To shape the concrete solution, special structures are used - formwork. These forms can have different designs and are made from different materials. One option is corrugated sheet formwork.

This option is usually used for the construction of floors and flat roofs of buildings. The technology of constructing floors using permanent forms has become widespread, since the resulting structures are highly durable and resistant to loads.

Is it possible to use corrugated sheets for formwork?

Corrugated steel is a popular building material for roofing and cladding work. This material has acquired its practical use due to its quality. It is very durable and adds the necessary rigidity to the monolith. In order to make a monolithic interfloor ceiling or a flat roof, the best material for formwork is a profiled sheet.

Formwork made of corrugated sheets

Corrugated sheeting can withstand enormous loads due to its load-bearing capabilities. When working with this material, you can significantly save on concrete and reinforcement of the monolith. This is especially suitable for industrial buildings and complexes.

Floor calculation

Drawings must be drawn up for the project, and calculations are made in accordance with the recommendations of SNiP, STO 0047 -2005 (preferably with the help of professionals). The dimensions of the building, the size of the installation step of the transverse beams, their length, the load on them and on the columns, the characteristics of the load-bearing profiled sheet (width, length, thickness of products, profile height) are taken into account. It should be assumed that each sheet along its length should be supported by 3 beams. Based on the planned load on the floor, the cross-section of the reinforcement and the height of the slab are calculated.

Its thickness is determined from a scale ratio of 1:30, depending on the distance between the transverse beams. A monolithic concrete slab can have a thickness from 70 to 250 mm. The weight that a monolithic floor will have will determine the type and number of metal columns, the parameters of their foundation, the type of beams, and the amount of load on one column. The depth of the waves of the sheet profile affects the distance between the beams: the greater it is, the more often the beams are installed, since the mass of concrete in the recesses of the profile increases when it is not practical to increase the thickness of the slab.

Reducing the span pitch eliminates sheet deflection. It is necessary to take into account the weight of the additional payload that the interfloor ceiling will take - 150 kg/m2 is taken as the norm, which should be increased by 33%. The total operating load is calculated with an error of up to 0.5 kg.

From it the cross-sectional dimensions and length of the beams are determined. Vertical rod anchors allow you to combine profiled sheets and reinforced concrete, which transfers part of the load to them. For a span of 3 meters wide, a material with a thickness of at least 0.9 mm will be required. In practice, calculations are compiled into software that allows the generation of working documentation.

Use of removable and permanent formwork for floors

Formwork is a structure for pouring concrete so that it does not spread and acquires its basic shape. Formwork is made from different materials. The quality and suitability of the foundation depends on the material. Corrugated sheets have become very popular for this use. All this is due to its durability, versatility and ease of installation. It is used as part of a building or removed and reused.

There are two types of formwork used in construction:

1. Removable formwork - a constructed structure of this type is disassembled after the concrete has hardened. It can be used again for another object.

2. Permanent formwork - this structure remains after concrete is poured.

Monolithic ceiling device

Profiled sheets, reinforcement and concrete are the components that form a monolithic concrete floor slab. This design, if supported by a beam frame, distributes the load onto the columns rather than the walls. Each column has its own foundation. Another option is when the cross beams are not laid or, if installed, rest on the walls.

In this case, the monolithic floor will have to load the walls of the structure and the foundation. Metal beams - I-beam (channel). Their edges are strengthened in the “pockets” of the walls (columns) and welded to the mortgages. Sheets can be attached to beams on the internal shelf, then the distance between the supports for short sheets is chosen to be no more than 1.5 m. On channels/I-beams, profiled material can also be installed on the external shelf on top so that sheets up to 6 m long can be placed .

They are installed overlapping along the length. A stationary beam is placed under the middle of the sheet elements. The profile waves should be perpendicular to the beams, and the corrugation extensions should be oriented downwards.

With a beamless version of the device, corrugated sheets will not have support points in the middle of the room. A mandatory element is volumetric reinforcement, which significantly increases the strength of the monolith. The reinforcement is connected by welding to beams and columns. To distribute the solution, external removable formwork can be installed. Concreting creates a smooth surface of the slab.

Fixed formwork made of corrugated sheets

Fixed formwork made of corrugated sheets

Permanent formwork made from corrugated sheets has enough rigidity to form an excellent foundation; it is laid on metal floor beams. The corrugated sheet base serves as formwork and performs reinforcing tasks. The corrugated sheet can be easily cut into the required parts, so any formwork can be assembled from it.

The use of this material reduces the weight of the building, which has a beneficial effect on the durability of the building. The monolith receives additional rigidity due to the resulting ribs.

Therefore, it has become practical to use this material for permanent formwork. This formwork also eliminates the use of a large number of supports; it is kept to a minimum. Particular attention should be paid to such advantages as:

- Structural strength.

- The sheets are resistant to moisture, which will protect your building from destruction.

- The sheets are resistant to dampness and fungi, which will have a beneficial effect on the safety of the building.

- Affordable price.

- Easy to use.

Composite boards

A composite slab is a slab that uses concrete and corrugated sheets for floors. The rigidity of the profile is used to further strengthen the reinforcement. The main indicator is the height of the corrugation. The higher the corrugation, the smaller the number of load-bearing beams.

A corrugated sheet is fixed into each wave, which increases the strength of the base. Such plates improve moisture protection and preserve their appearance from scratches. This design has a huge advantage to the fire safety of your building, which has a good impact on safety.

Fastening the corrugated sheet

Formwork is an important detail of the future building. To ensure reliability, its fastening must be carried out in strict sequence.

A number of preparatory works must first be carried out, including:

- drilling wells to clarify the hydrogeological conditions on the site;

- drawing up a foundation drawing taking into account calculations and laboratory information;

- clearing the area for the future foundation from vegetation;

- marking the foundation in accordance with the drawing;

- digging a trench with the required depth;

- drainage filling of the bottom of the trench with a 15-centimeter layer of river sand;

- compaction of drainage;

- checking horizontality using a high-precision laser building level;

- laying waterproofing over drainage.

Proceed to the immediate assembly of the formwork. The required stages of the process are:

- Installation of vertical metal beams (at least three).

- Laying corrugated sheets using the overlapping method in one or two waves. It is important that its ribs are located perpendicular to the supporting beam. It is recommended to use reinforced screws 5.5x32 mm as fastening elements. In places where metal sheets overlap, rivets are used to provide additional fastening.

- Creating a wooden partition at the ends of the formwork - its height should be identical to the thickness of the concrete layer being poured.

Creating a flat roof from corrugated sheets

Creating a flat roof from corrugated sheets with insulation

Flat roofing made of corrugated sheets is a modern and cost-effective solution. The most positive quality of such a roof is its price; it is affordable to every developer. The basis for this type of roof is the covering of the topmost floor of the building. Such roofs are most often called: “Without attics”. They help protect the structure from weather conditions. A flat roof will last you a long time.

Reinforcement

The internal metal frame in monolithic concrete provides compressive work, which ensures the original strength of the slab. The volumetric reinforcement structure is formed from a flat welded mesh with cells 15 x 15 cm and longitudinal sections of reinforcement laid on the bottom of each stiffener, which are united by vertical connections with ligation wire or welding. The volumetric dressing step is 20 cm. The ends of the metal rods and mesh are welded to the beams and columns.

For reinforcement, a steel rod with a diameter of 10 - 12 mm (grade A 400C) is taken. The mesh can be created from longitudinal rods with a diameter of 12 mm and transverse rods with a diameter of 0.6 cm. In order for the corrugated sheet to become an external reinforcement, notches (“reefs”) are created on the profile that adhere it to the concrete.

Required tools and materials

To build a foundation for a fence made of corrugated sheets with your own hands, you will need:

- shut-off valve;

- felt grater;

- rolling machine;

- shovel;

- big screws.

Required building materials:

- cement;

- brick;

- boards for formwork;

- sand;

- gravel for backfilling.

Useful Which poles are best to install for a chain-link fence and after how many meters

You will need a measuring tape and reinforcing bars for the frame.

Saving Tips

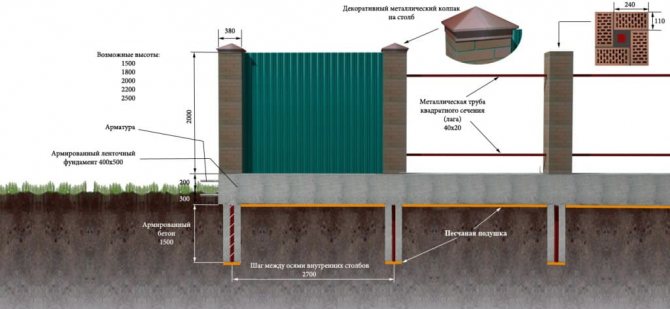

An economical option for building a fence from corrugated sheets is to lay a columnar strip foundation. The following recommendations will help make construction less expensive financially:

- It is recommended to purchase building materials, necessary tools and auxiliary equipment in advance.

- Tape construction does not require labor costs; with minimal construction skills, it is better to do it yourself (there is no need for additional costs for inviting builders).

To save time and money, columnar and ribbon types are recommended.

Installation of strip foundation

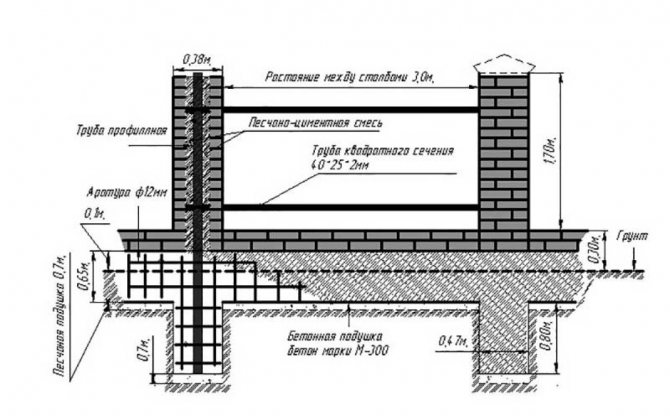

Installation work to create a column-strip foundation includes a strict sequence of work. It includes preliminary marking of the site according to the size of the future fence, carrying out excavation work, and creating a sand cushion. Next, the formwork is installed and the reinforcement is weaved. The last stage is actually pouring the foundation.

Useful How to properly make a strip foundation for a fence with your own hands

Stage 1: marking

Before installing the tape, you need to pre-mark the trench. The site does not require complex preparation; it is enough to remove debris and weeds. The only condition is preferably a flat area. When there are differences in height, these places are marked carefully.

The marking process includes:

- Taking measurements. The required distance at which the pillars are placed is determined. Most often from 3 to 6 meters.

- Installation of pegs. They are hammered in where the corners of the fence are planned, then near the gate and gate.

Expert opinion

Vladimir Ulyanov

I have been involved in fences for over 10 years, answering questions and helping people cope with the installation task on their own.

Ask a question to an expert

A strong cord is pulled between the driven pegs. The correct installation of the pole cloth depends on the correctness of the markings.

Stage 2: excavation

Earthworks include:

- Digging a trench. It is carried out along the length of the fence. The width of the trench is equal to the size of the foundation. The height of the walls is determined taking into account the characteristics of the soil. It is 50–70 centimeters.

- Alignment of walls. Afterwards, be sure to check the verticality of the walls using a plumb line. If necessary, alignment is done.

- Place for supports. In places where concrete supports are installed, additional recesses are made. It's easier to do it with a drill.

The bottom of the trench is carefully leveled, this improves the quality of the sand cushion.

Stage 3: preparing the sand bed

The sand and gravel cushion is an element that resists deformation due to frost heaving. Install the sand and gravel cushion:

- A 10-centimeter layer of sand is poured onto the bottom of the trench and compacted. The first layer is pre-shed with water.

- Next, add a layer of gravel. Spray with water, then compact.

Special equipment is used to compact the pillow. For additional savings, it is possible to build a rammer from logs.

Stage 4: reinforcement and formwork creation

A layer of waterproofing material is laid on top of the pillow; rolled roofing felt is recommended. Afterwards the reinforcing frame is mounted:

- On top of the pillow there is a brick lining.

- Reinforcing bars are laid on top.

- Horizontal rods are laid at a distance of 3-4 centimeters.

- Vertical frame elements are placed at the intersection of horizontal and transverse rods, with an interval between reinforcement of 50 centimeters.

- Horizontal and vertical rods are connected with soft wire.

Useful Advantages of a fence on screw piles, types of posts and installation features

For additional structural strength, horizontal rods are added. Afterwards, the wooden formwork is installed.

Stage 5: pouring the foundation

Before pouring the base, concrete pillars are installed in pre-prepared recesses. Concrete is poured in 2 steps:

- The holes around the support posts are filled first. The poured mass is compacted using a metal rod.

- Next, the trench is filled with cement-sand mortar. The solution is thoroughly compacted.

After pouring, the surface is leveled. Next, they are covered with a waterproofing material, usually polyethylene film. The formwork is carefully removed after 7 days, when the concrete has hardened.

Previous

Foundation and pillars How to properly install metal fence posts with your own hands, installation methods

Next

Foundation and pillarsStep-by-step instructions for concreting fence posts - Finnish technology

Manufacturing

To work you will need:

- sheet plywood 2 cm thick;

- formwork profile 120x60 mm;

- fasteners (screws);

- tape measure and pencil;

- level;

- metal cutting tool;

- welding machine;

- primer for metal;

- carpentry tools.

We work in this order:

- The plywood must be cut to the dimensions of the structure being poured.

- We cut the formwork profile according to the height and width of the formwork panels.

- We make a frame from a profile pipe. To do this, by welding we connect pieces of cut pipe into a rectangular structure and reinforce it with transverse jumpers from the same pipe. To check the evenness of the structure, you need to measure its diagonals. They must be equal.

- Since the metal structure may come into contact with the mortar, the steel frame must be treated with a primer to protect it from corrosion.

- The frame of the structure must be connected to plywood. To do this, we drill holes in the plywood and frame and connect all the elements with screw fasteners.

- After this, we drill holes around the perimeter of the structure and in its middle part. In each formwork panel, the alignment of the holes must be observed. After installing the shields, tubes and studs will be inserted into these holes and tightened with nuts.

If you have any questions about the manufacture of formwork from profile pipes, you can ask them to a specialist from our company. To do this, you need to contact us by phone listed on the website.

Filling ceilings using corrugated sheets

If possible, the floor is concreted at once or in whole spans of floors. If this is not possible, a schedule is accurately recorded taking into account the setting time of the material. It is advisable to use ready-mixed concrete grades from M300 and higher with a fine fraction of crushed stone (up to 5 mm), which can penetrate the formwork under the reinforcement. Vibropressing is mandatory.

Concrete work is done at positive air temperatures; at negative air temperatures, the concrete must contain anti-frost plasticizers. First, the solution is poured into the perforations of the sheet, and then along the platform. When attaching sheets to the inner flange of the I-beam, the mixture is poured to the level of the upper flange.

The solution is leveled with trowels and “ironized” with dry cement to protect it from external influences. The minimum thickness of a beamless ceiling is 250 mm (counting from the bottom edge of the profile), in the beam version - 70 - 80 mm (excluding profile height). Caring for the material includes regular moistening and covering with moisture-absorbing materials until the strength reaches 70% (10 - 14 days at 20 degrees).

In cold weather, the maturation of the stone is significantly prolonged; its surface should be insulated. Under optimal stone maturation conditions, temporary supports are removed after 28 days. The material is ready for further processing.