Pile-grillage foundations are used extremely rarely for the construction of houses made of aerated concrete, but sometimes this technology turns out to be the most effective and practical.

What are the features of a power structure, how to build a pile-grillage foundation for a house made of aerated concrete with your own hands, what reviews about such a foundation are described in detail in this article.

Conditions and features of use

The basis of such a foundation is made up of piles - support pillars that are buried 2-3 m into the ground. The depth of immersion depends on the soil freezing horizon; the piles should be approximately 0.5 m below this line. To connect the supports and improve the stability of the foundation system, a grillage is erected .

Grillages are classified according to the manufacturing method into the following types:

- Monolithic, which are continuous reinforced tapes;

- Prefabricated, mounted from reinforced concrete beams;

- Prefabricated monolithic (combination of the two previous types).

The grillages also differ in their location above the soil. High ones transfer the physical load of the building through the supports to a deeper soil horizon, while low ones partly take it upon themselves.

For the construction of private aerated concrete houses, it is optimal to use a pile-grillage type of foundation with a monolithic reinforced strip. This design will be as strong and stable as possible.

The construction of buildings on pile-grillage foundations is especially important in the following cases:

- Looseness and high soil moisture;

- On steep slopes;

- On soil with a freezing depth above 1.5 m;

- When constructing frame-panel buildings;

Types of foundations for a house made of aerated concrete

Screw piles can be installed on any soil and any terrain

Lightweight gas-filled concrete has the disadvantage of fragility; because of this quality, the walls crack at the slightest subsidence of the soil under the foundation. Strip foundations can only be made at shallow depths, because low-slung foundations will be pushed out by lateral soil pressure. In deep supports, the sides experience indirect stress, and the light weight of the structure cannot keep the structure from being pushed out by the heaving layer.

The foundation of a house made of blocks on screw piles is least subject to the forces of pulling, twisting and bending, because the walls have a small surface and rest with their tip on a solid layer of earth. The support rods have sufficient rigidity and are little deformed during the construction of the house and operation. The foundation of a building made of aerated concrete is chosen taking into account its stability in the ground, so that the walls do not experience fault loads.

Columnar

Columnar base

The pillars are placed at important points around the perimeter of the building. Little money is spent on such a basis, but its application is limited by certain conditions. You cannot install poles if the house is being built on a slope with a large difference in heights on one site. Landslide and loose soils are not suitable for columnar foundations.

Requirements for the foundation:

- a durable layer of soil with a low level of soil liquid is used;

- the heel of the element is located below the freezing mark by 20 - 30 cm;

- towards the bottom of the column it expands like a glass to increase the square of support;

- The rigidity of the structure is provided by a reinforced reinforced concrete grillage.

The pillars can be square or round, the material is wood or reinforced concrete, sometimes they make metal supports with insulation. The grillage is made by pouring into the formwork with the preliminary installation of the reinforcement cage.

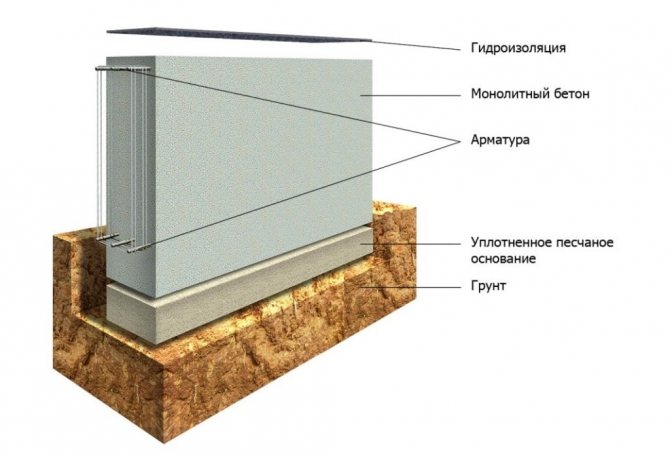

Monolithic

Foundation slab

It is a solid slab of concrete with stiffening ribs in which metal rods are installed for reinforcement. Mounted so that the bottom and side surfaces do not come into direct contact with the soil and do not absorb moisture. To do this, various cushions are made of sand, gravel, crushed stone, and geotextiles are placed under the base.

Types of monolithic slabs:

- the in-depth version is made below the freezing mark and is used in the construction of buildings with a basement;

- a floating type or a non-recessed one is placed on the surface if there is no basement.

In the construction of the foundation slab, two concrete layers are made (preparation and slab), a reinforcement cage in cross members for rigidity, a metal mesh is installed over the entire area, waterproofing and protection from the cold are laid. Concrete grades M250 and M300 are taken and anti-frost modifiers and additives against moisture absorption are added to the mixture.

Tape

Strip foundation

A buried monolithic foundation for a house with walls made of aerated concrete is not used; a foundation is made with a shallow immersion depth. Shallow concrete strips are placed so that their base is in the freezing zone of the soil. This option is suitable for dense soil, but in swelling layers it will be squeezed out when frozen. If the layer contains moisture or is fed by it from rain and snow, over time the shift will lead to the appearance of cracks on the walls.

It is not advisable to build a strip foundation under long-length aerated concrete walls. Concrete does not work well in bending and stretching, so increasing the length leads to a loss of strength. It is necessary to lay sand and crushed stone bedding, lay geotextiles and make thermal insulation of structures.

Construction Features

There are several types of piles and options for their immersion:

- Screw . Such supports are made from metal pipes with screw bands. Metaphorically speaking, these piles are huge screws that are driven into the soil using special equipment. After installing the supports, concrete is poured into the previously made hole in each of them. This method is very reliable, but requires considerable financial and labor costs.

- Printed . In this case, preliminary drilling of holes is required. M200 concrete is poured inside the asbestos-cement rods and reinforcement is applied. This method is less expensive, but constant professional quality control of the work is required.

- Bored . They differ from conventional pressed ones in that this option uses ready-made reinforced concrete supports or pipes.

- Hammers . Finished piles of various shapes are driven using special construction equipment. The optimal type of pillars is tubular piles with reinforced concrete rings.

In the construction of small private houses, it is best to use bored or screw piles.

Price list

Screw piles with welded tip

Ø 57 Ø 76 Ø 89 Ø 108 Ø 133

| Name | Standard | Premium | Cold zinc + Premium | Hot zinc (Galvanized) | Installation |

| SVSN-57/200/1500 | 700 rub. | 750 rub. | 9 00 rub. | 1,200 rub. | 700 rub. |

| SVSN-57/200/2000 | 800 rub. | 950 rub. | 1,000 rub. | 1,400 rub. | 750 rub. |

| SVSN-57/200/2500 | 900 rub. | 1,050 rub. | 1,100 rub. | 1,600 rub. | 800 rub. |

| SVSN-57/200/3000 | 1,000 rub. | 1,150 rub. | 1,200 rub. | 1,700 rub. | 850 rub. |

| SVSN-57/200/3500 | 1,200 rub. | 1,250 rub. | 1,400 rub. | 1,900 rub. | 900 rub. |

| SVSN-57/200/4000 | 1,300 rub. | RUB 1,350 | 1,500 rub. | 2,200 rub. | 920 rub. |

| SVSN-57/200/4500 | 1,500 rub. | RUB 1,550 | 1,700 rub. | 2,400 rub. | 1,050 rub. |

| SVSN-57/200/5000 | 1,600 rub. | 1,650 rub. | 1,800 rub. | 2,500 rub. | 1,150 rub. |

| SVSN-57/200/5500 | 1,700 rub. | 1,850 rub. | 2,000 rub. | 2,800 rub. | 1,250 rub. |

| SVSN-57/200/6000 | 1,900 rub. | 1,950 rub. | 2,100 rub. | 3,000 rub. | 1,400 rub. |

| Name | Standard | Premium | Cold zinc + Premium | Hot zinc (Galvanized) | Installation |

| SVSN-76/250/1500 | 900 rub. | 1,050 rub. | 1,200 rub. | 1,600 rub. | 800 rub. |

| SVSN-76/250/2000 | 1,000 rub. | 1,250 rub. | 1,400 rub. | 1,800 rub. | 850 rub. |

| SVSN-76/250/2500 | 1,200 rub. | 1,450 rub. | 1,500 rub. | 2,100 rub. | 920 rub. |

| SVSN-76/250/3000 | 1,300 rub. | 1,650 rub. | 1,700 rub. | 2,400 rub. | 960 rub. |

| SVSN-76/250/3500 | 1,500 rub. | 1,850 rub. | 1,900 rub. | 2,600 rub. | RUB 1,020 |

| SVSN-76/250/4000 | 1,600 rub. | RUB 2,050 | 2,100 rub. | 2,900 rub. | 1,050 rub. |

| SVSN-76/250/4500 | 1,800 rub. | RUB 2,150 | 2,300 rub. | 3,200 rub. | 1,150 rub. |

| SVSN-76/250/5000 | 2,000 rub. | RUB 2,350 | 2,500 rub. | 3,500 rub. | 1,300 rub. |

| SVSN-76/250/5500 | 2,100 rub. | RUB 2,550 | 2,700 rub. | RUB 3,800 | RUB 1,380 |

| SVSN-76/250/6000 | 2,200 rub. | RUB 2,750 | 2,900 rub. | 4,100 rub. | RUB 1,480 |

| Name | Standard | Premium | Cold zinc + Premium | Hot zinc (Galvanized) | Installation |

| SVSN-89/250/1500 | 1,100 rub. | 1,150 rub. | 1,300 rub. | 1,600 rub. | 850 rub. |

| SVSN-89/250/2000 | 1,200 rub. | 1,250 rub. | 1,400 rub. | 1,800 rub. | 900 rub. |

| SVSN-89/250/2500 | 1,300 rub. | 1,450 rub. | 1,600 rub. | 2,300 rub. | 950 rub. |

| SVSN-89/250/3000 | 1,500 rub. | 1,650 rub. | 1,800 rub. | 2,400 rub. | 1,100 rub. |

| SVSN-89/250/3500 | 1,800 rub. | 1,850 rub. | 2,000 rub. | 2,700 rub. | 1,150 rub. |

| SVSN-89/250/4000 | 2,000 rub. | RUB 2,050 | 2,200 rub. | 3,000 rub. | 1,200 rub. |

| SVSN-89/250/4500 | 2,200 rub. | RUB 2,250 | 2,400 rub. | 3,300 rub. | 1,300 rub. |

| SVSN-89/250/5000 | 2,300 rub. | RUB 2,450 | 2,600 rub. | 3,600 rub. | 1,400 rub. |

| SVSN-89/250/5500 | 2,500 rub. | RUB 2,650 | 2,800 rub. | RUB 3,800 | 1,500 rub. |

| SVSN-89/250/6000 | 2,700 rub. | RUB 2,850 | 3,000 rub. | 4,100 rub. | 1,600 rub. |

| Name | Standard | Premium | Cold zinc + Premium | Hot zinc (Galvanized) | Installation |

| SVSN-108/300/1500 | 1,300 rub. | RUB 1,350 | 1,500 rub. | 2,200 rub. | 900 rub. |

| SVSN-108/300/2000 | 1,500 rub. | 1,650 rub. | 1,800 rub. | 2,600 rub. | 950 rub. |

| SVSN-108/300/2500 | 1,700 rub. | 1,850 rub. | 2,100 rub. | 2,900 rub. | 1,000 rub. |

| SVSN-108/300/3000 | 2,000 rub. | RUB 2,150 | 2,400 rub. | 3,400 rub. | 1,200 rub. |

| SVSN-108/300/3500 | 2,300 rub. | RUB 2,450 | 2,700 rub. | RUB 3,800 | 1,250 rub. |

| SVSN-108/300/4000 | 2,500 rub. | RUB 2,750 | 3,000 rub. | 4,300 rub. | 1,300 rub. |

| SVSN-108/300/4500 | 2,700 rub. | RUB 2,950 | 3,200 rub. | 4,700 rub. | 1,400 rub. |

| SVSN-108/300/5000 | 3,100 rub. | RUB 3,250 | 3,500 rub. | 5,200 rub. | 1,500 rub. |

| SVSN-108/300/5500 | 3,400 rub. | RUB 3,550 | RUB 3,800 | 5,600 rub. | 1,600 rub. |

| SVSN-108/300/6000 | 3,700 rub. | RUB 3,750 | 4,100 rub. | 6,000 rub. | 1,700 rub. |

| Name | Standard | Premium | Cold zinc + Premium | Hot zinc (Galvanized) | Installation |

| SVSN-133/350/1500 | 1,600 rub. | RUB 1,750 | 1,900 rub. | 2,700 rub. | 1,100 rub. |

| SVSN-133/350/2000 | 1,900 rub. | RUB 2,050 | 2,300 rub. | 3,300 rub. | 1,150 rub. |

| SVSN-133/350/2500 | 2,200 rub. | RUB 2,450 | 2,600 rub. | 3,700 rub. | 1,250 rub. |

| SVSN-133/350/3000 | 2,600 rub. | RUB 2,850 | 3,000 rub. | 4,200 rub. | 1,300 rub. |

| SVSN-133/350/3500 | 2,900 rub. | RUB 3,050 | 3,300 rub. | 3,300 rub. | RUB 1,350 |

| SVSN-133/350/4000 | 3,200 rub. | RUB 3,450 | 3,700 rub. | 5,400 rub. | 1,400 rub. |

| SVSN-133/350/4500 | 3,600 rub. | RUB 3,750 | 4,000 rub. | RUB 5,900 | 1,450 rub. |

| SVSN-133/350/5000 | RUB 3,900 | 4,050 rub. | 4,400 rub. | 6,400 rub. | RUB 1,550 |

| SVSN-133/350/5500 | 4,200 rub. | 4,450 rub. | 4,700 rub. | 7,000 rub. | 1,600 rub. |

| SVSN-133/350/6000 | 4,500 rub. | RUB 4,750 | 5,100 rub. | 7,500 rub. | 1,700 rub. |

Screw piles with cast tip

Ø 57 Ø 76 Ø 89 Ø 108 Ø 133

| Name | Standard | Premium | Cold zinc + Premium | Hot zinc (Galvanized) | Installation |

| SVLN-57/150/1500 | 900 rub. | 950 rub. | 1,100 rub. | 1,200 rub. | 700 rub. |

| SVLN-57/150/2000 | 1,000 rub. | 1,150 rub. | 1,200 rub. | 1,400 rub. | 750 rub. |

| SVLN-57/150/2500 | 1,100 rub. | 1,250 rub. | 1,300 rub. | 1,600 rub. | 800 rub. |

| SVLN-57/150/3000 | 1,200 rub. | RUB 1,350 | 1,400 rub. | 1,800 rub. | 850 rub. |

| SVLN-57/150/3500 | 1,300 rub. | 1,450 rub. | 1,500 rub. | 1,900 rub. | 900 rub. |

| SVLN-57/150/4000 | 1,500 rub. | RUB 1,550 | 1,700 rub. | 2,100 rub. | 920 rub. |

| SVLN-57/150/4500 | 1,600 rub. | 1,650 rub. | 1,800 rub. | 2,300 rub. | 1,050 rub. |

| SVLN-57/150/5000 | 1,700 rub. | RUB 1,750 | 1,900 rub. | 2,500 rub. | 1,150 rub. |

| SVLN-57/150/5500 | 1,800 rub. | 1,950 rub. | 2,000 rub. | 2,700 rub. | 1,250 rub. |

| SVLN-57/150/6000 | 1,900 rub. | RUB 2,050 | 2,200 rub. | 2,900 rub. | 1,400 rub. |

| SVLN-57/screw/1500 | 800 rub. | 950 rub. | 1,000 rub. | 1,100 rub. | 600 rub. |

| SVLN-57/screw/2000 | 1,000 rub. | 1,050 rub. | 1,100 rub. | 1,300 rub. | 650 rub. |

| SVLN-57/screw/2500 | 1,100 rub. | 1,150 rub. | 1,200 rub. | 1,500 rub. | 700 rub. |

| SVLN-57/screw/3000 | 1,200 rub. | 1,250 rub. | 1,400 rub. | 1,700 rub. | 750 rub. |

| SVLN-57/screw/3500 | 1,300 rub. | RUB 1,350 | 1,500 rub. | 1,900 rub. | 800 rub. |

| SVLN-57/screw/4000 | 1,400 rub. | RUB 1,550 | 1,600 rub. | 2,100 rub. | 820 rub. |

| SVLN-57/screw/4500 | 1,500 rub. | 1,650 rub. | 1,700 rub. | 2,200 rub. | 950 rub. |

| SVLN-57/screw/5000 | 1,600 rub. | RUB 1,750 | 1,800 rub. | 2,400 rub. | 1,050 rub. |

| SVLN-57/screw/5500 | 1,700 rub. | 1,850 rub. | 2,000 rub. | 2,600 rub. | 1,150 rub. |

| SVLN-57/screw/6000 | 1,800 rub. | 1,950 rub. | 2,100 rub. | 2,800 rub. | 1,300 rub. |

| Name | Standard | Premium | Cold zinc + Premium | Hot zinc (Galvanized) | Installation |

| SVLN-76/150/1500 | 1,100 rub. | 1,150 rub. | 1,300 rub. | 1,500 rub. | 800 rub. |

| SVLN-76/150/2000 | 1,200 rub. | RUB 1,350 | 1,400 rub. | 1,800 rub. | 850 rub. |

| SVLN-76/150/2500 | 1,400 rub. | 1,450 rub. | 1,600 rub. | 2,000 rub. | 920 rub. |

| SVLN-76/150/3000 | 1,500 rub. | 1,650 rub. | 1,700 rub. | 2,200 rub. | 960 rub. |

| SVLN-76/150/3500 | 1,700 rub. | RUB 1,750 | 1,900 rub. | 2,500 rub. | RUB 1,020 |

| SVLN-76/150/4000 | 1,800 rub. | 1,950 rub. | 2,100 rub. | 2,700 rub. | 1,050 rub. |

| SVLN-76/150/4500 | 2,000 rub. | RUB 2,050 | 2,200 rub. | 3,000 rub. | 1,150 rub. |

| SVLN-76/150/5000 | 2,100 rub. | RUB 2,250 | 2,400 rub. | 3,200 rub. | 1,300 rub. |

| SVLN-76/150/5500 | 2,300 rub. | RUB 2,350 | 2,500 rub. | 3,500 rub. | RUB 1,380 |

| SVLN-76/150/6000 | 2,400 rub. | RUB 2,550 | 2,700 rub. | 3,700 rub. | RUB 1,480 |

| SVLN-76/screw/1500 | 1,100 rub. | 1,150 rub. | 1,200 rub. | 1,400 rub. | 700 rub. |

| SVLN-76/screw/2000 | 1,200 rub. | 1,250 rub. | 1,300 rub. | 1,600 rub. | 750 rub. |

| SVLN-76/screw/2500 | 1,300 rub. | 1,450 rub. | 1,500 rub. | 1,800 rub. | 820 rub. |

| SVLN-76/screw/3000 | 1,500 rub. | 1,650 rub. | 1,700 rub. | 2,100 rub. | 860 rub. |

| SVLN-76/screw/3500 | 1,600 rub. | RUB 1,750 | 1,800 rub. | 2,300 rub. | 920 rub. |

| SVLN-76/screw/4000 | 1,700 rub. | 1,950 rub. | 2,000 rub. | 2,500 rub. | 950 rub. |

| SVLN-76/screw/4500 | 1,900 rub. | RUB 2,050 | 2,100 rub. | 2,800 rub. | 1,050 rub. |

| SVLN-76/screw/5000 | 2,000 rub. | RUB 2,150 | 2,300 rub. | 3,000 rub. | 1,200 rub. |

| SVLN-76/screw/5500 | 2,200 rub. | RUB 2,350 | 2,400 rub. | 3,200 rub. | RUB 1,280 |

| SVLN-76/screw/6000 | 2,300 rub. | RUB 2,550 | 2,600 rub. | 3,400 rub. | RUB 1,380 |

| Name | Standard | Premium | Cold zinc + Premium | Hot zinc (Galvanized) | Installation |

| SVLN-89/250/1500 | 1,400 rub. | RUB 1,550 | 1,600 rub. | 2,000 rub. | 850 rub. |

| SVLN-89/250/2000 | 1,600 rub. | RUB 1,750 | 1,800 rub. | 2,300 rub. | 900 rub. |

| SVLN-89/250/2500 | 1,700 rub. | 1,950 rub. | 2,000 rub. | 2,600 rub. | 950 rub. |

| SVLN-89/250/3000 | 2,000 rub. | RUB 2,150 | 2,200 rub. | 2,900 rub. | 1,100 rub. |

| SVLN-89/250/3500 | 2,100 rub. | RUB 2,250 | 2,400 rub. | 3,200 rub. | 1,150 rub. |

| SVLN-89/250/4000 | 2,300 rub. | RUB 2,450 | 2,600 rub. | 3,500 rub. | 1,200 rub. |

| SVLN-89/250/4500 | 2,500 rub. | RUB 2,650 | 2,800 rub. | 3,700 rub. | 1,300 rub. |

| SVLN-89/250/5000 | 2,600 rub. | RUB 2,850 | 3,000 rub. | 4,000 rub. | 1,400 rub. |

| SVLN-89/250/5500 | 2,800 rub. | RUB 3,050 | 3,200 rub. | 4,300 rub. | 1,500 rub. |

| SVLN-89/250/6000 | 3,000 rub. | RUB 3,250 | 3,400 rub. | 4,600 rub. | 1,600 rub. |

| SVLN-89/screw/1500 | 1,200 rub. | RUB 1,350 | 1,400 rub. | 1,800 rub. | 750 rub. |

| SVLN-89/screw/2000 | 1,400 rub. | RUB 1,550 | 1,600 rub. | 2,100 rub. | 800 rub. |

| SVLN-89/screw/2500 | 1,600 rub. | RUB 1,750 | 1,800 rub. | 2,300 rub. | 850 rub. |

| SVLN-89/screw/3000 | 1,800 rub. | 1,950 rub. | 2,000 rub. | 2,600 rub. | 1,000 rub. |

| SVLN-89/screw/3500 | 1,900 rub. | RUB 2,050 | 2,200 rub. | 2,900 rub. | 1,050 rub. |

| SVLN-89/screw/4000 | 2,100 rub. | RUB 2,250 | 2,400 rub. | 3,200 rub. | 1,100 rub. |

| SVLN-89/screw/4500 | 2,300 rub. | RUB 2,450 | 2,500 rub. | 3,500 rub. | 1,200 rub. |

| SVLN-89/screw/5000 | 2,400 rub. | RUB 2,650 | 2,700 rub. | RUB 3,800 | 1,300 rub. |

| SVLN-89/screw/5500 | 2,600 rub. | RUB 2,850 | 2,900 rub. | 4,100 rub. | 1,400 rub. |

| SVLN-89/screw/6000 | 2,800 rub. | RUB 3,050 | 3,100 rub. | 4,400 rub. | 1,500 rub. |

| Name | Standard | Premium | Cold zinc + Premium | Hot zinc (Galvanized) | Installation |

| SVLN-108/300/1500 | 2,000 rub. | RUB 2,150 | 2,200 rub. | 3,000 rub. | 900 rub. |

| SVLN-108/300/2000 | 2,300 rub. | RUB 2,450 | 2,500 rub. | 3,400 rub. | 950 rub. |

| SVLN-108/300/2500 | 2,500 rub. | RUB 2,750 | 2,800 rub. | RUB 3,800 | 1,000 rub. |

| SVLN-108/300/3000 | 2,800 rub. | RUB 3,050 | 3,200 rub. | 4,400 rub. | 1,200 rub. |

| SVLN-108/300/3500 | 3,100 rub. | RUB 3,350 | 3,500 rub. | 4,800 rub. | 1,250 rub. |

| SVLN-108/300/4000 | 3,400 rub. | RUB 3,650 | RUB 3,800 | 5,300 rub. | 1,300 rub. |

| SVLN-108/300/4500 | 3,700 rub. | RUB 3,950 | 4,100 rub. | 5,800 rub. | 1,400 rub. |

| SVLN-108/300/5000 | RUB 3,900 | 4,150 rub. | 4,400 rub. | 6,200 rub. | 1,500 rub. |

| SVLN-108/300/5500 | 4,200 rub. | 4,450 rub. | 4,700 rub. | 6,700 rub. | 1,600 rub. |

| SVLN-108/300/6000 | 4,500 rub. | RUB 4,750 | 5,000 rub. | 7,200 rub. | 1,700 rub. |

| SVLN-108/screw/1500 | 1,800 rub. | 1,950 rub. | 2,000 rub. | 2,600 rub. | 800 rub. |

| SVLN-108/screw/2000 | 2,100 rub. | RUB 2,250 | 2,300 rub. | 3,000 rub. | 850 rub. |

| SVLN-108/screw/2500 | 2,400 rub. | RUB 2,550 | 2,600 rub. | 3,500 rub. | 900 rub. |

| SVLN-108/screw/3000 | 2,600 rub. | RUB 2,850 | 2,900 rub. | RUB 3,900 | 1,100 rub. |

| SVLN-108/screw/3500 | 2,900 rub. | RUB 3,150 | 3,200 rub. | 4,400 rub. | 1,150 rub. |

| SVLN-108/screw/4000 | 3,200 rub. | RUB 3,450 | 3,500 rub. | 4,800 rub. | 1,200 rub. |

| SVLN-108/screw/4500 | 3,400 rub. | RUB 3,650 | RUB 3,800 | 5,200 rub. | 1,300 rub. |

| SVLN-108/screw/5000 | 3,700 rub. | RUB 3,950 | 4,100 rub. | 5,700 rub. | 1,400 rub. |

| SVLN-108/screw/5500 | 4,000 rub. | 4,250 rub. | 4,400 rub. | 6,100 rub. | 1,500 rub. |

| SVLN-108/screw/6000 | 4,300 rub. | RUB 4,550 | 4,700 rub. | 6,600 rub. | 1,600 rub. |

| Name | Standard | Premium | Cold zinc + Premium | Hot zinc (Galvanized) | Installation |

| SVLN-133/350/1500 | 2,800 rub. | RUB 2,950 | 3,000 rub. | 4,100 rub. | 1,050 rub. |

| SVLN-133/350/2000 | 3,200 rub. | RUB 3,350 | 3,400 rub. | 4,700 rub. | 1,100 rub. |

| SVLN-133/350/2500 | 3,500 rub. | RUB 3,650 | RUB 3,800 | 5,300 rub. | 1,150 rub. |

| SVLN-133/350/3000 | RUB 3,800 | 4,050 rub. | 4,100 rub. | RUB 5,900 | 1,250 rub. |

| SVLN-133/350/3500 | 4,200 rub. | RUB 4,350 | 4,500 rub. | 6,400 rub. | 1,300 rub. |

| SVLN-133/350/4000 | 4,500 rub. | RUB 4,750 | 4,900 rub. | 7,000 rub. | RUB 1,350 |

| SVLN-133/350/4500 | 4,800 rub. | RUB 5,050 | 5,200 rub. | 7,600 rub. | 1,400 rub. |

| SVLN-133/350/5000 | 5,200 rub. | RUB 5,450 | 5,600 rub. | 8,200 rub. | 1,500 rub. |

| SVLN-133/350/5500 | 5,500 rub. | RUB 5,850 | 6,000 rub. | 8,800 rub. | RUB 1,550 |

| SVLN-133/350/6000 | 5,800 rub. | 6,150 rub. | 6,400 rub. | 9,300 rub. | 1,650 rub. |

Request the exact cost of the object Call our specialist

Construction of a quality foundation

When building a foundation for a house on aerated concrete piles, there are important features:

- the best option for the structure are piles with a diameter of 108 mm or more;

- supports are installed to a depth of 2 meters;

- to speed up the work, you can prepare pits for pile pillars, so it will be easier to screw them in;

- to drill wells for supports, you can use an automatic or manual hole drill;

- you can twist the pillars either manually or using a pile driver;

- It is mandatory to maintain a vertical level with a deviation of no more than 2 cm;

- the step between pile supports is 1500-2000 mm;

- It is necessary to fill the support cavity with cement mortar;

- tying the pillars is done using a channel or I-beam;

- A layer of waterproofing is required between the grillage and the blocks.

In order for a house made of aerated concrete on a pile foundation to serve properly and not require repairs for a long time, it is advisable to protect the ground part of the foundation with cladding made of bricks, blocks or other material. You can find out the details of building houses on stilts and order screw structures by phone or on the website!

Screw piles

Grillages

That part of the piles that is above the ground is connected with a rigid reinforced concrete grillage, subsequently forming a single foundation structure. A grillage is necessary for the even distribution of physical loads and, of course, the ability to build aerated concrete walls.

The grillage can be:

- Monolithic or prefabricated;

- Hanging, above ground or partially buried;

- Made from beams or solid slab.

Screw pile installation technology

Design the placement of pile supports in the corners of the building, in the centers of support of load-bearing walls with a minimum distance between piles of 1.5 to 2 meters.

One screw pile can withstand an axial load of up to 25 tons.

Installation of a screw pile

Installing screw piles is not very difficult. The head of the pile support consists of a metal heel welded to the upper end of the pile rod. This horizontal support has technological holes for fastening mounting equipment.

The mounting gate is secured through the holes. Two workers, turning the gate, plunge the pile into the ground. As the pile is screwed into the soil, it becomes compacted.

When the number of pile supports is large and their immersion depth is several meters, mechanized installations are used. The power equipment is equipped with a boom, at the end of which a rotating element is installed. It is connected with bolts to the head of a screw pile and imparts a rotational movement to it. As a result, many piles can be installed over a large area in a short period of time.

Calculation of the foundation for an aerated concrete building

The initial design stage involves inspection and assessment of the site. The geological structure, soil type, and groundwater level are taken into account. The main purpose of this procedure is to find out the degree of soil resistance and its bearing capacity.

At the next stage, it is necessary to calculate the vertical load on the future building. It is the sum of several terms, including:

- Weight of the building (grillage, walls, insulation, roofing, etc.);

- Weight of potential snow cover;

- Approximate weight of furniture and communication equipment used.

Next, the supporting area of the pile foundation is calculated. The previously obtained load with a margin of 20% must be divided by the soil resistance index. It is advisable to entrust all these calculations to a professional engineer.

Based on the supporting area, they find out the cross-sectional dimensions of the grillage and piles, as well as the required number of support pillars.

As a rule, the piles are lined up along the perimeter in one line, but if the grillage is long, it may be necessary to install the piles in several rows.

High-quality work on creating a screw foundation - from

The production company offers its clients the production of screw piles and the installation of high-quality foundations based on them.

Our professionals have more than 250 successfully implemented projects behind them and we do not stop there. Each client who contacts us receives guarantees of long service life of the foundation on screw piles. We pay close attention to the preparation of the project and its implementation. You will certainly appreciate the high quality of our services.

See also: screw piles for fences and terraces on screw piles

Installation of pile and pile-grillage foundations

First you need to prepare all the piles for external and internal walls, as well as reinforcement, if the design requires it. The average grillage height is 0.3-0.4 m, width is 0.3-0.6 m.

The direct installation process also includes the following steps:

- Preparation and marking of the site. First of all, the plant layer is removed to a depth of 0.4-0.5 m, and the surface is leveled. Next, the corners and contours of the external and internal walls are marked. Marks are made at the places where the piles will be.

- Drilling pits. Carried out using appropriate technology; It is possible to use a hand drill.

- Installation of piles. Asbestos-cement pipes or other shells are placed in pits, a reinforcement cage is inserted inside, and then the process of filling the cavity with concrete follows.

- Installation of grillage. After the installed piles have gained sufficient strength and durability, the spaces between the supports are filled with sand and compacted. Next, formwork panels are placed, a system for supplying and discharging water, and an electricity system are being thought out.

- This is followed by the process of waterproofing using rolled sheets, on which a reinforcement cage is then installed, connected to the pile rods. The concrete mixture is poured and the formwork is later dismantled. At the final stage, the sand is removed.

If the sand backfill is not removed, the lower part of the concrete strip in winter will be subject to strong pressure from the soil, which has expanded under the influence of cold. The grillage may be destroyed and the piles may be torn off, so the installation technology must be followed impeccably.

Strip monolithic foundation

This type involves the installation of monolithic reinforced concrete slabs , which are installed around the perimeter of the future house.

Advantages

- Sustainability.

- Does not require concrete pouring of slabs.

Plates installed around the perimeter create a rigid structure that prevents the walls from collapsing;

During installation, a trench is used, in which an embankment of sand is made, after which reinforcement is laid out and concrete is poured. Plates are installed on it.

Device

- Concrete plates;

- Trenches with sand and reinforcement.

Minuses

- High cost of concrete slabs and rental of heavy construction equipment;

- Installation of a strip foundation can only be carried out in the warm season , since pouring into frozen soil is prohibited;

- It takes more time for concrete to harden.

Cost calculation

The average cost is from 4 thousand rubles per square meter and depends on the area of the future building.