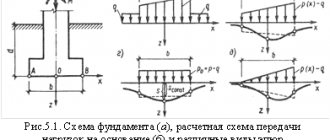

Calculation diagram for an example of determining foundation settlement using the layer-by-layer summation method. At the moment, there are a large number of different calculations of loads on foundations, on the basis of which the type of building materials, dimensions of the base base and other data are then selected.

The layer-by-layer summation method is used in cases where it is necessary to calculate the settlement of a free-standing foundation, taking into account the influence of external factors and additional soil influences.

Application of the method

It is recommended to use the layer-by-layer summation method if you need to determine not only the main precipitation factors, but also secondary or additional ones that arise only in specific situations.

The calculation allows:

- Determine the settlement of a free-standing foundation or a set of foundations located close to each other or connected to them.

- Used when calculating foundations made of heterogeneous materials. Such parameters are reflected in changes in the deformation modulus with increasing depth.

- As a rule, the method makes it possible to calculate settlement along several verticals at once, and here you can omit the parameters of angular variables and use central or peripheral parameters. But this can only be done if the foundation has layers along its entire perimeter and their thickness and structure are the same.

Such settlements often arise from neighboring foundations, because with increasing load on the site, soil subsidence inevitably occurs, especially when using powerful heavy structures. But here designers are often faced with the problem of creating settlement studies, because it is necessary to clearly determine along the vertical axis exactly those forces that arose from the influence of neighboring foundations.

Sometimes this is very difficult to do and you have to use empirical formulas. Then stress points are often found using the corner point method, and the results obtained in some cases are accepted as optimal for a given layered foundation.

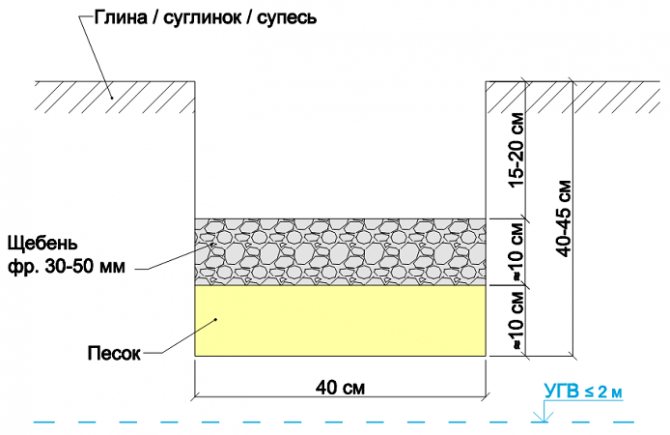

Construction of the base for the foundation

If you try to install a concrete foundation directly on crushed stone, without adding sand, part of the foundation strip or slab will be overloaded, and part will remain unloaded. In such a situation, the concrete casting of the foundation will quickly become unstable and cracks and deformations will form.

Functions of sand filling

Sand plays the role of glue and elastic cushion, which allows you to compensate and distribute all forces, including when the soil swells or the foundation settles.

The sand material used in preparing and filling the base must meet certain requirements and criteria:

- Gravel sand, very coarse and clean, is considered the best; fills made from such material have the lowest specific gravity, but at the same time easily allow water to pass through;

- Minimum amount of inclusions of clay, earth, lime and salt contaminants;

- Sand should not contain any forms of organic matter, silt, peat, plant remains - everything that natural bodies of water are rich in. When such material is used in preparing the base, after a certain period of time the sand cushion turns into a dense waterproof layer of mud, saturated with organic decomposition products.

Advice! The quality of sand can be easily checked using available tools. For example, if you pour 5-6 liters of water into a hole dug in the ground, covered with sand, then if the quality is good, the water will go away in a few minutes; in dirty sand, a puddle will remain on the surface.

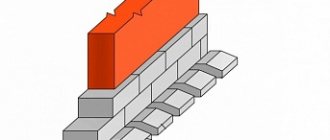

Classic foundation design for foundations made of crushed stone material

In the classic version, the technology for preparing a cushion under a concrete slab or tape uses crushed stone as a material that provides drainage and a rigid base. Therefore, the base is covered with at least one layer of crushed stone. The use of crushed stone material requires considerable costs associated with the purchase of building materials, delivery and planning work. Despite the high cost and scarcity of high-quality crushed stone, it is impossible to refuse its use in preparing the base for the foundation.

In cases where, in the process of surface leveling, large volumes of soil are removed and moved by bulldozers or excavators, crushed stone embankments are used to level the slope of the base. It is not always possible to perfectly level a gravel bed, so builders often use intermediate concreting or concrete preparation. Essentially, this is a thin layer of concrete laid on a sand-crushed stone base of the pillow and perfectly leveled with the horizon. After such preparation, it is enough to simply lay the waterproofing and insulation layer.

If the soil has high load-bearing characteristics, the preparation technology can be significantly simplified. In this case, the construction of the base for sand foundations is carried out in a simplified manner. A polyethylene film is laid on the leveled and compacted layer of sand, a layer of fine gravel or screenings is poured, and after compaction, a layer of waterproofing and insulation is laid. At the next stage, the reinforcement is laid and the concrete solution is poured.

Why is it so important to calculate foundation settlement?

Some foundations are characterized by weak bending and deformation strength due to large linear dimensions and small longitudinal thickness. As a rule, the layer-by-layer summation method is often used to calculate strip foundations, because they cannot provide the highest possible load per unit area of soil, and therefore settlement can occur almost anywhere quite spontaneously.

All calculations, formulas and recommendations are specified in detail in SNiP 2.02.01-83. To understand the method in more detail, you need to try to calculate the settlement of a strip foundation using a real example.

Types of shallow foundations

Shallow foundations include foundations with a laying depth of up to 4 m. The division of foundations by laying depth is directly related to the size of the foundation depth and to the operating conditions of the soil foundation under load and the methods of work during their installation. For shallow foundations, the loss of the bearing capacity of the soil foundation is associated with the formation of bulging soil mounds near the foundation on one or both sides. This phenomenon is not observed in deep foundations. The loss of bearing capacity of the soil foundation for these foundations causes a change in the structure of the soil within the soil mass. In addition, shallow foundations, as a rule, are erected in pits that have previously been dug to the full depth of the foundation.

The most common foundations in modern construction are reinforced concrete, concrete and rubble concrete foundations.

For foundations, heavy structural concrete with an average density of 2200 to 2500 kg/m3 should be used. It is allowed to use fine-grained concrete with an average density of over 1800 kg/m3. The compressive strength class of concrete is recommended to be no lower than B15. With appropriate justification, the use of class B20 concrete is permitted. The grade of concrete for water resistance is assigned in accordance with SP 52-101 “Concrete and reinforced concrete structures without prestressing reinforcement” [7]. So, for example, with possible occasional exposure to temperatures below 0 ° C, for foundations (a structure located in the ground), the waterproof grade W of concrete is not standardized. When designing concrete and reinforced concrete foundations intended for operation in an aggressive environment, the grade of concrete for water resistance is assigned in accordance with SNiP 2.03.11-85 “Protection of building structures from corrosion” [6] and must be at least W4.

Based on the manufacturing method, a distinction is made between monolithic concrete and reinforced concrete foundations and prefabricated foundations. Monolithic foundations are manufactured at the construction site, prefabricated foundations are mounted (assembled) at the construction site from structural elements made at construction industry enterprises. There are also mixed prefabricated monolithic foundations, when one, usually the lower part of the foundation, is made directly at its location, and the other, the upper part, is mounted.

Special preparation is made under the base of the foundations. It is recommended that under monolithic foundations, regardless of the underlying soils (except rocky), a concrete preparation device 100 mm thick should be provided and the base of the foundation protruding beyond the edges by 100 mm. Concrete preparation under the base of a monolithic foundation is accepted as class B10 [12]. The thickness of the protective layer of concrete for the working reinforcement of the base of the foundations in the presence of concrete preparation is taken to be at least 40 mm and not less than the diameter of the working reinforcement rod.

It is allowed to use crushed stone or sand preparation with a cement screed.

When justified, concreting of foundations without preparation is allowed. In this case, the thickness of the protective layer of concrete for the working reinforcement of the sole is assigned to at least 70 mm.

For prefabricated foundations, preparation is made of sand or cement mortar.

To protect the bases of foundations located in the level of aggressive groundwater (taking into account the possibility of their increase), it is necessary to provide:

· in acidic, weakly and moderately aggressive environments - a device for crushed stone preparation with a thickness of 100-150 mm from dense igneous rocks, followed by laying a layer of acid-resistant asphalt, and in highly aggressive acidic environments - additionally stick two layers of roll insulation over the acid-resistant asphalt, followed by laying a layer of acid-resistant asphalt;

· in sulfate, weakly and moderately aggressive environments - a crushed stone preparation device 100-150 mm thick with pouring hot bitumen until completely saturated, followed by preparation from concrete or cement-sand mortar or a layer of hot asphalt mastic, and for highly aggressive sulfate environments - preparation from concrete or cement-sand mortar on sulfate-resistant Portland cement.

The characteristics of aggressive environments are determined according to SNiP 2.03.11.

By the nature of their work, reinforced concrete foundations can be rigid or flexible. In rigid foundations, the line of ledges with the vertical forms an angle that does not exceed the angle of formation of the punching pyramid from vertical loads (Figure 24). In this case, no significant tensile stresses arise in the foundation body.

Based on the shape of the foundations in plan and the type of structures resting on the foundations, foundations are divided into free-standing, strip under the walls of the building, strip under the columns, solid (slab) under the walls of the building and solid under the columns.

|

Separate foundations

(Figure 25) are placed under columns and walls. In the latter case, to build walls under them, foundation beams (Figure 26) or plinth panels resting on foundations (Figure 27) are installed.

|

Strip foundations for columns

(Figure 28) take the load from a number of columns. Sometimes, under a grid of columns, strip foundations are made in two directions (cross strips). Strip foundations are used to reduce pressure on foundation soils and reduce uneven settlement of individual columns.

Strip foundations for walls

(Figure 29) preserve the geometry of the building walls in plan. In buildings with basements and technical undergrounds, strip foundations serve as the walls of recessed rooms.

Solid foundations

(Figure 30) are arranged under the entire structure or under part of it in the form of reinforced concrete slabs under a grid of columns and walls. Such plates bend in two mutually perpendicular directions. Solid foundations significantly reduce the pressure on the foundation soils compared to individual foundations and, with a significant thickness of the foundation slab, help reduce uneven settlement.

|

|

Calculation of strip foundation settlement

For example, you can take a strip foundation, which has a width of 120 cm (b) and a depth of 180 cm (d). It is built on three layers of soil. The total pressure under the sole on the soil is 285 kPa.

Each soil layer has the following indicators:

- Low-moisture soil of medium density and porosity, the main component is fine-grained sand, porosity e1 = 0.65, density γ1 = 18.7 kN/m³, degree of deformation E1 = 14.4 MPa.

- The second layer is thinner and consists of coarse-grained, moisture-saturated sand. Its indicators, respectively, are: e2 = 0.60, γ2 = 19.2 kN/m³ and E2 = 18.6 MPa.

- The next layer is loam, parameters JL = 0.18, γ3 = 18.5 kN/m³ and E3 = 15.3 MPa.

According to the geodetic service and topographic reconnaissance, groundwater in the calculated region is located at a depth of 3.8 meters, so their influence on the foundation can be considered almost zero.

Advantages of the layer-by-layer summation method

The need to calculate foundation settlement using the layer-by-layer summation method

- Thanks to the method, it is possible to calculate the shrinkage of almost any type of base, regardless of structure and size.

- You can use the parameters of multiple soil layers, and also take into account the level of groundwater.

- Suitable for calculating linear and monolithic foundations.

- You can also use the load-bearing stress parameters of the rocks on which the base is installed.

- You can use more than just the corner point method. The calculation is valid when using any vertical sections.

Among the disadvantages, it is worth noting the complexity of the calculations; only a professional builder can do them. Also, this method is time-consuming, so it is used when calculating foundations for large massive buildings with deep foundations. For small private houses the method is not practiced.

Design selection

When choosing a shallow foundation design, a number of factors must be taken into account. Geological conditions are of great importance: relief, soil type, groundwater level. The foundation must have sufficient strength and also have good resistance to overturning and sliding. Therefore, the weight of the building and its design features must be taken into account.

The soils underlying the foundation are calculated based on bearing capacity and deformations. In this case, it is necessary to take into account the influence of factors such as frost heaving forces, as well as the presence of ground and surface water, on which the physical and mechanical characteristics of soils depend. Local construction conditions and experience in operating buildings in engineering-geological conditions of a similar type should be taken into account.

The laying depth should ensure that the foundation is buried into the load-bearing soil by at least 10-15 cm. The situation should be avoided when there is soil directly under the foundation, the strength and deformation properties of which are significantly worse than those of the underlying layer. It is recommended that the installation depth be less than the groundwater level.

Different types of shallow foundations vary significantly in the cost of materials and labor costs. These factors should also be taken into account. Then the chosen option will provide the necessary operational characteristics of the foundation at optimal costs for its construction.