What is basement siding

Siding is a type of external cladding that forms a dense and airtight fabric with high decorative qualities. Initially, only wooden siding was used, which was narrow oblong panels installed primarily in a horizontal position. Over time, wood was replaced by more practical vinyl and metal sheets, although outwardly the surface realistically imitated wooden parts - timber, logs, ship plating, etc.

Basement siding appeared a little later. According to the manufacturers' plans, the finished walls were to be complemented by the design of the basement section of the foundation. This made it possible to obtain a harmonious exterior decoration of the walls of the house, repeating the traditional structure of a wooden house with a stone base.

To create contrast and visual separation of the walls from the base, this material imitated only stone or brickwork Source housefasad.ru

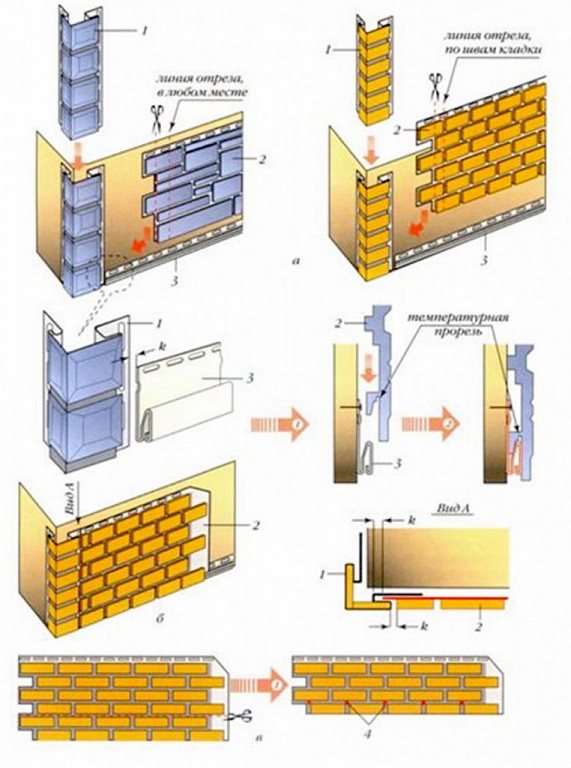

When creating the panels, the disadvantages of wall varieties of material were taken into account. In particular, the shape of the panels has been changed, becoming close to rectangular, with cutouts to form invisible joints.

Invisible joints will make the base of the house more neat Source montazh-saidinga.ru

Changing the panel configuration made it possible to simplify installation and reduce the number of components. In addition, the decorative effect of the basement siding fabric turned out to be much more significant, which expanded the scope of use of the material.

Siding began to be installed on the entire surface of the walls, obtaining a high-quality and attractive exterior finish Source m.2gis.ru

The absence of vertical seams, the highly realistic imitation of the material, and the overall informativeness of the finish were highly appreciated. Currently, the material is often called facade panels, which expands its scope of application. Basement siding, the installation of which is simple and does not take much time, has become more preferable than traditional types of wall cladding.

The quality of the surface is so close to natural stone or brickwork that it is difficult to distinguish them even close up Source obustroeno.com

Articles on the topic

Do-it-yourself homemade vibrating plate with an electric motor for soil compaction: dimensions Video

Tips for making your own concrete of any brand

Rotting floors in the house: tips on how to treat them to prevent them from rotting

Frame house on stilts: types, pros and cons + Step-by-step video

How to cover a columnar foundation of a private house: backfills, siding, natural stone

Reinforcing mesh for concrete floors: tips for choosing

The basement of the house - what is it for? We produce finishing + materials

Types of soil for the foundation of a frame house and their features

Reviews ()

Types of basement siding

Basement siding can be divided into several varieties. Depending on the material used:

- Metal.

- Plastic siding.

Plastic panels, in turn, are divided into the following subtypes:

- Vinyl.

- Polypropylene.

- Polyvinyl chloride.

The most common are vinyl panels. They have a noticeable advantage over metal ones, which are prone to corrosion, do not have elasticity and do not return to their previous shape when mechanical loads occur. The basement is the lower tier of the house, where the possibility of various influences is greatly increased. Dents and scratches on the surface of the canvas greatly spoil the appearance of the skin.

Vinyl panels are elastic, so not too strong impacts do not leave marks on their surface Source imagesait.ru

See also: Catalog of companies that specialize in finishing materials.

How to choose?

In order to obtain high-quality cladding as a result of finishing work, when choosing siding you should pay attention to some points:

- Coloring. High-quality panels should have the same shade on both the outside and inside. Cheap options usually have a lighter back side. But if you decide to buy such a product, then you need to at least ensure that the surface is painted evenly.

- Panel thickness - it should be the same throughout the entire height. To determine this, you need to look at the part from the end.

- The product must comply with the dimensions specified by the manufacturer.

- The perforations should be of the same shape and size, and have smooth contours.

- The absence of delamination and peeling on the surface is also one of the signs of good quality.

Advantages and disadvantages

Basement siding has noticeable advantages:

- Covering the house with basement siding allows you to get a stylish and solid appearance of the house.

- When installing the material, “wet” solutions are not used .

- Work can be carried out on a landscaped area without damaging design elements.

- The cost of basement siding is much lower than natural materials, and the result is almost indistinguishable.

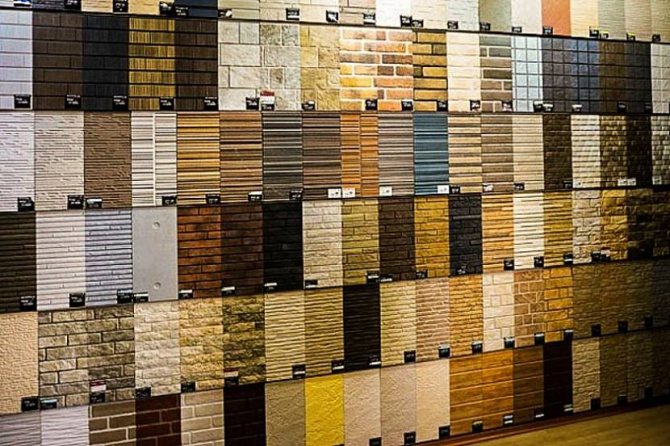

- There is a wide choice of colors and imitation materials.

- The material is accompanied by a full set of components (additional) parts necessary for installation and designing corners, transitions and openings.

- The sheathing fabric can be of any size without vertical seams, which distinguishes basement siding from conventional wall siding.

- It is possible to insulate a wall or base and create a ventilated façade without significant changes in installation technology.

The disadvantages of base siding are:

- The technology for installing house walls with basement siding requires taking into account a high coefficient of thermal expansion. This is especially true for vinyl panels.

- In cold weather, plastic types of panels become fragile and can burst under mechanical stress.

- Some types of panels emit a noticeable odor that gets worse on hot summer days.

- If a fire occurs, the panels melt , although they themselves do not burn.

The shortcomings of the material are considered insignificant and are many times compensated by its high visual appeal, ease of installation and relatively low price.

Siding emits a noticeable odor that intensifies on hot summer days Source stroyka-gid.ru

Composition and components

In addition to the main panels that form the sheathing fabric, the basement siding is equipped with additional elements:

- Start and finish bars.

- Corner strip.

- Inner and outer corner.

- Window trims.

- Low tides.

- Platbands.

- Soffits.

- Cornice strips.

In addition to these elements, the kit should include materials for creating the sheathing. These are wooden strips or metal plasterboard guides that form a flat vertical plane onto which the panels are installed.

All elements perform their own functions - some serve as supporting structures, others form transitions or corners, and are installed on eaves overhangs or openings. Houses finished with basement siding look very attractive due to the absence of empty spaces and the neat design of the junctions.

Basement siding is equipped with additional elements Source p4.rusteplo.com.ru

Main stages of work

Work on finishing the foundation with siding includes steps typical for any facing operations. They contain the preparatory stage, the manufacture of sheathing and the direct installation of siding.

Surface preparation

If the surface is flat, the panels can be installed without mounting rails

The peculiarity and advantage of finishing with siding is the minimum amount of preparatory operations. Under the siding panels it is possible to hide all the unevenness of the surfaces being finished made of stone or brick. In addition, its use eliminates such a labor-intensive operation as plastering. The only thing that draws attention to is the absence of thick sagging and sharp protrusions on the brick base planes.

After inspecting the walls and removing all irregularities, they proceed to arranging the frame (sheathing), made of wooden blocks or metal profiles. If the surface to be treated is perfectly flat, the plinth panels are installed directly on the wall.

Preference is given to metal sheathing as it is stronger and more durable.

Arrangement of sheathing and insulation of the base

When carrying out work, the following points are taken into account:

- The first guide profile is located at a distance of approximately 5-10 cm from the ground. If there is a concrete blind area, this position is reported from it.

- The gap between the wall and the sheathing is selected taking into account the thickness of the insulation, which can be “Penoplex” if its use is included in the project. If thermal insulation is not provided for in the work plan, a gap is left for the thickness of the profile.

- The profile is mounted in the form of intersecting straight lines, located parallel and perpendicular to the wall plane.

The result is a design in the form of squares with a size of approximately 50 by 50 cm. Particular attention is paid to the corners of the base part, which can be made curly if desired.

Installation technology

Finishing the foundation of a house with siding is done in stages. Let's look at the usual procedure:

Purchasing material

The beginning of work consists of purchasing all materials. You will need:

- Panels.

- Additional elements.

- Planks for creating sheathing.

- Direct hangers for plasterboard or suspended ceilings.

- screws with flat heads.

You can choose the most suitable material yourself, but it is better to entrust this procedure to the people who will carry out the installation. They have experience and will buy exactly the elements and materials that are needed.

Specialists will be able to more accurately calculate the number of parts and determine a certain supply Source gk-kratos.ru