How to insulate a pile foundation of a wooden house

The foundation of a house made using metal piles screwed into the ground is called a pile-screw foundation . This technology has been used for quite a long time, only over time it has changed a little. For example, previously wooden poles impregnated with various anti-corrosion compounds could be used as piles. This was necessary to increase the service life of the structure.

The technology was developed primarily for areas with marshy areas or heaving soils with unstable soil. The advantage of using a pile foundation is that the weight of the house is transferred through the piles to the lower layers of soil, which are much denser than the upper layers. Thus, the risk of destruction of the building is minimized.

Currently, to organize a foundation using this technology, piles are used, at the end of which there are blades resembling threads on a self-tapping screw; it is for this reason that the foundation is called a pile-screw foundation. To install such piles, special equipment can be used or they can be tightened manually.

The screw foundation can be classified according to the height of the grillage. The grillage is the first crown of the foundation, which rests directly on the piles; in some cases, it is also called the frame.

The grillage happens:

- Low , installed below ground level, i.e. the pile is completely in the ground. Based on this principle, a pile-strip foundation is constructed, which cannot be distinguished externally from a regular strip foundation.

- High when the grillage is at a certain distance from the ground surface.

- Intermediate , in this case the grillage is located on the very surface of the earth.

The answer to the question why it is necessary to insulate the foundation on screw piles is that the space under the floor of the building is blown by the wind and no matter how the floor insulation is carried out, it will not be as effective as if it is used in conjunction with the insulation of a screw foundation.

An insulated foundation is the key to a warm floor and significant savings on heating.

Insulation of a pile-grillage foundation with a low grillage level

Insulation of a strip-pile foundation can be carried out according to the same principle as a conventional strip foundation due to the fact that it is also buried in the ground and made of reinforced concrete. This means that you can use either sheet insulation for a pile foundation or loose insulation, and additionally insulate the structure using a warm blind area.

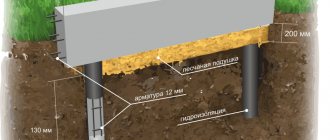

Insulation of the grillage of a pile foundation should begin by marking and preparing a trench with a width slightly greater than the thickness of the insulation, and a depth of 5-10 cm below the location of the support area of the piles located under the foundation.

At the next stage, it is necessary to clean the base surface and install insulation against moisture penetration, after which you can begin installing the insulation. To do this, you will need to have fasteners, polyurethane foam or other adhesive composition. Dowels for insulating materials, or in installer slang, “mushrooms,” are optimally suited as fasteners.

Do-it-yourself insulation and finishing of a pile foundation

If it is necessary to insulate the foundation and at the same time improve the appearance of the base, you can use insulation technology using bulk materials, together with base thermal panels.

The algorithm for this type of insulation is as follows:

- A trench is prepared with a depth just below the support pad of the piles and a width of 0.5 to 1 meter.

- Sand filling is being made.

- The trench is filled with insulation, slightly below the ground level, 5-10 cm is enough.

- Thermal panels are installed; they need to be slightly deeper into the loose insulation and secured with dowels.

- The blind area is being poured.

Final works

The base of a building is a very important component of any structure

It needs to be given special attention due to the regular impact of the environment on its structure. The facing material must have the following quality indicators:

- low thermal conductivity;

- reliability;

- solid grip;

- sufficient wear resistance and at the same time strength;

- low hygroscopicity.

Materials that work best:

- porcelain stoneware or clinker slabs;

- artificial or natural stone;

- profiled sheets;

- brick;

- decorative or mosaic plaster;

- siding or PVC panels.

To protect the plastered layer, it is additionally coated with acrylic, water-based, silicone, alkyd or oil paint. To ensure that the finishing of the plinth is inexpensive, you should opt for plaster. But it must be borne in mind that such a finish is short-lived and can easily be damaged by any object.

Experts do not recommend using enamel for painting. It is not environmentally friendly, and also does not allow air to pass through.

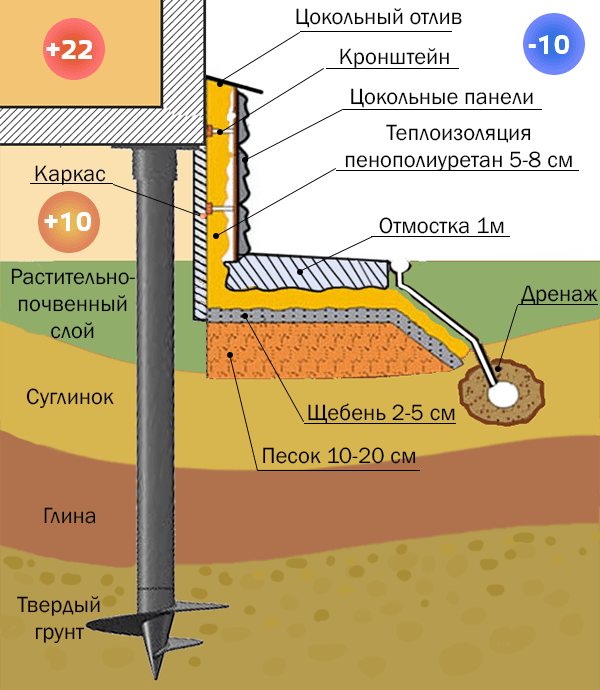

Insulation of the base of a pile-screw foundation with a high grillage

A pile-screw foundation with a high grillage is the most common foundation of this type. Depending on the design, the grillage can be at different heights. At the same time, it is simply necessary to protect and insulate the space under the house. For this purpose, the technology of creating a false base .

Such a base can be made of brickwork, or using a wooden frame on which insulation is mounted.

False brick plinth

Organizing such a base for a house on a pile-screw foundation is not the most popular way to solve the problem. Firstly, brickwork is quite expensive, due to the fact that it is necessary to use facing bricks, cement, crushed stone and sand to construct the cushion.

If you save on bricks and use a cheaper one, then you will have to spend money on exterior finishing. Secondly, in order to hide the piles, you need to remove the brickwork so that they remain inside, which is not always possible.

The process itself looks like this:

- A trench is being prepared for the construction of a sand cushion; its average depth is about 20 cm.

- Crushed stone is poured and compacted, then sand.

Tip: to better compact the sand cushion, it can be spilled with plenty of water and allowed to dry before starting laying.

- Brick is being laid. The masonry is used with an offset of half a brick, i.e. standard.

After the masonry is ready, it must be insulated from the inside .

For this, it is more convenient to use sheet insulation. This can be polystyrene foam, extruded polystyrene foam or analogues. Insulation using expanded clay will require additional costs for installing formwork. One of the best options is to apply polyurethane foam on the inside of such a base; it will reliably protect the structure from the penetration of cold.

Range of potential insulation materials

The following materials may be suitable for insulating the base:

- Styrofoam. It has the most attractive price, which also has a downside - if you compare it with other insulation materials, its thermal conductivity is quite high. Its durability also leaves much to be desired. The region in which the house is located also plays a role. For northern latitudes, the thickness of the slabs should be at least 150 mm, for middle latitudes - 100, and for southern latitudes - up to 50 mm.

- Mineral wool is a popular option, but it will require a waterproofing layer, which could be roofing felt.

- Penoplex, unlike the first on this list, boasts low thermal conductivity and sufficient strength, which has already brought many fans to its camp. In addition, rodents do not like penoplex, and its moisture resistance is excellent. These advantages made it an “expensive thing”, but it will serve for a long time.

- Polyurethane foam is fourth on this list, but in reality it is the winner, since its seamlessness speeds up the work significantly. There are also some drawbacks: polyurethane foam urgently requires expensive equipment.

To determine the required thickness of the material, a thermal engineering calculation is needed to help determine the intensity of cold penetration into residential premises.

Insulation of the base of a pile foundation

The panel plinth , or it can also be called a frame plinth, which will reflect its essence much more fully, is manufactured according to the following scheme:

- are double-tied from the outside . If the grillage is at a high height, the number of turns can be increased. The harness can be either metal or wood. Metal ones, as a rule, are fixed by welding; this is the most popular method; as for wooden ones, you can weld guide corners onto the piles and secure the strapping using wood screws. The second option is to use metal clamps.

- At the next stage, you can install thermal panels or sheet insulation. If you plan to insulate the base using polyurethane foam spraying, then the trim must be sewn up with tape, and then the insulation must be sprayed on both sides.

When using non-insulated panels to create a base, it can be covered with soil from the inside, but it is better to use expanded clay for these purposes. At the same time, do not forget about waterproofing the grillage.

The advantages of a panel base are obvious: simplicity of design, speed of installation, and a large number of insulation options both outside and inside.

If you plan to make a false base yourself, you will need to have the following tools and skills to work with them:

- welding machine for welding fasteners to piles;

- “grinder” for cutting metal corners;

- drill for drilling corners;

- a screwdriver for installing self-tapping screws that secure the insulation;

- construction level for leveling the piping horizontally;

- chainsaw for cutting wooden strapping.

Carrying out basic calculations

Before starting work, a preliminary analysis should be carried out. To obtain accurate calculations on the parameters of the thermal insulation layer and calculate its effective thickness, it is necessary to first make the following measurements:

- Building perimeter

- Room area

- Living room area

- Degree of load on the base

- Parameters of the screw piles used

- Number of people living in the building

- Features of the local climate

- Freezing level of the earth's surface

Only after taking into account all the above factors can you accurately calculate the required amount of thermal insulation material and the thickness of the layer used.

conclusions

A pile-screw foundation with a high grillage is popular due to its low cost and high practicality. Its downside is that it is a ventilated underground space.

To protect the house from the penetration of cold and simply to give it beauty, the technology of creating a false base is used. It can be done using insulated brickwork, but it is better to use the technology of an insulated panel base. Compared to brickwork, panel plinth is much cheaper and more efficient.