The foundation is the main part of the house.

The durability of the entire structure depends on how strong it is. If you do not attach importance to its waterproofing, after some time, as a result of exposure to soil, rainwater and low temperatures, it sags and becomes deformed. To neutralize their impact, foundation waterproofing is needed. [contents]

Doing this work with your own hands is not very easy. Its technology requires knowledge and understanding of the processes occurring in soil and concrete, as well as knowledge of waterproofing materials. Before you begin waterproofing your foundation, consult a specialist.

Do I need to waterproof a strip foundation?

Any type of strip foundation either consists entirely of or includes concrete. This material has a high ability to absorb water.

When the temperature drops below zero, it freezes, increases in volume and destroys the foundation, as if exploding it from the inside. The only way to prevent such a situation is to waterproof the tape, installing a waterproof cutoff that prevents moisture from penetrating into the thickness of the material.

If you neglect to carry out this procedure, the service life of the foundation is significantly reduced, and a building installed on a problematic foundation will be at risk of subsidence, destruction or other undesirable processes.

In addition, a wet base will become a source of water penetration into the wall material, causing destruction, corrosion of metal parts and other dangerous and undesirable processes.

Experts take waterproofing very seriously, considering it one of the most important procedures.

Main types of coating waterproofing materials

Compositions can be divided into 2 large groups:

1. Rigid 2. Elastic.

Mixtures from both groups are sold in the form of dry powder. The main difference between coating waterproofing from the second group is that it contains a polymer emulsion.

There are also differences in the preparation of the moisture-proof solution. Hard mixtures are diluted with water to the desired consistency. Polymer-cement waterproofing is prepared differently - instead of water, a pre-prepared polymer emulsion is added to the cement mixture. Since polymer-cement materials consist of 2 components, their cost is correspondingly higher. Therefore, the elastic coating waterproofing kit, along with the cement mixture, includes a container with a ready-made polymer emulsion. Recently, a number of foreign and domestic manufacturers have launched the production of coating polymer-cement waterproofing, in which polymers are present in dry powder form, and the solvent is ordinary water.

Differences between shallow and normal foundations

There is no fundamental difference in the installation of insulation. The only difference is in the area of application of the compositions, the amount of material and the duration of the process . The design of a shallow strip foundation differs from the conventional type only in the depth of immersion, so all technological methods are the same.

However, the difference in the immersion of the concrete base creates a significant difference in the density of contact between concrete and soil moisture. The usual type of strip foundation is immersed to a depth below the freezing level of the soil.

The base is in more risky conditions; changes in the level of soil water or the influx of rain and melt moisture create a noticeable threat to the material . Therefore, for conventional types of strip foundations, the installation of waterproofing requires greater care and quality of application.

Care of treated surfaces

It does not matter what type of coating composition was used to protect the room from moisture - all treated surfaces require subsequent care. To prevent the outer layers of waterproofing from drying out, it must be periodically wetted over the entire area. This can be done using a regular hose with a low-pressure water supply. To mechanically protect the coating from various damage, dust settling, and the ingress of chemically aggressive substances, you can use matting or tarpaulin. The listed activities are carried out within 2-3 days immediately after the completion of repair work.

If the layer of coating waterproofing is several centimeters, then certain temperature conditions must be maintained in the room and drafts should not be allowed. Otherwise, such waterproofing will become covered with a network of invisible microcracks and will begin to collapse over time. Elastic coating mixtures are more resistant to negative influences of this type. But even in this case, the recommendations of the manufacturers of the compositions indicate mandatory protection of the coating using plastic film or tarpaulin. Especially in the first days after applying the last layer.

What materials should be used

Foundation waterproofing can be implemented in various types:

- Rolled pasting materials. They are various membranes, films or thick bitumen materials (roofing felt, glassine, hydroisol). They are applied by sticking to a layer of mastic or using heat.

- Coating materials. These include bitumen (heating and application), cold mastics (sold in ready-to-use form, applied by coating surfaces with a continuous layer).

- Penetrating materials. Materials that can be absorbed into the thickness of concrete and crystallize inside, filling the pores of the material and preventing the penetration of moisture. Apply by brush or spray.

- Injection materials. They have an effect similar to penetrating compounds, but are applied by drilling wells and pumping material into them under pressure. As a result, the composition impregnates a larger volume of concrete, strengthening it from the inside.

- Painting materials. These include liquid rubber or liquid polyurethane foam, which, after application, harden into an elastic, water-repellent film. Application is simple, but in terms of strength these materials are inferior to rolled types. The service life of painting materials is relatively low, which limits the use of this type of waterproofing.

Materials and technologies

To insulate the base, floor and foundation of a house, coating waterproofing made from polymer and bitumen mastics, as well as weld-on insulation, are most often used. Such materials are suitable for basements of houses made of profiled timber, stone, brick, concrete.

Application of waterproofing by fusing method

Disadvantages of coated and weld-on insulation are swelling and peeling at low water pressure due to hydrostatic pressure.

More effective modern methods of insulating the base are penetrating waterproofing, mineral-based coating compounds, membrane materials, liquid rubber and glass insulation. Such insulation is suitable even for the old foundation of a house made of timber.

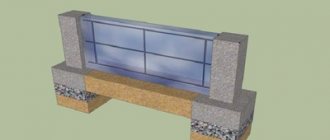

Rolled materials for waterproofing

Insulation of the base with roll materials on a bitumen or polymer base is called lining. Roofing felt, roofing felt, glass roofing felt, foil isolon, hydroisol, brizol are used. They can be glued to cold or hot bitumen mastic and fused. The method is suitable for houses made of timber and logs.

The waterproofing is glued to the cleaned and dried walls of the basement from the inside. To do this, bitumen mastic is first applied. It is necessary to overlap the strips by 15 cm. The material is also wrapped by 15 cm at the joints between the walls and the floor.

Advantages:

- low price;

- the ability to carry out work independently.

Flaws:

- at low temperatures such insulation becomes brittle and breaks easily;

- rolled materials are susceptible to damage by fungi and mold;

- the effectiveness of insulation depends on the quality of the work performed.

Membrane insulation

Previously, this type of roll waterproofing was intended for external pressure insulation of the foundation. But now a membrane material has appeared for internal use. It is ideal for basement insulation in houses made of profiled timber and other wood materials. Cone-shaped spikes on the surface of the material perfectly remove accumulated moisture.

Before using membrane protection, the basement walls must be cleared of debris, cracks and crevices between structural elements must be sealed, and the surface must be primed. The membrane is attached to the walls with dowels. The open ends of the membrane must be secured with a horizontal insulating layer.

Pros:

- long service life;

- Possibility of use on damp walls;

- Suitable for self-application.

Cons – cannot be used without horizontal waterproofing of the foundation.

Penetrating insulation

This insulation inside the house penetrates through microcapillaries and cracks in the basement enclosing structures and crystallizes there. The process occurs due to the use of penetrates (alkali metal carbonates, silica, aluminum oxide) in the composition. As a result, the foundation walls become impenetrable. Insulation is suitable for houses made of timber, stone, brick and concrete with block and concrete monolithic foundations.

Materials for foundation waterproofing

Advantages:

- high efficiency due to penetration deep into the material;

- the frost resistance of concrete basement structures increases;

- suitable for DIY application;

- thorough plugging of even small cracks;

- such insulation cannot be damaged;

- durability.

Application method:

- To open the pores of the concrete, the surface must be thoroughly degreased and cleaned. To do this, you can use a wire brush or a water jet.

- The solution is being prepared.

- The composition is applied to the damp inner surface of the foundation. In this case, first the joints between the walls and the floor and the corners are processed, and then the solution is applied to the walls.

- After two hours, you can apply the second layer of the composition.

- To ensure uniform hardening of the solution, the surface must be moistened for several more days after waterproofing.

It is important to know: in order for the solution to penetrate to a depth of half a meter in the foundation structure, several layers will need to be applied.

More details about the use of penetrating waterproofing can be seen in the following video:

Injection insulation

To install such waterproofing, a liquid gel-like composition must be introduced into special holes in the foundation. For these purposes, microcement, polyurethane, epoxy or acrylic gel are used.

Scheme of using injection waterproofing of the foundation from the inside

Advantages:

- acceptable price;

- the method can be used at any temperature and humidity level in the room;

- the surface does not need preparation;

- Suitable for hard to reach places.

There is only one drawback - the method is not suitable for doing it yourself, since you need to know the technique and have the skills to handle the tool to perform it.

Execution sequence:

- Using a puncher you need to make holes for injections.

- A pressure pump pumps the solution into the hole or crack. For this, special needles are used.

To learn more about the sequence of injection waterproofing, you can watch the video:

Liquid rubber and glass

Both compositions, when applied to walls, form a durable membrane, securely connected to the base. The advantages of such insulation include its maintainability, durability, low cost, the possibility of independent use, antifungal and anti-corrosion qualities. However, liquid glass is only suitable for concrete foundations with metal components.

Liquid glass and rubber are applied to the walls after they have been cleaned and degreased. More details about this in the video:

Basic methods of horizontal waterproofing

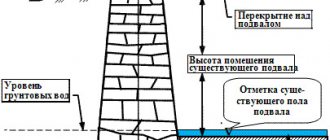

Horizontal waterproofing in the ground, as the name suggests, is installed on surfaces located in a horizontal plane.

In relation to a strip foundation, this is an underlying layer of insulation installed on a sand and gravel cushion (usually a layer of roofing felt), as well as a layer laid on top of the strip and designed to cut off capillary absorption of moisture by the wall material.

There are two types of horizontal waterproofing:

- Coating. Mastics or similar materials are used, applied to the surface with a brush or roller.

- Pasting. Rolled waterproofing materials are used.

The first option is only suitable for the top cut-off layer applied to the surface of the tape. The second option can be used both from below and from above.

In addition, different types of waterproofing are used depending on the type of action:

- Anti-filtration. Provides a tight seal against moisture penetration.

- Anti-corrosion. Designed to protect materials from the aggressive effects of chemical compounds present in soil waters or formed as a result of soil contact with rain, melt or ground moisture.

Horizontal waterproofing is considered more important and responsible, since it cuts off the effects of moisture coming from below and eliminates the capillary flow of water into the concrete mass. The most important element is the bottom (underlying) layer of roofing material, which is laid before pouring the formwork.

IMPORTANT!

The insulator is spread in a layer at least 10 cm wider on each side than the future tape. Subsequently, the edges of the roofing material are lifted and glued to the concrete with bitumen mastic, forming a kind of wrap.

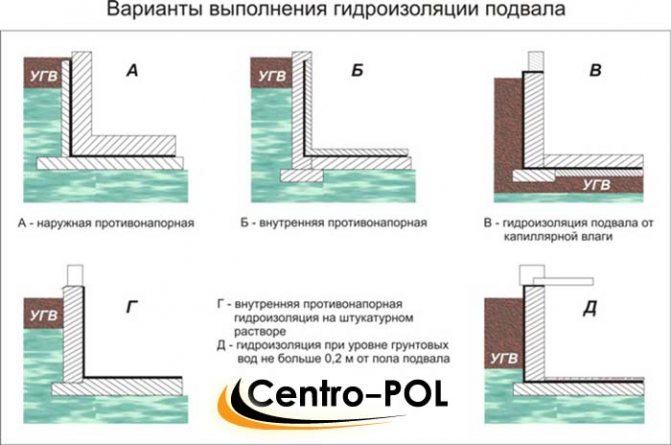

Features of internal waterproofing

But if problems appear during the operation of the finished house, then the only way out of the situation will be internal waterproofing of the basement from groundwater. At the same time, log houses are no exception, because their foundation can also be subject to the destructive effects of moisture below the base level. For internal protection of the foundation of a private house, special compounds can be used:

- paints with insulating properties;

- bitumen mixtures;

- rolled waterproofing materials, for example, roofing felt;

- sheet metal;

- compositions based on bentonite clay;

- polymer waterproofing mixtures.

Depending on where the base of the house gets wet, internal horizontal or vertical insulation can be performed. The easiest way to waterproof a foundation from the inside, which you can do yourself, is to treat the walls, floor and ceilings between the basement and the living floor with insulating paints. To be effective, it is better to use at least three layers of paint.

Vertical waterproofing methods

Vertical waterproofing is installed on concrete strip walls both outside and inside. The procedure is intended to protect the foundation from moisture, which results in the formation of mold, mildew, destruction of concrete, and frost ruptures in the massif in winter.

The most critical area is the outer side of the tape, but it is also necessary to install protection from the inside. This is necessary to prevent condensation formed on the cold surface of the foundation strip from penetrating into the concrete.

If there is a basement, then installation of waterproofing becomes a mandatory measure accompanying the organization of high-quality ventilation.

The choice of material for vertical waterproofing must be made carefully and responsibly. After filling the sinuses, access to the surface ceases, so everything must be done without mistakes.

For application to concrete tape the following are used:

- Coating compounds (mastic, heated bitumen). Recommended only for application on the outside of the tape, as they are only effective under direct moisture pressure. Application is carried out by spraying, painting or (most often) coating surfaces. It is most convenient to use ready-to-use mastic, since you have to use an open fire to heat the bitumen, which is not always possible.

- Roll materials. Traditional type of waterproofing, along with tar. The most common type is roofing felt; glassine and waterproofing are also common. Application is carried out either on a layer of hot bitumen or on mastic. Installation of the second layer can be done on the previous one by heating the material itself; the molten layer of bitumen connects the layers like an adhesive composition.

- Penetrating compounds. This type of waterproofing impregnation appeared relatively recently, but has managed to prove itself on the positive side. The compositions do not form a waterproof cut-off, but change the properties of concrete, stopping the ability to absorb moisture. There are compositions for surface application and for deep impregnation from the inside by pumping the composition into drilled holes. After application, the composition impregnates the base material, crystallizes, clogging all concrete capillaries and blocking the possibility of absorption.

When choosing the most suitable material, you should take into account the operating conditions of the foundation, the hydrogeological composition of the soil, the type of foundation and the depth of immersion. Experts recommend using penetrating compounds to obtain high-quality waterproofing of a new type.

NOTE!

When applying penetrating waterproofing compounds, it is necessary to ensure proper conditions (dry surface, temperature not below zero, absence of scorching rays of the sun or strong wind), and also follow the technology of use.

Tips for carrying out waterproofing work

If you are going to do all the work yourself, then special attention should be paid to:

- places where two surfaces join, for example, at the seam between the wall and the floor, the ceiling and the walls, corners;

- seams that formed during concreting or after removing the formwork, as well as seams between structural elements of walls and ceilings;

- places where engineering communications are laid;

- cracks formed during the shrinkage of the old house.

Vertical internal waterproofing

Waterproofing foundation walls made of stone or brick is called vertical. Moreover, such insulation is also needed for structures made of profiled timber or logs, because the base of a wooden house is also made of artificial or natural stone materials. Typically, internal vertical insulation is done at the level of the basement of the house.

For the inside of the basement walls below the plinth, traditional plaster waterproofing using modified mortars is suitable. This method is the simplest and most inexpensive, so you can do it yourself. Waterproofing can be done using the following materials:

- primer composition;

- polymer or bitumen mastics;

- brush and spatula of sufficient size.

Work on waterproofing the foundation walls below the base is carried out in the following order:

- First you need to thoroughly clean the walls of dust and dirt.

- All surfaces are primed.

- After the solution has dried, all that remains is to do the waterproofing.

- When the first layer has dried, you can apply the leveling layer.

Tip: the universal composition Penetron (penetrating insulation) is suitable for insulating concrete and monolithic basement walls. An equally effective remedy for any surface is liquid rubber, which can be applied to wet or dry basement walls, inside and out.

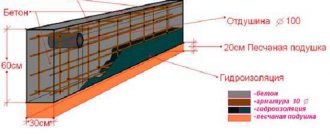

Horizontal internal waterproofing

Waterproofing the foundation requires treating the basement floor. This type of insulation is usually called horizontal insulation. The most inexpensive and accessible method of insulation is performed using roll and sheet materials. To lay horizontal insulation from bitumen roll materials, gluing with special adhesives is used, and the use of polymer materials requires the use of special primer solutions.

To carry out horizontal waterproofing of the basement floor you will need: roll insulating materials, primer, adhesives, a knife for cutting the material, a trowel, a brush. The work is carried out in the following order:

Price of work per m2 for foundation waterproofing

- If there is water in the basement, it needs to be pumped out and the room dried.

Important: in order to dry the basement well, you need to provide ventilation to the room.

- Then you need to clean the seams and cracks in the concrete floor covering to a depth of 5 cm.

- We treat the floor surface and cracks with a primer.

- We seal all cracks with cement mortar.

- Now you can waterproof the basement floor. To do this, we lay roofing felt or other rolled material on heated bitumen. It is better to lay two layers of insulation.

- Then you can fill the screed.

To insulate the basement floor of an old house, it is better to use two-polymer self-leveling insulation from a mixture of cement, sand and binders. This method is also suitable for houses made of timber or logs, where high-quality insulation of the basement from moisture is very important.

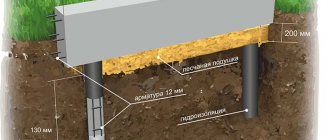

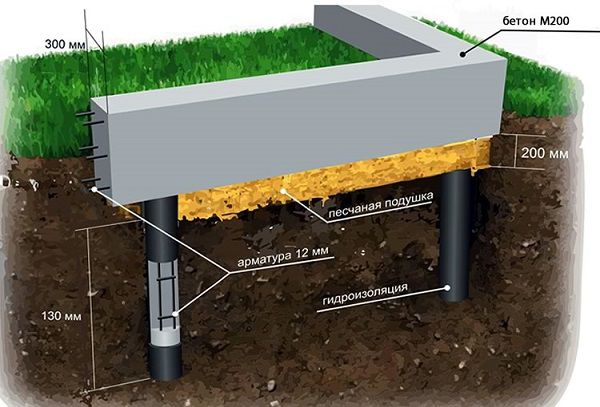

Pile-strip foundation

Do-it-yourself waterproofing of a pile-tape base consists of two stages - processing the piles themselves and applying insulation to the tape. To waterproof piles, appropriate techniques are used, depending on their type and method of immersion in the ground.

For example, bored piles are poured into tubes made of moisture-impermeable material. Driven piles are isolated in accessible areas . Modern types of concrete piles are made of concrete with hydrophobic additives, which prevent the penetration of moisture into the mass.

The tape is processed using one of the most affordable or suitable insulators for construction conditions.

Both traditional methods can be used - coating with hot tar, bitumen, pasting with roofing felt, etc., as well as more modern methods of impregnation or spraying of rubber-bitumen liquid emulsion or polyurethane foam.

The final choice is dictated by a combination of various factors and can only be made on the basis of an examination of the specific basis.

Bitumen-based coating waterproofing

The second, more well-known name for moisture-protective mixtures of this group is bitumen mastics. The undeniable advantages of bitumen mastics primarily include:

— high level of protection of treated surfaces from the destructive effects of moisture; — ease of use; — surfaces can be waterproofed even in subzero temperatures; - low price.

However, recently the demand for compositions based on bitumen mastic has been noticeably decreasing. The reason is that there are several serious shortcomings:

- short service life of the moisture-protective layer - no more than 6 years. However, after 3-4 years the deterioration in the waterproofing properties of the treated surfaces makes itself felt; — in the summer, due to the relatively high ambient temperature, bitumen-based waterproofing loses its elasticity and begins to crumble layer by layer.

It is for this reason that more modern cement-based mixtures are sold on the MPKM website. Their characteristics will be discussed further.

Which method is most optimal?

The most optimal waterproofing methods include impregnation of concrete with hydrophobic compounds. Unlike traditional options, which are labor-intensive and do not provide complete tightness, impregnation does not create an outer layer.

When backfilling or other work on the surface, the cut-off can be easily damaged, which will create the possibility of moisture penetrating into the hole. Impregnation eliminates this danger by compacting and sealing the concrete to a certain depth.

IMPORTANT!

Mechanical stress, contact with objects, loads when filling the sinuses will not damage the resulting protection, and the base will not lose its hydrophobic qualities.

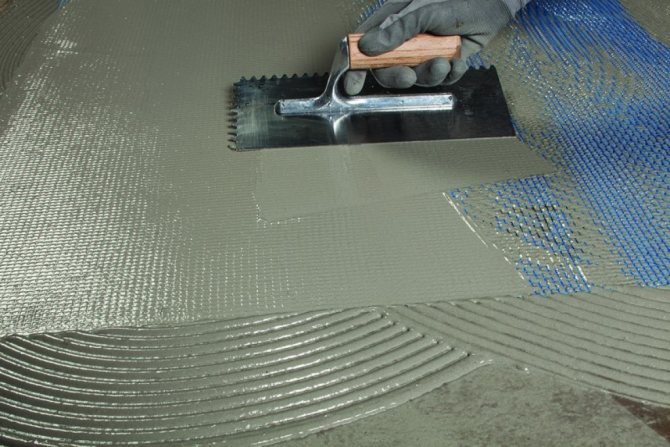

Applying coating waterproofing: how to do it correctly?

To maintain all the benefits of coating waterproofing, when applying it you must strictly adhere to certain rules. Below are the main stages of this work, there are 5 in total:

1. Cleaning the working surface 2. Wetting the working surface 3. Applying the first layer of solution 4. Letting the applied layer sit 5. Applying the 2nd and subsequent layers

1. Cleaning the work surface

At this stage, you should carefully remove dirt, dust, remnants of old paint, and all grease and oil stains. High-quality cleaning is required to improve the adhesion of the solution to the concrete base.

2. Hydration

Produced using a spray bottle. You need to moisten the entire area of the cleaned base. However, you should not overdo it in this matter, saturating the walls with water to the full depth.

3. Applying the first layer of waterproofing

The prepared solution is evenly distributed over the working base using a roller, spatula or brush. After applying the first layer, wait until it dries. There is one nuance here - the layer should set well, but not dry completely. After this, the next layer of waterproofing is applied to the wet and hardened first layer. The described cycle is repeated until the coating waterproofing of the required thickness is obtained.

IMPORTANT! The direction of movement of the brush when applying the next waterproofing layer should be strictly perpendicular to the previous one.

How to apply primer

A primer is a special bitumen primer that contains mineral components of a complex composition, all elements ensure optimal adhesion of the mastic to the concrete base. A primer is selected individually for each type of foundation, especially expensive primers for brick and rubble structures.

The primer is made from bitumen grades BN 70/30 or BNK 90/30, gasoline or nefras is used as a solvent, the heat resistance of the mixture is not higher than 80ᵒ, additionally it must be diluted with solvents.

A primer is selected separately for each type of mastic and applied in one layer evenly over the entire surface of the foundation. If at the base there are joints between concrete slabs of horizontal and vertical tiers, then application is carried out in two layers. For application, use a roller or brush; the primer must be left to dry for several hours. Technology for applying coating mastic:

- Bitumen mastic is always applied to a previously prepared surface exclusively from the water pressure side. As a rule, this is the outer side of the foundation, but in some cases, especially if there is a basement or underground garage, it is also applied on the inside.

- The mastic is applied evenly with a roller or brush in layers. Each layer is continuous, without breaks, uniform, applied in parallel. Apply mastic from bottom to top.

Subsequent layers must be applied in a similar way after the previous one has hardened.

The need to waterproof the foundation

There is an opinion that the foundation does not undergo any changes during the operational period. Supposedly, it is resistant to rotting, decomposition and corrosion. In fact, the foundation built under the house requires additional protection without fail. Many people are interested in whether it is necessary to waterproof a strip foundation?

Water located deep in the soil can penetrate into basements and even into walls located above the soil level.

It is no secret that seasonal freezing of water in walls contributes to their destruction. A similar process occurs with the upper sections of the object’s base. A structure whose foundation does not have a waterproofing layer will not last long.