Usage and Functions

These types of structures are mainly used in the construction of walls for industrial buildings, since they are able to withstand the weight of a concrete wall up to 25 m high, or brick walls 15 m high. The construction of such buildings involves the use of frame construction technology.

The construction method involves constructing free-standing foundations for internal and external walls. It is for their construction that reinforced concrete foundation beams are used, which hold together the frame of the entire foundation. The use of this material increases the rigidity of the structure and the speed of its construction.

Reinforced concrete beams have a very long service life

Foundation beams have the following undeniable advantages:

- strength;

- frost resistance;

- long service life;

- excellent moisture and heat insulation;

- corrosion resistance.

Since the construction of industrial buildings requires strong support, it is necessary to perform calculations of static and, possibly, dynamic pressure on the foundation.

Due to the increased requirements for stability, for the construction of buildings using foundation beams, it is necessary to develop a project with all the required drawings. Beams are also used for the construction of buildings in areas with high seismic activity.

Purpose of FB

Reinforced concrete support beams are widely used in the construction of industrial and agricultural facilities. When using them, there is no need to construct an expensive monolithic foundation used in the construction of residential buildings. Reinforced beams are in demand in the following situations:

- arrangement of self-supporting structures of block or panel type;

- construction of brick walls with curtain panels;

- when constructing solid walls and facades with door and window openings.

Based on the location of installation, building structures are divided into support beams, those mounted under external walls, connecting beams, and ordinary beams. As an alternative to strip foundations, prefabricated structures are characterized by ease of installation and low cost.

Classification of foundation beams

By labeling

Foundation beams are classified by size and shape:

- 1BF - the cross section of the product has the shape of a trapezoid with a base 20 cm long.

- 2BF - the section has a T-shaped upper base.

- 3BF – is an enlarged version of standard size 2BF, the upper base of the product is 40 cm.

- 4BF is the largest type of concrete beams with a T-section, having a 52-centimeter edge.

- 5BF is an average version of trapezoidal beams, which have a 32-centimeter base and a height of 30 cm.

- 6BF is a special series of products whose height is 60 cm.

Some products may have similar markings, but have different properties, so you should pay attention to their GOST drawings and standard sizes.

By application

Based on the type of application, reinforced concrete foundation beams are divided into several types:

- Wall - rand beams, which are used for the construction of external walls of a building;

- Ordinary – mounted between the tie and wall slabs;

- Ties - used to provide a strong connection between the supporting columns of the building;

- Ribbed - have a thickness of about 20 cm and are intended for plumbing purposes.

The project drawing must take into account the number of products used, taking into account their possible shortening and use at the ends of buildings.

By reinforcement

Beams are selected not only according to the grade of concrete, but also according to the type of reinforcement. Reinforcement can be prestressed or unstressed.

Prestressing is done in order to increase the resistance of concrete to tensile deforming forces. Typically, reinforcement is tensioned by heating it.

Application

Foundation beams are used to create structures on which the load-bearing walls of the building are erected. Such structures facilitate the initial stage of construction, reducing the time and costs of constructing the frame. As a rule, they are used to build large structures: agricultural, industrial and commercial complexes. In the construction of small private houses they are less common. The foundation beam (rand beam) is a profile made of reinforced concrete material. Concrete in combination with iron reinforcement has high strength properties under mechanical loads; resistance to aggressive chemical reactions of the external environment and moisture. Thanks to these qualities, their designs can be used in the construction of buildings:

- on loose soils;

- when operating buildings in low temperature conditions;

- with increased soil acidity, as well as high groundwater content;

- with high risks of seismic hazard.

The cross-section and shape of the beams are different. It will depend on the purpose of the foundation structure and the requirements for beam loads. Based on these characteristics, they are divided into types.

How to choose

The foundation beam is selected according to the drawn up project drawing: the more massive the future structure, the stronger and more stable the material will be needed. The price also depends on the characteristics of the product.

The standard length of products depends on the pitch of the columns of the structure, which is a multiple of six meters - this is usually 6 or 12 m. In the first case, the length will be 4.95 m, and in the second - 10.7 m.

The thickness of the product depends on the wall material. This is 38 cm or 51 cm for block walls; 25, 38 or 51 cm are useful for brick ones; For panel walls, reinforced concrete products with a thickness of 200, 240, 300, 400 mm are suitable. To the size it is also necessary to add a weight reserve for support on both sides. The section size is also selected based on the load. For common materials there is a maximum load factor.

You can find it out from the manufacturer or use the tables in their series, which indicate the recommended markings for various walls. Load calculation is very important for drawing up the design part of the project and executing drawings.

We recommend watching a video of how load endurance is checked in the factory.

Types of frames

Depending on the quality of the metal rod used to reinforce reinforced concrete structures, there are two types of products used in the construction of foundations.

- The unstressed frame is made without heating or elongating metal structures. Foundation beams of this type are made of M150 and M200 concrete and cannot be longer than 6 meters.

- The stressed frame of reinforced concrete products is made from annealed or stretched rods. The length of such products can be any; concrete M250 and M300 are used for pouring.

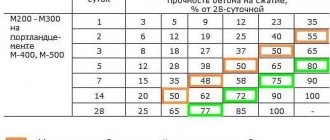

The choice of concrete type for pouring reinforced concrete structures is determined by the type of building walls.

- For foundations of concrete structures, lighter grades can be used.

- For supports under brick walls, it is preferable to choose a material designed to withstand significant loads.

In modern construction, beams are used in the construction of buildings with columns.

Performance

Each foundation beam is characterized by the following parameters:

- frost resistance,

- heat resistance,

- rigidity,

- strength (determined by tempering, transfer and age indicators).

Building

Industrial buildings are subject to increased requirements not only in terms of reliability, but also in terms of distributed placement of equipment and support systems in production.

Every detail must be taken into account in the approved project. Installation is carried out only by construction organizations that have received a license to carry out such work.

Changes in decisions of production work projects are also not allowed without the approval of the structures that approved them.

Calculation and design

For the construction of an industrial building, geological studies are carried out, the composition of the soil and its properties are determined, and the load on the soil from the structure is calculated.

Installation

Installation begins upon completion of all preparatory work, namely:

- construction of a prefabricated (or monolithic) foundation;

- dividing the base for reinforced concrete beams;

- delivery and storage of materials;

- material quality control;

- performing markings according to design drawings.

The accuracy of beam installation is ensured by detailed alignment work and constant instrumental monitoring of the accuracy of installation work provided for by the technology.

To divide the space for the installation of beams mounted along the perimeter of the building, from the main axes by measuring the distance (according to the project), the installation axes are divided parallel to the main ones. The location of the axes is fixed with marks and the edges of the concrete pillars, which serve as supports for the foundation beams, are painted. Marking the end sides of reinforced concrete products is also done with marks of oil paint.

Installation of beams

At the production stage, metal loops are built into the body of products intended for foundation construction, through which a cable can be passed during installation. Loading and unloading operations and installation of such reinforced concrete products are carried out using lifting mechanisms (winches or cranes), since even a small-sized product of the 1BF series (with a length of 1.45 m) weighs 100 kg.

Scheme of installation of the foundation beam on the supports

The structures are used for assembling a grillage and for constructing strip foundations from blocks. In the first case, the installation of reinforced concrete products is carried out by installing them on piles or pillars, in the second - directly on a backfill of sand and gravel (“pillow”).

Foundation beams with trapezoidal cross-section

The installation step of vertical supports is selected depending on the size of the supporting structures. For products of the 1BF-4BF series, the distance between the supports is set within 1.4-6.0 meters. Products of other series require the installation of supports, which are located along the perimeter of the base (step - 12 meters). Installation and assembly of structures is carried out by fixing the beams with clamps or by welding the metal frames of the beams and support posts.

Compliance of longitudinal frame elements with GOST standards

The reliability of reinforced concrete structures is determined by strict adherence to the requirements of current GOSTs during the production process. This guarantee is provided by the Moscow Concrete Products Plant 4. The plant’s products fully comply with regulatory requirements.

When purchasing reinforced concrete beams for any purpose, you can be sure that the materials used in the production process comply with the set parameters.

- floor beams are made of heavy concrete using prestressed reinforcement.

- Foundation beams are produced in accordance with GOST 28737-90 also from heavy, dense concrete. The reinforcement is assembled into a welded frame. Such products are offered in the most popular length: for a column spacing of 6 m. With this support spacing, not only wall panels are used, but also self-supporting walls are erected from bricks and small blocks.

Beams have different widths and heights and are designed to withstand different loads. The T-section not only allows you to save materials in the manufacture of the product, but significantly reduces the weight of the structure and reduces its cost.

Ask a Question

Checkout

Foundation beams ( rand beams ) are reinforced concrete products that are made from reinforcement and heavy concrete and are used in the construction of industrial premises; they rest on a columnar or strip foundation and are capable of bearing heavy loads. Application Reinforced concrete foundation beams have found their application in the construction of walls of industrial buildings, which are erected using a frame type. Such construction involves the construction of separate foundations for internal and external walls, the construction of which takes place using these reinforced concrete products. Their main purpose is to serve as a load-bearing element in a wall structure made of piece material. Moreover, this is the component that separates the highly porous wall material from the ground, since such material without waterproofing protection should not come into contact with the ground. These reinforced concrete products are irreplaceable in seismic areas: the foundation beams, which are mutually connected at the point of support on the foundation, act as a continuous strapping belt that absorbs the horizontal forces acting in the wall plane. Beams are used for external and internal wall structures made of brick, block stone, and panels. They are used under solid walls and under structures with door and window openings. With a column pitch of 6 m, the standard length of reinforced concrete products will be 495 cm, and with a pitch of 12 m, the product will have a length of 1070 cm. The thickness of the element depends on the type of wall: with a brick wall its width will be 25, 38 and 51 cm, with a panel wall - 20, 24 , 30 and 40 cm, block - 38 and 51 cm. Manufacturing Since the durability of the entire structure depends on the strength of these products, the process of their manufacture is a responsible process, where the size of the beam: its length and width, as well as the strength of the product are strictly regulated by technological documentation and this manufacturer's standard. The strength of reinforced concrete products depends not only on production technology, but also on the quality of the materials from which they are made. Reinforced concrete foundation beams consist of a strong frame (metal reinforcement) and a special heavy type of concrete. Steel class A-IV and AI I I are used as reinforcement for foundation beams. Reinforcement of rand beams allows concrete to withstand significant loads in torsion, tension, and bending. Stressed and non-stressed reinforcement is used. The first option is justified in the production of long-length reinforced concrete products, when special channel formers are used, which are removed after concreting. Pre-tensioning of the reinforcement threads is used in the manufacture of the frame to increase the resistance of the product to static loads. The optimal beam configuration is calculated taking into account the following parameters: the total load created by the building; geometric size of the structure; foundation depth and type of material. The technological process for manufacturing beams is not much different from the production of other reinforced concrete products. These products are produced by the vibration casting method, when a concrete mixture is poured into a mold with a frame installed on a vibration table. The operation of the vibrator helps compact the mixture, after which the mold is moved into the room, where the product is completely hardened, which after 24 hours acquires the calculated level of hardness and is ready for use. Types of technological process: - monolithic method involves casting elements on the construction site; — the prefabricated method is carried out by assembling an element from reinforced concrete at the factory; — the prefabricated monolithic process involves the use of some factory elements and parts that are cast on site. Monolithic production requires inventory, prefabricated formwork, which facilitates stripping. Types of reinforced concrete beams: - connected, they are installed between the columns, so that the axes of the beams coincide; — wall-mounted, they are laid near external wall structures; - ribbed, these are sanitary products that have a thickness of 220 mm; - ordinary, installation is carried out between wall and tie slabs. Installation Those enterprises that have the appropriate licenses for their production have the right to install foundation beams. Such work must be carried out by workers who have undergone special training and have the appropriate skills to perform construction and installation work. Such work can begin only after approval of the work plan. Installation of beams is carried out after the following actions: - final completion, correct execution and acceptance of previously carried out work on the installation of a monolithic or prefabricated foundation; — breakdown of bases and foundations for reinforced concrete foundation beams; — delivery, storage, control of reinforced concrete products; — marking of foundation reinforced concrete products.

| FB 6-1 Dimensions (L x W x H in mm): 5950x260x450 Weight (in kg): 1600 |

| FB 6-2 Dimensions (L x W x H in mm): 5050x260x450 Weight (in kg): 1300 |

| FB 6-3 Dimensions (L x W x H in mm): 4750x260x450 Weight (in kg): 1200 |

| FB 6-4 Dimensions (L x W x H in mm): 4450x260x450 Weight (in kg): 1200 |

| FB 6-5 Dimensions (L x W x H in mm): 4300x260x450 Weight (in kg): 1100 |

| FB 6-6 Dimensions (L x W x H in mm): 5950x260x450 Weight (in kg): 1600 |

| FB 6-7 Dimensions (L x W x H in mm): 5050x260x450 Weight (in kg): 1300 |

| FB 6-8 Dimensions (L x W x H in mm): 4750x260x450 Weight (in kg): 1200 |

| FB 6-9 Dimensions (L x W x H in mm): 4450x260x450 Weight (in kg): 1200 |

| FB 6-10 Dimensions (L x W x H in mm): 4300x260x450 Weight (in kg): 1100 |

| FB 6-11 Dimensions (L x W x H in mm): 5950x400x450 Weight (in kg): 1800 |

| FB 6-12 Dimensions (L x W x H in mm): 5050x400x450 Weight (in kg): 1500 |

| FB 6-13 Dimensions (L x W x H in mm): 4750x400x450 Weight (in kg): 1400 |

| FB 6-14 Dimensions (L x W x H in mm): 4450x400x450 Weight (in kg): 1300 |

| FB 6-15 Dimensions (L x W x H in mm): 4300x400x450 Weight (in kg): 1300 |

| FB 6-16 Dimensions (L x W x H in mm): 5950x400x450 Weight (in kg): 1800 |

| FB 6-17 Dimensions (L x W x H in mm): 5050x400x450 Weight (in kg): 1500 |

| FB 6-18 Dimensions (L x W x H in mm): 5950x400x450 Weight (in kg): 1800 |

| FB 6-19 Dimensions (L x W x H in mm): 5050x400x450 Weight (in kg): 1500 |

| FB 6-20 Dimensions (L x W x H in mm): 4750x400x450 Weight (in kg): 1400 |

| FB 6-21 Dimensions (L x W x H in mm): 4450x400x450 Weight (in kg): 1300 |

| FB 6-22 Dimensions (L x W x H in mm): 4300x400x450 Weight (in kg): 1300 |

| FB 6-23 Dimensions (L x W x H in mm): 5950x400x450 Weight (in kg): 1800 |

| FB 6-24 Dimensions (L x W x H in mm): 5050x400x450 Weight (in kg): 1500 |

| FB 6-25 Dimensions (L x W x H in mm): 4750x400x450 Weight (in kg): 1400 |

| FB 6-26 Dimensions (L x W x H in mm): 4450x400x450 Weight (in kg): 1300 |

| FB 6-27 Dimensions (L x W x H in mm): 4300x400x450 Weight (in kg): 1300 |

| FB 6-28 Dimensions (L x W x H in mm): 5950x520x450 Weight (in kg): 2200 |

| FB 6-29 Dimensions (L x W x H in mm): 5050x520x450 Weight (in kg): 1900 |

| FB 6-30 Dimensions (L x W x H in mm): 4750x520x450 Weight (in kg): 1800 |

| FB 6-31 Dimensions (L x W x H in mm): 4450x520x450 Weight (in kg): 1700 |

| FB 6-32 Dimensions (L x W x H in mm): 4300x520x450 Weight (in kg): 1600 |

| FB 6-33 Dimensions (L x W x H in mm): 5950x520x450 Weight (in kg): 2200 |

| FB 6-34 Dimensions (L x W x H in mm): 5050x520x450 Weight (in kg): 1900 |

| FB 6-35 Dimensions (L x W x H in mm): 5950x520x450 Weight (in kg): 2200 |

| FB 6-36 Dimensions (L x W x H in mm): 5050x520x450 Weight (in kg): 1900 |

| FB 6-37 Dimensions (L x W x H in mm): 4750x520x450 Weight (in kg): 1800 |

| FB 6-38 Dimensions (L x W x H in mm): 4450x520x450 Weight (in kg): 1700 |

| FB 6-39 Dimensions (L x W x H in mm): 4300x520x450 Weight (in kg): 1600 |

| FB 6-40 Dimensions (L x W x H in mm): 5950x200x300 Weight (in kg): 800 |

| FB 6-41 Dimensions (L x W x H in mm): 5050x200x300 Weight (in kg): 700 |

| FB 6-42 Dimensions (L x W x H in mm): 4750x200x300 Weight (in kg): 700 |

| FB 6-43 Dimensions (L x W x H in mm): 4450x200x300 Weight (in kg): 600 |

| FB 6-44 Dimensions (L x W x H in mm): 4300x200x300 Weight (in kg): 600 |

| FB 6-45 Dimensions (L x W x H in mm): 5950x300x300 Weight (in kg): 1000 |

| FB 6-46 Dimensions (L x W x H in mm): 5050x300x300 Weight (in kg): 900 |

| FB 6-47 Dimensions (L x W x H in mm): 4750x300x300 Weight (in kg): 800 |

| FB 6-48 Dimensions (L x W x H in mm): 4450x300x300 Weight (in kg): 800 |

| FB 6-49 Dimensions (L x W x H in mm): 4300x300x300 Weight (in kg): 800 |

Ask a Question

Checkout

Installation procedure

The purpose of the foundation beam is to act as a load-bearing base for the walls. Most often, such products are used to create three-dimensional structures. The use of beams is determined by the rules and regulations of construction. Although products are classified into different types, the installation process is almost always identical:

- Before construction begins, calculations are made. It is necessary to take into account the height of the building, weight, volume and other parameters. Without accurate calculations, construction work is impossible.

- Foundation beams are installed on the finished monolith of the original foundation. Before starting work, all surfaces are cleaned of dirt, debris, and water.

- The beams are raised to the required level by means of mechanical transportation. It is strictly prohibited to install products in places not designated for this purpose.

- It is important to carry out lifting work smoothly and gradually, checking the reliability of the supporting structures. The product is installed on a special pillow. In this case, the upper section should be above the ground, but below the main plane of the floor.

The process of installing beams is labor-intensive and requires special skills and equipment. Carrying out such work on your own can lead to unpleasant consequences.

Application benefits

The use of prefabricated reinforced concrete support structures in the construction of buildings has significant advantages.

- The beams take a significant part of the load from the walls.

- When the blind area settles, installing beams at the base protects the building from heat loss through the floor.

- If the project involves installing panel curtain walls, the foundation beams will not carry the structural load, but their installation can significantly extend the life of the bottom of the panels.

- Installation of structures of this type reduces the labor intensity of the process during foundation construction.

An operational advantage of using products should be the ease of laying tunnels and channels under them for communications.

T-bar foundation model with mounting loops