A grillage is an element of a pile foundation that serves to connect piles into a single structure.

The strapping is arranged for various types of pile supports: screw, reinforced concrete, bored.

Main functions of the grillage:

- connecting piles into a single structure;

- uniform redistribution of load on piles;

- increasing the bearing capacity of the foundation;

- giving additional rigidity to the base;

- preventing uneven subsidence of the house;

The installation of a grillage is recommended for the construction of private houses and cottages, regardless of the type of soil. It is not advisable to arrange a grillage for log houses, in which the lower crown will perform the piping function, and for frame houses, where the lower metal piping is made. When building cottages from piece materials on a pile foundation, the installation of a grillage is mandatory. For light small houses, outbuildings, gazebos, the grillage can be a full-fledged ground part of the combined foundation.

Important! Many people confuse the concepts of “strip foundation” and “grillage”. In design, these elements are indeed often very similar (especially monolithic ones). However, the functions of the elements are different: the grillage redistributes and at the same time absorbs part of the loads from the structure, and the strip foundation rests on the ground and absorbs the bulk of the weight of the structure.

Types of grillages for pile foundations by location

There are many options for constructing a grillage for a combined pile foundation. When choosing, you need to decide how the structure will be located relative to the ground. Based on this criterion, the following types of grillages are distinguished:

- Hanging or tall. The distance between the ground level and the bottom of the structure is at least 30 cm. Suitable for houses on heaving, swelling soils, areas with a risk of flooding, and with high groundwater levels. To install a hanging grillage, a complex calculation of the load-bearing capacity of piles is required, because they will take up to 70% of the load.

- Elevated. The base of the structure coincides with the zero level, and the structure itself rises 10 cm above the zero level. The installation of such a piping is possible only on soils with good bearing capacity. The disadvantage of this type is the lack of an air gap between the grillage and the soil, which leads to increased heat loss at home. To minimize heat loss, 10-15 cm of soil is excavated under the grillage to form an air cushion.

- Shallow. The grillage is buried 10-20 cm into the ground. This is the best option, because... in this case, the structure evenly distributes the load on the piles and foundation. A shallow grillage can only be made on stable soils. If the soils on the site are loose and watery, then adding a layer of soil 0.5 m thick will be required, which increases the cost of construction.

- Recessed. More than half of the grillage is underground. The design is reliable, but its implementation requires a large amount of excavation work. Therefore, this type of strapping is rarely used, mainly for the construction of massive 2-4-story townhouses and brick cottages.

Advantages of a foundation on bored piles

Bored piles are installed below the freezing level of the ground and wrapped in two layers of roofing felt (in construction this is called a “jacket”) to waterproof and reduce pressure on the piles. This pressure occurs in winter and can push the entire structure out.

This method of foundation construction has a number of advantages:

- no danger of dynamic impact on nearby structures and buildings;

- piles are driven to the maximum depth of freezing of the ground;

- piles are ideal for sloping, relief and unstable soil;

- no harm to the environment;

- the foundation is laid on any convenient site, which is unacceptable for the construction of other types of foundation;

- piles are suitable as a foundation for the construction of any house (frame, brick, log house, etc.);

- cheap type of foundation compared to a monolith or strip;

- fast construction - 4-7 days.

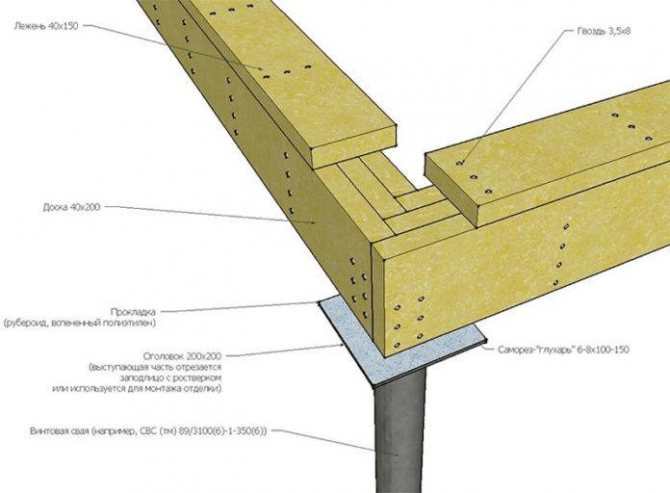

Wooden grillage for foundation

This is the easiest and cheapest type of binding. For wooden light buildings, the first crown can perform the piping function, but when building a frame bathhouse or outbuilding from gas silicate blocks, a grillage is required. The technology for installing the structure is simple: pre-prepared boards are laid along the future walls and connected to the pile heads. More information about the installation and requirements for the grillage can be found in the SP standard “Wooden structures”. When performing wooden strapping, it is important to follow the following rules:

- A wooden grillage can only be hanging or raised. Once in the ground, the tree will quickly become unusable.

- This type of strapping can only be used for light buildings.

- It is desirable that the piles be screw. For supports made of concrete, you will have to make metal heads, because... It is impossible to bind concrete to wood rigidly.

- The boards for the structure must be chamber-dried, treated with an antiseptic and waterproof compound.

- The section of the boards is selected depending on the weight of the structure: for one-story buildings - 15x15 cm, for houses with an attic - 15x20, 20x20 cm.

- The boards are installed strictly vertically!

- After installing the structure, a bench is installed - a horizontal board that improves the geometry of the structure.

The advantages of wooden strapping include ease of manufacture and no need for insulation. Waterproofing of the structure is necessary: a film of foamed polyethylene is placed at the junction of the piles with the tree, as well as under the bed. Disadvantages of a wooden grillage: limited use, service life 10-15 years.

Metal grillage for foundation

Metal grillage is reliable and suitable for massive houses. A pile-grillage foundation with metal elements is made primarily on screw supports, but it can also be connected to bored and driven piles using reinforcement allowances. The metal grillage is made from an I-beam, channel or square profile. In terms of cost and ease of use, the channel is best suited.

The size of the channel depends on the diameter of the piles:

- channel 12, 14 and 16 are used for supports 108 mm, and the heavier the structure, the larger the metal structure should be;

- channel 16, 18 and 20 are used for supports 108 and 133 mm.

For a 2-story cottage, the best option is channel 20, for a one-story cottage - 16 or 20, for an outbuilding or bathhouse - 14, 16. The metal grillage relative to the ground can be located higher, shallowly or deeply buried. When installing a buried pile-grillage foundation, the metal structure must be treated with an anti-corrosion compound or purchased galvanized products. The grillage is connected to the heads of screw piles or the outlet reinforcement of concrete supports by welding, forming a strapping unit. Welded seams are treated with a primer.

The main advantage of a metal grillage is its strength; the structure forms a rigid and reliable bond. Disadvantages include labor intensity, the need for welding, and susceptibility to corrosion.

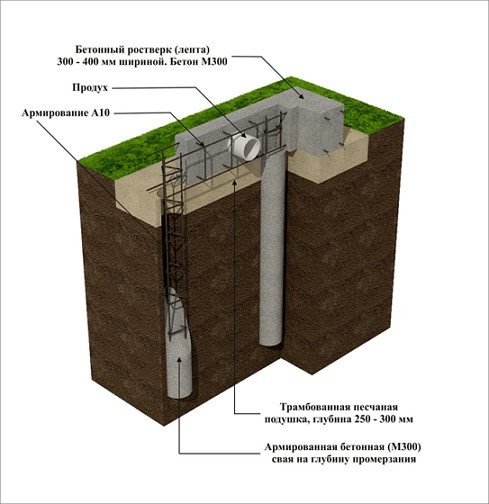

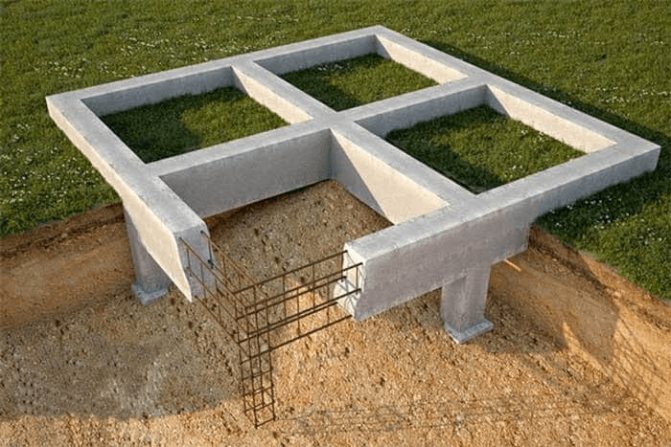

Concrete grillage for pile-grillage foundation

The concrete grillage has the form of a reinforced concrete tape that connects all the piles along the perimeter of the foundation and along future load-bearing walls. According to their design, the following types of grillages are distinguished:

- prefabricated, consisting of ready-made reinforced concrete structures, for example products RS1, RB, etc.;

- monolithic, poured on site into prepared formwork.

A prefabricated grillage is more expensive; when constructing it, difficulties often arise with connecting the pile and ground parts of the foundation. Therefore, in most cases, monolithic strip piping is chosen for the construction of private houses.

On the Internet you can often come across the concept of “monolithic slab-type grillage”. This definition is erroneous, because in this case we are not talking about piping, which is the main function of the grillage, but about a full-fledged pile-monolithic slab-type foundation. It is also important to understand that when talking about a concrete grillage, we mean a structure with reinforcement, i.e. reinforced concrete. A grillage made of concrete alone cannot be used for strapping, because the structure must bend, and a concrete solution without reinforcement will not last very long.

Technology for constructing a grillage on bored piles

The technology for constructing a bored foundation with a hanging grillage is as follows:

- mark the area of the future foundation and take out the main axes;

- construct trenches and perform additional excavation work;

- installation of a sand cushion with a height of at least 20 cm;

- install piles to the depth of expected soil freezing;

- equipping a waterproofing layer;

- installation and assembly of formwork panels;

- securing communications and ventilation;

- pouring concrete mixture;

- removal of formwork.

Electric boiler for heating a house 220V - getting ready for winter.

How to choose and how to use an expansion tank for heating?

Technology for constructing a bored foundation with a recessed grillage:

- mark the area of the future foundation and take out the main axes;

- construct trenches and perform additional excavation work;

- installation of a sand cushion with a height of at least 20 cm;

- place a special geofabric;

- pour concrete mixture;

- reinforce the grillage;

- install waterproofing;

- remove the formwork.

Calculation of pile-grillage foundation

The calculation of a combined base with a reinforced concrete grillage consists of two parts:

Pile field calculation

The structure and principle of calculation depends on the type of supports used. For screw supports, the calculation determines their diameter, the size of the blades, the depth of installation, and the distance between the piles. When calculating bored supports, it is necessary to determine the depth, diameter and pitch, as well as make an additional calculation of reinforcement.

Calculation of reinforced concrete monolithic grillage

The purpose of calculating a monolithic pile foundation grillage is to calculate the punching capacity of the structure, its ability to withstand bending loads and determine the strength of the section when exposed to shear forces. The calculation process is described in detail in SNiP 3.03.01-87, SP “Design and installation of pile foundations” and GOST R 52086-2003. In the field of private housing construction, it is not advisable to make these complex calculations. It is enough to determine the main dimensions of the piping for the pile foundation:

Grillage depth

The depth of the foundation directly depends on what type of foundation was chosen. Let us recall that, relative to the ground level, a pile-grillage foundation can be suspended, elevated, shallow and deeply buried. The pile part of the combined pile-grillage foundation is laid at least to the depth of soil freezing. The optimal depth for laying the grillage is 10-30 cm below the zero level. The heavier the mass of the house, the deeper the grillage should be buried.

If the grillage is not deep enough, the foundation may shrink, which will lead to the disappearance of the air gap between the soil and the monolithic strip.

Width of pile foundation grillage

The width of the monolithic strapping tape is determined by the formula:

B = M/L*R

where: B is the width of the tape; M - mass of the house (materials + loads); L is the length of the grillage; R is the soil bearing capacity coefficient, determined from the tables in SNiP.

Sergey Yurievich

Construction of houses, extensions, terraces and verandas.

Ask a Question

The length of the grillage is the sum of the perimeter of the foundation and load-bearing walls. The formula is suitable for calculating the width of an elevated and recessed base. Another way to calculate the width of the strapping tape without using a formula: the width is equal to the diameter of the piles used plus 25-35 cm. The width of the hanging grillage is determined through complex calculations that can be made using special engineering programs.

Height of the pile foundation grillage

The height depends on the type of building material from which the house will be built. For aerated concrete, a height of 40 cm is sufficient, for silicate blocks - 50 cm, for heavier materials - 60 cm. Relative to the width, the height of the grillage should be 90-110%.

If the grillage will also serve as the base of the house, then it should be made higher - 50-60 cm. This is necessary for the installation of vents, which are located at a height of 30-40 cm from the zero mark.

An example of calculating a grillage for a pile foundation: a house is being built from aerated concrete with a length of load-bearing walls of 100 m on dense sand using screw supports with a diameter of 108 mm. The weight of the house is 55 tons. The depth of the grillage, taking into account the weight of the structure, is taken to be 0.2 m. We calculate the width: B = 55 t/100 m * 75. The width is 41 cm (according to another calculation, 10.8 cm + 30 cm = 40, 8 cm). The height of the grillage will be 40 cm, of which 20 cm will be buried underground.

Preparation

You can build a solid foundation for a house with your own hands, having the necessary materials, tools, free time and a minimum of experience. Since the construction of a grillage on bored piles does not require special skills.

- At the beginning of the work, the necessary geological measurements are carried out, the properties of the soil are examined, and the location of groundwater is determined. To explore the geological features of the development area, wells are used. The soil is developed to a depth lower than the base of the foundation. Knowledge of the geological features of the soil in the area allows you to determine the required step and strengthen the structure without errors.

- The installation of bored piles includes mandatory reinforcement with reinforcing bars. For construction you will need: sand, roofing felt, reinforcement, concrete, plastic pipes.

- When constructing the structure, the parameters of the grillage section, the distance between the pillars, and the depth of the piles are taken into account. You can watch the video to see how to make the foundation correctly.

Step-by-step instructions for installing a reinforced concrete grillage:

- Preparation of tools and materials. Ordering concrete class B17.5…22.5. If necessary, you can add small crushed stone or gravel under the future piping.

- Installation of formwork. The height of the formwork should be 10 cm higher than the height of the strip grillage. For formwork, you can use boards or panels, which must be strong enough to withstand the load of concrete.

- Reinforcement and connection of the pile part and grillage. A reinforcing frame of rods is created on special stands that allow the rods to be positioned in space. The reinforced frame is knitted manually using a special hook or gun. Longitudinal and transverse rods are connected with wire with a cross section of 0.8...1.5 mm. It is recommended to cut the wire in advance. The reinforced frame is installed in the formwork, where it is connected to the reinforcement of the piles. The connection should be as rigid as possible.

- Pouring formwork with reinforced frame with concrete mixture. To properly pour concrete, you need to distribute the mixture in equal horizontal layers 10-15 cm thick. After pouring, each layer is compacted with a vibrating tool. Then the next layer is poured.

- Caring for concrete during the hardening period. The structure must be protected from wind, precipitation and UV rays. In dry weather and temperatures above +22 C, concrete should be periodically moistened.

- Dismantling the formwork. First of all, the spacers and fastenings are dismantled, and then the boards. The formwork should easily move away from the hardened concrete; if this does not happen, then the mixture has not completely hardened and has not gained strength.

When mixing concrete yourself, it is important to strictly follow the recipe for the selected class. For example, to prepare a mixture of B22.5 (M300), it is necessary to maintain the cement/sand/crushed stone ratio = 1.2/4.4/3, and for the water/cement ratio = 0.53...0.55/0.60.

Construction stages

The construction of a foundation on bored piles with a grillage begins with the removal of fertile soil. Initially, a wooden cast-off is made and installed at some distance from the future foundation. This will allow you not to interfere with excavation work. A cord is tied into its boards to indicate the axes of the future house. After marking is completed, drilling of wells, reinforcement and pouring of pillars begin.

All loads are pre-calculated and must be taken into account during the work process. Drilling is carried out in full accordance with the markings. Using a drill, the required depth in the soil is reached. Afterwards, formwork is installed in the finished pit. You can see how to make this design in the photo.

The soil at the base is well compacted, then a sand mixture is poured onto the bottom and the necessary cushion is formed. Its thickness is about 40 cm. Reinforcement of bored piles will strengthen the entire structure and extend its service life.

When preparing a concrete mixture, the depth of laying the elements is taken into account. Laying concrete does not require any special skills. The foundation includes tying individual elements using a grillage. It is made monolithic using reinforced concrete. This technology is comparable to the construction of a non-damaged strip foundation. The area of reinforcing bars should be no more than 3% of the cross-section of the entire tape. For the construction of a grillage, you can use A400 reinforcement. Since it is a bendable part of the foundation, “lean” concrete is not used in the construction.

To erect a grillage on bored piles you must:

- install the formwork correctly;

- construct a reinforcement frame structure;

- pour concrete once;

- perform vertical waterproofing;

- carry out horizontal waterproofing.

If the soil includes clay or sandy loam, then a damping layer is used. Such a measure will prevent damage and provide the element with reliable strength. Lay a layer 10 centimeters above the soil surface.

To properly make the gap, use a sand cushion. After pouring the structure, it is removed. You can use polystyrene, which should be left in the structure. Reinforcement outlets are connected from piles to the grillage frame. Pouring is carried out into a previously prepared formwork cavity. To make a frame, two methods are used:

- welding;

- tying the rods with strong wire.

Welding can be combined with strapping. When erecting a structure, the gap between the soil and the grillage should be about 10 cm. When the soil swells, this measure prevents deformation. In special cases, durable foam can be laid under the structure.

Waterproofing of pile-grillage foundation

The foundation with grillages needs waterproofing, which protects the foundation from moisture. The installation of waterproofing for buried pile-grillage foundations is especially important. For raised grillages, it is also advisable to waterproof them. The following waterproofing options are available:

- coating - the piping is covered with a layer of bitumen mastic;

- rolled - a monolithic tape is coated with a thin layer of mastic, and a roll of waterproofing is laid on top;

- sprayed - a liquid composition with water-repellent properties (such as “liquid rubber”) is applied with a spray gun;

- penetrating - a solution with high adhesive properties, which is used to treat the foundation to protect it from moisture.

The choice of waterproofing depends on the groundwater level, soil type, type of grillage, financial capabilities and personal preferences of the owner. Different types of waterproofing have their own advantages and disadvantages, which are recommended to be taken into account when choosing.

Insulation of pile-grillage foundation

Thermal insulation of the grillage helps prevent heat loss through the floor of the house. The following can be used as insulation:

- polystyrene foam or extruded polystyrene foam in slabs;

- sprayed polyurethane foam thermal insulation.

It is impossible to use mineral wool insulation for the foundation, because... they actively absorb moisture and become unusable. The main parameters that you need to pay attention to when choosing a heat insulator for a foundation on piles: thermal conductivity - must be at least 0.035 W/μ and water absorption no more than 4%. Also, the insulation must have noise-insulating properties, be resistant to rodents and aggressive environments. The insulation boards are attached to the top and bottom of the grillage using glue and dowel-nails. A reinforcing mesh and a plaster layer or other type of finishing are mounted on top. To remove moisture and maintain the integrity of the foundation, it is necessary to make a blind area.

You can ask your question to our author: