A sign of style, desire for functionality and ease of use of all systems of individual household ownership are sliding gates on screw piles, which are equipped at the entrance to the territory. This optimal solution provides significant savings in the use of yard space compared to conventional swing gate systems. Remote control using a miniature remote control allows you to save not only time, but also health in adverse weather conditions, when the sash is opened by a narrow gate with automatic closing.

Pile-screw installation of fences and gates

The use of a concrete foundation in this type of development requires compliance with certain weather and technological conditions. Due to the maturation of the solution, installation will take several working days.

If you don’t have much time or the spring-summer season is over, choose another method - install a fence or gate on screw piles, especially since it has many advantages:

- suitable for any type of soil and changes in relief;

- withstands even high loads;

- quick installation in any weather conditions;

- development without disturbing the landscape and large-scale earthworks;

- saving time.

Let's take a closer look at the types of gates that can be installed using screw piles.

Certificates

We sell exclusively high-quality products. Each of the devices has the appropriate certificates. Close cooperation with trusted companies allows us to provide customers with the best products with all the required documentation and quality guarantees.

Swing and retractable. Which gate to choose?

How to choose the type of structure that is perfect for the local area of your cottage or will last for more than one year on your summer cottage? Let's find out!

Sliding gates

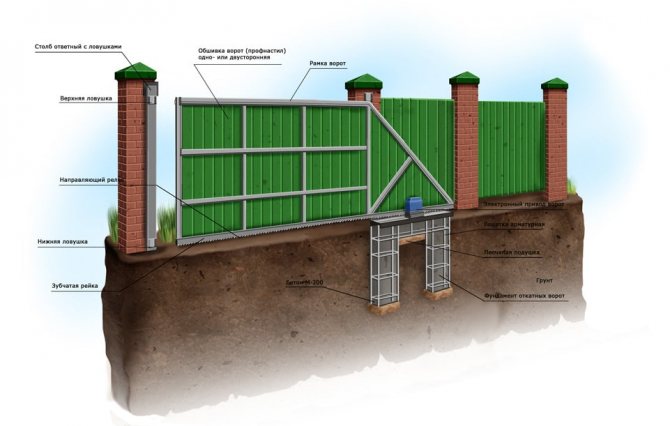

The convenience of sliding systems that open automatically will ensure a comfortable entry into the local area. The dimensions of the opening itself may vary depending on the intended purpose, and even a corner space is suitable for installation. For the manufacture of such a structure, corrugated sheeting and stiffening ribs from a profile pipe are used.

The filling for the gate is selected in accordance with the budget and can be represented by a wide variety of materials: from corrugated board to real wood picket fence. However, due to harsh weather conditions, buyers more often give their preference to profiled sheets.

According to the type of fastening, sliding gates are divided into suspended (top guide), which limit the height of the entrance, and cantilever (the entire load of the mechanism is directed to the pile, which is fixed on the side. Automatic opening is ensured by a special electric drive, which is selected in accordance with the individual requirements of the customer (opening speed, presence of sensors and other properties).

As for piles, the standard diameter for supports of a sliding structure (no more than 4 m) is considered to be 89 mm. If you increase the opening, the diameter also increases in order to withstand the load and ensure a long service life for the mechanism. Piles must be treated with an anti-corrosion coating.

Sliding gates on screw piles have a number of advantages:

- lack of bottom guides. This allows you to forget about endless cleaning of rail grooves, increases service life and facilitates repairs in case of breakdown;

- suitability for almost any soil;

- quick installation;

- the ability to move the gate to a new location.

Installation of this structure will not take much time, but it is important to pay attention to all the installation nuances. The algorithm itself will look like this:

- Soil testing (if you have to build not only a gate, but also a fence) and marking building lines;

- Drilling shallow starting holes, only as a mark for piles;

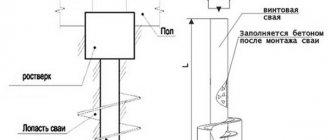

- Screwing process. Usually only three piles are installed: two for support and another on the opposite side for catchers. The process of screwing in piles is quite simple: you can immerse the support using a crowbar and pipes attached to it (a homemade lever structure) or speed up the process using a drill and a special attachment.

Helpful advice! Installation of screw piles is never done alone. This procedure will require at least three people: two pull the levers, the other holds the pile vertically and does not allow it to deviate from its axis.

- Alignment of piles in height;

- Filling internal cavities with concrete solution;

- Connection with heads and embedded elements on which the roller bearings and drive will be attached.

- Installation of mechanisms and automation;

- Installation of sheets for gates.

It is not difficult to install such gates yourself, because... this will require a small number of piles. However, if you do not have the appropriate qualifications and are not confident in carefully maintaining equal distances between the supports and their straight vertical installation, then do not worry and entrust the work to professionals. Remember, any deviation of the piles can lead to breakage of the catcher. The roller mechanism is very precise; if you make it unevenly, the gate will not be able to open.

Foundation technology

Making the foundation for sliding gates with your own hands requires a fair investment of time and effort. For the correct installation of the support, it is necessary to perform accurate calculations and follow the technology recommended by professionals. The most common and rational is a frame-monolithic foundation; the sequence of its creation is given below.

Scheme development

To calculate the dimensions of the foundation, the following indicators are determined:

- soil type;

- opening width;

- weight and dimensions of the gate.

Foundation diagram for sliding gates

The optimal depth of the foundation is in the range of 150-250 cm, it depends on the level of soil freezing, a sufficient width of the foundation is 50-70 cm. At the entrance area on one side there should be an indentation necessary for rolling back the canvas. All dimensions and calculations are entered into the diagram, a drawing is drawn up, on the basis of which further construction activities are organized.

Preparatory stage

To create the base you will need the following materials and tools:

- crushed stone, cement and sand are used to mix concrete mortar;

- console blocks;

- wooden building materials (if the work will be carried out with formwork);

- concrete mixer or trough with a shovel;

- crowbar, tape measure;

- longitudinal steel channels;

- reinforcement that will be laid in the sheathing;

- welding machine;

- building level;

- hacksaw, axe, hammer.

It is necessary to carefully level the area around the entrance, remove vegetation and extract roots. Next, they begin to dig a trench in accordance with the diagram; sand and gravel are sequentially laid and compacted at its bottom. This cushion will prevent the foundation from being pushed out in the spring when the ground is unstable.

Assembling a metal frame

To make the foundation reliable and strong, it is strengthened with the help of an embedded component - a U-shaped frame. The racks of the latter are made of reinforcement with a diameter of 12 mm; a horizontal channel 20 cm wide is used here - it will help to evenly distribute the load throughout the entire product. The length of the mortgage is determined by the dimensions of the opening - standardly this is half the same parameter of the entrance area, that is, for a 4-meter gate a 2-meter frame is required.

The U-shaped profile requires transverse reinforcement in increments of 30-40 cm; 2 methods are used for its assembly:

- welding of the reinforcement frame and further fixation of the channel;

- welding rods and angles to a metal workpiece.

To tie the reinforcement, welding or steel wire is used. The top of the metal pins should not protrude above the soil surface. The building level will help check the horizontal installation of the workpiece - this way you can avoid distortion of the structure.

Pouring the foundation for sliding gates

To mix the solution, use sand and cement in a ratio of 3:1; adding crushed stone will increase the strength of the product. The trench is filled with concrete so that the reinforcement is approximately 2/3 covered with the mixture. In such conditions it will be easier to install the gate. It is necessary to install the pillars supporting the entrance group in advance; in this case, the foundation will cover the cantilever supports and the entire opening. Thus, the entire plane under the movable doors will be completely concreted.

It is important to prevent the frame from skewing

It is important to prevent the frame from skewing. For the structure to function properly, the space under the roller segments must be wide and level.

A stable and reliable foundation is formed by using high-quality cement, the optimal variety is M500, the permissible crushed stone fractionation is 30-40. The foundation will strengthen in 2 weeks, but before use it needs to stand for 28 days.

To make a high-quality base for sliding gates, special attention should be paid to the calculation stage: given the large weight and mobility of the structure, you need to find the optimal ratio of operational and strength characteristics. With strict adherence to construction technology, you can expect proper functioning of the automatic system in all seasons, the absence of distortions leading to jamming, long-term maintenance-free use and an impressive service life

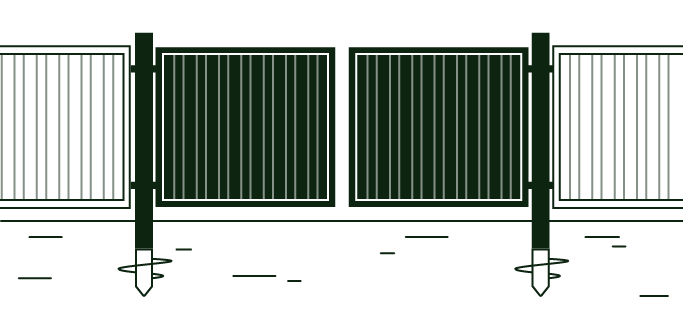

Swing gates on screw piles:

Such designs usually have significant weight, given that in modern suburban areas the standard width is 3-4 m. The weight of the doors is directed towards the pillars to which the doors are attached, and often wind loads and constant use displace them from the vertical axis. This causes the stems to sag along an inclined plane: not only the quality of their appearance is reduced, but also their ease of use.

Usually, to install swing gates, holes are dug, ordinary pillars are immersed there and filled with concrete - such a structure is unlikely to last more than 3 years, after which it will have to be repaired or rebuilt.

Instead, use piles - since their depth reaches solid layers of the earth, and screwing ensures a tight fit of the soil, wind loads will not affect the quality of their use. Piles for such gates are usually mounted in two different ways. In the first, the doors are attached directly to the piles - the integrity of the structure imparts rigidity, in the second - the piles are immersed in the ground for their entire length, and pipes are built on top. With this type, it is important to strengthen the seam between the pile and the door supports.

When installing swing doors, select the diameter of the piles in accordance with the parameters of the gate itself (length, width, weight). With a standard height of 2m, piles with a diameter of 73mm are suitable; if you plan to install a larger structure, contact professionals for calculations.

Installation of piles occurs in exactly the same way as when installing supports for sliding gates. The main task is to strictly maintain the vertical position and screw in the piles to a sufficient depth. Remember that in case of deviation or incorrect installation, it is no longer possible to unscrew and use the pile nearby, because the density of the soil and the strength of the supports are reduced.

A few words about foundations in general.

It is assumed that the foundation rests on a non-freezing layer of earth. That is, on soil that does not experience freeze-thaw cycles. This is the “freezing depth”. Such a device significantly increases the lifespan, especially if the gate is made by hand. It is usually almost impossible to find clear explanations of what this depth is.

Foundation concrete is a different story. It is made from cement, from mixtures, crushed stone, and soon someone will realize that it can be made from plaster compositions.

More reinforcement. This is also an interesting set of facts, with references to standards, intimidation that you can’t reinforce it with your own hands without welding, and other horrors of the latest technologies.

There are several more “recommendations”, like that “the foundation needs to be strengthened”, however, they usually keep silent about how exactly, that the gate can “float”, without indicating the direction, and other stories of about the same cost.

So, what is a foundation for a gate, from the point of view of a practical person who is ready to do this not the most difficult job with his own hands?

How to choose a gate?

Which type is right for you? Determine the purpose of use and purpose of the structure. If you use them only as an entrance/exit, then there is no point in spending money on an expensive mechanism, just buy a gate, it can also be installed on stilts. If driving a car is important to you, consider purchasing automatic sliding gates - this will create the most comfortable conditions, especially when leaving in bad weather.

You can easily install screw piles yourself, but this will require much more time and consumables. If you want to save effort and money, turn to professionals!