Do you need a foundation for a fireplace? Features of the construction of a foundation for a fireplace, types and sizes.

If you decide to build a classic fireplace in your home, then construction work must begin by preparing a solid foundation. A properly executed foundation for a fireplace is of great importance in the context of the further operation of the entire heating structure. At the same time, neglect of basic building standards will irreversibly lead to deformations and subsidence of the fireplace already in the first year of its use. Therefore, we will consider in detail the main recommendations of experts on pouring (laying) the foundation with their own hands under the fireplace.

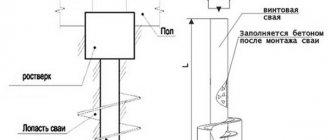

Foundation design options

- In the form of a separate structure that is not connected to the main foundation;

- As a single whole with all underground structures.

If to build a house you use a massive reinforced concrete slab, which is installed in accordance with all building codes, there is no need to separate the foundation of the heating device. This base will perform all functions, prevent uneven shrinkage of different structures, and will be a reliable fireproof apron in a wooden country house.

Pouring the foundation for the fireplace stove

When it is not possible to pour a high-quality reinforced concrete slab, it is best to build a separate foundation. It should be placed at a distance of 5-7 cm from the main supporting structures of the building. The free space must be filled with sand. This scheme will allow you to avoid cracks in the above-ground part of the fireplace, which can also form on the walls of the house due to uneven shrinkage.

Preparatory work

Work on arranging a corner fireplace begins with the construction of the base. It is strictly forbidden to connect the foundation of the structure under construction with the base of the main building - this will lead to very unfavorable consequences.

To determine the optimal width of the foundation, add about 50 mm to the width of the front plinth row. Determine the length in accordance with the dimensions of the side row of the plinth. In general, the dimensions of the base should be slightly larger than the dimensions of the future fireplace.

When choosing a place for arranging the foundation and the fireplace itself, make sure that in the future the smoke exhaust pipe does not pass through the elements of the roof rafter system and beams.

The foundation is made extremely simply - a pit of the required size is dug, the bottom of the pit is covered with waterproofing, a layer of a mixture of sand and crushed stone is poured on top, reinforcement is laid and mortar is poured.

Building a foundation for a fireplace

Building a foundation for a fireplace

Allow the foundation to gain strength and cover it with a double layer of roofing felt.

While the foundation hardens, begin preparing building materials for upcoming use. So, the clay must first be soaked in water for a couple of days. Soak the bricks for the same amount of time.

Fireplace foundation laying diagram

Pre-calibrate the bricks you have. Elements with significant deviations from the previously mentioned size cannot be used for masonry.

To prepare the solution, use a standard and proven recipe. Pour the dry sifted sand into the clay pulp, and then mix the resulting mixture thoroughly. Determine the required amount of water individually. The finished mixture should have the consistency of jelly.

Fireplace mortar

Check the finished solution. To do this, roll a sample out of it into a “sausage” about 1.5 cm in diameter. If the sample does not stick to your hands, holds its given shape normally and does not fall apart, everything is fine.

Also check how the solution you prepared behaves directly on the brick. To do this, place the mixture on the building element. It is necessary that the solution does not stick to the trowel, does not fall apart and does not spread over the brick under its weight.

When should you start laying out the foundation?

It is best to start installation at the beginning of building construction. You need to carefully consider where the heating device should be placed and what materials will be used. The design of the fireplace is also quite important. It is necessary to calculate what load the heating device produces. The larger it is, the higher the requirements for all structural elements of the stove.

If you need to carry out installation in an already built house, you need to take into account that this is much more difficult to do. It will be necessary to dismantle the floor covering and carry out excavation work inside the building.

Reinforced foundation

The foundation for the fireplace must be a separate structure. This will prevent a negative impact on the main load-bearing elements.

When installing the stove, you can remove unnecessary partitions if they bother you. But do not forget that you cannot touch load-bearing walls.

Chimney in a wooden house

After installing the foundation, you can think about installing a chimney. This work can also be done with your own hands. The chimney must function smoothly and remove combustion products. Its dimensions are calculated in accordance with strict rules. Therefore, when choosing a chimney, you need to take into account the size of the fireplace and the type of fuel.

The diameter of the chimney and the smoke outlet pipe must match. Otherwise, this may lead to poor-quality removal of combustion products. The system will begin to smoke, and soot will quickly form in the chimney.

The chimney should have a round cross-section, since in pipes with a square or rectangular cross-section, turbulence can form, which also contributes to the formation of soot.

Fireplace requirements

In addition to decorative functions, a number of additional requirements are imposed on the fireplace, such as:

- do not create smoke in the room;

- warm up the air;

- look proportionate to the interior of the room.

If all these conditions are met, we can assume that the fireplace was installed correctly.

You need to build a fireplace structure in order. This is a detailed diagram that indicates where each brick of the future fireplace should be located. There are no trifles in this important matter.

Optimal sizes

When arranging a base for a fireplace in your country house, consider:

- the minimum foundation depth is 0.5 m. This figure may increase if the building is built on unstable soils;

- if the fireplace is located in a room that is not constantly heated, the base of the base should be 0.2 m below the seasonal freezing depth of the soil;

- the surface of the foundation must protrude at least 0.05 m from the walls of the furnace;

- the top point of the foundation should be at -0.150 relative to the level of the finished floor.

Foundation with ash grate

To build modern stoves in a wooden house, you can use different design schemes. If the heating device will be located in the corner of the room, use a regular columnar foundation for the fireplace. The slab base is suitable for any type of heating appliance.

Main functions of fireplaces

For a long time, the fireplace has been assigned the following functions:

Cold protection

It was supposed to protect the room from the cold, and at one time there was no alternative to such heating, but not these days. Today, centralized and individual heating copes with this function much better, although no one is going to give up the fireplace.

Cooking

You can cook food on the fireplace. It is clear that a modern kitchen is crammed with such equipment that there simply cannot be any problems with preparing any dish. But can such food, in terms of aroma alone, compare with that cooked over a fire? And here the fireplace, on which you can bake both meat and vegetables, is simply an irreplaceable thing.

Decor

The fireplace today is a decorative decoration of the entire room; we can say that the fireplace is its soul. Today, a fireplace is comfort, joy and inspiration for all guests and household members.

It is for this reason, most likely, that even if it is impossible to have a real fireplace in a room, you can often see its imitation - with lifeless fire and the fake crackling of fake firewood. But still, even from such a fireplace your soul becomes a little warmer and happier.

Installation features

If you decide to install a stove in your country house, follow these instructions.

- Dig a hole 0.8-1 m deep, depending on the type of fireplace and its design.

- Cover the bottom with a layer of sand 0.15-0.2 m thick, which must be thoroughly compacted.

- Lay a crushed stone cushion 0.2-0.3 m thick. Compact it well.

- If necessary, install reinforcement cages. Use metal wire or regular reinforcement with a diameter of 5-10 mm. The distance between the rods is 0.1-0.2 m.

- Pour a concrete slab 0.2 m thick. It should protrude 0.2-0.3 m.

- Next, proceed to laying the brick. To securely fix the layers, prepare a regular cement-sand mortar. Rubble stone can be used to build the foundation.

- When the upper edge of the underground part of the furnace is at floor level, use a building level to check the horizontalness of the surface. Even slight distortions can cause uneven shrinkage.

After installing the foundation, you can begin constructing the above-ground part of the furnace. It is necessary to constantly monitor the verticality of the walls, which will make it possible to evenly distribute the load from the heating device.

Combustion chamber

There are open and closed combustion chambers. The closed structure must necessarily include additional components - a gate and transparent doors made of fire-resistant glass. The simplest option would be to purchase a ready-made combustion chamber - this will significantly simplify the installation work, and cast-iron closed fireboxes look very good.

Arrangement of the fuel chamber is one of the most problematic and difficult stages of installing a fireplace. The firebox located under the chimney must have a chimney tooth, which is necessary for the efficient operation of the entire structure. To extend the service life of a metal firebox, it is advisable to line its internal walls with fireclay bricks, which will minimize the contact of open fire with the chamber material.

Since the main working process takes place in the firebox, it is worth considering it now:

- The fuel is removed from the fuel basket, which is usually located under the firebox, and placed on a grate located in the chamber;

- The ignited firewood is set on fire, and the intensity of its combustion is regulated using a slide valve, which provides oxygen access to the working area (if the fireplace has an open firebox, the combustion process can only be changed by adding firewood);

- The burned fuel becomes ash and ends up in the ash pan, located directly under the grate (collected ash must be removed periodically, so the best option would be a retractable ash pan);

- The gas released during combustion goes outside through the chimney (for maximum efficiency, it is worth equipping the chimney with a forced draft, which will also allow you to regulate the heat transfer of the fireplace).

The second option is somewhat more difficult to arrange - it involves installing the back wall at an angle of 30 degrees towards the inside of the fireplace. If you make a fireplace with your own hands using such a scheme, the advantage will be increased reflection of thermal energy into the room.

Additional recommendations

The foundation for a fireplace can be made of various materials:

Brick for decorating a fireplace

- rubble stone;

- mixtures of different materials;

- ceramic bricks;

- reinforced concrete.

You can use broken stone, brick or other materials that you can get. To securely fix the layers, prepare a mortar - cement, cement-sand, cement-lime. Sometimes a chamber is provided directly inside the foundation for collecting ash.

The walls of this design are made of concrete blocks or ceramic bricks. Every 2-3 rows a metal corner is laid.

Air supply to the fireplace

Also inside the underground part of the furnace there can be a ventilation duct that goes into the basement. In this way, air is taken in for burning wood, which significantly increases the productivity of the stove.

If you take into account all the nuances, you can easily install a fireplace in your country house. The strength and reliability of the stove depends on the constructed base. Be sure to choose the right materials, calculate the required depth of the sole and select the optimal sizes.

Chimney installation

If the chimney is not assembled according to all the requirements and rules, then it will be impossible to ensure the operation of even the highest quality fireplace. There are a few simple rules that are best followed in any case:

- First of all, the chimney cannot be built into external walls.

- It is better to place the chimney pipe as close to the ridge as possible. It is better if the section of pipe sticking out on the street is as small as possible.

- Brick is the best material for making chimneys.

- It is better not to place reflectors and umbrellas at the chimney outlet.

- The fireplace will not work if there is no air supply.

- Compared to closed structures, open ones benefit.

By creating the necessary draft, the chimney serves to remove air and gases from any smoke structures and remove combustion products. Among other things, the chimney must be resistant to the effects of an aggressive mixture of condensate and soot, withstand the temperature of the exhaust gases, and comply with operational, fire and building standards.

For each chimney, in principle, processes such as fastening the smoke exhaust structure and its assembly, installation, installation and construction are considered individually. For a brick chimney, the process is as follows:

- Foundation

- Order

- Composition of the solution

- Mopping

- The head and the need for a chimney.

If the chimney is made of ceramics, then the following must be done:

- Foundation and fastening of modular elements

- Audit

- Connection tee.

Most actions are performed for stainless steel chimneys:

- Mounts and brackets

- Pipes “for smoke” or “for condensate”

- The use of bends or elbows to deflect the channel from the vertical

- Passages through floors and roofs

- The head and the need for an umbrella

During the installation process, it is necessary to take into account the thermal expansion that occurs during operation. It is unacceptable to violate the tightness of the installed channel. At the design stage of the fireplace design, the order of installation of the chimney, the correspondence of the component elements, cross-section and height are calculated.

The possible cost of a mistake is the cost of dismantling the defect and building a new staircase

If, as a result of an erroneously made decision or errors in calculations, the foundation for the stairs in the house was made incorrectly, the hastily manufactured structure may become warped already in the first year of operation. This statement is especially true for stairs located outside the house. Due to frost heaving of the soil and movement of the foundation, they can become deformed and begin to collapse in the first winter. This certainly could have been avoided if, before starting work, the owner of the house had considered it necessary to consult with specialists and began installing the stairs, having received answers to at least a few simple questions. Such as:

Types of materials for manufacturing

A special feature of construction work on the construction of a foundation for a fireplace is the layer-by-layer filling of a pre-prepared recess with concrete mortar of various compositions. The following materials can be used in the work:

- sand – river or quarry sand, free of foreign impurities and debris;

- cement material is the main binding component for concreting. To obtain a high-quality foundation, it is necessary to choose this material correctly - the cement must be homogeneous and loose in consistency, and not have lumps or expired shelf life. Its brand must be no lower than M400;

- crushed stone is a not very large stone of natural origin. The most commonly used is limestone gravel or granite. The first option is not expensive, the second has better frost resistance;

- rubble stone is a natural material, represented by large pieces of rock, the weight of which reaches fifty kilograms.