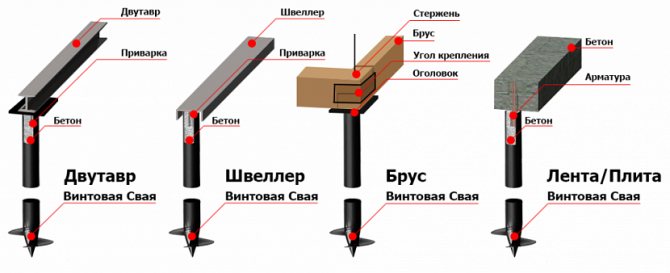

A steel profile, reinforced concrete beam or wooden beam can be used as a grillage.

If you use a slab as the base, then you can choose ceramic tiles or natural stone for the flooring.

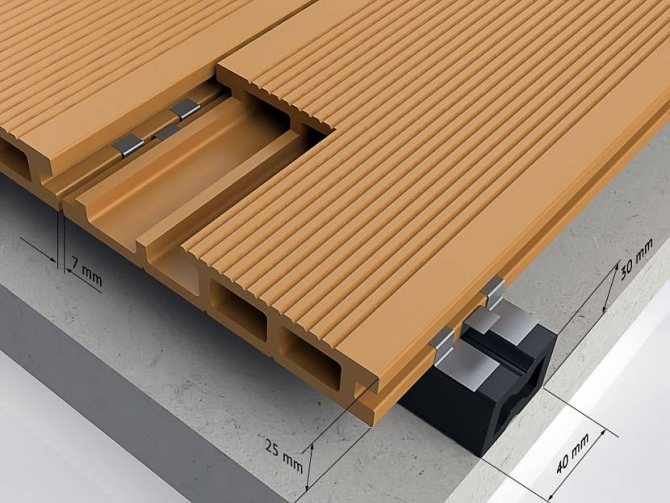

Options for installing a base for a terrace floor using a screw foundation Source balkonsar.ru

Foundation slab

A slab, as a foundation for a terrace to a house, is a universal option that can be used both for laying tiles and for installing decking (terrace boards). Moreover, in the latter case, there are several options for installing the coating:

- On a wooden beam . But the logs are not laid directly on the concrete base, but stands are used. They will perform two functions at once - they provide a ventilated gap and protect the wood from direct contact with concrete.

Here we used legs that can be adjusted in height Source pinterest.ru

- On a metal profile . It is also raised above the level of the slab.

In this case, a galvanized profile with protective painting was used Source idei-dachi.ru

- On plastic guides.

Adjustable supports were also used here Source nasha-besedka.ru

Note : Unlike the slab foundation of a house, for a terrace you can use a prefabricated base made from standard road slabs or floor slabs.

The arrangement is carried out according to the standard scheme: excavation of a layer of fertile soil, leveling of the bottom, a cushion of sand and crushed stone, waterproofing, installation of a slab.

How to choose screw piles for the foundation?

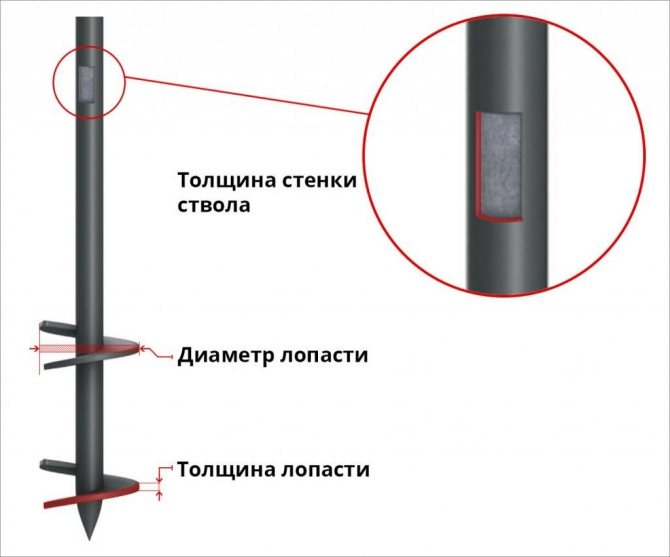

Structurally, screw piles are hollow metal rods with a pointed end, equipped with helical load-bearing blades. They differ in such parameters as the diameter and length of the supporting trunk, the configuration and number of blades, the thickness of the rolled metal and the type of tip.

The purpose of this material is not to consider all possible options for screw piles; we will only talk about those that are used in the field of country house construction.

Let's decide on the diameter and length of the piles.

- Everything is simple with the diameter of the piles: even the thinnest supports are suitable for installing a terrace. For example, piles with a barrel diameter of only 57 mm can withstand a weight of 1 ton, and since the load will be evenly distributed between many supports, this is more than enough.

- The length of the pile shaft is calculated based on the soil characteristics. Screw piles are screwed to the depth of soil freezing, and they must rise at least 30 - 50 cm above ground level. Thus, if the freezing depth is 1.5 meters, we will need supports at least 2 meters long.

- The trunks of the vast majority of screw piles for the installation of country outbuildings, verandas and other light objects are made from carbon steel of ordinary quality St3 (GOST 380-2005). In this case, the most optimal choice is the so-called mild steel (St3sp) - a homogeneous ductile alloy characterized by high corrosion resistance.

- For the manufacture of pile blades, carbon structural steel St10 (GOST 16523-97), which is characterized by surface hardness, is used. For the construction of facilities in cold regions, it will be justified to use piles made of more expensive St20 structural steel, which can withstand significant loads at low temperatures (down to -40C) and are suitable for use in aggressive soils.

According to the configuration of the blades there are:

- Narrow-bladed piles (the diameter of the screw blades does not exceed 1.5 times the diameter of the trunk), which are used when working with dense seasonally freezing soils;

- Wide-face piles (the diameter of the blades is 1.5 times or more the diameter of the trunk), which are suitable for dispersed soils with low bearing capacity.

In turn, wide-bladed piles are divided into single- and multi-bladed. Single-blade piles are relatively easy to install, but are not very resistant to horizontal loads, and are therefore not suitable for weak soils. Multi-blade piles, on the contrary, are able to withstand pull-out, indentation and lateral loads with equal efficiency, which makes them the optimal choice for sandy loam, loam and peaty soils.

What should be the wall thickness of the pile shaft?

For the construction of gazebos, terraces and verandas, mainly thin-walled piles are used, the wall thickness of which does not exceed 3.5 mm. Modifications with thicker walls (up to 4.5 mm) are used when working with particularly dense soils, since they are able to withstand greater loads when screwing. Thick-walled piles (6 mm or more) are practically not used in civil engineering, but they can also be used in the construction of light structures on soils characterized by strong chloride and sulfate aggression.

Selecting the type of pile tip

According to their shape, cone-shaped and cylindrical toothed tips are distinguished (the shape of the latter resembles a diamond bit for drilling concrete), as well as tips with an oblique cut. Piles with tapered tips are suitable for most types of soil. Serrated tips were developed for construction in permafrost conditions. Screw piles with an oblique cut have proven themselves when working with rocky soils.

Let's summarize: what kind of piles are needed to build a terrace?

For the foundation for a terrace adjacent to a country house, erected on non-aggressive soil in central Russia, screw piles with a diameter of 57 mm and a length of 2 meters, equipped with cone-shaped welded tips and having the following characteristics are suitable:

- single-bladed with a trunk wall thickness of up to 4.5 mm, a blade diameter of up to 500 mm and a blade thickness of up to 6 mm (for dispersed soils with low bearing capacity);

- multi-bladed with a trunk wall thickness of up to 3.5 mm, a blade diameter of up to 300 mm and a blade thickness of up to 5 mm (for dense soil with good load-bearing capacity).

As for the number of piles, you need to proceed from the area of the veranda. The calculations look like this. The piles are placed in several parallel rows, with one support at each corner of the structure, and the distance between adjacent piles should not exceed 1–1.5 meters. An example of a pile foundation for a rectangular extension is shown in the photo below.

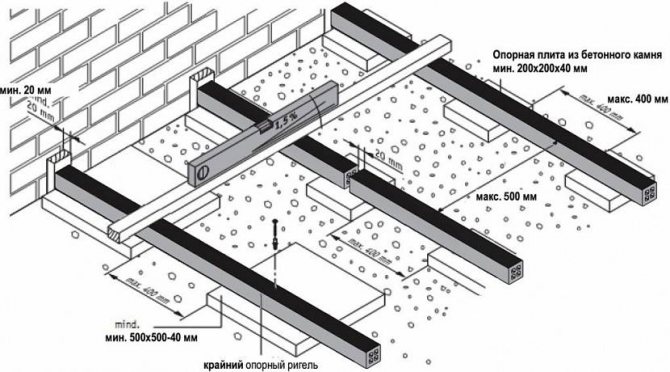

Terrace without foundation

An open terrace can be attached to a house without a foundation. To do this, you need reliable support under the load-bearing beams and the rigidity of the structure on which they rest. To some extent, such a terrace can be compared to a grandstand and concert venue in the central square of the city during a holiday. Normally laid paving slabs of a blind area or platform will act as a solid foundation.

A steel profile structure with welded plates at the base is a reliable foundation for a high terrace near the house Source as-elit.ru

If you need to attach a terrace to your house just above ground level, then in this case use the following scheme:

- The fertile layer of soil is cut off.

- They pour out a cushion of sand.

- Spread a layer of geotextile.

- Concrete tiles are laid as a base under the logs.

- Form a slight slope away from the house.

- Installation of logs.

- Attach the terrace board.

Installation of a terrace “on the ground” Source tat-remont.ru

Stages of installing a terrace on screw piles

You will need:

- shovel,

- mounting head for screwing piles,

- a rod for fixing the mounting head (this can be scrap steel or reinforcement),

- a pair of pipes (used as levers),

- magnetic level,

- concrete mixer,

- welding machine,

- grinder for cutting piles,

- funnel for convenient pouring of concrete.

M200 concrete is suitable for pouring screw piles, which is also used for the construction of foundations for low-rise, shallow buildings. The table below shows the volumetric ratios of the components for preparing the solution.

| Component | Proportions |

| Cement M400 | 1 |

| Sand | 2.8 |

| Crushed stone | 4.8 |

| Water | ⅕ of the total volume |

Now you can proceed directly to the installation of the foundation. For convenience, we have divided the entire process into steps.

Step 1.

Before starting work, the area is cleared, after which the top layer of soil (about 15–20 cm) is removed, which is replaced with sand. Then, using pegs and twine, the installation locations for the screw piles are marked.

Step 2.

In the marked places, piles are installed and screwed. To do this, a mounting head is put on the pile, which is fixed to the trunk using a rod or crowbar, and metal pipes of a suitable diameter are used as levers. Installation is most conveniently carried out by two people.

Screwing is carried out to the depth of soil freezing (for central Russia - 1.5 meters). Before this, the piles can be treated with bitumen, which will provide additional protection against corrosion.

During screwing, it is necessary to control the angle of inclination of the trunk using a magnetic level attached to it: the screw pile must be installed strictly vertically.

Step 3.

After deepening, the piles are trimmed so that each support rises above the ground level by at least 30 - 50 cm.

Step 4.

Concrete is poured inside the piles. This makes it possible to increase their stability by increasing their mass and provides protection against corrosion, since concrete displaces all the air from the internal cavity that contributes to the oxidation of the metal.

Step 5.

After the concrete has hardened, a cap is welded to the upper end of the pile, which will subsequently serve as a support for the grillage.

Step 6.

The grillage is installed. In its simplest form, it consists of beams made of softwood with a cross-section of 150*150 or 200*200 mm, laid on piles parallel to each other and fixed to the heads with bolts. The timber is also laid along the contour of the foundation, forming a wooden frame. At the corners, the beams are joined using half-timber groove joints, as shown in the photo below.

Step 7

Aluminum logs are laid perpendicularly on the beams at intervals of 50 cm. They are fixed to the beams using self-tapping screws.

Step 8

Wood-composite decking is laid on top of the logs. It is conveniently fixed using hidden dovetail mounting terminals or similar. This approach eliminates the need to use self-tapping screws and does not spoil the appearance of the terrace.

It is important to know

To ensure that the foundation for a summer veranda with your own hands serves you for a long time, you can install not only the foundation on pillars, but also on tapes. The strip base is suitable for heavy buildings with massive wall materials. Also, if there is slate or metal tile on the roof of the veranda, then your choice should also fall on a strip foundation. If the terrace is made of wood, then pillars are suitable for support.

How to properly tie the foundation of the veranda to the house? The answer is no. These two bases cannot be connected with each other. Each building must have its own separate foundation. Therefore, the foundation for the veranda at the dacha is placed with your own hands about four centimeters from the house.

If you doubt your choice, do not know what kind of soil you have, then it is better to seek the help of craftsmen who will tell you exactly how to properly pour the foundation for the veranda.

The two depths of the base - the terrace and the house - must be identical in size. It is very important. But as mentioned above, there should be a small gap between them, but the roofs should be laid with an overlap so that water does not flow into the gap.

Foundation depth

The depth at which the pillars are laid depends on several factors. One of them is the type of structure created. It is also important to take into account the geological characteristics of the soil on the site.

Based on the depth of foundation, the foundation is divided into 3 types:

- recessed;

- shallow;

- not buried.

The first type of foundation is installed below the freezing level of the soil on the site. A shallow foundation is erected 40-70 cm below soil level. The third type of foundation indicated is located on the surface of the earth. But it is worth remembering that the fertile layer of soil must be removed in any case.

Strip foundation - is it economically profitable?

For soils that are not heaving and not prone to flooding, a strip foundation can be poured under the veranda. The optimal depth is up to 50 cm. It is very unprofitable to make a deeper foundation for a simple extension. But at the same time, if all the properties of the soil are not taken into account, after winter the shallow foundation may crack. Therefore, when choosing this type of foundation, you need to proceed from the budget and its need in a particular situation.

The installation of a strip foundation is also carried out in stages:

- The place for the foundation is marked using pegs with stretched twine. The outer contour corresponds to the dimensions of the veranda, and the inner contour is responsible for the width of the foundation. The angles must be exactly 90⁰.

Types of pole arrangement

Like strip foundations, columnar structures vary in the degree of depth of the supports

Like strip foundations, columnar structures vary in the degree of depth of the supports. For the construction of a house or other large building, the supports are made so that the base is located in stable soil layers, 25-30 cm below the level of maximum soil freezing. In this case, you can count on the stability of the supports under significant design loads on their base.

Types of columnar foundations

However, often the weight of the building is so insignificant (veranda, gazebo) that the pillars do not require much deepening of the base. In this case, shallow supports are made based on the minimum vertical load.

The main criterion, taking into account which columnar foundations are classified, is the material (method) of constructing the support pillars. Here the division of supports into types occurs as follows:

- concrete (pouring with reinforcement);

- concrete (laying ready-made blocks);

- brick (masonry);

- wooden (installation of treated logs).

Often a columnar foundation is combined with pouring a slightly buried reinforced concrete strip around the perimeter. In this way, they create a continuous support for the construction of walls and increase the resistance of the pillars to horizontal ground movements. This type of foundation for the construction of houses is called a columnar-grillage foundation, and this type is used when constructing walls from lightweight block building materials (foam concrete, expanded clay concrete).