Most modern Russian private houses have a basement. There are different offers of materials for its construction on the market. Some people choose foam blocks, some build from cinder blocks, others from monolithic concrete. But more and more often, compatriots are choosing a plinth made of FBS, since it is durable and at the same time not very expensive to construct.

Use FBS to create a base

Advantages and disadvantages of FBS

Many people want to build a basement from conventional FBS blocks, simply weighing their advantages and disadvantages compared to their competitors. It’s quite easy to do this in advance today - information about all building materials is widely available. So what are the advantages of such blocks?

Their list is quite wide and includes:

- Low price, which is affordable even for those with a limited budget.

- Availability of material that can be easily purchased in all regions and localities.

- There is no need to work independently with concrete, where the slightest mistakes can lead to dire consequences.

- A high level of cold resistance, which makes it possible to use the blocks even in the Far North.

- Wide range of sizes.

- Resistance to the destructive influence of the external environment.

In this video we will look at a base made of FBS:

All these positive qualities appeared thanks to the FBS manufacturing technology. Thus, for their high level of frost resistance, they should thank the presence of special additives added to the concrete solution at the production stage. The use of high-quality cement grades allows us to achieve good resistance to various external factors.

But, like any material, these blocks have their drawbacks. Their number is inferior to the number of advantages, but they are still worth taking into account when choosing a building material for the construction of a basement floor.

- Despite all its cheapness, a structure made from such slabs is one third more expensive than a monolithic one.

- Construction cannot be completed without the use of special equipment - the blocks are so heavy that people cannot simply lift them.

- This design requires extremely careful waterproofing of the base due to the presence of interblock seams.

But all these disadvantages for the majority are easily offset by the above advantages.

How to choose FBS

When building a monolithic basement floor, it is necessary to choose the right grade of concrete. When choosing blocks for the plinth, there is no need to worry about this. But this does not mean that you can purchase any building material offered.

As in the case of foam concrete, the first thing you need to do is make sure that the purchased FBS is of a sufficient level of quality. This can be guaranteed by a passport, which every seller must have. It should contain the following information:

- manufacturer;

- batch number;

- brand;

- weight;

- block dimensions;

- production time;

- level of frost resistance;

- compression resistance level;

- moisture resistance;

- operating standards.

The buyer can additionally check the blocks for deviations. To do this, select several pieces at random and measure the dimensions. The deviation should not exceed 6 mm. If it is more, then the product is considered defective. It is worth remembering that not all types of blocks are good for basement floors.

Blocks are selected based on the thickness of the walls. The presence of cladding near the house also plays a role. In the latter case, the FBS basement blocks should be 10 cm wider than the main wall. This will allow the cladding to rest on them. If the walls will not be additionally lined or heavily insulated, then you can take material of the same width as they are. This will not affect the load-bearing capacity.

Attention! You can calculate all the necessary parameters using a special calculator.

Initial calculation

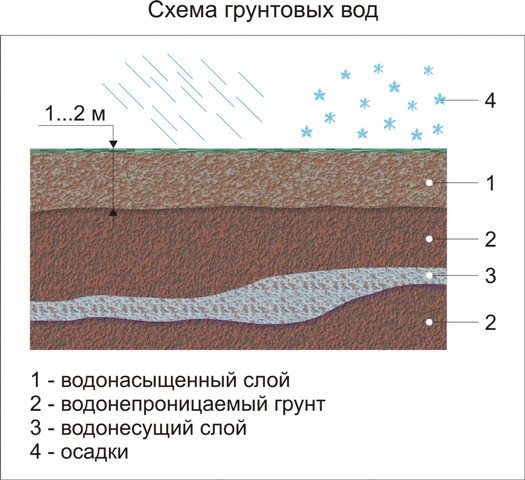

Before you start building the foundation first, it is necessary to determine the groundwater level.

Before laying a foundation of blocks, you should take into account that it is necessary to carry out waterproofing. To implement it, it is important to make a calculation and identify: at what level the groundwater is located, what forces of soil swelling are observed in the post-frost period, how heterogeneous the soil is and what are the conditions for using the building. If the highest level of soil water is located below the base of the foundation at a distance of more than 0.9 m, then vertical coating waterproofing can be done, and horizontal waterproofing can be done using a material such as roofing felt. If the water level is higher, but does not reach the basement level or rarely reaches it, then you need to make the insulation yourself more reliable. Perform the horizontal layer in 2 layers, covering with mastic. For vertical applications, use coating and pasting methods. As an addition, you can treat the foundation blocks and basement with penetrating waterproofing. If it often rains in the area where the house will be built, you will have to make a drainage system around the building. If we take into account the economy of the material, it is better to choose bitumen. A complex of different types of insulation will require large investments.

How to arrange a basement floor using FBS blocks

The construction of a basement floor from FBS is in many ways similar to the construction of a monolithic basement. In particular, the similarities in the main stages of construction work. At the same time, the building material itself dictates the main differences - after all, here concrete is not poured, but blocks from it are laid in the required order.

Main stages of construction work:

- site preparation;

- pit construction;

- foundation waterproofing;

- walling;

- waterproofing walls;

- insulation;

- finishing work.

It is clearly seen how important protection from moisture is when constructing a basement floor made of FBS. If it is not provided at the proper level, water will quickly begin to have a destructive effect on the walls, penetrating through seams and cracks. And in the basement it will be extremely uncomfortable.

FBS is an economical material for creating a base

How to install the plinth

Construction of the basement begins with preparatory work on the site. They largely correspond to what needs to be done if a base is built from foam or cinder blocks.

The first step is to carefully clear the area of debris and level it. If it is overgrown with grass, then remove the top layer of soil. After that, markings are made based on the project according to which they are building. It indicates the location of the supporting structures and the pit.

It is important to correctly determine the depth of the pit. It depends on factors such as:

- ground floor area;

- soil type;

- depth of groundwater.

So, if the aquifer is too close to the surface, you cannot make a base deeper than 1 m. When determining the depth of the pit, it is also worth taking into account the need for the pit to be 50 cm deeper than the floor floor, since a sand-gravel cushion in combination with waterproofing material will take about 30 cm.

The next stage is digging a pit. This is done in accordance with the applied markings. You can dig either manually or using excavators. Where the load-bearing walls will be located, trenches are dug, the depth of which should be at least 40 cm. Such a depth will allow the installation of blocks with a margin of up to 10 cm.

The bottom of the trenches made is covered with fine crushed stone and reinforced with mesh, and the walls are fixed with wooden elements, such as boards. After this, concreting is carried out and they wait until the concrete hardens.

Attention! Concrete usually takes up to 3 weeks to harden.

They act somewhat differently when organizing a slab foundation.

For the construction of wall floors, when a base is built from FBS blocks, classical technology is used. That is, they are placed on top of each other, fastened with cement mortar applied to the surface. Since the blocks are quite heavy, they are placed using special equipment. It is important to ensure that the discrepancy between structural elements is as small as possible.

It is also worth remembering the need to ensure that the structure has an entrance and (if the project provides for this) windows, otherwise you can build solid walls.

At the final stage of work, you can surround the base with additional support made of brick or reinforced concrete elements. It will serve not only for strengthening, but also for leveling. Internal and external wall decoration depends on the project, the preferences of the owner, as well as the purpose of the room.

If the base is planned to be used as a place to store food, then plaster or simple paint will be sufficient. The walls must first be leveled and possible cracks or seams must be repaired. Any material from concrete to wood can serve as a floor covering. The role of the ceiling is the covering of the basement floor with a monolithic slab.

Selecting suitable materials

Bitumen guide material is inexpensive, resistant to mechanical stress and static pressure.

Roofing felt, profiled membranes, liquid rubber, plaster compositions - what materials are not offered for waterproofing the foundation! What is suitable for a particular foundation is determined by the climate of the area where the house will be built or repairs done with your own hands. These include air humidity, rising groundwater, and the likelihood of precipitation. The higher the degree of their impact on the house, the more powerful the material and the more accurate calculations need to be used. One of the frequently used materials of our time is bitumen overlay material. It is affordable, versatile, resistant to mechanical stress, as well as static and hydrostatic pressure. In addition to its main property, low water absorption, it is flexible: it can be attached by free laying directly onto the base in a continuous direction in one layer. You can protect the basement from the outside using a waterproofing membrane. It will create an obstacle to water and drain it from the soil into the drainage.

After the mastic dries, a dense monolithic waterproofing membrane is formed.

Waterproofing mastics, which do not contain harmful toxic substances, are also considered popular materials for FBS insulation. However, be careful! It is better to work with them outside, as they are flammable. Where the soil is especially wet, you can cover the blocks with roll materials yourself, using several layers. All components must be secured with mastic.

To carry out waterproofing you will need the following tools and materials.

Materials:

- FBS;

- concrete;

- cement;

- bitumen mastic;

- used machine oil;

- roofing felt;

- geotextiles;

- gravel or crushed stone.

Tools:

- shovel;

- concrete mixer;

- sieve;

- bucket;

- roller or brush;

- gas-burner.

Expensive but durable liquid glass is among the favorites; it can be replaced by penetrating treatment of the foundation with a special solution.

How to do insulation

External insulation of the basement is necessary if you plan to live in it. To do this, during the construction of the basement floor from FBS blocks, its walls are covered with special materials. But insulation is done not only to maintain temperature, but also to reduce humidity in the room and avoid steam condensation.

Before insulation, you need to take care of creating a special sand cushion up to 20 cm thick. It should be adjacent to the bottom of the foundation and will serve as a support for the insulation. The sand must be compacted well.

The most common heat-insulating materials that are well suited for such premises are:

- expanded polystyrene;

- penoplex;

- Styrofoam.

This is due to the fact that they are in the form of slabs that are glued to the walls. Depending on climatic conditions, insulation can be done in either one or two layers. In the first case, it is important to properly process the joints. They are insulated using polyurethane foam. In the second case, the sheets are laid with an overlap of 10 cm. Particular attention should be paid to insulating the corners, which are especially prone to heat loss.

Important! Additional protection can be provided by a layer of moisture-resistant and windproof material. Geotextiles are well suited for this role.

Ventilation system

A feature of any basement floor is an increased level of humidity, due to which condensation forms, mold appears, and microorganisms harmful to health develop. To minimize such unpleasant consequences, ventilation communications should be installed during the construction stage.

When installing foundation blocks, you need to remember to create exhaust ducts, since subsequently it will be extremely difficult or completely impossible to create natural ventilation.

The basement should have two channels located at different heights:

- 15cm-30cm from the floor;

- 15cm-30cm from the ceiling.

Natural ventilation will cope with the problem of humidity only in the summer. With the arrival of cold weather the situation will worsen. That is why experts recommend installing supply and exhaust systems that combine the functions of forced and natural ventilation.

How waterproofing and backfilling occurs

Waterproofing the basement floor using FBS is an extremely important stage in construction work. Since the structure is in contact with the ground in many parts, it is necessary to insulate both the foundation and the walls from moisture.

Roll insulators are used to waterproof the foundation. Roofing felt may also work. In addition to the insulator itself, the foundation must be protected by a special blind area. It is built around the perimeter using brick or concrete. In this case, it is important to use the highest quality materials.

Waterproofing walls occurs somewhat differently, although the same materials are used for it as for protecting the foundation. But, in addition to them, bitumen mastic is used. First, the walls are covered with it, after which the insulating sheets are laid. On top it is again covered with a layer of mastic.

Sand is used to backfill the floor walls.