Strengthening the foundation may be necessary when, during a small reconstruction of the house, cracks in the walls suddenly appear, windows and doors jam, and even to the eye you can see that the house is slightly askew... the serious diagnosis is clear - the foundation requires strengthening. The reasons may not necessarily lie in the additions and reconstructions made to the house. And there are situations when in the spring it is necessary to strengthen and reconstruct the foundation of a house, the construction and occupancy of which was completed the previous fall.

Reasons for the destruction of strip foundations

The strip foundation constantly experiences destructive influences.

These include:

- Frosty soil heaving.

- Soil subsidence.

- Construction or excavation work taking place nearby.

- Seasonal ground movements.

- Floods, changes in groundwater levels.

- Presence of slope.

In addition, negative consequences can be caused by:

- Low quality building materials.

- Failure to comply with technological requirements during construction.

- Change in the weight of the building caused by the construction of an additional floor or other reasons.

- Violations of house operating rules.

The listed impacts can occur either individually or in combination, which creates extremely difficult operating conditions for the foundation.

Over time, concrete begins to lose its strength, and additional stress accelerates the destructive processes many times over. The solution to the problem may be to strengthen the strip foundation .

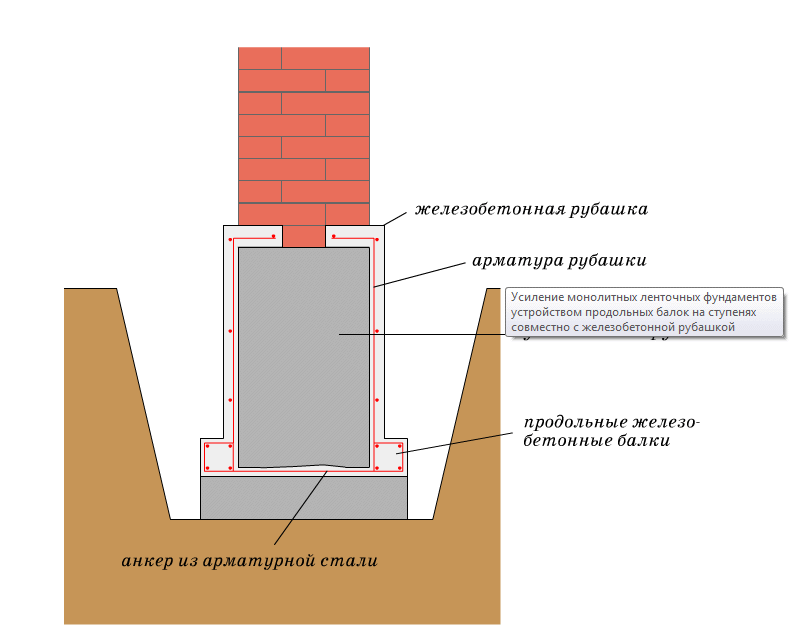

Pouring reinforced concrete jacket

A common way to strengthen the foundation is to pour a reinforced concrete jacket.

The foundation for pouring the concrete jacket is dug taking into account the length of the fills no more than 3 m

This method is quite simple. A person with the slightest skills in construction can fill a reinforced concrete jacket alone. To do this you will need the following materials:

- concrete grade M400;

- reinforcement for tying the frame with a thickness of 16–18 mm.

Work order

- The foundation for pouring the concrete jacket is dug, taking into account the length of the fills no more than 3 m. First of all, the corners are dug out and strengthened. The earth deepens 50 cm below the base.

- The reinforcement frame being installed must cover the underground part of the structure from the outside. Anchors are used to increase the maximum load. The reinforcement cage rods should be positioned vertically and horizontally with tying wire tied around the intersecting points.

All reinforcing bars must be connected with tying wire - Concrete solution is poured into the assembled formwork. The resulting reinforced concrete frame can significantly strengthen any type of platform.

To protect the structure from moisture, after the concrete has hardened, it is necessary to create slopes

When is amplification required and what is it?

The need to strengthen the foundation arises in different situations:

- When it is planned to build an additional floor, an extension, or otherwise change the size of the house.

- When cracks appear on the walls or foundation strip.

- If the waterproofing of the tape is broken, causing the concrete to crumble.

- Mechanical damage to the tape.

- Rising groundwater levels destroying the tape.

- Aggressive environmental influences.

All these cases require immediate intervention. Reinforcement is an increase in the load-bearing capacity of the strip base by installing additional elements, increasing the cross-section of the strip, injecting special substances or other measures.

The choice of a specific method depends on the condition of the belt, the cause of the problem and the extent of the intervention required. In any case, before starting work, it is necessary to thoroughly examine the structure and make a decision with the participation of experienced specialists.

NOTE!

Self-indulgence in such matters is absolutely excluded, since instead of the expected results, you can get exactly the opposite consequences.

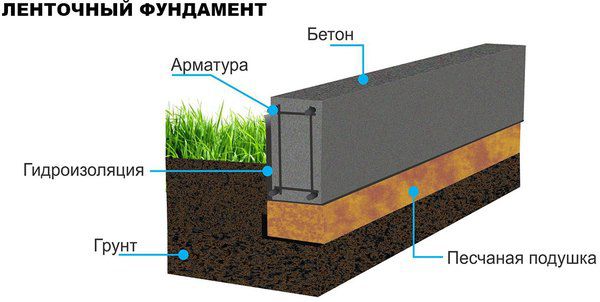

Sole widening

In practice, home owners most often resort to the classic, proven method of strengthening the foundation - the method of widening the base. The sole is a reinforced concrete pad on which the foundation rests. This method is the simplest, most reliable and relatively inexpensive. Several people with certain skills can handle the job.

- An additional foundation is laid around the house, acting as an auxiliary support.

- The sole along the entire perimeter of the structure is fixed at several pre-marked base points, the number of which depends on the size of the building and the degree of destruction of the main foundation. Typically the distance between points is 2.5–3 m.

- Excavation is carried out on the sides and under the foundation.

- A reinforcement screed is laid under the foundation and filled evenly with mortar.

- Using a concrete vibrator, air bubbles are removed.

- The side walls of the sole rise to the base by 15 cm.

The method of strengthening the foundation by widening the sole is the simplest, most reliable and relatively inexpensive

Diagnosis of the problem

Diagnostics is a set of measures aimed at obtaining complete information about the condition of the supporting structure, the presence of mechanical damage, cracks or deformations.

The condition of the underlying soil, sand cushion and other elements that bear the load from the weight of the house is examined.

The procedure is carried out in stages:

- External inspection of visible parts of the tape . Visual detection of tape damage is carried out from the outside, from the basement (if possible). Looks for visible signs of problems with adjacent layers of soil - subsidence, gullies, etc.

- Underground inspection . The tape is dug around the perimeter, the condition of the trench is checked, the surface of the tape is inspected and any damage that has occurred is detected. The immersion depth of the tape and the base material are assessed.

A defect report is drawn up, which includes all detected damage. A foundation plan is drawn up , on which points of damage, cracks, and deformed areas are noted.

Based on the documentation compiled, a decision is made on measures to solve the problems that have arisen.

During these works, a monthly check of the belt immobility is carried out . Special control beacons are installed on the surface and their condition is recorded.

After a month, their position is checked. If there are no changes, it means that the tape has completed settling.

To perform complex work, unloading of the foundation is required . Its purpose is to transfer the weight of the house to an auxiliary support system, allowing the soil under the tape to be removed for replacement or waterproofing.

Replacing the base

If collapse or destruction of the platform occurs in the area of the base, this part must be replaced. It is easiest to replace under a wooden structure, since it weighs less than stone or brick.

The easiest way to replace the base is under a wooden building

Under a structure made of stone or brick, the base is replaced in parts no longer than 1 m with intervals between sections of at least 3 m. To carry out the work you will need:

- fittings;

- cement;

- sand;

- crushed stone;

- plasticizer;

- concrete mixer;

- chain saw for concrete to cut out the necessary sections of the base;

- perforator;

- welding machine for fastening reinforcing elements.

How to replace the base yourself

- To install the formwork, you need to go down into the underground, so disassemble the section of the floor in the house where the foundation is strengthened.

- Make 5–10 cuts with a chain saw, maintaining a distance of 1 m between the outermost ones.

- Divide the area into small pieces with several horizontal cuts.

- Place the cut pieces aside and clean the surface of the base as well as the underside of the building.

- Build the formwork in two parts: one for the outside of the house, the other for the inside. There should be holes for reinforcement on the sides of the formwork. The formwork should be 5–7 cm wider than the wall on the outside and inside.

- Remove the prepared formwork and install the vertical pins of the reinforcing structure into holes with a diameter of 18–22 mm. The pieces of reinforcement should rise 10–15 cm above the foundation. Attach long pieces to them. After this, weld the horizontal rods so that they coincide with the holes in the formwork. It is not recommended to connect reinforcement with tying wire, as this reduces the strength of the structure.

If the base is made of reinforced concrete, the house can be raised with jacks - Install the formwork and pour the concrete using plasticizers and a minimum amount of water.

- Remove the formwork after 2 days.

- After 25 days, begin replacing adjacent sections of the base.

Video: replacing the base with raising the house

How to strengthen a strip foundation

The actions that need to be taken to strengthen the tape are determined by the size and causes of the damage. In some cases, it is enough to update the waterproofing ; in other situations, a set of complex technical measures is required, such as installing additional supports or expanding the tape.

Let's take a closer look at these methods:

Strengthening a shallow foundation with a concrete jacket

A concrete jacket is a reinforcing concrete casting installed on a problem area of the wall.

To create it, perform the following steps:

- The surface of the tape is exposed, and all soil in the problem area is removed from the trench.

- The waterproofing layer is removed from the concrete tape. The surface of the material must be absolutely clean, as after pouring.

- Transverse holes are drilled through the tape into which reinforcing bars are inserted.

- A reinforcement frame is knitted and welded to rods inserted into the holes of the tape.

- The formwork is being installed.

- Concrete is poured and left for the required time.

- After the curing period has expired, the formwork is removed, the concrete surface is waterproofed and further actions are carried out.

The dimensions of the reinforced concrete jacket depend on the size of the damaged area, but not less than 1 meter.

Creating a concrete frame

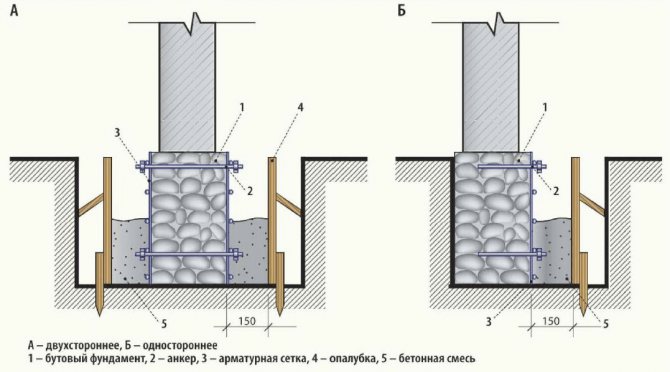

The concrete collar forms an additional layer of material on both sides of the tape. The technology resembles the method of installing a reinforced concrete jacket , but an additional layer is poured on both sides of the problem area of the tape.

All actions are carried out both inside and outside the tape . As a result, a significant thickening of the foundation is formed , capable of withstanding high loads.

IMPORTANT!

Many experts express distrust in installing clips. They argue this by the lack of a qualitative connection between the old concrete and the new casting. The processes occurring in fresh material do not allow the layers to join together properly, so the technique is suitable only in the presence of relatively minor damage.

By using piles

The method of strengthening with piles is quite complex and varied. Piles are being installed to create additional support for the tape. They rest on dense layers of soil, stopping subsidence or increasing the bearing capacity of the foundation to accommodate increased loads from extensions or new structural elements of the house.

Different types of piles are used:

- Micropiles.

- Pressable.

- Bored.

- Screw.

- Remote.

Each type of pile performs its own function and is used in certain situations where their use is the best solution to the problem. Thus, screw piles can be installed manually using the most gentle methods possible.

Pressed-in piles require the use of special equipment, so their use for reinforcement is limited.

External piles are installed at some distance from the perimeter of the old tape, then metal beams are passed through it and connected to the piles. As a result, the house appears to be “suspended” on the beams, receiving additional support .

The weight of the building is distributed between the old and new foundations, which allows it to bear increased loads.

With the help of tides

The technique is used to strengthen a tape made of piece elements - brick or rubble stone. The ebb tides are designed to perform the functions of an armored belt .

They are installed on the surface of the tape on both sides, pressed out so that the upper part does not contact the surface of the wall, and the lower part is pressed against it as tightly as possible.

After this, the structure is firmly fixed using jacks. A trench is dug to form a form for pouring concrete. As a result, an additional reinforced concrete layer is formed around the tape, enhancing the load-bearing capacity and strength of the base .

Strengthening with shotcrete

Shotcrete is the process of applying concrete using a special spraying method . Special equipment is used for this. The essence of the method is to supply a dry mixture of cement and sand, called a gunite mixture, under compressed air pressure.

Simultaneously with the supply of the mixture, water is supplied from another tank to mix the mixture. As a result, a layer of dense and durable concrete appears on the reinforced surface , which has improved characteristics compared to conventional types of material.

NOTE!

The technology is complex and requires the involvement of specialists and the use of sophisticated equipment.

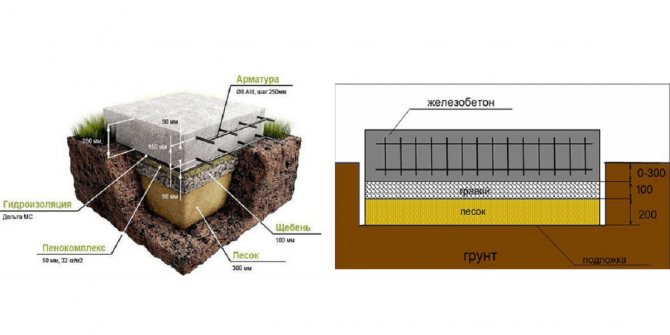

Pouring reinforced concrete pad

The advantages of strengthening the platform by pouring a reinforced concrete pad are:

- reduced pressure on the soil due to the large base area;

- additional soil insulation. This prevents frost heaving, which is considered the most common cause of foundation failure.

The disadvantages of the technology include the inability to fill the entire foundation, but only in sections of no more than 2 m, and the need to observe the drying time of each section before pouring the next one. Therefore, this method is used to strengthen one of the corners of the foundation or in the event that the time and cost of pouring the foundation around is not important.

The reinforced concrete pad reduces the load on the ground and allows it to be insulated

Pouring the pillow under the foundation occurs in several stages:

- The area to be repaired is dug up from the outside and inside of the building. At the same time, the blind area and floor are removed, the earth around the base is dug out in the form of two trenches with a length of 3.0 m to 3.5 m and a depth of ¾ of the depth of the foundation.

- The condition of the foundation is assessed for the presence of cracks and damaged areas.

- If the foundation is in order, a hole is dug for the cushion, up to 2 m long and 0.4–0.5 m deep relative to the foundation. The bottom of the pit must be level.

- Geotextiles are placed in the hole, sand is poured in a layer of 3–5 cm and a 10 cm layer of crushed stone with a fraction of 30–40 mm is poured.

- To level the surface, clean sand is poured over the crushed stone, and then a 5-centimeter layer of foam is placed.

- A reinforcing structure is laid on top and formwork is installed.

- The base is poured with concrete and compacted using a vibrator.

- The formwork is removed after 2 days.

- You can begin repairing the next section no earlier than in 25–28 days.

It is important that the concrete contains as little water as possible. The optimal proportion of water to concrete is 1:4. But too thick concrete is difficult to pour into a trench, so it can be diluted with a plasticizer sold in hardware stores.

The height of the finished reinforced concrete pad must be at least 10 cm of the foundation section being repaired. This will strengthen the base and reduce pressure on the ground.

In winter, it is not recommended to repair the foundation by pouring a concrete pad. If there are still dug trenches, protect them from frost heaving: cover them with earth and cover them with foam plastic.

Video: strengthening the foundation by pouring a concrete pad

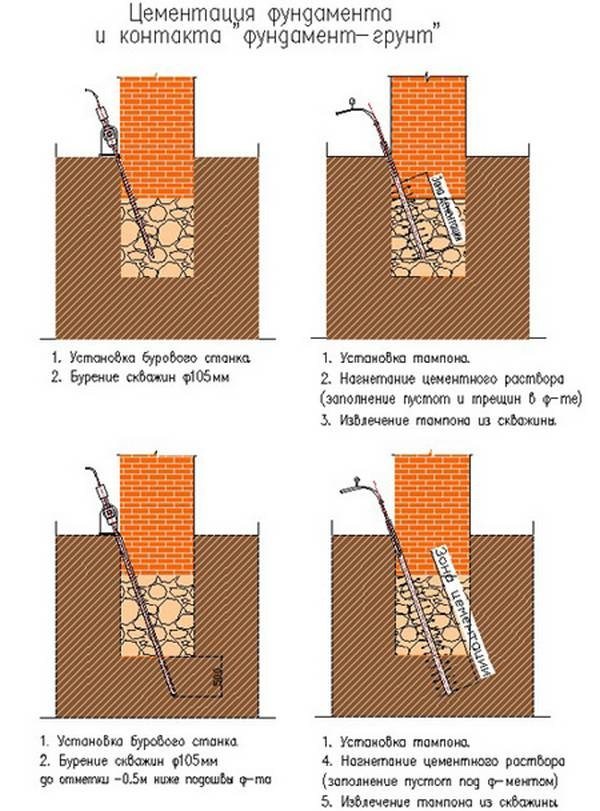

Cementation method

The cementation method is also called injection. This is explained by the introduction of hollow tubes into the cracks of the platform. As a rule, it is used to impart strength to a rubble foundation that has many voids. Mortar is poured into them, and small cracks are covered. This method is considered quite affordable, but it is used only for foundations with preserved load-bearing capacity.

- First, wells are drilled in the foundation.

- Hollow tubes are installed in them with an extension of at least 40 cm beyond the holder and fixed with a solution.

- Two days after the ferrule has hardened, the tube cavities are filled with not very thick cement.

The cementing composition is introduced using special injectors