The ventilation of the space under the basement floor of a structure is one of the disadvantages of pile foundation technology, which leads to significant heat loss, accumulation of dirt and the risk of rodents in the house.

The problem can be solved by covering the lower part of the side surfaces of the building with facing material.

In this article we will talk about cladding technologies, as well as the materials that are used for these purposes.

Why cover the foundation on stilts?

According to construction standards, the supporting frame on the heads of the supporting elements must be at least 20 cm above the ground surface in order to compensate for the forces of frost heaving of the soil and prevent soil moisture from entering the walls of the structure.

Finishing and closing the pile foundation performs several functions at once:

- reduces heat loss;

- improves the aesthetic appearance of the house;

- prevents the accumulation of debris and dirt under the basement floor;

- protects against fungus, mold, rodents and insects.

The main requirements for facing material are durability, attractive appearance, and affordable price.

general information

They are screwed into the ground manually or using special equipment, always below the freezing level.

At the end of the pile products there is either a combined thread for deepening into the soil, or special blades.

Reference! Screw piles equipped with blades are considered a more reliable solution, since during drilling they better compact the ground, giving the foundation even greater stability.

A pile-screw foundation is suitable for all types of soil, excluding rocky ones, it can easily withstand both compressive longitudinal and transverse loads and is not afraid of soil heaving.

One of the most important stages in the installation of a screw foundation is the strapping, which is most often done with boards, timber, channels and some other materials, as well as finishing the foundation on screw piles and closing. Particular attention should be paid to this if you want to make a basement in your house.

You can also familiarize yourself with the pros and cons of a foundation on screw piles, or with its calculation.

How to sheathe the bottom of a house?

Two technologies for external cladding of the base are practiced:

- installation of the screen on a suspended sheathing welded or nailed to the piles;

- laying a shallow strip of brick or stone around the perimeter of the house.

The design features of the hinged screen make the technology effective in the case of metal or wooden piles.

The advantages of this technology are low costs, fast construction speed and sufficient ventilation of the underground space.

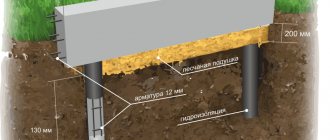

Shallow foundations are often built around reinforced concrete supports. This is a rather labor-intensive method, since you first need to dig a trench, lay a drainage pad, and build a ribbon of brick or stone on top with vents for ventilation. At the same time, this fundamental cladding is distinguished by its resistance to external factors and long service life.

To reduce heat loss in the house, experts advise insulating the suspended base. To do this, mineral wool or eco-wool is placed into the frame cells on the inside of the skin. In cold regions, a layer of insulating material is also placed on top of the sheathing under the outer sheathing.

Operating rules for foundation ventilation

In the test above, we figured out how to make ventilation in the foundation. However, even the most effective ventilation will not give the expected result if the system is not used correctly.

Therefore, all owners of houses on pile or strip foundations must adhere to the following rules for operating foundation ventilation:

- First, close the vents during the cold season. Otherwise, the water vapor contained in the air will settle on the warm basement floor, saturating it with excess moisture. In addition, cold air cools the basement space of the house, lowering the temperature in living areas.

- Secondly, open the vents in the warm season, after the snow has completely melted and the spring frost season has ended.

As you can see: the operating rules are very simple, but this does not negate the effectiveness of the above recommendations. Operating in this mode, the foundation ventilation system will ensure a very long service life for the foundation of the house.

Technologies

There are 2 main technologies for cladding the bottom of a house. The materials used may vary.

Frame system

The frame system for covering the plinth is as follows:

- vertical and horizontal guides are attached to the piles;

- a wooden or metal sheathing is mounted on top;

- Acrylic or vinyl siding is attached to the sheathing with a gap of at least 1 mm, compensating for temperature deformation.

The disadvantage of the technology is the excessive consumption of material as a result of cutting and fitting , since non-standard sheet sizes may differ from the height of the base.

Leaf system

The technology involves fastening cement-bonded and asbestos-cement boards to wooden or metal sheathing.

Porcelain tiles, soft tiles or other budget sheet material are laid over the entire surface of the cladding.

Since the base in this case will be solid, it is necessary to equip ventilation openings, which are covered with grilles during facade work.

Advantages of the technology:

- warm and durable foundation cladding;

- a wide variety of finishing options.

The disadvantage is the labor intensity of the work and the high consumption of building materials.

The feasibility of closing vents

When deciding whether it is necessary to close the foundation ventilation for the winter, the owner of the building must understand whether the influence of negative factors, which an effectively working vent system is designed to eliminate, ceases during the cold season. It is obvious that the soil continues to release moisture and radon even in the cold season, although in somewhat smaller quantities. Therefore, protecting wooden or concrete structures from moisture and increased concentrations of harmful substances in underground air is still necessary.

In addition, an important task of the vents at the base of the house is to maintain the temperature at the level prescribed by the Code of Practice - that is, at most, 2 degrees higher than outside. This also cannot be achieved without constant ventilation, which is carried out using vents.

Which material is better to choose?

When deciding how and with what to cover a pile foundation, you need to rely on aesthetic considerations and financial capabilities. Finishing a suspended plinth does not require significant material costs and is characterized by quick installation, so facade work can be done with your own hands.

Basement siding remains the most affordable and easy-to-implement way to close an underground space. From the point of view of compatibility with external wall decoration, the material can be replaced with corrugated board or composite tiles. If the owner does not have experience in construction work, then it is better to immediately turn to professionals who can simultaneously build a blind area for the house.

Only a specialist can lay out the laying of a shallow brick strip correctly. As a rule, developers undertake to deliver building materials, and in this case, in addition to stone, it is also necessary to supply sand, crushed stone and cement.

Insulation

Insulating the base of a pile-screw foundation is a stage that should not be neglected, since when installing such a foundation, a fairly large empty space remains under the house up to the soil level. The disadvantage of this is the cold floor, which is very uncomfortable to walk on.

This can be avoided by creating a heat-insulating layer between the floor covering of the interior and the foundation, for example, by insulating the pile-screw foundation of a wooden house using one of the modern industrial insulation materials.

Reference! Some of the most common materials are mineral wool, polystyrene foam or penoplex, but they all require additional waterproofing due to increased sensitivity to moisture. Waterproof polystyrene foam and foam glass do not have this disadvantage.

Do-it-yourself insulation of a screw foundation is carried out according to the following algorithm:

- Starting to solve the problem of how to insulate a pile-screw foundation, all irregularities on the plinth wall are eliminated and treated with a primer for more reliable attachment of the insulation sheets.

- Insulation sheets are glued from the inside using an adhesive composition or a special adhesive foam. In the latter case, the insulation is temporarily attached with special umbrellas to avoid damage to the sheet when the foam swells.

- The joints of the sheets are worked out especially well to prevent cold from entering the house.

- From the inside, a little soil or expanded clay is added to the wall of the insulated base to prevent blowing.

Important! How to insulate a foundation on screw piles efficiently? The insulation is usually glued in two layers and a metal mesh is installed on top of it to protect against rodents.

Blind area

The blind area of the screw foundation helps prevent the penetration of rain moisture from the soil and the seepage of shallow groundwater into the underground. For this reason, the floors in the house always remain dry and the microclimate is comfortable. It protects the foundation from plants growing through it and gives it a more well-groomed appearance.

When creating a blind area, the following must be considered:

- It should have the widest possible width, ideally 60-100 cm (for heaving soils).

- The blind area includes a large number of layers, which are laid at an angle to the foundation (minimum 1.50).

- The bulk layers of the blind area usually include dense clay (15-20 cm thick), crushed stone and sand (each layer takes up approximately 5 cm). When the soil freezes deeply, layers of foam plastic are laid underneath.

- Where the blind area is adjacent to the house, it is necessary to make an additional insulating seam, for which two layers of bitumen or roofing felt are used.

- The top layer of the blind area must have waterproof properties. Suitable materials include asphalt, reinforced concrete, paving slabs, all types of stone or simply cement pouring. It would not hurt to install trays on the blind area as elements of storm drainage.

>Useful video

Visually check out the option of finishing the foundation base on screw piles, as well as finishing with facing bricks in the video below:

Application of bricks

The process of creating brickwork requires the presence of serious support; it will ensure the structure's reliability and durability.

Creating a foundation for masonry

There are two ways to do this:

- The first method resembles the process of creating piles with a grillage. The peculiarity is that the tape is poured into a small depression level with the ground. A cohesive structure is created that will serve as support for the masonry.

- The second method is used when the piles are made of pipes. Corners are welded to the base at a short distance from the ground; for reliability, the place under them is compacted and a support is created. Rolled metal is welded on top, the thickness of which depends on the load.

Arranging a shallow foundation is considered a more reliable option, but if groundwater is close to the groundwater, this option is impossible, and in such a situation the brick is placed on a metal support

Brick laying technologies

- The base is covered with waterproofing. Roofing material is suitable for this.

- The first row is built according to the level to eliminate differences. The element is fixed to the required amount of solution.

- Adjacent parts are fastened at the ends. For ventilation, the edges are not coated at certain intervals; the resulting gaps will not be noticeable.

- The second strip is laid offset. The joints of adjacent lines must not coincide.

- A connection is being made. To do this, the wire is placed between the rows and in some places fixed to the piles.

- At the last stage, when the masonry is completed, the seams are formed.

When finishing the pile foundation from the outside, take into account that different options are suitable for this process. The main thing is to ensure reliable fixation of the selected products.