You can make the foundation for a private house with your own hands, but you should remember to follow the rules and construction technology, because the foundation will serve as a support for the entire building. The foundation for a country house can be of a simplified design if the structure itself is light in weight and the soil on the site has good bearing capacity. This article is all about foundations for houses and cottages.

Foundation installation technology

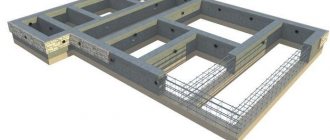

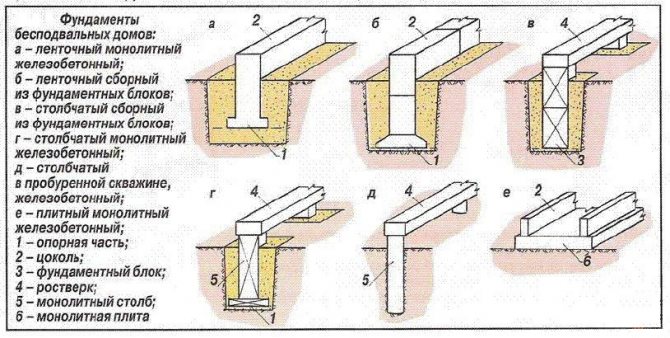

There are many foundations that can be classified as monolithic concrete foundations. They differ in specifications, components used, etc. Among the main types, the following are especially in demand:

- Columnar foundation - The foundation structure of this type of foundation involves a construction of individual pillars connected to each other by concrete crossbars and poured along the edges of the future structure. The result is an excellent base for small buildings and low-rise buildings made of wood and brick. The work process in this case does not require the use of heavy and complex construction equipment;

- Strip foundation - the structure of the foundation is a strip of reinforced concrete, deepened below the freezing level of the soil. The main parameters of the construction of such a foundation, its width, the type of concrete used, structure and height are determined at the design stage, based on the weight of the future building, its structure and the number of floors. As a rule, such foundations are chosen for the construction of stone private buildings with basements or garages in the basement;

- Reinforced concrete monolithic slab - is selected mainly on difficult soils, on clay, peaty soil or with a large freezing depth. The main advantage of constructing such a foundation is that the slab is a solid base that can withstand heavy loads and maintain the integrity of the structure;

- Pile foundation - successfully used on slopes, frozen, bulk, soft soils. In this case, special attention must be paid to the choice of supports and monolithic grillage;

- Pile-slab foundation is a unique invention in the construction industry, used mainly for the construction of multi-story structures. It consists of several important elements - grillages, reinforced concrete piles, characterized by excellent stability and increased strength.

Work on the installation of monolithic foundations requires the use of specialized construction equipment, since the excavation of large volumes of soil is required. In addition, reinforcement is carried out in several layers over the entire base area of the structure. In this case, a lot of steel reinforcement will be required; it will need to be pre-welded and tied using a special technology.

Little tricks

Pay attention to the advice of specialists involved in the construction of foundations:

When marking the future foundation, check the diagonals. Be sure to determine where to place the sewer pipes and how to supply water.

Foundation for a garage - description of construction technology and selection of the optimal type

Which foundation is better - how to make the right choice depending on the type of soil

Building a foundation - where to start building a foundation and a step-by-step description of the construction technology with your own hands

Be sure to compact the pillow poured into the trench well.

If you want to reuse boards from the formwork, take care of this even at the stage of formwork installation. It is possible, in order not to clean the boards from the frozen mortar, to lay roofing felt from the inside of the formwork.

To make pouring easier, mark the required level. Do not do this with a pencil; if the solution is poured from a mixer, you will have no time to monitor its safety, and it will be difficult to find when leveling.

Features of constructing a concrete foundation

The technology for constructing a foundation of this type of foundation requires mandatory reinforcement with metal rods. This allows the foundation to move with the soil - in winter it rises, and in spring it begins to fall. This prevents the building from collapsing.

Such foundations are called floating; they are especially relevant when there is high pressure on the foundation, during construction on weak soils that are periodically compressed, in seismically dangerous areas, and also where the ground freezes to great depths. On such foundations it is convenient to erect any buildings and carry out major and cosmetic repairs, including repairs of soft roofs.

The use of this type of foundation guarantees a reduction in the amount of work on the ground, a reduction in labor costs and savings in materials used in the construction process.

Today, different types of monolithic foundations are used:

- box-shaped;

- ribbed;

- solid.

The last option is used in the case when the planned structure will have no base. In this case, the slab will act as the floor. In the construction of residential buildings, the slab usually has a ribbed or ribbon surface. The ribs are made from monolithic concrete, sometimes blocks.

For buildings with several floors, box-shaped foundations are chosen that can withstand heavy loads. The height of the ribs is equal to the height of the walls in the underground part of the building.

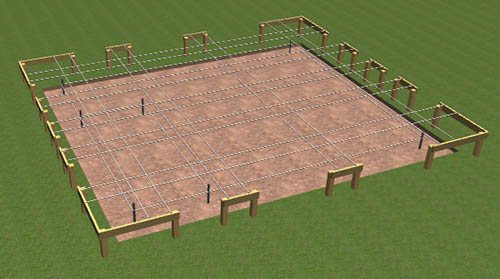

Axle breakdown

So, we already know that dimensional axes are special lines that show on the ground the general dimensions of the foundation for a house, as well as the features of its configuration. To find the overall axes, it is necessary to place 2 points on the prepared area that define the longest horizontal axis. After this, on the foundation diagram you need to indicate the distances between all the guides, as well as the connection of the foundation to them.

The process of laying out the foundation can be divided into 3 stages:

- Determine the principal axes.

- Apply them to the area.

- Make a cast-off.

Determining the principal axes is the most difficult task and is usually done by professional surveyors. This is a pair of perpendicular lines that start from the central points of the load-bearing walls. The place where they intersect must clearly coincide with the intersection point of the diagonal axes extending from the corners of the building. To transfer the contour and axis of the drawing to the site, you only need to determine the location of this point of intersection of the axes. After this, using the available data, you can easily determine the remaining points. The place where the main axes intersect must be marked with pegs and secured in the center with a nail.

If you are working with a small house of a simple shape, it is not necessary to do a breakdown and you can immediately start finding the dimensional axes. They should stay on the site as firmly as possible and not become loose, so it would be better to secure them with wooden stakes or scraps of reinforcement.

There are two generally binding rules that should be followed when marking the foundation:

- If the house has a square or rectangular shape, be careful to ensure that all corners are right (90°).

- If large-hollow concrete panels will serve as floors, it is necessary to ensure that the dimensions of the foundation fully correspond.

Below in the video is a breakdown of the foundation axes:

"Golden Triangle"

You can break the foundation in another way with the beautiful name “Golden Triangle”. For some it may seem simpler and more understandable. The accuracy of the results if the instructions are followed is guaranteed.

How to lay out the foundation with a “golden triangle”:

- Select a base angle.

- Drive a peg into the ground from which a string will stretch, setting the direction of the load-bearing wall.

- Pull 4 m of cord in the desired direction and drive in a second peg, pulling the guide as tightly as possible.

- Measure strings longer than 3 and 5 m. Tie the short one to the first peg, and the longer one to the second. Mark distances of 3 and 5 m on the strings with rags or knots.

- Bring the ends of the strings together and place another peg at the intersection point. As a result, you will get a triangle with absolutely perpendicular sides (the base angle is 90°).

- After this, you can start marking the walls. Take the twine and lay 4 and 6 m long guides parallel to the legs of the triangle. Drive in the pegs. You now have 3 ready-made corners of the future building.

- Now it is very easy to find the location of the fourth and final corner. To do this, set aside 4 and 6 m on the other side and install a peg at the intersection of the twines.

- Check the identity of the diagonals. If they match, then you can drive the stakes into the ground more tightly so that they stick out only 30-40 cm. After this, pull the string around the entire perimeter and level it so that the marks coincide and are strictly horizontal (use a building level).

Axle wear

Once you have installed the main axles, it is still very early to start digging as all the pegs will immediately fall out and you will have to start all over again. To prevent this from happening, it is necessary to perform a washout. To do this, you need to drive a couple of wooden posts into the ground and fix a board 80-10 cm long between them so that 90-120 cm remains between it and the ground. This way you will mark the control axial points.

Install the cast-off approximately 1.5 m from the walls of the future house. Transfer the size of the pit, the location of the walls, their thickness and other data onto the board. Be sure to level the top edge of the board between the pillars using a building level, then drive nails into it so that they show the location of the building's axes. To transfer the axes to the cast-off, you can use a geodetic device - a theodolite. In this case, you can be sure that the corners of the house will be even and correct. If you couldn’t get a theodolite, you can do the work manually using an Egyptian triangle with dimensions of 3.4 and 5 units of length.

All that remains is to stretch the string between the nails - this will be a level. Check the distance between them diagonally so that the level of the house is zero. After breaking down the main walls, you can move on to the rest. In order not to damage the cast-off, it is best to dig a pit or trench at a distance of 1.5 m. If the depth must be large, it is recommended to make the cast-off continuous, placing pillars with boards between them along the entire perimeter.

How to check the correctness of the breakdown:

- Lay out the diagonals and make sure they are identical. At the same time, the height of the peg is also important, especially on uneven ground. Make sure they are driven in at the same level.

- Before digging a trench, move the pegs driven into the corners a couple of meters outside the house and hammer them in there so that they do not interfere.

- The cord stretched during the laying out process can be used to calculate the required trench width and the dimensions of the base. This can be easily done using a plumb line, taking 50 cm from the cord inside the house, and 10 cm outside. In this case, the walls will fall squarely in the center of the foundation and base. If you retreat an equal distance on both sides of the string, the walls will end up outside the boundaries of the facade.

Additional extensions (terrace, porch or veranda) should be calculated based on the main contour of the building.

The video below shows how to lay out the foundation:

Devices and types of strip base

Depending on the depth of their occurrence, strip monolithic foundations can be deep or shallow. Foundations buried to a shallow depth are mainly used on ordinary soils with excellent load-bearing capacity, for light-weight wooden structures or frame houses.

The construction of deep monolithic concrete foundations is used mainly for heavy buildings. They are lowered below the freezing level of the soil by about 15 cm, provided that it has good bearing capacity.

The monolithic strip foundation technology involves the arrangement of formwork that gives the concrete the desired shape and does not allow it to spread. However, formwork requires not only additional costs for materials, but also time for its arrangement.

What to consider when pouring

First of all, you need to remember that you cannot save on concrete; you should also choose only a high-quality type of cement. The higher the quality of cement, sand and additives, the stronger the concrete foundation will be.

It is practically impossible to pour a monolithic foundation on your own without professional help and specialized equipment. To ensure the speed of pouring work and the required volumes of concrete, it is sometimes necessary to use several concrete mixers at once.

There are many ways to pour a monolithic concrete foundation. Some people directly feed concrete from a concrete mixer using a special box, compacting the finished mixture in place, while others use a vibrator or other devices that raise the total cost of the work and the price of the base itself.

You can build such a foundation yourself, however, it is sometimes necessary to consult with professionals who have experience in various fields of construction. The general technology for arranging a monolithic foundation for a house is universal. The duration of work may vary depending on the type of soil, the presence of groundwater, the level of shrinkage, the degree of freezing in different periods, etc.

Concreting

It is preferable to use ready-made concrete mortar prepared in a factory, but you can prepare the mixture manually at a construction site using coarse sand, crushed stone, cement and water.

The concrete mixture is poured into the foundation formwork with mandatory compaction using deep vibrators. The strip foundation should be poured from both sides at once, which will help to quickly distribute the mixture in the formwork, avoiding uneven hardening.

Watch a video of how work is carried out on the construction of the most popular type of foundation - strip.

The upper surface of the foundation tape is leveled to perfect smoothness. Caring for concrete involves sheltering it from the sun and constantly moistening the foundation surface. It is not allowed to continue the construction process until the concrete reaches its design strength. This procedure usually takes up to 28 days, but in some cases the concrete mixture takes longer to dry, which will require a long time for the foundation to gain strength.

The finished foundation structure is sprinkled with earth, filling the voids and cavities. The soil to be laid is compacted as much as possible. Particularly narrow cracks can be filled with coarse sand.

The main advantages of a monolithic foundation:

- excellent ability to withstand horizontal and vertical loads;

- high resistance to moisture;

- reliability, strength and rigidity, adaptability to various types of soil;

- ability to withstand any ground movements, earthquakes, increased loads;

- durability;

- The internal arrangement of the walls in the building can be anything. First you can build the foundation, then start planning the room;

- absence of rodents and insects;

- there is no need to install an expensive floor insulation and waterproofing system.

To build a foundation, you need a lot of materials - sand, steel reinforcement, cement, additives, crushed stone. This composition guarantees strength and accelerates the hardening of concrete.

Considering the structural features of this foundation and the complexity of its arrangement, for its implementation you should use the services of only qualified specialists with extensive experience. In addition, special construction equipment will be required.

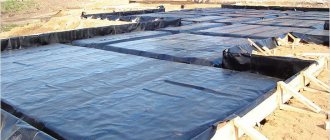

Waterproofing device

The monolithic base has pores that act like capillaries in the presence of even slight humidity. An unprotected base in this case will absorb moisture, which will lead to negative consequences:

- reduced strength;

- moisture will crystallize in the pores, which will lead to an increase in its volume;

- dampness and mold will appear in the building.

If you do not first waterproof the base, over time it will become unusable, which will affect the general condition of the building. In modern construction, different methods of protection are used:

- coating is characterized by high efficiency, simple arrangement and provision of high-quality protection from moisture. Mastic or an emulsion specially designed for this is applied to the foundation. It is necessary to take into account the manufacturer's recommendations for application; the composition can be used in a normal or heated state;

- A modern and fairly effective version of waterproofing is penetrating, providing a high depth of penetration into concrete. The mixture crystallizes in the pores, making it difficult for moisture to enter;

- The roll method is the most popular. In this case, moisture-resistant materials in rolls are used.

A decision is made to choose one or another waterproofing option, taking into account the location of aquifers, the amount of precipitation in a particular area, the presence of drainage systems close to the structure, the design features of the base and the financial capabilities of the customer.