The technology for constructing strip foundations involves the installation of hydraulic insulation on the external surfaces of the underground part. This is necessary to protect the concrete monolith from the effects of groundwater and the basement from flooding.

Today, in most cases, foundation waterproofing is made from coating and roll materials on a bitumen or other penetrating base. But there is another reliable way to protect the underground structure from moisture. This is a waterproof clay castle around a foundation that was widely used by builders in the past.

A brief excursion into history

Until the mid-19th century, when constructing basements on moist soils, traditional and reliable technology was used: the foundation, made of brick or rubble with lime mortar, was coated with a layer of clay 8-10 cm thick, which was then covered with natural matting.

A layer of crushed brick was poured from below as drainage, and when the soil was significantly moistened, drainage pipes were laid. Many European cities in regions with wet soil are built this way.

In Russia, striking examples are St. Petersburg and Kaliningrad (Konigsberg), many of their basements are located below the groundwater level and remain dry. Systems of underground drainage and clay insulation were found by archaeologists during excavations of structures from the 14th century in Novgorod.

Leaks in the basements of ancient buildings occur in cases where, when laying communications, current builders violate the ancient clay waterproofing and try to restore it using modern, familiar means.

Very high quality fatty clay ideal for waterproofing

Cob floors, which are still found in old country houses, remain completely dry even in humid climates until water is spilled on them from above. In rich ancient houses and churches, the floors were made of brick lining, with a clay layer 10-15 cm thick placed on top.

The clay was carefully compacted with chains (threshed), poured with ox blood, tar water or slurry. The floor made in this way was covered with stone or ceramic tiles, again using clay solutions as glue.

Clay is suitable not only for making dishes, it is a valuable building material

In the 19th century, bitumen and tar began to be introduced into construction as waterproofing materials, gradually displacing traditional methods. In modern construction, mainly highly industrialized modern materials are used - waterproofing materials based on petroleum bitumen, cement and polymers.

However, it is too early to write off clay in this capacity. Waterproofing structures with a clay castle is used quite widely to this day, not only in the Russian outback, but also in rich and advanced countries from a construction point of view.

Underground structures and foundations of houses in old St. Petersburg, built practically on a swamp, stand on wooden piles and are waterproofed using a clay castle and asphalt-coal coatings

Scope of application of clay insulation in our time

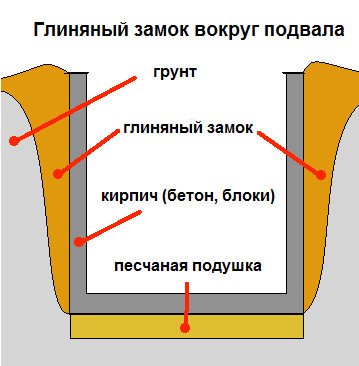

As in former times, clay is used to protect basement floors and building foundations from moisture. The ideal option is the combined use of modern and traditional methods. Surface insulation can be made with bituminous materials (rolled or coated) or with a polymer-cement composition. Build a clay castle outside. This solution will greatly increase the reliability of waterproofing.

Very often builders make mistakes when constructing buildings in clay soils. They dig a pit, build a basement floor, and backfill it, as is customary, with a sand-gravel mixture to neutralize the heaving effect of clay on the foundation. Builders want the best, but it turns out “as always.” Clay soil retains water, while sandy soil, like a sponge, absorbs well. After the rain, all the water goes into the sand and remains there. The backfill around the building is saturated with water for a significant part of the year, regardless of the groundwater level.

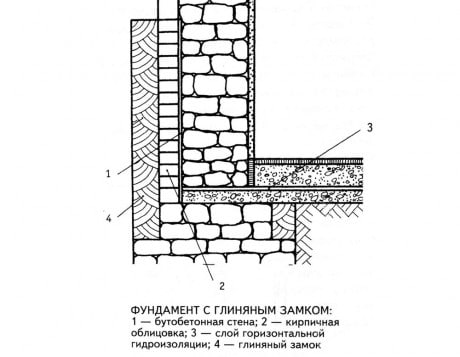

One of the options to build a dry basement. If the basement walls are concrete, the brick lining can be replaced with coating or adhesive insulation

If there is even the slightest hole in the surface insulation of the base, water will definitely find its way inside the house. This problem can be eliminated by installing a clay castle or expensive underground drainage. When building on clay soils, it is better not to use sand bedding at all. It is better to place a layer of crushed stone under the foundation cushion, put the clay removed from the pit back and compact it. This recommendation does not apply to shallow foundations built in heaving soils.

Clay is the most popular waterproofing material for the construction of ponds and reservoirs. Retains water perfectly without any additional measures. However, the use of film will only improve the properties of the pond, preventing erosion of the clay layer.

The property of clay to retain water is used in the construction of ponds

The industry produces high-tech waterproofing materials containing clay components. American products are quite well known in the West - three-layer waterproofing mats “NaBento”, made from bentonite clay in a geotextile shell.

The mats expand after filling the sinuses of the pit, tightly “packing” possible cracks; they are used to isolate critical underground structures in difficult conditions. Clay-based mats are produced by a number of enterprises in the USA, Canada, European countries and China.

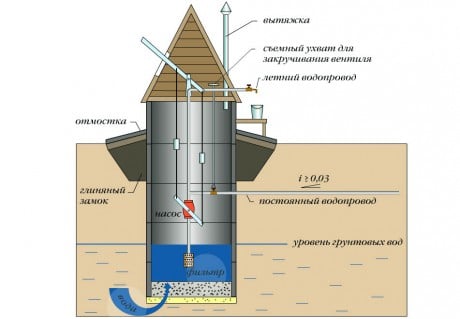

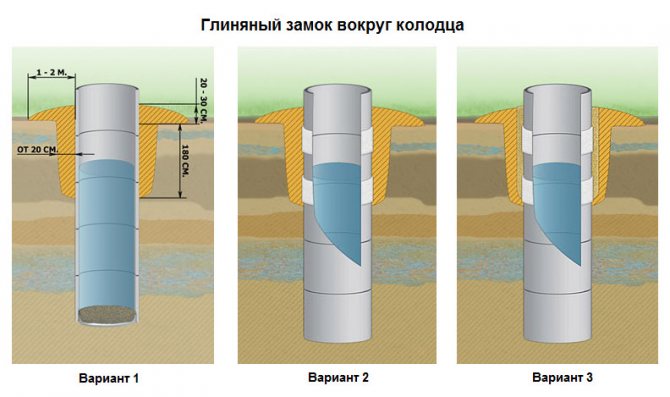

The construction of a clay castle when constructing a village well for drinking water is mandatory. Otherwise, dirty surface water will leak inside along the walls.

The clay castle and the well blind area must have an outward slope

Properties of a clay castle

- Clay has no shelf life and does not deteriorate. Clay insulation does not fail and does not require repair.

- Clay is a fine and plastic mineral. Cracks cannot appear in a clay castle; it will not be washed away by groundwater. The clay castle should be protected from storm water runoff from the roof.

- Clay does not allow water to pass through, but not moisture. A foundation without surface insulation will not get wet, but will become slightly damp. The best solution is the combined use of surface insulation and a clay castle.

- Clay tends to expand significantly when frozen. If the clay castle is made in sandy or sandy loam soil, this does not matter. If the soil at the construction site is clayey, the foundations of the structure should have a smooth surface, the outer profile of the foundation should not expand upward so that it is not squeezed out by the forces of frost heaving.

- Very often clay is lying around underfoot and is worth nothing. A nice bonus.

The best way to make a castle is to tamp it layer by layer in formwork, which does not have to be even.

What is a clay castle

A clay castle is a waterproofing structure made of clay of a certain quality around foundations, wells, cellars, pools, installed where it is necessary to limit the flow of water. The characteristics of such structures were regulated by Building Codes and Regulations (for example, SNiP II-53-73 “Dams made of soil materials” is no longer valid).

Clay serves as a waterproofing agent because it consists of small particles (less than 0.002 mm in size) that are shaped like flakes, like fish scales or lentils. The pores between the clay particles are also small, their size is about 0.005 mm.

When moistened, clay particles swell and block access to water; more precisely, water passes through the clay, but very slowly. And if it has another path, then the water will choose it instead of the extremely leisurely seepage through the clay.

How does a proper clay castle work?

The structural features of clay (small flat particles-flakes) determine the functioning of a clay castle. SanPiN 2.1.4.1175-02 “Hygienic requirements for the quality of water from non-centralized water supply. Sanitary protection of sources" (replacing SanPiN 2.1.4.544-96) recommends its installation during the construction of wells. In particular, paragraph 3.3.4 of this document states: “A castle should be made along the perimeter of the well head from well-pressed and thoroughly compacted clay or rich loam 2 meters deep and 1 meter wide.”

If you are planning to build a clay castle, pay attention to these recommendations - depth and width. And the most important thing is that you need to use clay or fatty loam, that is, rocks containing more than half of the clay particles or at least 40% (fatty loam). And not just loam or even sandy loam, where there are no more than 10% clay particles.

The clay for the castle must be well kneaded - only then will it become waterproof.

It is also important that the clay is well kneaded and then thoroughly compacted. When the clay is crushed, its flat particles occupy a position parallel to each other: the “lentils” are tightly nested into one another. At the same time, the pores of the soil decrease, and the clay stops allowing water to pass through - it becomes a clay castle.

Why do you need a clay castle around the foundation?

The design of the clay castle itself performs several functions:

- Protection of the foundation from moisture.

- Additional dense cushion for the sole of the base.

- Reducing the pressure of groundwater and melt water on foundation walls.

Of course, modern materials cope with waterproofing several times more effectively. But a clay castle has the main advantage of being cheap and accessible . After all, you don’t have to buy clay, but collect it from reservoirs or quarries.

This material has several more pleasant features:

- fat content, which makes it possible not to use additional materials in the sole area for insulation from moisture;

- the density of the dried substance prevents the foundation from cracking or crumbling;

- ease of use, meaning any amount of material can be used for the lock.

But for all its splendor, clay also has some not very pleasant sides:

- Short-lived protection - after 5-6 years the lock should be rebuilt, removing the previous layer.

- Not always good quality - due to sand impurities, the clay becomes less fatty and freezes strongly, losing its properties.

- Low waterproofing of vertical surfaces - additional waterproofing is required for the external and internal walls of the foundation.

Even with such nuances, you should not refuse a clay castle around the foundation. This will save significant amounts of money on insulation and other construction work.

It is worth knowing that the closer the groundwater comes to the foundations, the more short-lived the castle will be. Therefore, to drain water from foundations, drainage is often performed along the entire perimeter near the base of the house.

Why does a well need a clay castle and is it needed at all?

Why does a well need a clay castle? In order to prevent water from flowing down the outer wall, seeping through the seams, and, ultimately, moisture that has not been treated enters the well.

As stated above, clay waterproofing will only work if the clay is properly prepared and installed. Therefore, simply some kind of clay mixture, poured and even compacted when laying with feet or hand tools, will not provide a waterproofing effect. But it will be perfectly susceptible to frost heaving - an increase in the volume of soil when water freezes in its pores. This is especially true for clay soils.

In winter, the clay around the rings expands. And since it cannot expand in the horizontal direction, it does so vertically - along the shaft of the mine, while tearing off the upper rings. Cavities form under the clay layer: the soil around the rings continues to shrink for several years, and the castle has a different density and structure. Water and all kinds of debris, including the corpses of dead small animals, get into the resulting cavities.

An improperly constructed clay lock does not prevent untreated surface water from entering the well, but further aggravates this process. Therefore, if you are not sure that the waterproofing layer of clay will be laid correctly, it is better not to create unnecessary problems for yourself.

A well is a water intake structure

Often, thoughts about the good construction of wells for their future owners come down to determining the required number of concrete rings, purchasing them, finding the “right” team of diggers and choosing the design of the well house. Meanwhile, a well is a water intake structure, the structure of which is somewhat more complicated than just a hole in the ground.

The water in the well is not always clean

You can read about well rings in the publication Some misconceptions of those who want to have a well: about well rings. Choosing a team of well masters is generally an intimate question, one might say, almost the same as choosing a marriage partner: everyone has their own views on what an ideal master should be. Therefore, let's turn to that part of the well that is above ground level - to its head.

There should only be water in the well

I won’t go into detail about what kind of well houses there actually are - the purity of the water does not depend on what color you paint this structure. However, it is necessary to ensure that nothing foreign gets inside the well, namely: debris and dust, leaves, small animals and insects.

Nothing foreign should get inside the well

A living frog, oddly enough, will not spoil the water in the well. They say that our grandmothers and great-grandmothers even deliberately threw a frog into milk so that it would not quickly turn sour. But an amphibian that gets into a well will most likely not be able to get out along the steep walls. A frog dying of hunger will not add purity to the water.

The neck of the well must be securely closed. The neck of the well must be securely closed - this will protect against the entry of plant debris, prevent the death of the poor frog and protect your own youths from accidents. Even if you do not plan to install a water supply system, it is advisable to install a pump, for example, a manual one, on the well. This way it’s easier to lift the water, and the hole is always closed, and you can’t splash around in the water with an unsterile bucket.

Install a hand pump above the well - it's practical

Well house

A house is often built over a well. In most cases, its function is purely decorative. But the installation of a roof over the well is also more important than just a design element of the site. The canopy should perform the same role as the roof of the house - to protect against precipitation getting inside. Therefore, it is worth making the slopes wider, so that the water flowing along them falls to the ground as far as possible from the well.

The canopy removes atmospheric water from the walls of the well

This will reduce the amount of water flowing down the walls of the well in the ground. This means that untreated water will not get into it.

About frost

A house above a well can also serve another utilitarian service - to protect it from freezing in winter. Previously, when wood was most often used to strengthen the mine, freezing was less of an issue. Concrete rings conduct the cold inside better. If you have the desire and opportunity, you can additionally insulate the well trunk in the upper part to the freezing depth. For example, with expanded polystyrene, and before you finally fill the soil around the head or make a clay castle.

To protect the well from freezing, a tight lid is enough

Although in most cases, just a tight lid covering the hole in the shaft is enough.

How to determine the quality of clay?

Clays for construction come in different fat contents or plasticity, but fatty ones are more suitable for making a clay castle or clay lubricant. In turn, the fat content depends on the content of impurities in the clay - the fewer impurities, the fattier it is. The fat content of clay differs even in the same quarry.

Fatty clay almost does not allow water to pass through and is washed away with great difficulty by water, which is why fatty varieties are best suited for constructing waterproof or waterproof lintels, dams, dams, locks around water wells and cellars, and blind areas around buildings.

Fatty clays are also suitable for constructing clay-straw roofs, since the fatter the clay, the less it will be washed out of the straw by rain and melted snow water, and the longer the roof will last without repair.

Medium clays are also suitable for waterproofing work, but for this they must be cleared of sand by elutriation (the technique is described below).

There are many ways to check the quality of clay. Experienced craftsmen simply need to rub a clay sample between their fingers, but this requires a lot of practice. If you have no experience, you can use one of the methods below.

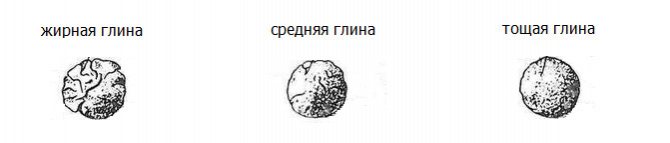

Method one (accurate)

Take an empty faceted glass and dilute the clay in it with water. They wait, and when the sand settles, they compare different types of clay. Based on the results of the inspection, a conclusion is drawn using the following rating scale: fatty clays contain 10-15% sand, medium clays - 15-25%, lean clays - more than 25%.

Method two (the easiest)

take a sample of clay that is not contaminated with soil, peat and grass roots, and rub it between your fingers. If the raw material is fatty, then when rubbed you will not feel sand, pebbles, etc., the material is soft, like lard, and plastic, that is, it softens easily and takes on any given shape.

A formed clay ball with a diameter of up to 5 cm should not crumble when kneading it with your hands, but should look like good dough or putty. If cracks form on the surface of the ball or it crumbles, then such material is unsuitable for waterproofing and roofing work.

A ball of fatty clay, thrown from a height of 1 m onto a concrete or wooden floor, takes the form of a cake that does not crack or crumble.

If the surface of a ball of clay soil dried in the sun and wind is severely cracked, then the fat content is high; if it cracks slightly, the fat content is medium; does not crack at all - the clay is thin.

Pure fatty clay does not creak when tested “by the tooth”, and sand is not felt in it.

Method three

It is used when there are several types of different clays and takes about 1 day. For analysis, take 50 g of each type of clay and make one ball from each sample. The balls are dried slowly in the shade, without wind. After drying, all the balls are simultaneously lowered into small containers of water.

A ball of thin clay falls apart after 2 hours. This material is completely unsuitable for constructing a clay castle, waterproofing and roofing work.

A ball of good fatty clay does not fall apart for 24 hours (and sometimes more). Intermediate options indicate average fat content.

How to prepare material for work

Clay of any color is suitable for insulation work. The main thing is that it has as little sand in it as possible. It is better to take clay that takes a very long time to get wet. This is a criterion for small sand impurities in it.

It is important to remember that the less sand there is in the clay, the better and denser the castle around the base of the building will be.

The best option is to prepare the material in the fall, six months before future use. For clay, it is necessary to allocate a certain place where it will be exposed to frost, precipitation and other weather conditions. This way, in the fall and spring, the wind will be able to sift out the sand from the top layer. And frost in winter will add strength and durability to the material due to cycles of freezing and thawing.

In the spring, immediately before use, 3-4 days before use, the clay should be filled with water and covered with film. Let it become a homogeneous viscous material. Then it will be easier to lay and compact it. And its characteristics will improve.

Some owners prefer to make the clay mass 1-2 days before use. This is not important. But it is better to let the clay brew to the required condition.

You can easily check the readiness of the mass. Take clay into your fist and squeeze it tightly for half a minute. If a dense lump remains on your open palm and does not crumble, the material is ready for use. Otherwise, you should fill the clay with water and let it sit for a little more time. This takes from several hours to a day. And after such a procedure, checking the readiness of the clay should be repeated.

Making a clay castle for foundations

Waterproofing the base of a house with a clay castle can be divided into several steps:

- soil preparation before laying the material;

- laying the first layer of clay - primary waterproofing of the base of the foundations;

- construction of a dense castle made of wet clay with mandatory compaction;

- waterproofing with a second layer of material for greater strength.

The soil must be leveled and any roots or stones present in the soil at this level must be removed. If necessary, the soil can be treated with herbicides to remove deep roots.

Now it is imperative to lay a sand or gravel cushion at the bottom of the resulting trench in front of the foundation. The pillow is generously moistened with water and compacted.

Next comes the turn of the clay castle, which is laid out in a not very thick layer so that it can be carefully processed and compacted. After a while, a second layer of wet, greasy clay is applied with mandatory compaction.

Next, the clay screen can be filled with a thin layer of mortar to protect it from contact with the reinforcement. Experts recommend this procedure so that the reinforcing belt lasts longer and the foundation shrinks evenly.

Schemes and methods of design

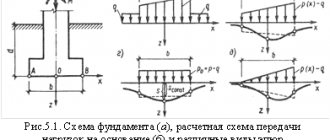

Clay castle around the foundation or basement -

time-tested one of the most reliable methods for waterproofing the basement and foundation. The diagram of a waterproofing clay castle is shown in the corresponding figure on the right. During construction, crumpled fatty clay is laid in even horizontal layers. For foundations with a depth of up to 2.0 m, the minimum width of the clay castle is: in the lower part - 0.4 m; at the top - 0.25 m. You can make a castle in two ways:

- The first method is to lay the prepared material in layers 5-10 cm thick in adjustable formwork (or directly into the foundation pit). Each laid layer must be compacted and compacted

; - The second method is to lay out a clay castle around the foundation or cellar with cakes or wet lumps of clay. Clay cake is a lump of soft clay the size of a watermelon, and to obtain cakes, this lump is squeezed on both sides.

During breaks between work, the laid clay is covered with a moisture-proofing film. In addition, the surface of the clay castle for the foundation must be covered with a film until work on the construction of the blind area begins. In this case, if necessary, it is necessary to organize rainwater drainage.

Construction of the blind area begins no earlier than 2 weeks after waterproofing is done using a clay castle.

Clay castle around the well -

- option 1 (see picture) - to install a clay castle, the well shaft is dug from the outside to a depth of 150-180 cm from the surface of the earth (to the second seam) and a width of 50-60 cm. The trench is filled with clay and compacted periodically. A mound is poured on top 15-20 cm above the surface of the earth with a slope from the well or a clay blind area is made;

- option 2 – more advanced. Unlike option 1, before the trench is filled with clay, the seams of the well are wrapped with geotextile fabric or other filter material (if they are not available, then you can use polyethylene). The filter will protect the well from clay if the top seams of the well burst;

- option 3 - the trench is dug wider than in option 1 and option 2. The seams of the well are wrapped with filter material. Sand is poured around the well in a layer of 10 cm to the entire depth of the trench dug around the well, and clay is placed in the remaining part. In this case, the likelihood of the well seams diverging is reduced, but even if this happens, the seams are protected by a filter.

Construction stages

At the preliminary stage of construction, clay should be selected. Recently, bentonite is increasingly being used, which practically does not shrink and does not crack.

The next step is to prepare the clay mass. To do this, it is filled with water the day before the start of work.

An important condition for preparation is not to let the clay mass dry out, so it is better to carry out work in the autumn. It should not crumble when compressed and be plastic.

Next, an adjustable formwork is constructed, for which not only its thickness is taken into account, but also the depth of the foundation.

The height of a clay castle should not be greater than the height of the base of the structure, and it narrows slightly towards the top.

The clay is applied in layers of 10 cm, since each layer must be carefully compacted. In case of breaks between laying the material, it should be covered with a moisture-proof film to prevent drying out and the appearance of cracks.

At the final stage, a mandatory construction requirement is the arrangement of the blind area. Its main task is to protect the clay castle and the foundation of the house from the negative effects of moisture.

The blind area is built two weeks after the completion of work, and throughout this period the castle must be protected from precipitation with plastic film. It is also necessary to construct a drainage system for precipitation.

Common errors

- When building a foundation, basement, cellar or well, it is not always possible to obtain clay (loams) suitable for constructing a clay castle. In this case, the material needs to be purchased, so in order to reduce the cost of construction for a clay castle, they use everything that remains in the soil dump;

- The clay poured into the castle is not crushed or compacted, but simply compacted with feet or a tamper (a piece of log with handles). With this technology, the structure of the clay does not change and it cannot become a reliable waterproof barrier. Clay must be kneaded - in the old days it was kneaded with feet;

- During construction, the dimensions (volumes) of the clay castle are not maintained. They are made significantly less than required, so the clay castle turns into a blind area made of clay.

.

Sources

- https://GidroGuide.ru/material/glina-dlya-gidroizolyacii.html

- https://7dach.ru/NatashaPetrova/nekotorye-zabluzhdeniya-zhelayuschih-imet-kolodec-ustroystvo-glinyanogo-zamka-153718.html

- https://RuFundament.ru/zashhita/glinyanyj-zamok-vokrug-fundamenta.html

- https://podomostroim.ru/kak-svoimi-rukami-postroit-pogreb-glinyanye-smazki-i-glinyanyj-zamok/

Drainage and blind area

To drain water directly from the walls of the well, in addition to installing a wide canopy over the well, you need to make a soft blind area, and, if necessary (if the well is located in a hollow in the relief), drainage drainage.

A properly constructed well will not create problems with its use

Then your water source will be fed only by groundwater, and you will be able to avoid problems with regular well repairs: settling rings that have come off after winter, trying to keep them from regular seasonal movements using metal plates and bolts, and other troubles.