Pile foundation Any foundation that will be built for a house must be reliable and durable. Among the sufficient number of foundations, a special place is occupied by the pile foundation, which is suitable for a house that will not have significant weight (made from light building materials).

The construction of such a foundation does not present any great difficulties, but in order to install a pile foundation with your own hands, you need to clearly understand all the intricacies of the technology. This is exactly what will be discussed in this article.

Advantages and disadvantages

Before installing the structure, you should familiarize yourself with the positive and negative sides of the issue and study important operational characteristics.

The advantages of a foundation made of reinforced concrete piles include:

- Positive results of construction in problem areas (except for rocky soil)

- Rapidity. The structure can be installed within 24 hours, while the traditional method of constructing a foundation requires at least 7 days. After this, the construction of load-bearing structures can be carried out immediately (the monolithic foundation allows work to continue only after 3-4 weeks).

- Reducing construction and excavation materials to a minimum.

- All-season. It is possible to form a foundation on driven reinforced concrete piles at any time of the year, regardless of climate and weather.

- Duration of use. Reinforced concrete piles for the foundation are very wear-resistant and can withstand any weather disasters. The term of their suitability can be about one and a half hundred years.

- Strength. Reinforced concrete foundation piles, in the construction of which metal rods are used, are characterized by the ability to carry multidirectional loads, which is a necessary quality in unstable areas.

The foundation on driven reinforced concrete piles has only a few disadvantages.

- Possibility of subsidence or curvature of the foundation. There is always the possibility of unreliable characterization of deep soil, since it is not possible to consider a multi-meter layer.

- Mandatory use of expensive specialized equipment for installing piles.

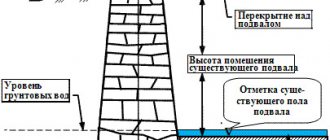

- The lack of a basement and basement is a real inconvenience that people who decide to build a foundation on reinforced concrete piles will have to face.

Types of piles

When constructing premises with a small number of floors or frame houses, it is possible to use these types of supports.

- Reinforced concrete. The most widely used. They are available in any landscape; a large number of companies specialize in both the production and installation of piles. The operational period ranges from 50 to 150 years. There may be differences based on certain criteria:

- supports with prestressed and non-prestressed metal rods;

- types of sections: round, square, T-shaped and hollow;

- shape: prismatic and cylindrical;

- structure: solid and subject to assembly;

- base: expanded, bound or hollow.

- Wooden. They are very popular in the construction of log houses made of wood and frame structures on a wooden base. Their degree of reliability is lower than that of the previous ones, so they can only be created from certain types of wood. Recommended for use on heaving soils. The above type of supports are usually made from cedar, oak, larch, and other hardwoods. Wood supports with a diameter of 20-40 cm and a length of three to 8 meters are used. When used on hard ground, it is necessary to use a shoe - a steel cap with strapping, which is attached to the bottom of the sharpened end of the pile. Weather conditions, climatic changes, and soil characteristics have a huge impact on the performance characteristics of wooden supports. If all rules are followed, the service life is at least 50 years.

- Steel. There is a wide range of materials for the production of this type of piles: rails, channels, pipes, etc. They are used infrequently, as a rule, for temporary buildings or utility structures. The approximate period of operation is 40 – 60 years.

Types of installation

The method is determined based on the indicators of geological research and the design features of the planned structure. In order to adequately separate the gravity, reinforced concrete supports on the foundation are lowered to the level of the solid stable layer. The following types of installation are allowed:

Driven. The most commonly used method. The supports are installed using a device with a hydraulic or pneumatic hammer.

- By pressing method (constant pressure is applied).

- Vibratory deepening. Instead of the extracted layer of earth, hollow shell supports are placed, and concrete is poured.

Reinforced concrete piles for construction are poured using the following methods:

- Bored. Formwork is installed in a pre-drilled hole, metal rods and concrete are placed.

- Buroinjection. It consists of supplying concrete under pressure into a drilled hole followed by installation of metal rods.

- Soil-cement. A mixture of cement and soil is poured into the drilled hole. The cement capacity and reliability of such a support are 2 times lower than that of cement concrete.

Classification of concrete piles

Piles are usually divided depending on the material of manufacture, so concrete support rods include reinforced concrete supports and concrete piles.

Reinforced concrete driven supports are usually manufactured industrially, while concrete ones can be poured directly on the construction site, while the work of constructing a pile field under the building can be done with one’s own hands. Installation of driven supports cannot be done manually; driving the rod into the ground will require the use of expensive pile-driving equipment, which will significantly increase the cost of construction of the facility.

The disadvantage of driven piles is that they are installed using special equipment

Depending on the installation method, concrete supports can be divided into two groups: cast-in and driven-in.

According to the work technology, driven supports are installed in pre-prepared wells (pits), which are performed using special drilling equipment. The driving rods are immersed in the ground (sandy or clay) without preliminary preparation.

It is customary to subdivide piles depending on the cross-sectional shape; there are reinforced concrete supports with round cross-section rods, as well as square and rectangular ones. Round-section supports are used on weak, heaving soils, the basis of which is clay; for more rigid soil foundations, rods with a square or rectangular cross-section are used.

Piles are distinguished by the type of load they accept; supports are divided into central and auxiliary. The central ones take on the entire load from the foundation belt, the auxiliary ones - only the load with eccentricity.

Calculation

Correct calculation of driven reinforced concrete piles for the foundation makes it possible to make the foundation of your building stable. In addition to the correct calculation of the number of reinforced concrete piles, it is necessary to pay attention to the depth of their installation, which can have an amplitude from three to ten meters, and the cross-sectional size should be from 150 to 250 mm.

To calculate the basic indicators of the foundation, the following factors must be taken into account:

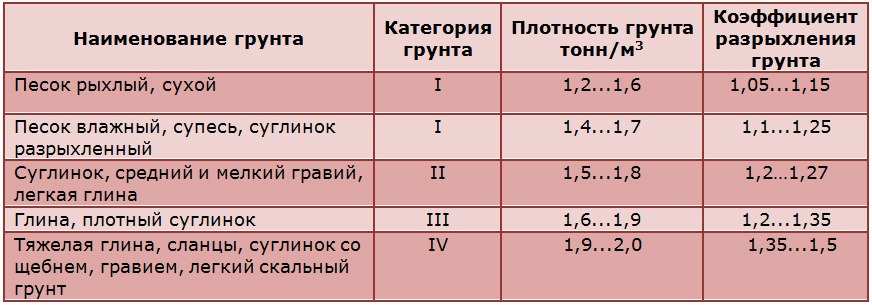

- Type of soil. It is best to ensure that a geological survey is carried out, but it is possible to obtain the necessary information from a reference book.

- Weight of the building. It can be calculated taking into account the amount of materials used for construction. You should separately calculate the weight of the coating, floors, concrete grillage and decorative materials. The weight of the interior furnishings (approximately 7-10 tons) should be added to the result obtained.

This operation should be carried out without forgetting the safety margin. In this regard, the resulting figure needs to be increased by a third. Let's say the building weighs 180 tons. The length of the reinforced concrete pile is 4 meters. Such a pile can withstand an average load of 20 tons (for loamy soils); from which it follows that 9 piles have the ability to reliably and proportionally divide the full load of the structure.

When can you use a pile foundation?

Of course, before you start telling us how to properly install a pile foundation with your own hands, you need to understand not only how this is done, but also what structural and soil features such a foundation will be suitable for.

The first thing you need to pay attention to when choosing this type of foundation is the quality of the soil cover in the area where construction will take place.

Pile foundations can be effectively used on weak soils that have a large freezing depth, high groundwater levels, and unstable topsoil (silt, clay, sand, loam, peat, purulent deposits).

This area of construction of this foundation is due to the fact that the construction of a pile foundation provides for a depth of immersion of piles greater than the same indicator of the level of soil freezing, that is, they are installed in hard soils located at a significant depth.

The second thing you need to pay attention to is that a pile foundation can be used for certain houses. In individual construction, houses standing on stilts should not have much weight, that is, they should be built from lightweight building materials (gas-foam concrete, wood, frame versions of the house). The construction of heavy structures is not recommended. Now we can move on to talking about the stages of its construction.

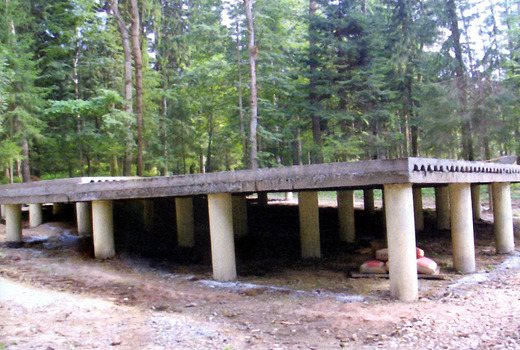

Application of grillage

A grillage is an element of the foundation structure that connects piles into a solid structure and provides support for load-bearing components. According to some reviews, you can do without it. However, the foundation on driven reinforced concrete supports with a grillage is more reliable and stable than in a situation without it.

There may be no grillage when constructing a building made of timber. The grillage function is performed by the lower crowns of the structure.

According to the manufacturing method, reinforced concrete and metal are distinguished.

To obtain the first, the solution is poured into a pre-prepared formwork with a built-in and fixed reinforcement frame.

To make a metal grillage, rolled metal products such as I-beams, rails, and channels are used. They are placed on supports driven in level and welded to iron rods that are visible outside the supports. The components are fastened together by welding or bolts.

This type is used for non-permanent or utility premises, such as a gazebo, warehouse, garage.

There are three types of grillage:

- hanging. It is located at a considerable distance from the soil; there is an uninsulated hollow space under the floor. It is used in the construction of temporary buildings: baths, attics, small country houses. In this case, the use of mini reinforced concrete piles is allowed.

- shallow. It sinks to a small depth into the ground. They cannot act as a support, they are used as a means of protecting the space under the floor, the building from unfavorable climatic conditions, changes in the movement of air masses;

- recessed To create it, dig a trench similar to a strip base. It provides extra support for the building, strengthens the foundation on piles, and is ideal for the construction of a solid year-round building.

Bored piles

One type of concrete piles is bored supports. Bored piles are reinforced concrete structures, the installation of which (pouring) takes place in specially prepared wells.

A bored pile consists of reinforcement strapping, shell pipe and poured concrete

The design of bored supports consists of two elements:

- Concrete rod - frost-resistant concrete M200 and M300 is used to fill the support.

- Frame made of reinforcing steel - for reinforcing piles, ready-made frames made in an industrial way can be used; it is allowed to manufacture reinforcing cages directly on the construction site, for which smooth and corrugated reinforcement is used. The longitudinal rods of the reinforcing frame are made of corrugated reinforcement with a diameter of 12 to 20 mm. Transverse jumpers are made of smooth rod with a diameter of 8 mm. The frame is welded using electric arc welding machines. The connection points of the reinforcement must be carefully treated with protective compounds against corrosion.

To solve various construction problems, two types of bored piles are used: conventional cylindrical supports and rods with a widened support base. The widening at the bottom of the pile (heel) is performed to increase the support area of the pile rack. Such supports have increased stability and are able to bear increased load from the weight of the structures.

The support expansion can be formed using special drill strings, as well as using a specially prepared explosion.

Construction stages

After all preparatory activities have been completed, the necessary materials have been prepared, special equipment has been ordered, preliminary calculations have been made, construction work can begin to install the foundation of the building.

- At the initial stage, it is necessary to remove vegetation and debris from the site, free up space for installing piles and space for building materials. The top part of the soil should be removed.

- At the next stage, work is carried out on marking the base and identifying areas for driving piles.

- After completing the previous stage, the size and proportions of the pore should be re-monitored.

- Installation of piles is carried out using specialized equipment: a machine with a hydraulic or pneumatic hammer. While lowering the pile, its strict vertical position should be monitored. If you notice that the pile behaves unusually during driving and deviates from the specified trajectory, it means that it has encountered an obstacle or fallen into a hole underground. This means that the installation site of the reinforced concrete pile should be moved to the side or the length of the existing structure should be increased.

- After deepening the piles into the ground, it is necessary to remove the top of the support in order to reach the metal rod and bring the height of all supports to the established standard.

- The next construction step focuses on the type of foundation. It is possible to build formwork for a strip foundation on driven reinforced concrete piles or to place floor slabs if the base is pile-slab.

- There is also a pile-tape type of foundation. In this case, it is necessary to fill the metal frame pre-fabricated in the formwork with mortar. After four weeks, the foundation will be settled to allow construction work to continue.