SHARE ON SOCIAL NETWORKS

FacebookTwitterOkGoogle+PinterestVk

Thermal protection is an important task that must be completed in order to reliably protect the box from the negative effects of atmospheric forces, and create a favorable microclimate inside the house. Insulation of the foundation of a house from the outside is most often carried out using polystyrene foam or other insulation materials. Sometimes a combination of technologies is used for more reliable protection. When choosing a material, it is important to take into account all environmental conditions.

Insulating the foundation from the outside allows you to protect the building and create an optimal microclimate inside

Why do you need to insulate the foundation?

In an ordinary private house without thermal insulation, of which there are a great many built, in winter you almost always feel cool in the lower zone of the premises. No matter how well the heating system inside a residential building works, this coolness in the feet remains and causes discomfort for the people living in it. You will say - you just need to insulate the floors, and everything will be fine. But in fact, this is not enough, because there are several reasons why it is worth insulating the foundation:

- as noted above, heat loss through floors causes significant inconvenience to people;

- the amount of heat lost can be quite significant, which increases the cost of heating a private home;

- the foundation and its above-ground part - the base - without insulation are exposed to moisture and freezing, which contributes to the slow destruction of the structure;

- in areas with heaving soils saturated with moisture, the effect of frost heaving may occur. It puts additional stress on the base until it cracks.

If everything is clear with the first item on the list, then the rest require clarification. The fact is that the share of heat losses through cold floors reaches 20% of the total amount of heat lost by the building. Therefore, all attempts to save energy resources by thermally insulating all structures of the house except the base will not achieve their goal.

Imagine that the cold penetrates inside over the entire area, and insulating the floors from the inside does not fundamentally solve the issue; for this it is necessary to insulate the foundation from the outside.

Concrete, from which the vast majority of foundations are made, has very low resistance to heat transfer. During cold weather, the concrete wall freezes, causing condensation to form on its inside, which is absorbed into the thickness of the material. As frost intensifies, this moisture turns into ice crystals and leads to the destruction of the structure. That is why you should not insulate the foundations of private houses from the inside; this will help protect against the cold, but will not protect the structural elements from destruction.

The same freezing moisture with which loess soils are saturated causes them to swell when frozen, exerting shock loads on the base. As a result, cracks may appear in the concrete, which is at least unpleasant. All of the above reasons are equally relevant for all types of houses, including wooden ones, where it is also necessary to insulate the foundation. The exception is structures on screw piles, which will be discussed below.

Conclusion. If you analyze everything said above, the answer to the question of whether it is necessary to insulate the foundation or basement of a house without a basement will become clear. Definitely - yes, it is necessary, and the presence of a basement does not play any role, thermal insulation of the base is always necessary. Modern building codes also state this.

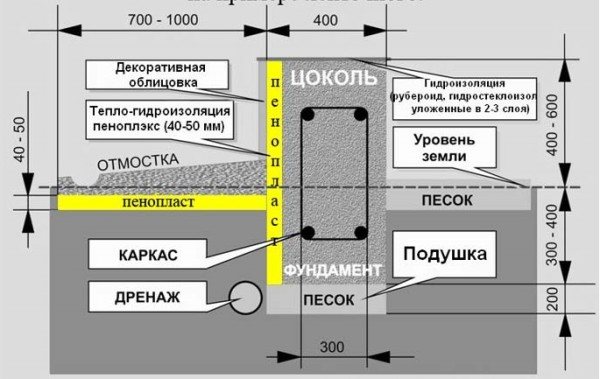

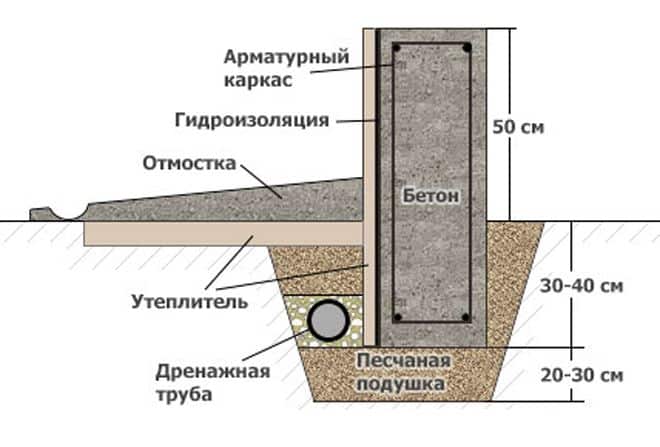

Strip foundation insulation scheme

It is impossible to develop a unified method for insulating the foundations of residential buildings due to differences in operating conditions of buildings, soil characteristics and building structures. In practice, various thermal insulation schemes for strip foundations are used, among which the most popular are:

- Vertical insulation of the foundation is designed to maximally prevent heat loss from the house to the environment and cooling of the home;

- Insulation of the blind area (horizontal insulation) of the strip base counteracts the spread of soil deformations around the house, when the swelling of icy soil pushes the house out of the soil, provoking the destruction of the building structure (Especially relevant for shallow foundations).

Scheme of insulation of the blind area and foundation (instead of polystyrene foam it is better to use extruded polystyrene foam).

We recommend: Technology of insulation of finely buried strip foundations.

Insulation of the foundation with polystyrene foam and penoplex

In reality, there are not so many materials suitable for these purposes. A simple rule applies here: the service life of the heat-insulating layer should be close to the durability of the structure itself, otherwise the procedure will have to be repeated periodically. It is for this reason that it is better not to use such popular and cheap polystyrene foam as insulation for the foundation.

Judge for yourself: the durability of reinforced concrete is at least 100 years, and thermal insulation made of foam plastic will crumble after 20-25 years. Despite the fact that the material will be literally buried in the ground, it is not possible to control its condition. The deterioration of the properties of the insulating layer will become noticeable only in terms of sensations and heating costs. Also, one should not discount the difficulties and cost of re-insulating the foundation, even if it is done with your own hands and again with inexpensive polystyrene foam.

The decision to use foam plastic for covering the base has the right to life and is even often implemented. But this is a manifestation of short-sightedness and an unfounded approach to the matter. In extreme cases, polymer can be used to insulate the part of the foundation protruding above ground level from the outside - the base.

In modern construction, more suitable polymer materials are used for such work:

- penoplex (otherwise known as penoplex);

- extruded polystyrene foam.

There is no fundamental difference between these polymers, especially since they are made on the basis of the same material - polystyrene. There are differences in foaming technology, but for us they are not significant. It is important that penoplex and extruded polystyrene foam have high strength and low thermal conductivity, and therefore are well suited for insulating the foundation of a private house. In addition, they practically do not absorb moisture and are very durable.

For reference. These materials have higher thermal resistance than foam. Therefore, for thermal insulation of the base, you need a layer of penoplex of a smaller thickness (usually 50 mm), which is very convenient. And the strength of expanded polystyrene allows you not to hide it under a brick before filling it with soil in order to protect it from damage.

The advantage of external insulation

Insulating the foundation of a house

With external insulation, you protect concrete from temperature changes. It does not suffer from cold and microcracks do not appear in it. With internal insulation of basement rooms, only the basement is protected from the cold, and the concrete is exposed to the destructive effects of temperature changes.

Protecting a building with internal insulation helps prevent condensation, which often forms in any basement conditions. But do not forget that the outer side of the foundation in this case will freeze, it will be affected by groundwater - which will negatively affect the ability to withstand loads, durability and strength of the foundation - cracks may form.

Insulation of the foundation outside a wooden house

In addition, during prolonged frosts, deformation of the base may occur. Most often, this drawback is almost unnoticeable, but with frequent temperature changes, the base may collapse. After installing the internal thermal insulation, it is covered with plaster or decorative panels.

It is imperative to insulate the house; this affects not only the level of heat loss, but also the service life of the residential building. Insulating the foundation from the outside with your own hands can significantly increase comfort in living quarters and protect the lower part of the house and walls from damage caused by freezing moisture.

The most important thing in this case is to follow the sequence and rules of work, try to reduce possible disadvantages of the material and use only high-quality products.

VIDEO: All about insulating the foundation of a private house. The cheapest and easiest insulation option

Thermal insulation during construction

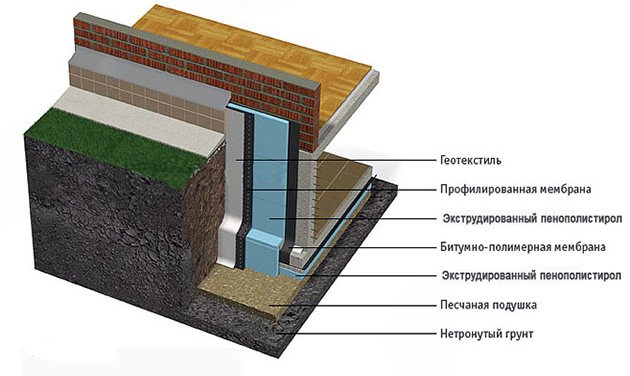

The best way to properly and reliably insulate the entire foundation with penoplex is to do it yourself at the stage of building a house. In this case, special bitumen mastic is most often used to glue polystyrene foam boards to concrete. First, the surface is leveled with cement mortar, then cleaned and covered with the first layer of mastic (primer). Rolled waterproofing is glued onto it, and insulation is placed on top. The whole “pie” is shown in the diagram:

As can be seen in the diagram, an additional protective coating of geotextile can be laid on top of the thermal insulation layer, although often the penoplex is simply covered with soil. Additional protection will not require much expense, but will significantly extend the service life of the insulation. The technology for insulating foundations with expanded polystyrene using bitumen materials is shown in detail in the video:

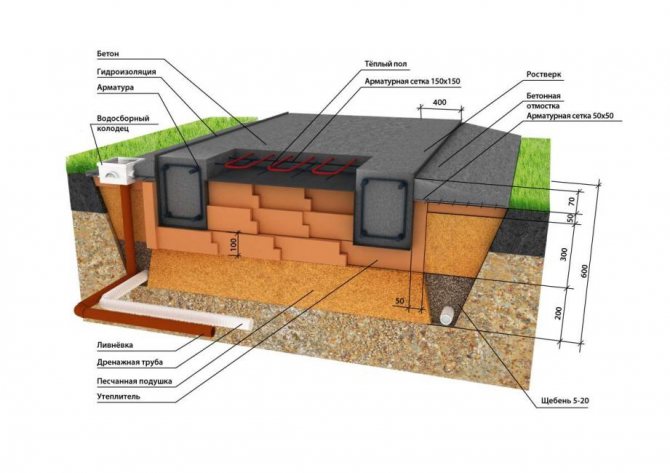

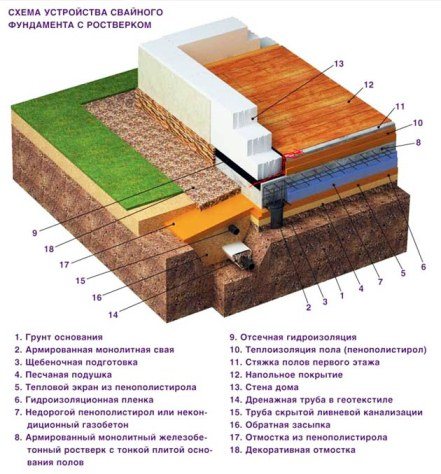

Another interesting way to insulate the base of a house without a basement is used in cases where the foundation is a solid concrete slab. The essence of the method is that polystyrene foam is laid on a sand bed, and a monolithic concrete base is poured on top of it. In this case, it is possible to immediately install a heating circuit for heated floors inside the monolith. This design is called the Swedish stove; a diagram of its structure is shown in the figure:

Here you can see that the Swedish slab refers to shallow foundations, insulated not only from below, but also from the sides. In terms of energy efficiency, this technology is one of the best, but it requires a very scrupulous approach to the work. Failure to comply with technological requirements can lead to cracks in the slab and damage to the underfloor heating system.

The main disadvantage of the Swedish stove is the inability to carry out repairs in case of cracking. But if the insulation of the slab is laid correctly, then such a foundation will easily stand for several decades. At the same time, the use of a solid slab is possible on various subsidence soils. In practice, this insulated structure is often used to build wooden houses instead of a traditional strip foundation.

In what ways can you insulate the foundation?

There are two main ways to insulate foundations. They differ depending on the period during which the work is carried out. One option is to insulate the foundation at the stage of pouring it, and the second is subsequent insulation, carried out after the concrete casting has matured.

The most preferable is to insulate the foundation during the construction phase. This comprehensive approach allows you to get good results. In order to achieve reliable thermal insulation of the foundation, even in the conditions of central Russia with harsh winter periods, the insulation process must be carried out on both sides.

The most logical approach to insulating the foundation during construction is permanent formwork.

Insulation of the foundation with permanent formwork

Permanent formwork is a spatial structure into which concrete mortar is poured. At the stage of hardening of the solution, it acts as a regular wooden formwork, that is, it limits the spreading of the concrete solution. However, unlike wooden formwork, after the concrete has matured, permanent formwork is not removed, but remains on the thickness of the concrete as an insulation layer.

permanent formwork for foundation

Permanent formwork can be made from various materials. Particularly popular is the construction of permanent formwork from polystyrene foam boards. These are plates made of foamed polymer material containing many tiny air bubbles.

At first glance, the disadvantage of such formwork is its high cost. The costs of its purchase and installation are several times higher than the costs of classic wooden formwork. However, such a foundation will not need to be subsequently insulated, so the final costs will be quite comparable.

Insulation of the foundation of an already built house

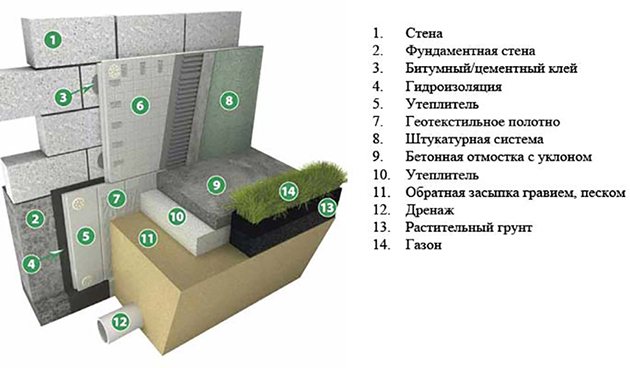

In this case, dismantling work cannot be avoided. You will have to remove the basement cladding and open up the old blind area around the building. If the foundation of the house is a shallow strip foundation, then it makes sense to dig down to its bottom in order to cover the entire surface with thermal insulation material. Another, more popular option is to insulate the base and lay penoplex under the blind area in order to prevent freezing of the underground part of the base. The ideal option is to insulate the entire foundation and soil under the blind area, as shown in the diagram:

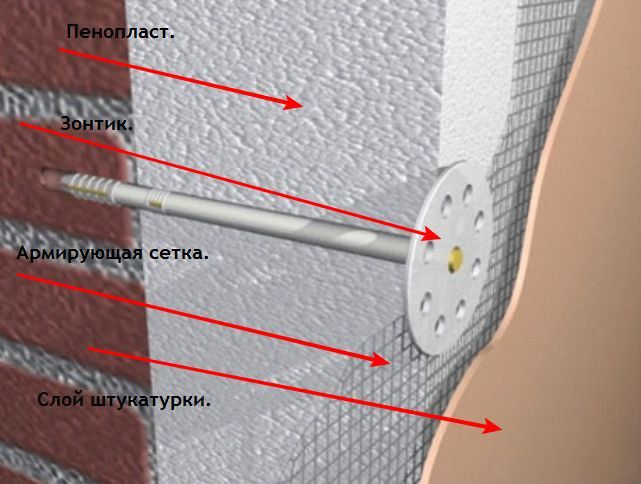

If you decide not to dig to the ground, you should still dig a hole at least 1 m wide along the entire wall to a depth of 200-300 mm, and compact the soil. Next steps are:

- clean the surface of the base, remove all sagging, and seal the depressions and cracks with mortar;

- Using the prepared adhesive mixture, attach the polystyrene boards to the base. Additionally, secure them with special dowels - umbrellas;

- pour a layer of sand at least 100 mm thick into the hole, level and compact;

- lay out slabs of penoplex or expanded polystyrene, laying geotextiles (as in the diagram);

- fill the blind area and line the base.

How the foundation of a built house is insulated in practice is shown in detail in the video:

Instructions for insulating the foundation from the outside with your own hands

The technology for installing thermal insulation on the foundation depends on the type of base structure and the time of year the work is carried out.

To insulate the underground part of the strip foundation, it is necessary to ensure free access to the surface of the building structure. This is easier to do for a building under construction. The insulation is installed immediately after the formwork is removed before backfilling is carried out.

For buildings that are already in use, it is necessary to dig a trench around the perimeter of the house, at least 500 mm wide and deep, to the point where the soil freezes.

The slab base is insulated with heat-insulating boards only during installation of the structure.

Strip foundation

The most common option for insulating vertical walls of a foundation strip from the outside is the use of extruded polystyrene foam boards.

The procedure for performing installation work in this case is as follows:

- dig a trench along the perimeter of the building at least 0.5 meters wide and deep to the bottom of the foundation or the freezing point of the soil;

- Thoroughly clean the wall surface from soil residues and other contaminants and allow time to dry thoroughly;

- apply a layer of bituminous primer 2 times, which can be purchased ready-made or made from a primer;

- using hot bitumen, stick two layers of rolled waterproofing material, roofing felt or other similar material onto the foundation wall;

- begin the installation of polystyrene foam boards by laying the bottom row, ensuring primary fixation using a special assembly adhesive;

- perform final fastening using plastic mounting nails with a wide head, using at least 5 pcs. for one slab.

When laying slabs, it is necessary to maintain an interlocking connection between adjacent insulation elements. The vertical seams of the second row should not coincide with the seams of the first.

After completing the installation of polystyrene foam slabs, it is necessary to backfill the trench with a layer-by-layer tamper. The installation of a blind area can only be done after a year, when the final shrinkage of the soil occurs.

Insulation with polyurethane foam

The thermal insulation properties of this material are not inferior to penoplex, but its application to the surface of a concrete foundation for insulation has its own characteristics. One of them is the need for special equipment, which automatically increases the cost of work. In this case, polyurethane foam is applied manually in layers up to 50 mm thick, which is why the surface is not perfectly flat.

This means that the method is good for the underground part of the base, but on the base the insulation layer will have to be leveled in order to make the cladding. What the base of a wooden house with polyurethane foam insulation looks like can be clearly seen in the photo:

Before applying thermal insulation to the foundation, waterproofing with coating or roll materials is still required. In addition, the width of the trench must be sufficient to carry out the work, that is, at least 0.7 m.

Despite the high efficiency of polyurethane foam as insulation, its application to the foundation is associated with higher financial costs. In addition, there is a question about the durability of the material.

High strength sealed board using PU foam

Polyurethane foam or PPU is a modern building material with many advantages. It is characterized by low thermal conductivity, strength, durability and environmental friendliness. Working with polyurethane foam is easy - no additional fasteners are required for installation, and it is applied to the surface quickly. PPU has high waterproofing properties that prevent moisture from entering, thereby protecting the building.

The main advantage of using polyurethane foam as insulation is the inability to spoil the result - the final coating is always obtained without cracks, irregularities and joints.

How to work with polyurethane foam?

Insulation of the foundation with polyurethane foam occurs by spraying insulation onto the surface using special installations. The resulting foam is firmly connected to the base of the structure, filling all cavities. The result is a high-strength slab, very hard and airtight. Since the material has a closed structure and there is no air gap, condensation cannot appear in such a product.

Thermal insulation of the foundation with polyurethane foam is the most effective method. It is suitable for both new buildings and for thermal protection of an old house. But the cost of such insulation is high and it is impossible to carry out the work yourself, since special equipment is required.

There are many options for waterproofing and insulating the foundation; all you have to do is choose which one is most suitable.

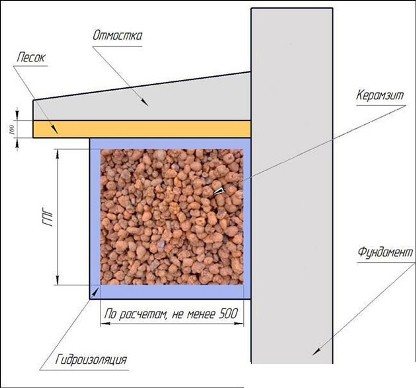

Insulation with expanded clay

The main advantage of expanded clay over other materials is durability. The layer of this insulation will last as long as the concrete foundation itself. In addition, the insulation technology is quite simple: expanded clay is simply poured into the cavity between the base with waterproofing and the ground, and a blind area is placed on top. How to do this correctly is shown in the diagram:

The problem with expanded clay is its thermal conductivity; as a thermal insulation material, it is significantly inferior to any modern polymers in this indicator. To verify this, just look at the table, which shows the thermal conductivity values for different insulation materials:

Note. The lower the thermal conductivity value, the better the thermal insulation properties of the material.

It turns out that to create a layer with the same properties of expanded clay, you will need to pour several times more, which is reflected in the diagram. If you need to use it to insulate the base, you will have to build a retaining wall from facing bricks, which immediately complicates the whole process and leads to higher costs. In addition, a retaining wall also requires its own foundation or it must be erected on an existing one and, again, its underground part must be insulated.

Insulation of the foundation using mineral wool

This method is used extremely rarely, because to carry it out it is necessary to build a frame, provide good protection for the mats from getting wet, and also build a protective wall from some finishing materials.

Execution technology:

- The surface of the foundation is cleaned and dried, defects are eliminated.

- It is used to make a frame for mineral mats made of metal profiles.

- Thermal insulation mats are laid on the frame and secured. The surface of the insulation is protected from external moisture by a vapor-permeable wind and waterproof film.

- Protective brick walls or a ventilated frame are erected.

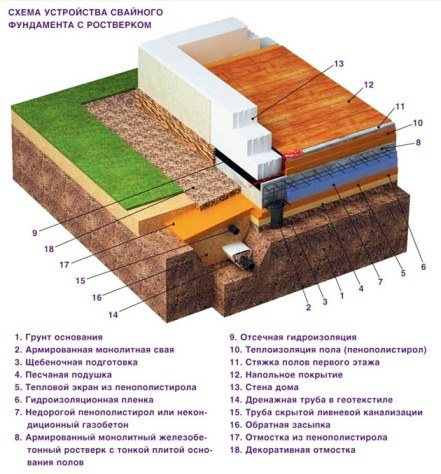

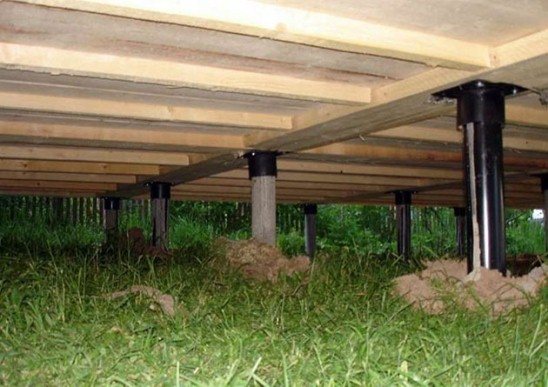

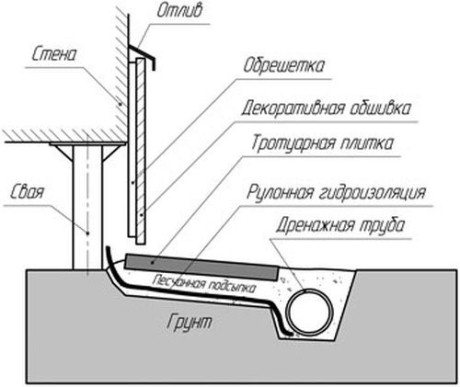

Insulation of a pile-screw foundation

The fundamental difference between this type of foundation is that initially there is a gap between the ground level and the lower part of the building, which can be of different sizes. This is especially noticeable in situations where construction was carried out on an area with uneven terrain or simply on a slope. Accordingly, in most cases, insulation of a pile foundation as such is not carried out; the issue is resolved by thermal insulation of the floors of the first floor.

Under some conditions, thermal protection of the pile foundation is still carried out, for example:

- when the piles are interconnected by a single monolithic slab - a grillage;

- if the homeowner decided to build a false base and close the gap, thus constructing an underground technical floor with communications passing through it.

Since the grillage is the same concrete slab, it should be insulated using any of the methods described in the previous sections. At the stage of constructing such a foundation, insulating material can be laid under the grillage, as suggested in the illustration:

In the second case, the gap between the ground and the house is sewn up with any type of panels or filled with brick or granite, and a blind area is built outside. Now, in order to always have a positive temperature in the underground space, the false base must be insulated from the inside with any of the materials listed earlier.

Spraying polyurethane foam works well here, since you don’t need to dig anything and the appearance doesn’t really matter, which is reflected in the photo:

Gluing the foundation tape

The process of insulating a pre-prepared foundation

The depth of insulation is an important criterion; it is advisable to insulate the entire concrete surface in the ground, but not less than 60 cm (over the entire width of the sheets). Less depth will not give the desired result. The thickness of the sheet when insulated with penoplex should be 50-60 mm.

The work technology allows you to do all the work yourself. After stirring the glue in a low container according to the instructions, apply it to the sheet with a notched trowel in an even layer of 6-10 mm. In this case, point fastening cannot be used; the properties of the heat-insulating adhesive will be lost.

Start from the corner, first fit two empty sheets and make vertical marks, monitoring the connection of the lock along the corner. Then they smear and glue both sheets, glue the side of the foundation halfway, and then from the second corner, in a circle. The sheets usually meet in the middle of the strip foundation. Make sure that when pressed, air should come out; apply force from the center of the sheet to the edges. Gradually putting him in his place.