The basement is a structural part of the building, the task of which is to prevent groundwater from entering the first floors of the building.

The base consists of rough building elements: concrete, ordinary red brick or large foundation blocks. They firmly hold thistles, but often spoil the appearance of the building.

Without additional finishing, these building elements do not retain heat well inside the building and are destroyed by the negative effects of precipitation. To level out all the shortcomings, use plinth bricks.

On swampy soils, houses are built on screw and columnar foundations, where an enclosing structure for the lower zone of the building is erected from basement bricks.

Features of basement elements in wooden buildings

The basement element in a wooden house is represented by the ground part of the foundation. It provides thermal insulation and moisture protection, protects against temperature changes, and participates in creating a normal microclimate in residential premises.

The plinth performs the following functions:

- used as an additional decorative element of the building;

- hides the insulation if it was installed outside;

- protects against negative weather conditions;

- provides protection of the foundation from destruction.

Wood is susceptible to biological factors, such as rotting processes, mold or mildew. Therefore, to protect the load-bearing structures, a monolithic or strip concrete foundation is installed. The base element is made of a similar material. The latter needs thermal insulation and insulation, additional decorative finishing.

Dimensions

There are two size standards used in our country:

- Russian - brick comes in three types: single 250x120x65 mm; one and a half 250x120x88 mm; double 250x120x138 mm. The length and width do not change, the only difference is the thickness.

- European – rarely used: DF-240x115x52 mm; 2 DF-240x115x113 mm; NF-240x115x71 mm; RF-240x115x61 mm; WDF-210x100x65 mm; WF-210x100x50.

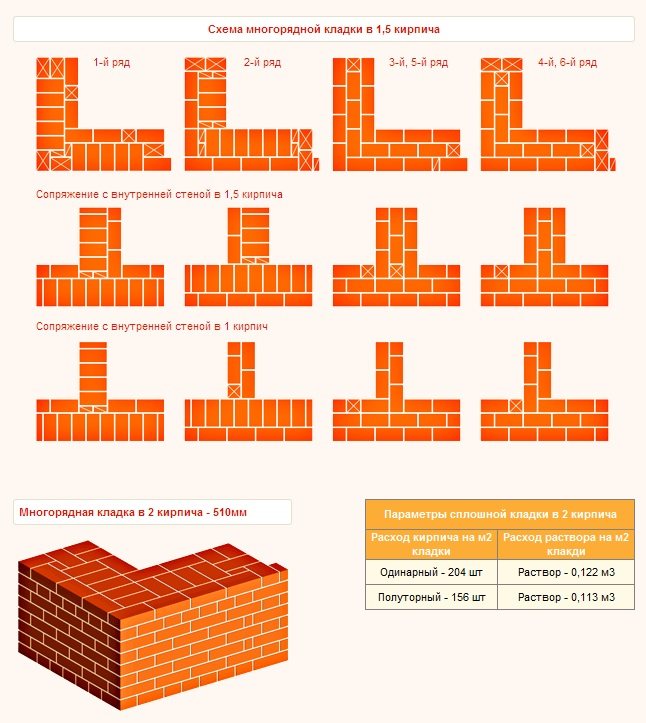

The laying of basement bricks is no different from the façade

What to cover: materials for cladding with photos

There is a wide choice of materials for finishing the base of a wooden house foundation. You can choose any of them depending on the color and texture of the rest of the surface and the façade cladding.

Natural stone contrasts favorably with wooden facades . It provides additional protection from negative external factors, penetration of cold and moisture. For finishing you can choose granite, sandstone, slate, flagstone.

The coating is protected from temperature changes and high humidity. At the same time, the cost of the material is higher than other coatings; installation skills are required to cover the base element.

Artificial stone has the advantages of natural material . An additional advantage is the affordable cost. The coating is lightweight and thin. It is suitable when there should not be large differences between the facade and the basement element.

Artificial stone also looks good against the background of wood trim. It is protected from the effects of biological factors and reduces the likelihood of mold and mildew appearing on the surface of the wood.

Wood can act not only as a facade , but also serve as a plinth element. In this case, durable rocks with minimal moisture permeability are used. It could be oak or larch.

There are two design options - a contrasting base in a dark shade with a horizontal arrangement of wooden panels, one material for the base element and the facade.

Siding can serve as finishing for the base . In this case, it imitates a wooden or stone finish. Individual panels are equipped with a special fastening to facilitate the installation process. You can choose contrasting elements of a dark shade or make a minimal difference in color and texture with the main material.

The base thermal panel is in harmony with wooden facades . In this case, there is no need to install an additional layer of thermal insulation. Expanded polystyrene is used as a base, which is one of the effective materials for preserving heat.

The coating is characterized by the absence of cold bridges, good ventilation, and high strength. The only drawback of thermal panels is the relatively high cost.

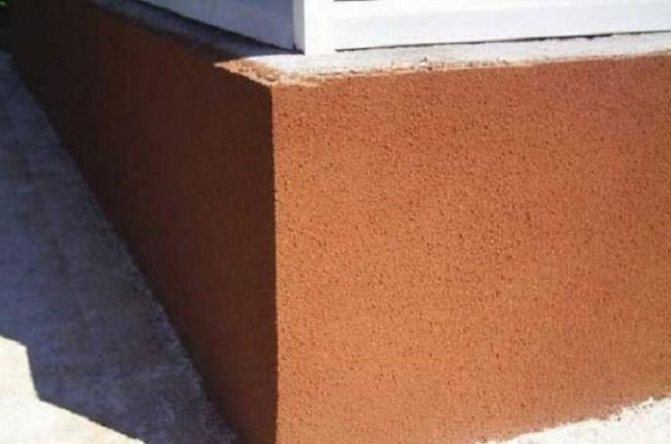

Plaster is becoming one of the simplest ways to finish a concrete base element. For finishing you need to choose a composition for exterior finishing. It provides protection from high humidity and does not require professional assistance.

When selecting plaster for a wooden facade, it is necessary to carefully select the appropriate shade so as not to introduce disharmony into the overall stylistic solution.

The corrugated sheet looks good against the background of a wooden facade . The optimal solution is to choose a similar profiled sheet for the roof and finishing of the base element. The material is resistant to physical and climatic influences. In this case, during installation it is necessary to organize a frame of metal crossbars. During work, welding is used.

Porcelain tiles are distinguished by their durable coating and reliable connection . The individual elements are installed end-to-end without seams. This forms a single coating that is protected from moisture and water penetration. Thanks to the variety of shades and textures, the material is combined with wooden buildings and provides additional protection from biological factors.

Clinker tiles are resistant to mechanical stress , alkalis and acids. When installed properly, the resulting surface resists the penetration of water and moisture.

Some of the best materials for finishing the base of a wooden house are artificial or natural stone, siding, and thermal panels. They provide a good combination with a wooden surface and additionally protect the building from cold penetration and heat loss.

It is important to be careful when choosing wood finishes, plaster, clinker tiles and porcelain tiles. The materials are high cost. At the same time, they need to be selected so that they contrast with the wooden facade, but are combined with other buildings on the site.

In addition to its composition, plinth bricks vary in structure and evenness of edges.

By structure:

- Full-bodied - has no fullness inside. Due to this, it is more durable and reliable. Solid brick is heavier than hollow brick;

- Hollow - has cavities inside. Due to this, strength and reliability are slightly reduced and weight is significantly reduced.

For plinth cladding, differences in strength are not important. It is better and cheaper to use hollow bricks.

By the evenness of the edges:

- Ordinary - with uneven edges. It is used for cladding the base followed by plastering of the masonry;

- Facing - with smooth edges. Used for lining the plinth for jointing.

Necessary tools for work

To finish the base, a standard set of tools is required. You need to prepare everything you need in advance to complete the work without delays or interruptions.

To finish the basement in a wooden house you will need the following:

- hammer drill or drill;

- screwdriver for securing frame elements;

- building level for precise alignment of the frame and finishing material;

- metal scissors (used when arranging the frame);

- nail puller;

- hammer;

- pliers.

Special tools are not required to finish the base of a wooden house. The above equipment will be needed at each stage of installation work.

Finishing the plinth with porcelain stoneware

Porcelain tiles have unique strength, resistance to moisture, mechanical stress and any weather conditions. She is not afraid of either water or fire. Porcelain stoneware is a timeless finishing material.

Porcelain tiles are available in different versions; they can be polished, matte, glazed, embossed, or with a special wax coating. This would be an ideal option for finishing the base of a house, if not for the only drawback - the high cost, which is actually not surprising for a material with similar characteristics.

Description of technology

There are some nuances in finishing the base of a wooden house. This is due to the vulnerability of the material compared to other coatings.

It is important to consider the following points:

It is necessary to wait for complete shrinkage. In most cases, the raw materials have high humidity. After the construction of the house, the structure undergoes serious shrinkage.- At the next stage, the future lining areas are treated with a special antiseptic composition.

This is necessary to protect against biological factors - the development of microorganisms, mold and mildew. An antipyrine compound is also applied for additional fire safety. - Waterproofing is carried out with bitumen mortar, one or two layers of roofing felt. Install a membrane to protect against excess moisture.

- Install insulation. Foam plastic, mineral wool or extruded polyurethane foam are used as such material.

- At the final stage, the base is installed. You can choose wood, natural or artificial stone, siding or special panels with decorative texture.

Protective compounds are easier to apply using special sprayers. This increases the quality of the coating and the speed of work. You also need to wear a protective suit and use personal protective equipment.

Plastering and painting

Finishing with decorative plaster is the easiest way to give the facade of a wooden house a beautiful and neat look. This is a budget finishing option that does not require large financial investments. Plasters and paints are quite affordable, and there are as many design options for the plinth and blind area as you like.

The base can be painted with facade paints, which form a durable coating and protect the base from destruction and atmospheric influences.

A good option is to plaster the facade with finishing plaster; there are many color options, so choosing a shade to match the color of the facade will not be difficult.

You can go even further and use a design technique in the design of the plinth: creating the effect of cobblestone finishing. The cobblestone is an ordinary concrete solution from which “stones” are molded by hand. Then the “stone blocks” are applied in random order to the plastered surface and painted. The resulting finish looks like the photo on the left.

An excellent way to give the facade an individual flavor is to apply mosaic plaster to the base, which, after drying, creates a mosaic effect. The coating not only has excellent decorative characteristics, but also serves to protect the base from adverse factors.

Another good example of the design of a plinth is covering the base with bark beetle plaster. After applying the plaster, the surface resembles the structure of wood eaten away by a bark beetle, which looks very original. Mosaic plaster contains a resin that makes the coating waterproof.

Average prices in the Russian Federation for materials

The cost of decorative finishing for the plinth depends on the choice of materials:

| A natural stone | 1800 rub. per sq. m. |

| Fake diamond | 1200 rub. per sq. m. |

| Tree | 1000 rub. per sq. m. |

| Clinker tiles | 1300 rub. per sq. m. |

| Porcelain tiles | 1500 rub. per sq. m. |

| Plaster | 1000 rub. per sq. m. |

| Siding | 800 rub. per sq. m. |

| Thermal panels | 950 rub. per sq. m. |

| Profiled sheet | 800 rub. per sq. m. |

The choice depends on the quality of the coating, the required protective properties, and the size of the budget for decoration.

Sheathing with fiber cement panels

Facade slabs are made using a special technology based on cement with the addition of plasticizers and polymers.

Fiber cement panels have shown excellent performance characteristics:

- are lightweight, which simplifies installation;

- resistant to corrosion, ultraviolet radiation and temperature changes;

- do not absorb moisture;

- have good sound and heat insulation properties;

- fireproof.

Fiber cement panels are available in a wide range of colors and different textures. The slabs can be attached directly to the base or to the sheathing, completely hiding all the unevenness of the walls.

Siding finishing

Covering the base with plastic and metal siding is one of the most affordable finishing options. Despite their inexpensive cost, PVC panels have very decent characteristics:

- are moisture resistant;

- tolerate low temperatures well;

- do not burn;

- their service life is about fifty years;

- plastic panels are light in weight and do not create a load on the foundation.

The siding is installed on a metal sheathing, which allows you to insulate the house. Penoplex or expanded polystyrene slabs are usually laid between the aluminum guides.

PVC panels can be used to cover the base of a log house built from any lumber. In addition, siding can be used to finish the basement of a house on screw piles.

The design of siding is very diverse; a log and timber house can be faced with panels to resemble stone, brick, wood, or tile. Manufacturers offer a wide palette of colors, so it’s easy to choose a material to suit any design solution.

When choosing a material, you need to take into account that panels intended for interior decoration, as well as facade siding, cannot be used for cladding the base. Basement siding differs from conventional types in its manufacturing technology, as well as the presence of special additives in its composition.

Finishing with flat slate and corrugated sheets

Flat slate is made from a mixture of asbestos, Portland cement and water.

Two types of slate are made: pressed and unpressed. To finish the base, it is better to use the first one, which is more durable. Flat slate has many advantages: it is not afraid of corrosion, temperature changes, sunlight, provides good sound and heat insulation, is durable, and has a low cost.

Today, quite often, metal profiles are used as cladding for the bottom of a house. It must be said that the professional sheet is not the best, although it is a fairly inexpensive option.

The base, finished with a metal sheet, firstly, looks very simple. Secondly, it is not recommended to cover the lower part of houses made of rounded logs, laminated veneer lumber or profiled timber with metal profiles. Due to high humidity, this material is subject to corrosion, which can lead to wood rotting.

How to prepare the surface?

At the preparatory stage of work, the construction site itself is prepared. Equipment for mixing concrete is set up in advance and a sufficient availability of water is checked. Install additional lighting for work in the evening. Before starting work, prepare the surface for cladding. Dirt and dust are removed from the surface of the foundation, which makes it possible to examine defects in the structure and cracks in detail, and rub them with special mixtures. Next, the following algorithm is performed:

- Waterproofing works using two-layer mastic.

- Primer with hydrophobic material in 1 layer.

- Laying a layer of insulation.

- Arranging a ventilation gap. For additional ventilation, special holes are made along the lower masonry row of the house walls.

- Construction of blind areas for further work.