Today there is an alternative to a conventional foundation - you can make a foundation from reinforced concrete sleepers. For building a house, it is better to use already used sleepers, rather than new ones, because the external impregnation contains substances harmful to humans, which, if evaporated, can cause health problems. Waste material that has already been exposed to air does not contain harmful components. Basically, reinforced concrete sleepers are used to make foundations for outbuildings - garages, sheds, greenhouses. Reinforced concrete foundations have advantages over wooden ones:

- longer service life - reinforced concrete options will last at least 100 years;

- sleepers are much cheaper than other building materials;

- any building erected on reinforced concrete structures will be much stronger and more durable.

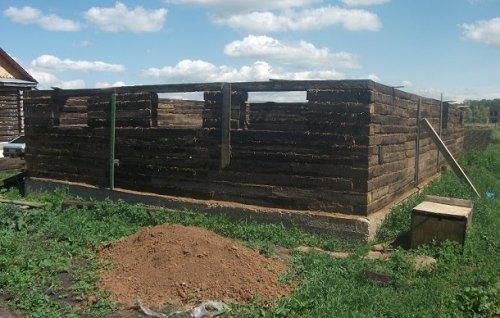

You can build a strip foundation from reinforced concrete sleepers; usually, they are used to build a foundation for a greenhouse, garage or bathhouse.

The only drawback of such structures is their heavy weight (about 200 kg), but if you use special equipment, you will not have any difficulties moving and installing structural elements in the trench.

Base made of reinforced concrete sleepers

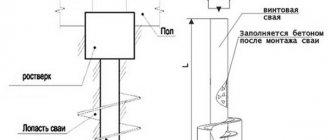

As in the first case, two types of foundations can be made from this material - pile and strip. The use of reinforced concrete sleepers when constructing a pile foundation with a grillage will allow you to build a cottage or house from any material with a high specific gravity.

Characteristics and dimensions of reinforced concrete sleepers

Important! For construction, it is better to purchase used piles, since the impregnation used to protect concrete from adverse environmental conditions can negatively affect health. It is worth noting that in used sleepers, over time, the harmful components of the impregnation evaporate, and used material costs much less than new.

The advantage of concrete bases

Compared to a foundation made of wooden sleepers, a foundation made of reinforced concrete products has undeniable advantages:

Foundation structures made of reinforced concrete products

- the service life of such foundations is 100 years;

- the cost of sleepers is much less than other materials for arranging foundations;

- waste material can be obtained free of charge, since when repairing railway tracks they are usually written off;

- The design of this material is strong and reliable.

Reinforced concrete sleepers have one drawback - during construction you will have to use heavy equipment, since one sleeper weighs 200 kg. You won't be able to put it in a trench yourself.

Options for constructing various types of concrete foundations

Disadvantages of foundations on sleepers

Now let's talk about the bad. Why you shouldn’t use such a foundation for residential buildings. I impregnate the sleepers with a special poison - creosote, so that various bugs do not eat them. Creosote is considered a potential carcinogen, a substance that can cause the formation of malignant tumors in humans and animals. And in hot weather there will be a specific smell.

Therefore, I don’t understand people who, in addition to the foundation, build the walls of their house from sleepers.

We evaluate negative and positive qualities

A competent owner, before building a bathhouse from sleepers, will try to obtain as much information as possible from available sources. First of all, find out how seriously a bathhouse made of sleepers affects your health, whether it is harmful or not.

The positive aspects of the option of building a bathhouse from sleepers with your own hands include the following:

- Extremely low price for the material; used sleepers can be purchased for 12-15% of the cost of a new product. On average, the price for model A-1, with a cross-section of 25x18 cm, ranges from $2 per piece;

- Long service life, a ten-year sleeper in a bathhouse box will easily last another 15-20 years. They practically do not rot, are not affected by microorganisms and pathogenic microflora, insects, and rodents.

The durability of the bathhouse box largely depends on how to make a bathhouse from sleepers, what kind of foundation and finishing design is planned to be used when arranging the room.

The second condition is the quality of the material. Therefore, the design of a bathhouse made of sleepers, the method of constructing any sleeper buildings, is chosen based on the actual conditions on the ground and the quality of the purchased material.

Advice! You should not completely trust reviews of bathhouses made from sleepers published by the owners of buildings. Only a few percent of respondents give an objective assessment of the emerging problems.

Negatives of building a sleeper bath from ten-year-old sleepers:

- Possibility of poisoning by vapors of creosote, phenol. Under the influence of heat, flying sleeper structures intensively release carcinogenic substances that provoke the development of oncology;

- High flammability of the sleeper box of the bathhouse. It is no longer possible to saturate the sleeper with fire retardants; the surface layer of flammable creosote interferes. And sleeper baths burn several times more often.

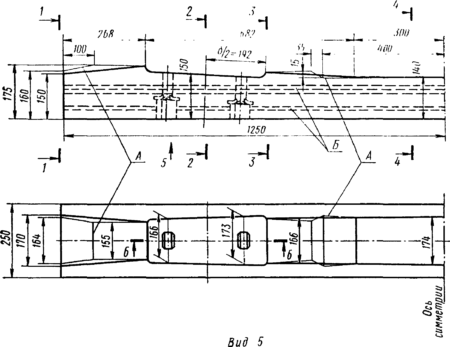

Technical parameters of reinforced concrete sleepers

Monolithic beam for laying the foundation - reinforced concrete pillars, manufactured according to the requirements of GOST 28737-90.

The finished product is characterized by a T-shaped, trapezoidal cross-section. The material can be used as a base for load-bearing walls of a building if it is planned to construct industrial buildings from concrete or brick blocks.

Reinforcement of products is carried out with steel type III, A IV, class A.

Schematic designation of pile parameters

The strength of the material is ensured by an internal steel frame, which redistributes the load, increasing overall durability.

The raw materials are resistant to frost and retain their original characteristics for a long time.

The dimensions of the sleepers and cross-section are related to their purpose and markings. Types of raw materials:

- trapezoidal 1BF, upper base - 20 cm;

- T-section of pile 2BF, 30 cm wide;

- 3 BF in shape - something between the two options, but 40 cm in size;

- the largest edge is 32 cm, formed at 5BF beams.

The standard version is 2.7 m long, 30 cm wide, 23 cm high. The concrete must be of a grade of at least B40, frost resistance F200 or more.

Types and characteristics of beams

A monolithic beam for the construction of a foundation is a reinforced concrete product manufactured in a factory in accordance with the provisions of GOST 28737-90. It has a T-shaped or trapezoidal cross-section and is used as a support for load-bearing walls in the construction of mainly industrial facilities made of brick or concrete blocks. Installing beams during the construction of low-rise buildings with your own hands is complicated due to their significant weight and requires the use of special equipment or devices.

Reinforced concrete sleepers are used as beams

The technological process of manufacturing reinforced concrete structures takes place on production lines, where the overall dimensions of manufactured products are strictly regulated. For reinforcement, steel of classes A III and A IV is used. The metal frame ensures the strength of the beams, resistance to mechanical damage and the ability to withstand significant loads. Other advantages of such elements include:

- frost resistance;

- long service life;

- preservation of technical characteristics during operation.

The overall dimensions and cross-sectional shape of reinforced concrete products are determined by their purpose and marking. The following types are distinguished:

- 1BF with a trapezoidal cross-section and an upper base of 20 cm;

- 2BF with a T-section and a width of 30 cm;

- 3BF is the same in shape as the configuration of the previous beams, but its width is 40 cm;

- 5BF with a top edge width of 32 cm.

Installation of a foundation made of beams

Reinforced concrete elements marked 4BF and 6BF are classified as large-sized products. Monolithic products are also classified according to the quality of the steel rods that are used for reinforcement.

Based on this criterion, beams are divided into the following types of products:

- With a relaxed frame, which is made of wire that is not subject to heating or elongation. These include reinforced concrete structures with a length of no more than 6 m.

- With a tense frame. Its installation is carried out using annealed or stretched wire. This category includes products of any length.

The tension of the reinforcement increases the strength of structural elements to bending loads.

Sleeper base for home: harmful or not

Foundations constructed using reinforced concrete elements are ideal for technical buildings. It will be durable and stable.

The use of this material to create a foundation for summer kitchens, baths, and living quarters is highly not recommended. Its availability may be attractive, but it has a fairly strong unpleasant odor and cannot boast of high environmental friendliness. Simply put, its use is harmful to the body during the construction of a house.

BUT. The above applies only to elements of the construction of railway tracks that have been manufactured recently and are impregnated with creosote. Old ones (that have served their time), which do not emit a specific smell, are quite suitable for building the foundation of a house, but it is still better not to do this.

Creosote is a poisonous impregnation agent.

Another reason for refusing this material is the high cost of delivery, almost equal to the transportation of reinforced concrete blocks.

It is possible to use wooden sleepers to build a foundation, but such a structure will have insufficient strength and there is no point in taking such a step when building a house.

In what cases is it advisable to build a foundation from sleepers?

Before deciding to use this material in the construction of the foundation, you need to take into account some nuances that can play an important role in the construction of the foundation:

- the opportunity to inexpensively buy sleepers that have already served their useful life at an inexpensive price;

- transportation and delivery of material to the site, if the sleepers are located far from the construction site, then transportation and transport costs can reduce your savings to zero;

- the structure installed on a foundation made of wooden sleepers must be small and light;

An example of installing a greenhouse on a sleeper foundation - the foundation will be arranged independently, without the involvement of third-party labor.

From sleepers you can create classic types of foundation with your own hands, and it will be reliable and durable, provided that construction technologies are followed. Also, each developer has the choice to build a foundation from reinforced concrete sleepers or choose wooden ones, it all depends on the construction budget.

The process of installing a foundation made of reinforced concrete sleepers

Some are wary of using wooden sleepers because of the creosote impregnation that makes the wood durable and rot-resistant. This impregnation has an unpleasant odor and is a toxic substance. But there is no need to be afraid of this, since over many years exposure to air in a railway structure is expensive, weather conditions do their job, and the smell disappears, as do the toxic properties of creosote. A significant advantage is that sleepers for the foundation can be obtained completely free of charge; when repairing railway tracks, they can be obtained as waste material.

This is what used reinforced concrete sleepers look like

In addition, you can build a foundation with your own hands, since the material does not require special processing and is quite easy to use. It is enough to have one assistant who will drag the sleepers with you from place to place and help in laying the material in the foundation trench.

Foundation examples

Let me give you a few living examples.

Foundation for a garage

Foundation for a temporary structure

Foundation for a house

When does a greenhouse need a foundation?

Foundation for a greenhouse

One of the best options for a greenhouse is to use sleepers. You can do it yourself.

First, you need to decide whether this building needs a foundation, and only then choose the foundation option and how to solve the question of how to make it yourself. A foundation for a greenhouse is needed if it:

- it is closely adjacent to the house and serves all year round;

- located in a place that is not guarded;

- deepened into the ground below the soil freezing line;

- built from wooden materials;

- built on unstable ground;

- built on a site with a slope;

- has dimensions that exceed standard ones.

What to pay attention to when bookmarking

The choice of sleepers for the foundation must be very careful. If they are very worn out, then the foundation will be of very low quality, and after a certain period of time it will have to be repaired.

And this will be quite expensive. And everything that was saved earlier will be reduced to zero. Therefore, if a house is not being built on its own, then it is necessary to strictly control the work of contractors.

You can also use reinforced concrete. They will last much longer than wooden ones. But in no case should you discount wooden ones. Especially if the foundation is built with your own hands.

Areas of application of sleepers in the construction of foundations

Before making a decision to use such material for the construction of the foundation, the developer must take into account certain features that can play an important role in the construction of the foundation:

- purchasing sleepers that have reached the end of their intended service life at an affordable cost;

- possibility of transporting purchased material to the construction site. The fact is that transportation costs and payment for loading and unloading operations can “eat up” all your savings;

- the structure proposed for construction must be light in weight;

- performing all the work on building a foundation from sleepers with your own hands, without involving a construction team.

Using sleepers, you can build a classic version of the foundation, characterized by reliability and a long operational period, but the technological conditions of the work must be observed.

In addition, the developer has a choice - to use reinforced concrete sleepers for construction or opt for wooden analogues. Everything here is determined by your financial budget.

Some are wary of using sleepers made of wood material impregnated with creosote, which gives the wood a long service life and protects it from rotting. This impregnation has an unpleasant odor and is considered poisonous. But all the fears are in vain - over the entire period of operation on the railway track, the sleepers have long been weathered of creosote, and its dangerous properties have disappeared.

A good advantage is that decommissioned sleepers for foundation construction can be obtained almost free of charge during repair work on railway tracks. In addition, construction of the base is possible on your own, because the material does not require special processing and does not cause installation difficulties. You just need to have an assistant on hand to help move the sleeper to the right place and lay it in the foundation trench.

Sleepers can be used to build a bathhouse or outbuilding, for a garage and gazebo, for a barn or a light country house. But most often, a foundation made of sleepers is in demand for a greenhouse. As a rule, a foundation is erected for such a structure in the following cases:

- installation of a greenhouse close to a residential building and its year-round operation;

- its location in an unguarded place;

- penetration into the soil below the freezing point of the soil;

- use for lumber construction;

- construction on a site with unstable soil composition or uneven terrain;

- construction of greenhouses of non-standard sizes.

Use of reinforced concrete sleepers

Concrete sleepers are a durable building material. It differs from reinforced concrete blocks in dimensions, therefore, according to the criteria of strength and ability to withstand weight loads, there is every reason to use it as a foundation.

But the material has a significant drawback: irregular shape. There is a flat plane on one side of the product. All the rest are broken. But this is still not an obstacle to the use of reinforced concrete sleepers for the construction of foundations for small buildings.

It should be noted that the installation of such a base will cause installation difficulties and will require accurate calculations of the load-bearing capacity.

Wooden sleepers

Such sleepers are suitable not only for building foundations. They are also suitable for mounting the lower trim. In this case, it is recommended to choose timber that has not been treated with creosote. This will prevent the appearance of unpleasant odors from under the floor.

But such sleepers must be coated with 2-3 layers of antiseptic, which prevents rotting, damage by insects and increases the moisture resistance of the wood. If you decide to use bars treated with creosote to build the base, it is advisable to completely immerse them in the ground.

When heated by the sun, the material begins to emit an odor, which disappears after several years.

What kind of sleeper base is there?

Columnar foundation made of wooden sleepers

Two types of foundations can be made from this material.

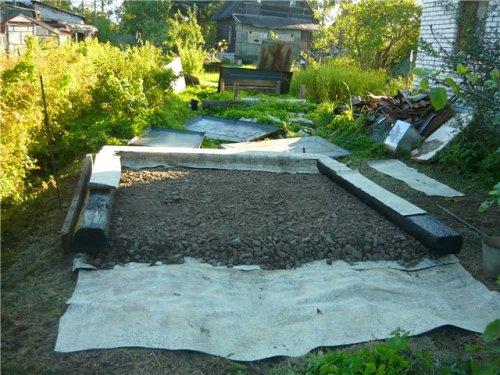

The strip base is made with the joining of logs along the entire length of the building. If the sleepers are laid horizontally, the markings are carried out according to plan, and then 2-3 rows are made for the base.

A layer of crushed stone with sand is placed under the foundation, compacted thoroughly and well moistened. And only then sleepers are laid on top. They are arranged with overlapping joints, in the manner of brickwork. You can use staples to secure the joints at the ends. Easy to do with your own hands.

It is possible to make a columnar foundation from sleepers. To do this, the logs are placed vertically at a calculated distance from one another.

In preparation for the construction of the foundation, the sleepers are treated with a special antiseptic and coated with bitumen. Such a foundation serves for quite a long time (more than half a century).

Strip foundation made of sleepers

Let's take a closer look at the construction of a strip foundation made of sleepers. There are two options: to arrange a shallow or non-buried foundation and a deep foundation. The first method is ideal for any outbuildings, such as a barn, greenhouse, or garage. The second is for more capital ones, for example for a bathhouse.

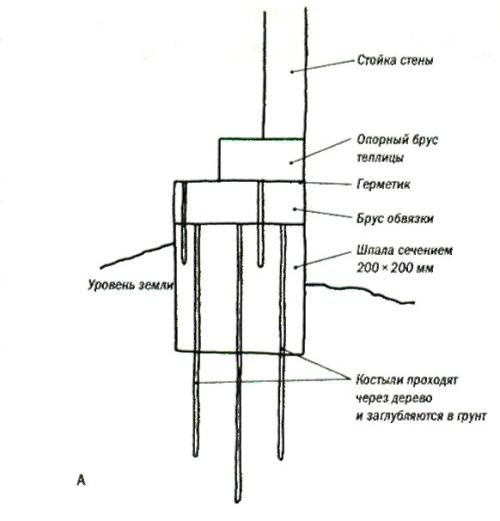

Before laying sleepers you need to make preparations. To do this, remove the vegetable ball of soil and fill the trench with gravel 10-15 cm thick and compact it. We lay the sleepers. They need to be fastened both to each other and to the ground. They are fastened together with a strapping beam, and into the ground with the help of crutches. The support beam is laid on the strapping beam and then the wall is erected.

A deep foundation is laid in the same way as any other prefabricated foundation. That is, a trench is dug, preparations are made and piles are laid, tied and fastened together. The drawing above shows a detailed assembly of the foundation.

Sleepers as a foundation grillage

Foundation made of wooden sleepers on pillars

It is worth noting that the use of railway elements is optimal as a grillage - horizontal elements of the foundation (piping). The process for creating a base is as follows:

- A trench or pit is being dug. Their depth should be about 0.4 m.

- Wells are drilled around the perimeter. The distance between them should be 1.35 and 2.7 meters. To carry out this process with your own hands, you can use a drill with a diameter of 0.3-0.4 cm. The depth of the holes is selected depending on the weight of the future structure, but cannot be less than 1 m.

- Roofing felt and a frame with reinforcement are placed in the well. The first should be rolled up in the form of a roll, and the second should look like 4 vertical pins connected by elements (strapping) in increments of 0.3-0.4 cm.

- Wells are filled with concrete.

- After arranging the supports, the turn comes to the grillage. It is important that the supports gain maximum strength. If the distance between the supporting elements was chosen at 1.35, then the sleeper will rest on 3 supports, and if at 2.7 - on 2. The first method is ideal for a garage or barn, and the second - for small structures with low mass.

Features of installing reinforced concrete beams

To get a solid foundation, you will need to strictly follow the work technology.

Before laying, each pole is checked for integrity and quality. Beams treated with poison lose their destructive qualities when left in the fresh air for a long time. If it is ventilated for a long time, it can be used to erect buildings for living beings. New batches of material should be avoided.

New beam

It is recommended to use sleepers to form the foundation for a house only for frame structures. This is due to the weight of the future building - sleepers are not intended for heavy structures.

Due to the large weight of the columns for installation, a winch, crane, and hinges are used to simplify the task.

Depending on the construction, the piles are mounted on a sand and gravel bed or pillar supports.

If a strip foundation is chosen, a compacted cushion is poured, columnar supports are used when forming a point grillage.

You can install sleepers with a relaxed frame assembled with wire. Raw materials cannot be heated or extended. This option is applicable only to reinforced concrete up to 6 meters long. The tense frame is mounted with burnt, stretched iron wire and is suitable for beams of any length.

Mandatory stages of work are reinforcement, construction of formwork, pouring concrete mortar. Beam - foundation for external walls, plinth.

Before installing reinforced beams, metal rods are treated with anti-corrosion compounds.

Formwork for pouring is often made from wooden boards, but sheet iron can be used. If insulating material is used, the form is permanent and cannot be dismantled after the concrete has dried.

It is necessary to perform concreting so that there are no voids left that reduce the strength indicators. To compact the foundation, immediately after pouring the area, they often pierce the screed with a reinforcement bar and shrink it with a construction vibrator.

Nuances of creating a foundation

Before work, you need to carefully check all materials for quality.

Many newcomers to the construction trade consider the use of sleepers to create a foundation unsafe, citing the impregnation of this material - creosote. The fact is that this substance has a rather pungent odor and contains components that can harm human health. But all these fears are not justified, since only recently made sleepers cannot be used for the construction of houses, and products that are exposed to the open air for a long time are quite suitable. Precipitation and sunlight have removed the harmful substance from the surface of the material, and now it is safe for humans.

It is recommended to use sleeper foundations for the construction of frame houses. Such a building will be much lighter than its counterparts built using standard materials.

Before you begin, you will need to prepare the following tools and materials:

- reinforced concrete products;

- cement;

- crushed stone and sand of fine or medium fraction;

- equipment for lifting sleepers;

- metal staples and pins;

- bitumen;

- antiseptic solution.

Sleepers can also be used to construct garages or sheds.

Foundation Tools

Foundation construction process

When building any foundation with your own hands, you need approximately the same set of tools:

- shovels with hand drill;

- plumb and level;

- boards for formwork;

- construction tape;

- staples;

- brick or stone;

- a mixture of gravel and sand;

- moisture-proofing material, tar can be used;

- roofing felt with cement;

- solution container;

- reinforcement and equipment for cutting it.

DIY sleeper base: step-by-step instructions

Overlapping sleeper connection diagram.

A sleeper base is a very effective and simple option for installing a greenhouse base. It is necessary to provide recesses that can be made from pipes in those places where the pins are structurally placed to bury them in the ground.

When building any type of foundation, you will need approximately the same set of tools. In each specific case, you can determine for yourself which of the following tools you will or will not need:

- shovel and bayonet;

- hand drill;

- plumb line;

- building level;

- hacksaw;

- boards for formwork;

- tape measure 10-20 meters;

- staples;

- nails;

- hammer;

- scrap;

- axe;

- broken brick;

- Stone;

- Sand and gravel;

- logs;

- sleepers;

- tar or other moisture-proofing material;

- roofing felt;

- cement;

- brick;

- container for stirring the solution;

- reinforcing wire;

- reinforcing bar;

- device for cutting reinforcement.

Diagram of a strip foundation made of sleepers: 1 - sleeper; 2 - waterproofing, which should already be present on the sleeper; 3 - concrete shoe (option 1), brackets (option 2); 4 - sand cushion (option 1), wooden support (option 2); 5 - sand cushion.

Prepare a site of suitable size, level it, and remove vegetation. Make markings in accordance with the known dimensions of the greenhouse. Dig a trench about 20-30 cm deep. Level the horizon.

Install logs (sleepers) of the required length around the perimeter. Excessively long ones need to be sawed off. Double-check the level relative to the horizon of the laid logs (sleepers). Fasten them together using construction staples.

Measures for waterproofing the structure are carried out in the same way as when constructing other foundations. A foundation made of wooden or concrete sleepers must be coated with bitumen and a layer of waterproofing applied, which can be polyethylene film, roofing felt and other similar materials. If possible, the sleeper base can be insulated. The design requires the implementation of exactly the same protective measures as a foundation made of any other building materials.

If all the work on laying the foundation for a house, greenhouse or any other outbuilding made from sleepers was carried out in accordance with established norms and rules, and the protective waterproofing and other treatments were carried out with high quality, then even wooden sleepers will last a very long time. Experience shows that such a foundation can last up to half a century without loss of quality and reliability.

It is necessary to mention that a pile foundation made of sleepers is a semblance of an ordinary pile foundation. Provided that a reliable reinforced concrete grillage is installed, even a fairly heavy building can be erected on such a foundation.

Making a foundation from wooden sleepers

This material is not only used to build the foundation, but also to construct the bottom row of the frame. It is advisable to use sleepers that have not been treated with creosote, otherwise they should be completely immersed in the soil.

Before use, the surface of the wood is coated several times with antiseptic compounds to prevent rotting, exposure to moisture and insects. Before processing, the material is carefully inspected for defects that could cause weakening of the entire structure.

There are several ways to build a foundation from wooden sleepers with your own hands.

When construction is planned on support pillars, the sleepers are placed vertically and tied. This installation option is suitable for small rooms whose load-bearing walls do not create a large load.

The sleeper foundation for the greenhouse is mounted using the method of installation on the surface of the earth. This base is easy to adjust in height, installation work does not take much time. The same method is used to build foundations for light garages and country houses. A foundation made of wooden sleepers for a barn laid on the surface of the earth is also reliable and can last for several decades.

Under walls constructed from heavy materials, railway sleepers are laid horizontally in a prepared foundation trench. A cushion of crushed stone or sand is first placed at the bottom.

A layer of waterproofing material is laid between the foundation base and the walls of the facility, which at the same time creates protection from the creosote odor. The depth of laying sleepers is determined taking into account the characteristics of the soil composition on which construction work is being carried out.

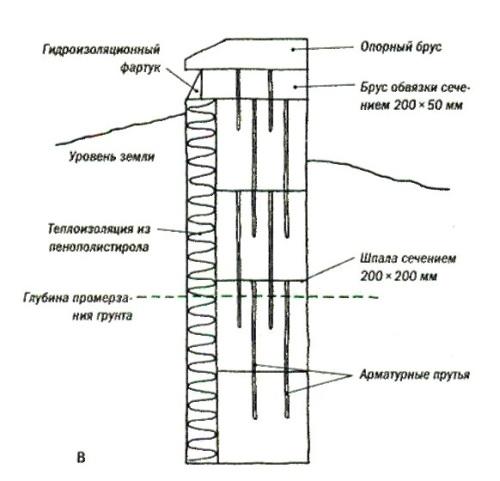

Let's take a closer look at the vertical installation of sleepers.

Here it is important to take into account their length and the need to immerse below the freezing level of the ground.

Installation work is carried out as follows:

- The position of the supports is noted at intervals of two to two and a half meters. The installation step depends on the expected loads on the foundation and can be reduced;

- pits of the required depth are formed;

- the bars are placed vertically;

- the pits are filled with rubble stone, compacted and concreted. To add additional strength, you can use reinforcement from metal rods.

Making a foundation from reinforced concrete sleepers

A foundation made of reinforced concrete sleepers is considered a more expensive option than its counterpart made of wood material. However, its range of applications is wider. You can even build a foundation for a frame house from reinforced concrete sleepers, if the number of floors in it does not exceed two levels.

Installation of a columnar base

Preparation for laying a columnar base includes the involvement of a drilling rig, the search for rope, twine, and an increased supply of roofing material that will replace the formwork.

They use a rope to mark the construction site and drill vertical trenches for sleepers. The pillars will be placed at a depth of about 1.5 m, leaving a distance of at least 2 m between them.

The bottom of the pit is covered with sand and crushed stone, making dense cushions, waterproofing material is laid, and sleepers are inserted into a permanent place.

A supply of reinforcing bars remains on top of the pillar, to which the reinforcing center of the grillage is attached, roofing material is tightly wound around the sleeper as a form, and the cement mixture is poured.

Foundation construction procedure

The construction of the base must be treated with great responsibility. It is necessary to carefully analyze the condition of the products that will be used for such work. If they are damaged, the created foundation may turn out to be of poor quality and after a certain time it will be necessary to carry out restoration procedures.

Before laying sleepers, they must be thoroughly treated with special water-repellent solutions.

It is best to create such foundations on soil with high hardness to prevent the possibility of settlement under the load of the house. The foundation made of reinforced concrete sleepers can be of different types:

- Columnar;

- tape;

- pile;

- slab.

The optimal solution for using such material are tape and columnar varieties. For a strip base, logs must be laid around the entire perimeter. A layer of sand and crushed stone is preliminarily laid under the foundation, which will need to be thoroughly compacted and moistened. Then sleepers are placed on top, which are placed with overlapping joints. For fastening you need to use metal staples and pins.

If it was decided to use a columnar base, the logs should be placed vertically with a certain interval from each other. During preparation, it is necessary to treat the sleepers with a special antiseptic and bitumen. This type of foundation has a fairly long service life, which can last up to 50 years. The sleepers are laid on a concrete base and gradually covered. They are then connected to other sleepers installed in a similar pattern.

The following video will help you learn in more detail about the procedure for creating a foundation from sleepers with your own hands.

Tape base made from sleepers

For two-story wooden houses, it is best to create a strip base. In this case, concrete sleepers are laid in a special formwork made of wood, which allows you to save a lot on pouring cement. The whole procedure consists of the following steps:

- First, a trench is dug. Its depth must exceed the soil freezing level.

- The formwork is being created. Often boards are used for manufacturing. It must be securely fastened from the bottom of the pit to the top of the basement.

- A layer of sand is added to a height of up to 20 cm. This will help prevent damage to the foundation.

- A cement mixture or concrete is prepared.

- Concrete is poured along the entire perimeter of the pit to the required height, after which the sleepers are installed. They will be used as buta. Then a new layer of concrete is poured and the sleepers are laid again. They need to be installed not on top of each other, but in a checkerboard pattern. According to this scheme, the base is poured to the top of the formwork. This will prevent the tape from cracking. The height interval between sleepers should be about 50 cm. The distance between the edges can vary from 50 to 70 cm.

Columnar base made of sleepers

To install such material you will need to use special equipment.

This type of basis is the most economical. It can be used for frame or wooden buildings, as well as buildings made of foam concrete blocks.

A foundation made of reinforced concrete sleepers allows you to save a lot of money, but you need to take into account that such material has a fairly large mass. Not every master will be able to place it in the formwork or pit with his own hands. For these purposes, you will need to use special equipment, which will greatly simplify the work. Creating a columnar foundation consists of the following steps:

- The first step is to dig a hole for each post. The interval of their installation depends on the design of the building. The depth of the hole can vary from 1.5 to 2 m. The width should allow you to install the material and pour cement mortar around it.

- At the bottom of each pit you will need to create a cushion based on sand and fine crushed stone.

- After which the installation of reinforced concrete products is carried out.

- Each hole is filled with cement mortar.

Creating a columnar base from non-standard materials is not so difficult, the main thing is to carefully follow the work technology.

Using sleepers for bases is a good solution. Thanks to this material, you can save a lot on building a house. The main thing is to carefully select products to ensure a long service life.

Assembling the strip structure

To lay the foundation from sleepers0, you will need to prepare the necessary things in advance and hire special equipment.

The materials you will need are: reinforced concrete products, concrete mortar, sand, crushed stone, clean water. Consumables - metal pins, staples, bitumen-based mastic, antiseptics, fittings, boards for formwork, nails.

You need few tools, just take a building level, a shovel, a hammer, a crowbar, a construction mixer, and an electric drill with an attachment.

The markings are applied with a tape measure, pegs, and rope.

A trench is dug along the perimeter of the future foundation, 80 cm deep and 30 cm wide.

The bottom is first covered with crushed stone, compacted, covered with sand in layers, periodically irrigated with water to increase density. The total size of the pillow is 30 cm minimum.

They move on to laying waterproofing made of dense polyethylene, roofing felt, and laying beams.

The finished structure on the cut will look like the periodicity of layers of basic materials with concrete pouring. Reinforced concrete is laid overlapping, in a checkerboard pattern.

The length of the piles should correspond to the length of the ditch. The parts are fastened with metal staples.

The formwork is installed, tied, a reinforcing belt is inserted, and concrete is poured.