Where are screw piles used?

This type of support is used in the construction of civil and industrial facilities: wooden houses (frame-panel, laminated or rounded timber), houses made of blocks and SIP panels, brick, cinder block, foam and gas blocks, houses made of LSTK; bathhouses, gazebos, fences and other fences, lamp posts, structures on the water (piers, lighthouses, moorings, marinas), shops, shopping centers, power lines, hangars, industrial premises, transformer and pumping stations.

Price

How much a pile costs depends on several parameters. First of all, of course, on its technical characteristics - its diameter, length, thickness of the materials from which it is made. On average, it costs from one and a half thousand rubles, and if a turnkey installation is expected, the calculator will most likely give a price of 3.5 thousand rubles.

Naturally, the DIY technology has the advantages that the pile costs clearly less. In general, today it is most convenient to calculate costs using a calculator. In general, we can confidently conclude that a pile-screw foundation is not only a worthy competitor to other types of foundations, such as strip foundations. In many respects, it is a natural choice for many categories of consumers. If you are building a country house, then you won’t find a better option. It allows you to quickly install all structures with your own hands, at any time of the year. And how much it costs is affordable for almost any wallet.

How to calculate the number of screw piles?

Before purchasing piles for the foundation, you need to determine the length and diameter of the screw pile, taking into account the load on the designed foundation, as well as the optimal distance between the piles depending on the sagging characteristics of the material chosen for the grillage. When calculating, many other factors are taken into account: type of building, material, structure design, types of loads (static, dynamic, pull-out loads), type of soil with its freezing depth, region of construction.

Is it possible to make them yourself?

Of course, factory-made piles are considered to be of the highest quality. Especially if they are equipped with all the necessary certificates, and their tips are cast. It still happens that financial considerations or construction features require you to think about making them yourself. It is quite possible to make screw piles yourself, as is described in detail in the video.

Before starting fabrication work, you need to determine the depth of soil freezing on the site, since this is the main parameter for determining the length of the piles. They are required to be able to enter a depth of 30 centimeters greater than maximum freezing.

The production work itself can be divided into seven stages:

- Searching for a piece of steel pipe whose length would correspond to the required one;

- Cutting out the blades. They are made from durable sheet steel. The diameter must match the internal diameter of the pipe;

- You will also need a conical tip that is welded to the end of the pipe. With its help, screwing will occur. You can replace it by cutting triangular-shaped petals from the end of the pipe, and then bending and welding them like a cone;

- Welding the petals at the cone. Welding must be done as efficiently as possible, otherwise the petals will fall off;

- At the end that remains on top, holes with a diameter of at least 2.5 centimeters are made. They will be used during screwing as sockets for levers;

- When the pile as a whole is ready, it is cleaned and coated with an anti-corrosion compound. Leaving metal in the ground for a long time can accelerate its destruction, so this is important;

- Finally, you need to let the pile dry. Only after this will it be finally ready for use.

Homemade screw piles are especially suitable for building fences and gates.

Is a pile-screw foundation cheaper than a strip foundation?

Strip foundations have a high degree of shrinkage; if the soil is inhomogeneous or the calculations are inaccurate, this can affect the quality of the structure. Due to the large mass of concrete and reinforcement, this type of support is labor-intensive and expensive. In non-compacted soils, if the groundwater level is high, this type of foundation has low bearing capacity. Frost heaving and precipitation reduce the service life of the strip foundation. A foundation on piles does not have all these disadvantages. Saving of all resources – up to 50%.

Construction of buildings

Base

The peculiarity of a pile foundation is that it does not have a classic base or basement. Usually the base for it is made of false panels on a metal or wood frame. At the same time, it is necessary to preserve the empty space between them and the ground, which is laid with paving slabs.

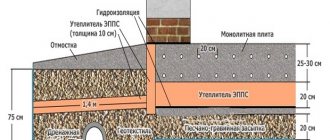

Foundation insulation on screw piles and waterproofing

The design feature of a pile-screw foundation, as can be seen in numerous videos, implies that there remains a gap between the floor and the ground. As a result, the first one requires insulation. For this you can use mineral wool or polystyrene foam.

Foundation insulation scheme

But before insulation, waterproofing is needed. To do this, all joints and open parts are treated with special compounds. The latter, like the strapping, can be insulated with rolled material. The underground space should be covered with expanded clay, thanks to which the wind will not blow.

Basement

A house on a pile-screw foundation does not have a basement in the classical sense, as a strip one allows it to be made. But it can be replaced by digging a pit. In this case, the foundation pit is made before the piles are installed, and a reinforced concrete slab is placed on its floor. This is necessary because the piles or piping will not hold well in the ground of the pit. The pit must be insulated and waterproofed.

A cellar can be a good substitute for a pit. In any case, the work will cost more than a simple installation of a pile-screw foundation.

How to screw in screw piles manually?

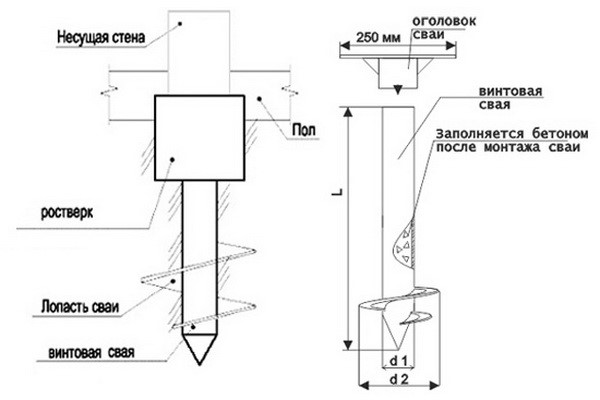

The pile kit should contain instructions with illustrations and a technological map. In short, you first need to plan and mark the site. In the places marked with stakes, holes are drilled, installed and leveled with the level of the pile. The excess is cut off with a grinder. Concrete is poured inside (the ratio of sand and cement is 4: 1) and the heads are secured. The last stage is the installation of the grillage (wooden beam, channel, reinforced concrete).

The screw pile must be screwed in so that the blade is completely immersed in the non-freezing soil. In this case, the depth of the freezing layer and the dimensions of the part of the pile with blades are taken into account. The pile must be screwed in evenly, constantly monitoring deviations. A serious error (2 degrees or more) leads to the need to unscrew the pile and move it to another place.

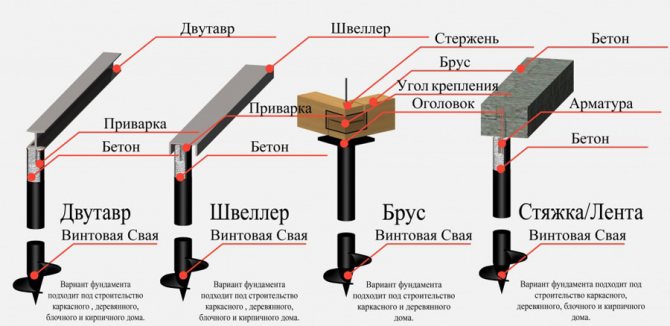

Grillage

A grillage is a design in which all products on the field are connected to each other. The obvious advantages that this technology provides are that the load is evenly distributed over the entire surface of the foundation. The most reliable is the harness that uses channels.

The technology provides for reinforcement to be tied onto screw piles. Its diameter should be between 1.2 and 1.8 cm, and the distance between the rods should be uniform and correspond to 15–30 cm. The dressing is done with knitting wire. After which the formwork is installed and concrete is poured.

Materials from which the harness is made

The grillage strapping can be made from different materials:

- Channel;

- Brusev;

- Metal corners;

- Profiled pipes.

The choice and installation of a particular material depends on what load the calculation showed. The advantage of metal frames is naturally that they can support heavier buildings.

Which screw piles are suitable for clay?

For screw piles of any type, only rock is not suitable. A screw pile in a clayey place perfectly resists the force of frost heaving. At a level higher than the freezing depth, the clay slides along the trunk, which is very smooth and easily allows it to pass through. The blade keeps the trunk from moving. Water-saturated clay contracts in winter and expands in spring, causing deformation of windows and doors with a traditional foundation. Screw piles solve this problem, since they are not afraid of heaving soil.

DIY installation

The pile foundation, regardless of which piles are used, is arranged according to an almost identical algorithm. It includes:

- Topographic survey with markings;

- Preparation and clearing of the site for piles;

- Their installation;

- Trimming to level followed by pouring concrete;

- Welding the channel or fastening plates.

Details can be seen in the video.

A distinctive feature of screw piles is that you can install them yourself. Manual screwing is not so difficult, but a special work technique is used for it.

Installing a screw pile with your own hands

There are certain restrictions on the type of piles that you can install yourself. They are primarily related to the physical capabilities of a person.

Thus, products are screwed manually, the diameter of the blades of which does not exceed 300 mm (the diameter of the pile itself is 108 mm), and the length is four meters.

The required number of workers depends on the size of the screw pile. For the maximum possible size of 108x300, you will need a team of three to four people. The tools required are two crowbars or cuttings of reinforcement, one and a half to two meters long. The latter are needed for screwing, since they are the ones capable of providing the required average torque of 450 kilogram-force meters. A bubble level is used for leveling.

After the preparatory work in the form of topographic survey and clearing the site of debris is completed, two workers take the first pile and insert it into the holes from above along the crowbar on both sides at an angle of 45 degrees. This is how they form levers. Another worker applies a level and uses it to help install the pile vertically.

Twisting is done clockwise. A worker with a level constantly ensures that it occurs vertically. This technology requires the application of quite a lot of physical strength. At the same time, you should not drive all the piles to the same depth, since soils with different characteristics may appear in the same area. The required depth is determined by achieving a certain torque. Control is carried out using a dynamometer. Instead of a dynamometer, in practice you can use simple tightening “all the way” when deformation processes have already begun.

The minimum depth of screw-in of a screw pile corresponds to the maximum depth of soil freezing in a given area. Often, screwing in with your own hands can be quite labor-intensive due to the characteristics of the soil. This is especially true during the dry season.

The solution may be to wet the hole with water, since the product penetrates into wet soil more easily.

But in the case of loose soil, the piles are connected with a welded frame.

The average productivity of a team engaged in manually screwing in screw piles is up to a dozen of them per shift.

What soils are suitable for screw piles?

Any type of soil is suitable for a pile foundation, except rocky (even permafrost), but it is most advisable to use this type:

- when building houses in areas with high groundwater levels;

- if the upper layers of the soil are characterized by weak bearing capacity, and the dense layers are located deep enough;

- with a freezing depth of 2 m;

- in complex landscapes (elevation differences, lack of free space, large number of plantings).

Construction of the foundation

Building a foundation on screw piles is both simple and complex. Simple, because their design allows you to significantly simplify and speed up work. Complex because it requires precise calculations and a certain sequence of work.

Geology

The construction of the foundation should begin with engineering and geological surveys. To carry them out, geologists who have the right to do so are hired. If we are talking about a cottage or dacha village, then surveys are often carried out at the stage of dividing the plots.

Their task is to determine the type of soil and its physical characteristics.

Calculation

Perhaps the most difficult stage in the construction of a pile foundation is the accurate calculation. Despite the fact that all the details are given in SP 24.13330.2011 “Pile foundations”, they still require some experience.

Today you can find a calculator that will automatically calculate both the standard size of piles and their number. The parameters on which the standard size depends include the size of the building, its type, soil type, including its moisture and density. A good calculator takes them all into account.

Step

One of the most important characteristics determined when calculating the foundation is the pitch. Of course, it can be calculated based on what the calculator shows, but there are certain properties that are always the same.

So, the step should not exceed two to three meters, otherwise it can be dangerous for the house. In general, it should be 20–30% smaller than the size of the load-bearing walls. From the video clip you will learn how to correctly calculate the required number of piles.

Structure weight

Each part of the house structure has its own weight, which affects foundation calculations. It depends on the materials used in construction, as well as the size, whether the house is one- or two-story, etc.

Typically, external walls and ceilings carry the greatest weight. So, in a wooden house on two floors, measuring 6 by 8 meters, the first will weigh approximately 16 tons, and the second - 10 tons. The total weight of all structures can reach 71 tons. When calculating the load, this number is increased by thirty percent. A special calculator will allow you to calculate everything in more detail.

Snow and wind load

For the domestic climate, it is very important to take into account in the calculations the load that snow and wind have on the house. If in some regions the second is especially important, then for most it is the snow load that is paramount. For Central Russia it is at least 100 kilograms per square meter.

Number of piles

The quantity is calculated based on their standard size, soil characteristics, and the load exerted by the house. All this can be calculated by a calculator. You can do the calculation manually, strictly following the instructions of SNiPs.

Length

The main characteristics that influence the length are the physical properties of the soil and the depth to which it freezes. The weaker the soil and the higher the freezing depth, the longer the products.

Step-by-step plan for opening a business

Having studied the sales market and competition in the field of pile production, you can proceed to the following steps:

- Select premises for the workshop, taking into account the expected volumes of finished products;

- Study the raw materials market, suppliers of seamless or welded pipes;

- Purchase equipment (line or complete with individual units);

- Select personnel with good qualifications for both the production and installation process of screw piles;

- Prepare ways to sell products and pile installation services.