About concrete.SU / Information / Foundation There is still such a stereotype that the construction of a house should be carried out only in the warm season. Modern developers are trying to break this misconception by proving to customers that construction can be carried out year-round.

Let’s say it is preferable to install a log house in winter, since the structure shrinks better and the material does not rot and mold. But before installing the log house, you need a reliable foundation, which can be poured in advance.

At what temperatures does the formation of cement stone end?

To fully understand at what temperature in the fall, without reducing the characteristics of the supporting structure the foundation can be poured , it is necessary to take into account the processes occurring inside the concrete during hydration. Water is present inside the resulting structural material in a chemically and mechanically bound state.

When the outside temperature decreases, the liquid in the capillaries and crystal lattice does not freeze immediately:

- at -1 degree up to 20% ice is formed

- at -4 degrees its amount increases to 60%

Concrete has some thermal resistance, so inside the reinforced concrete mass the liquid phase of water can persist even at -30 degrees. The worst option for autumn concreting is the freezing of the structure within 30 minutes after laying the mixture. In such a foundation there will be 90 - 97% ice, there can be no talk of any design characteristics.

If the concrete has gained a certain amount of strength, the situation changes:

- ¾ brand strength – 14 – 22% ice at a temperature of -3 – -5 degrees, respectively

- half the design strength – 20 – 27% ice at similar temperatures

- 1/3 strength – 30 – 48% ice

Attention: If the amount of ice in concrete does not exceed 20%, the material continues to gain strength at negative temperatures within -5 degrees.

As soon as the temperature drops below this value, the liquid phase of water, instead of maintaining the hydration process, causes microcracks to open. The main factors in the iciness of concrete are the water-cement ratio, degree of hydration, and hardening time. Influencing these characteristics makes it possible to obtain a reinforced concrete structure with the specified characteristics during the autumn pouring of the foundation.

Cement stone has a finely porous structure, so the liquid contained in the capillaries tends outward, into a zone of lower temperatures. Thus, the perimeter of the foundation becomes more saturated with water than the core of the massive structure. When freezing, the volume of water increases by 9%, and large cavities form in the surface layers.

After thawing, the cavities increase the moisture permeability of the structural material. Therefore, the most dangerous temperature barrier for concreting foundations in the off-season is -3 - - 5 degrees.

Attention: If the mixture is placed in formwork and kept there at a temperature within -2 degrees, it is guaranteed to gain 60% strength without additional effort on the part of the developer. There is no need for insulation or the use of anti-frost additives.

However, even at -5 degrees, the foundation will not be able to gain more than 18%, which is not enough to continue the processes of cement stone formation in the spring after thawing. In the absence of heating and chemical reagents at -10 degrees, concrete is not able to gain strength at all.

Where do legs grow from?

One famous movie character once said that smart choices come with experience, but stupid choices lead to experience. When everything is done correctly, we sometimes don’t even think about what serious troubles we avoided, but we remember our mistakes for the rest of our lives.

It all started with the construction of a small garden house. The classic strip foundation was chosen. To tell the truth, I didn’t even know about anything else at the time, and it began...

Many people then advised me to pour the foundation before winter, so that for a good quarter of a year the foundation would stand and find its place. Then, they say, not only a house, but an entire house can be built without fear.

No sooner said than done, at least I had to work hard.

First, I cleared the selected area of debris and leveled it in a horizontal plane, and therefore had to take up the shovel even before digging the trench.

Then markings. For this purpose, I hammered pegs into the ground and pulled the lacing along the lines of the future foundation.

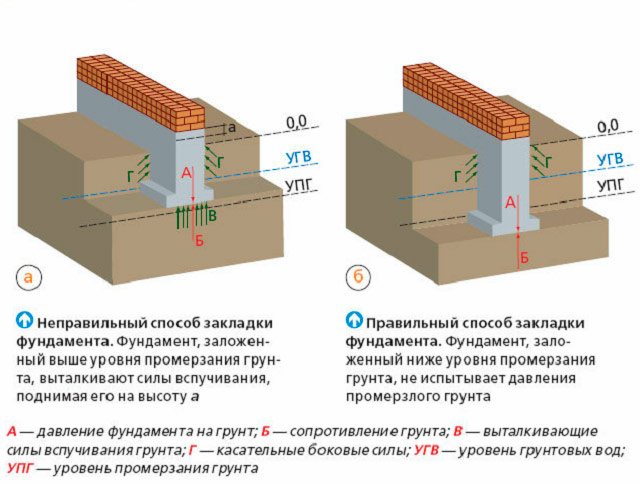

But we had to dig a lot. Our freezing depth is more than a meter, and the tape cannot be raised shallower.

Then I put up formwork from the boards, poured out a small sand cushion,

And then I filled everything with homemade concrete grade M 350.

It’s a pity that at that time I was too green, and therefore, after listening to the assurances of my neighbors, I decided not to lay reinforcement in the foundation.

Let me remind you that all this happened in late autumn (oh, damn those advisors) and the first surprises were not long in coming. The frost hit exactly two weeks after pouring, while concrete needs at least 28 days to gain full strength. Not pleasant, right?

No, I knew that in the spring the hardening process would continue, but the result would still not be the same.

After wintering, another “gift” was waiting for me - this is the level, or rather, its complete absence (and I wasted so much time to clearly set the formwork).

“You see,” the friend continued. “And the house could have sunk!”

But the soils were reliable, and the weight of the foundation was not so significant that the difference after subsidence was up to 5 cm.

The enemy came from where they did not expect: frost heaving. I thought that if I put the foundation on non-freezing soil, I would be completely protected from it, but that was not the case.

It turns out that heaving acts on the foundation and through the side walls tangentially, however, these forces are insignificant and cannot lift the entire house, but they are quite capable of handling an unloaded belt. Therefore, the frozen soil twisted the foundation as it wanted. To top it all off, the base cracked in several places.

My “joy,” as you can guess, knew no bounds. How much cement was wasted, and how much labor... But I didn’t want to put a stone building on a defective foundation, and therefore, as soon as the soil melted, I started construction again.

I decided not to touch the old foundation, but simply pour a concrete strip along its outer perimeter. At the same time, the house increased in length and width by almost a meter, but the prospect of digging a concrete monolith out of the ground made me shudder.

Despite the fact that the foundation pit was dug in April and the formwork was installed, I only started concreting in mid-May. The lesson was learned, and therefore I did everything according to science. So, knowing at what temperature concrete sets best (which is 15-20 ° C), I took time so that the thermometer could reach this mark at night.

Autumn concreting technology

Laying the mixture inside the formwork at positive temperatures in the fall is no different from standard technology. Heat is released during chemical reactions, so it is enough to store it inside the structure along with the water necessary for the formation of cement stone.

In 30 degree heat, the structure gains the required 70% strength in 3–4 days. In the fall, the process drags on for several weeks, but if normal hardening is ensured without freezing the foundation in the first three days, the concrete will continue to gain strength in the spring when the weather warms up.

Labor costs and construction estimates largely depend on what type of foundation is included in the project, geological conditions, and region of operation.

Attention: Any foundation can be poured in the fall. However, less effort and money will be needed when protecting piles from freezing, more for a floating slab, MZLF.

Water-cement ratio W/C

For the chemical reaction of cement stone formation (hydration), 1/3 of the mass of cement is enough water. However, such a solution has zero mobility, plasticity, layability, air cannot escape from the mixture even when compacted with a vibrator. Therefore, in concrete, an obviously excessive amount of water is used, which is necessary to prepare a plastic mixture.

When temperatures are positive in the fall , concrete can be mixed on site, significantly reducing the construction budget. An individual developer should consider:

- the higher the water-cement ratio (maximum 0.8), the faster the structure will gain strength

- W/C can be reduced only by increasing the grade of cement, which is more expensive

- The foundation can in the fall only if the technology is strictly followed (from mixing to stripping)

- compaction with a deep vibrator is a prerequisite, since the solution has minimal plasticity even with the addition of a Superplasticizer

The simplest way to calculate the required proportion of water for the maximum possible W/C is the test mixing technology:

- 3 shovels of cement mixed with a shovel of sand (by volume)

- field of adding a small amount of water (necessarily from a bucket, not from a hose, to control the amount) the components are mixed

- then add 5 shovels of crushed stone

Next, the concrete is mixed with the addition of water to obtain a thick solution. A lump (ball) is formed from the mixture and placed on a hard surface. The minimum volume of water sufficient for normal mixing of the components must be remembered in order to prepare the required volume in a concrete mixer.

The mixture should not stain your hands with cement, and the ball should not spread when it dries for 5 to 15 minutes. The delamination of concrete in a lump indicates a lack of water, and the melting of the form indicates an excess.

Attention: With the maximum water-cement ratio, using Portland cement M400 - M500, you can reduce the time to gain strength by up to 75%. After which, the reinforced concrete structure is not afraid of freezing. In the spring, the foundation thaws and continues to gain original strength.

What supplements should I use?

The use of anti-frost additives (AMD) is economically beneficial only at negative temperatures in autumn in the range of -2 - -5 degrees. In severe cold weather, apart from heating the formwork and concrete, this technology will not save; at above-zero temperatures, it is quite possible to do without chemical reagents. The following types of PMD are most in demand:

- sodium formate - accelerates the hardening process of cement stone, recommended consumption is 2 - 6% of the total mass of the solution, often used in combination with naphthalene lignosulfanol

- sodium nitrite - used in severe frosts, toxic, consumption 0.1 - 0.4 l/kg of cement, reduces the crystallization temperature of water

- potash - concentration within 30% by weight, is a retarder, without sulfite-yeast mash, sodium tetraborate reduces the strength of the mixture

Attention: Manufacturers produce special PMDs of various brands with complex modifying additives. Following the instructions on the packaging, you can fill the foundation in the fall within the specified range of day and night temperatures.

PMD additives are mixed in water during the preparation of the mixture. After mixing is completed, it is prohibited to increase the plasticity of concrete by adding water.

Heating the mixture components

At temperatures below +5 degrees, the foundation can be filled with a heated mixture. Moreover, only water and fillers are heated before mixing. Cement loses strength as the temperature rises. In this case, you need to take into account:

- sand, crushed stone can be heated with steam, water, calcination on metal sheets up to 35 degrees with periodic stirring

- water can be heated in autumn up to 40 degrees

In the latter case, water is pre-mixed with fillers, then a binder is added to the mixture. If you pour hot water over cement immediately, it will “steam” and lose its properties.

At what temperature can the foundation be poured - features of the work

Work on the construction of the foundation is considered an important construction stage. The main factor influencing the final result is the air temperature and the quality characteristics of the concrete mixture. Today we will consider at what temperature the foundation can be poured so that the foundation for the future structure is reliable and has a long service life.

The influence of temperature on the characteristics of concrete

Everyone knows that the solution hardens faster if the weather is warm, but the heat can have a detrimental effect on freshly poured concrete.

At temperatures ranging from 5 to 15 degrees above zero, the composition sets naturally, while the concrete releases heat into its environment. But on hot days this does not happen.

In such conditions, the concrete frame begins its formation with an even increased volume of material. When the temperature is lost, the surface gradually settles, and the formed crystalline structure creates obstacles to this process. Ultimately, due to the tension created inside, the foundation becomes covered with cracks in the fourth to twelfth hour from the moment the pouring is completed.

In order for the foundation to maintain its integrity at twenty-five degrees Celsius and above, it is necessary to use quick-hardening Portland cement to prepare the concrete, pouring it with water five to six hours after the end of concreting and shading it with available materials.

Slowing down of hydration is achieved by introducing plasticizing and modifying additives. Appearing cracks indicate that it is necessary to re-compact.

When is it better to build a foundation - attention to goals and opportunities

Experts distinguish two construction seasons: from April to December and from November to May. Needless to say that it is extremely difficult to build a structure in winter? But this is possible, especially with experienced and knowledgeable specialists. It goes without saying that starting in January, when the ground is already frozen, construction is quite problematic (special equipment, additional equipment for warming the soil, as well as protected places for storing building materials are required). But if smart calculations have been made and all the raw materials required for construction have been purchased in advance, it is possible to carry out work all year round, without delaying deadlines and saving the customer’s budget.

The most important thing is laying the base. When should the foundation be built ? Today, design and construction work can be carried out continuously, it’s just that a certain time is appropriate for each stage. There are many nuances regarding this matter, regarding the implementation of the construction of walls, ceilings and other types of work.

What time of year is the best for building a foundation? So, two options are acceptable:

- The foundation is laid in April-May, the walls are completed until October, and the construction of walls, roofs, and finishing is carried out until December. A continuous production process is guaranteed here; by winter the entire structure already has a roof, that is, it is completely protected from precipitation. It is important here - if you are planning a basement, then it is worth waiting out the spring flood and starting the construction of the foundation at the end of spring.

- The foundation is laid before severe frosts, in the fall (November is the optimal temperature for this), the walls are finally erected by March of the next year, then there is a break until May and finishing continues. This option also has its advantages. By the start of active construction work, the foundation had already given good shrinkage, and this guarantees the reliability of the house and simplifies the finishing work. The masonry is much stronger during this period, because in the summer the mortar dries out quickly and does not have time to gain the necessary viscosity and strength. The only drawback is the duration of the work and the need for breaks between some stages.

Optimal temperature for pouring a foundation

When planning the construction of the foundation, you should take into account the temperature conditions, the brand of cement material and its quality condition. Particular attention is paid to special additives that reduce the temperature of crystallization of water, and to maintaining proper conditions during the hardening of the concrete mixture.

The poured solution sets within twenty-four hours, after which it gains the necessary strength over the course of four weeks.

The standard temperature at which the base is formed is from three to twenty-five degrees Celsius.

Filling at minimum temperature

In order to properly maintain concrete mortar to critical strength levels, you should know the features of existing methods for this, their advantages and disadvantages.

Note that certain methods are used in combination with some analogues, in most cases with preheating of the concrete solution.

Conditions conducive to proper curing must be created outside the building. They consist in maintaining a certain temperature around the concrete.

And yet, is it possible to pour a foundation at sub-zero temperatures? The problem is that in such work at subzero temperatures, the main problem is associated with the slow hardening of the concrete solution.

If pouring is carried out at zero temperature, the processes occurring in the solution during its hardening simply stop. The moisture remaining inside the foundation significantly increases its volume, tearing the surface.

To avoid such negative manifestations, builders use certain technological techniques:

- certain components of the mortar mixture and the formwork structure are heated;

- a special wire is laid inside the structure to provide heating;

- heating devices are installed around the foundation;

- Special antifreeze additives are introduced into the concrete solution, accelerating hardening or lowering the temperature at which water begins to freeze.

If you have to pour concrete under the foundation in winter, it is recommended to reduce the amount of water used for mixing the solution.

You must be prepared for the fact that the listed methods will significantly affect the construction budget in the direction of its increase. Such methods, as follows from the reviews, are rarely used by novice developers.

Particularly popular is the winter concreting method, which involves reducing the amount of water and cement material in the mixture. But in this case, the components must be mixed in strict proportions.

In such situations, a quick-hardening cement composition is used, preparing the solution in a certain way:

- two parts of water are heated to seventy degrees;

- mixing with sand or crushed stone is carried out;

- Cement is fed into the concrete mixer and the remaining amount of water is poured.

Before pouring concrete, ice is removed from the formwork and the underlying cushion is heated. The structure of a strip or other foundation is covered with polyethylene so that the heat near the foundation is retained for as long as possible.

Knowing to what temperatures the foundation can be poured, it is still necessary to clarify the weather forecast. It is quite possible that you will have to think through the heating system. In addition, even at subzero air temperatures, it will be necessary to install waterproofing.

There are many reasons why concrete is poured onto the foundation during the cold season. But there are some advantages to such work that are recommended to be taken into account:

- Without preheating the solution, you can concrete the foundation in the part of the object located below the surface of the earth. In warm weather, loose soil crumbles, but in frosty weather, concrete can be poured calmly, because the soil will hold its shape;

- Having figured out what temperature is best for pouring the foundation in the winter season, you will save a lot on the cost of materials, for which prices do not increase at this time of year.

For those who are interested in how to fill a foundation in winter at sub-zero temperatures, we note that there are certain disadvantages. First of all, you will face a labor-intensive process of constructing a pit, because the soil will freeze and will be difficult to excavate. In addition, the work will be carried out at a slow pace, and you will expect additional heating costs.

Which foundation and when is it better to build?

The process of building a foundation is extremely simple if professionals do it. The InnovaStroy team knows what the customer needs, because each of you is connected by several things. Clients strive to get a comfortable, durable, strong home that will last for a long time and will not create problems in operation. At the same time, the goal is to minimize costs and bring the project closer to completion. Therefore, we offer cost-effective solutions regarding the choice of foundation for a house, focusing on the characteristics of the soil, climatic conditions, the depth of freezing and occurrence of groundwater, the weight and dimensions of the future building.

So, after specialists have carried out surveys on the territory allocated for construction, careful calculations are made and a specific type of foundation is selected.

If your site has sandy gravelly soils with deep freezing, then in this case a shallow strip foundation, lying to a depth of no more than 70 cm, is perfect. This is an excellent foundation in terms of price and strength, which does not require the presence of a cellar or basement. If dusty, fine sands are found, then a deep foundation is needed down to reliable earthen rocks.

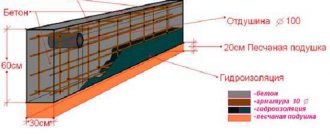

For the construction of a serious, strong house on peat and clay soils with high heaving rates, experts offer a turnkey monolithic foundation. Excavation work for such a foundation is not needed, just filling a sand cushion of 20-30 cm. Professionals will not offer this option if they detect even the slightest slope of the site. In this case, the slab will gradually “slide”, and the solution will be a pile foundation at a price that is much more attractive than other types of foundations.

What time of year to lay a foundation is, of course, a difficult question. You can lay the foundation in winter. But is such a rush and additional costs necessary? Today, there is a lot of special equipment that can be used to warm the ground and build a foundation in the winter. But it is also worth considering that in the spring there will be a noticeable shrinkage, different from what is usual for the summer period.

Will supplements help?

Experts say that you should not fill the foundation in winter without using special additives in the solution. It is believed that such additives solve all problems, since this method is the easiest for concreting at sub-zero temperatures, especially at night.

As developers assure, using additives, it is possible to pour a foundation at sub-zero temperatures without organizing heating. But if you work comprehensively, then by heating you will reduce cash costs.

If the minimum temperature for pouring the foundation causes you doubts, use one of the types of additives:

- substances and compounds that reduce the freezing point of water. With their help, normal hardening is achieved at negative temperatures. This group includes potash, calcium and sodium chlorides, sodium nitrite, combinations of such components and similar substances. The type of additive is determined taking into account the sub-zero temperature to which concreting is allowed;

- components and compounds that accelerate hardening. Among them are molasses, modifiers based on calcium chloride and urea, etc.

Additives are introduced in an amount of two to ten percent by weight of the cement material. Their volume is selected based on the temperature regime required for hardening of the artificial stone.

At what temperature in winter should additives be added? Builders use them at sub-zero temperatures of up to 25 degrees. But private developers should not resort to such experiments, since in reality such additives are used only at the first night frosts or with the onset of spring, when a foundation is needed for a specific period, and there are no other options for its construction.

Solving the problem of concrete freezing

The next insurmountable problem for builders of past years was that in frost, concrete loses its qualities, becoming brittle. This happens because its components do not mix under such conditions due to crystallization of water due to exposure to frost. Therefore, pouring the foundation in the fall, and even more so in winter, was something unrealistic.

Now everything is solved with the help of chemical additives that prevent water from freezing. In addition, special concrete is sold, which already contains substances that promote its normal hardening at sub-zero temperatures. Its properties are no different from its summer counterpart.

However, there is an opinion that it is undesirable to use chemical additives in the concrete of a residential building, because many of them are poisonous. Therefore, when constructing a building, you need to take this nuance into account.

Also, to pour the foundation, in October or February - it doesn’t matter, salt is added to the solution. Its content should not exceed 2%; it does not allow water to harden. Accordingly, all ingredients are fully mixed and frozen. Without heating, this method can be used down to -5 ° C, and if the temperature drops even lower, then it is worth using heating, which will be discussed later.

You can also make the solution not subject to freezing using acid additives. They are added, after which a chemical reaction occurs in the mixture, which increases the temperature. Under this influence, the concrete dries out. And, of course, in severe frosts, the foundation should be additionally covered so that the generated heat does not immediately evaporate.

What happens if the temperature regime is not maintained?

If you are in doubt at what temperature is best to pour the concrete mixture, consult with experienced builders. If existing requirements for concreting at certain times of the year are not met, negative changes may occur to the concrete base of the building:

- cracks will appear. As a rule, they are formed at temperatures exceeding twenty degrees Celsius, unless the uniformity of moisture drying and the process of hardening are controlled. As a rule, the poured base is covered with a film and periodically moistened;

- Microcracks form inside the foundation. At what temperature in spring and at what autumn does this happen? If the air does not warm up above three degrees Celsius, the water begins to transform into ice, increasing its volume. Then it dries, leaving behind microscopic cracks that contribute to the destruction of the concrete base;

- displacements are observed. When frozen sand or gravel is used to mix a concrete mass, pieces of ice get into the mass, forming void areas. Under the influence of the maximum load, the foundation base shifts;

- tension increases. The reinforcement frame of the future foundation, welded at a negative temperature, will expand in volume in warm weather and create increased stress on the structure, leading to emergency situations.

Is it worth building a foundation in the fall and a house in the winter?

The characteristics of the soil on which your site is located plays a big role. During cold weather, wet soil can expand and push out the foundation of a house, especially if it was not laid deep.

Therefore, if housing is located in a wetland, in the spring its owners may encounter certain troubles (for example, a cracked structure). To a greater extent, this applies to reinforced concrete monolithic foundations.

Cracks that occur in a monolithic reinforced concrete foundation Return to contents

Pouring concrete in the fall: where to start?

When planning the construction of a concrete structure in the autumn, you should know what weather factors affect the quality of the final product or structure. There are several objective factors, and they are well known to construction specialists:

- Ambient temperature. The optimal temperature regime for setting and strengthening of concrete is a temperature “differential” from 16 to 25 degrees Celsius. As the temperature decreases, cement hydration slows down, which has a positive effect on strength gain. It is very important that the concrete does not freeze. If this happens, the frozen water will literally “tear” the flooded structure from the inside. This is the main danger that comes with pouring concrete in the fall;

- Increased environmental humidity. This is a positive factor that allows us to exclude constant wetting of the concrete surface from the technology;

- Rain and downpours erode concrete, wash cement out of the surface and reduce its strength. This is a negative factor;

- Groundwater. A negative factor that requires either carrying out measures to dry the site, or using special construction technology, or postponing construction to the summer.

At the same time, if you think through and prepare everything before carrying out work, you can avoid the influence of negative factors and take full advantage of the positive aspects of autumn - the absence of summer heat and high environmental humidity.

As already mentioned, the main danger for hardening concrete is a drop in temperature below 0 degrees Celsius. Moreover, given that concrete gains strength within 28 days, low temperatures will pose a danger within one month after pouring.

Precipitation and groundwater can only cause harm in the first 48 hours after pouring, and their harmful effects can be easily dealt with. Therefore, when pouring concrete in the fall, the structure should be protected from frost and the construction rules stipulated in the current SNiP 3.03.01-87 “Load-bearing and enclosing structures” should be strictly observed.

Concrete hardening factors

Often, in order to have time to build a house in the spring and summer, the owners are always interested in whether it is possible to pour the foundation in October, so that in the spring, when it gets warmer, they can immediately begin building the house. After all, when the foundation is ready, construction will go much faster. And this is especially important when the building is planned to be large, and there is a risk of not having time to rebuild it before the next cold weather.

The quality of concrete is influenced by the following factors:

- volumes and dimensions of the structure;

- proportions of fill elements;

- quality of cement and its grinding;

- climate;

- possibilities for heating and insulating concrete.

In order for the cement to react faster, it needs to be ground as finely as possible, then pouring the foundation in October will be of much better quality, because voids will not form in it. Only the aggregates and water need to be heated. Under no circumstances should this be done with cement, because it will lose the properties that are necessary for a high-quality foundation. But this is very undesirable.

When adding warm water to cement, its temperature should not exceed +30 °C. If it is added to the filler first, then it can be done hotter. If the solution is well mixed, it will withstand the temperature longer. In addition, it fills the mold more tightly, penetrating into all corners and crevices.

Protection of setting and hardening concrete from frost

Partial or complete freezing of concrete until the strength reaches 75-80% is a guaranteed partial or complete destruction of the structure after thawing. As you know, Russian autumn is unpredictable.

Frosts can occur as early as late September or early October. Therefore, you need to be prepared to protect a freshly poured concrete structure in one or more ways:

- Carefully covering the surface with available heat-insulating materials. The method is only suitable for protecting foundations and other structures located no higher than the zero level. If the air temperature suddenly drops to minus 5-10 degrees Celsius, the surface is covered with sawdust and covered with mineral wool or other heat-insulating material. You can also rent or build a temporary tent over the structure. The soil cools down over several weeks, and heat is generated as the concrete hardens. In this regard, with high-quality implementation of this activity, you can win back 1-2 weeks from nature, however, in severe frosts this method is ineffective;

- Use of antifreeze additives. Depending on the type, antifreeze additives allow concrete to “calmly” gain grade strength when the temperature drops to minus 10 and even minus 25 degrees Celsius. Among the most popular antifreeze additives are: calcium nitrate (“works” down to minus 25 degrees Celsius), M15plus and M25plus (“works” up to minus 15 and minus 25 degrees Celsius, respectively), MorozStop (“works” up to minus 15 degrees Celsius), Potash (“works” down to minus 25 degrees Celsius), calcium formate – lowers the freezing point to minus 20-25 degrees Celsius, depending on the concentration;

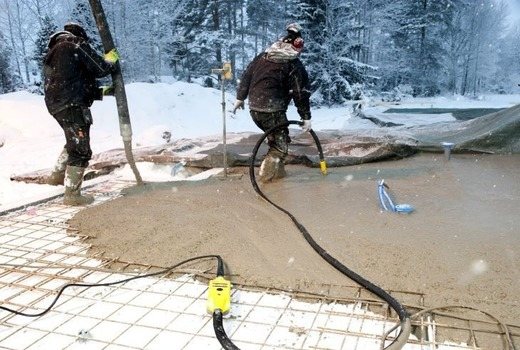

- Active heating in one or more ways: a heating cable located on the surface of the concrete, covered with thermal insulation, a heating cable located in the thickness of the structure (remains there forever), a tent and heat guns (electric guns, infrared lamps, etc.) or thermal formwork. In this case, it is very important not only to warm up, but also not to overheat the concrete. Therefore, active heating of concrete should be trusted to specialists.

Rules for preparing and pouring concrete in the fall

- The solution should be prepared using heated water (no more than 70 degrees), in a heated room or in installations with active heating;

- The mixing time of components increases by 25% compared to “summer” standards;

- When erecting structures using mixtures without anti-frost additives, it is necessary to ensure that the base and formwork are heated to a temperature of at least 5 degrees Celsius;

- When the air temperature drops to minus 10 degrees Celsius, the steel reinforcing belt of densely reinforced structures should be heated to a positive temperature. If the filling is carried out with a solution with a temperature above 45 degrees Celsius, the reinforcing belt may not be heated.

To summarize, it should be noted that starting from the end of September, pouring concrete will require additional material costs. Therefore, this work should be carried out at the very beginning of autumn, and later concreting should be carried out if absolutely necessary.

The strength characteristics of a construction project depend on the quality of the foundation pouring. This serious stage of work requires a thorough approach. Time and weather factors sometimes change the plans of developers. Situations arise when the foundation is poured in the fall.

There is an opinion that the construction of buildings is carried out exclusively in the summer, when the ambient temperature is 16 °C - 25 °C. Professional builders have proven that this position is not justified. Completing the foundation in the fall is possible. However, it has positive and negative aspects. By taking a responsible approach to organizing the work, you can ensure the solidity of the foundation, which will be no different from the foundation poured in the summer.

If you make serious mistakes, you risk in early spring, instead of constructing a building, you will begin to remove parts of the cracked base and dispose of them. To the question whether it is possible to pour the foundation in the fall, we answer in the affirmative. We will tell developers in detail about the features of autumn pouring, methods of protection from freezing temperatures, and advise on the best way to lay concrete.

Modern builders are proving that pouring concrete can be done in the fall if the necessary recommendations are followed.

How does concrete hydrate?

People are often interested in when it is possible to pour the foundation in the fall, and whether it is even worth doing it at such an unpredictable time of year. Now let’s look at how concrete hardens in order to better understand all the processes and plan construction accordingly:

- at the initial stage, a crust appears on the surface of the mixture; it is sodium hydrosilicate;

- after this, the harder particles of the foundation surface harden;

- the next stage of solidification is contraction of the shell due to evaporation of the liquid;

- this process begins to move towards the center until the mixture acquires the stated strength.

Based on this diagram and answering the question whether it is possible to pour the foundation in October, experienced builders confidently say: “It is possible!” And we will describe why, comparing this process in summer and autumn-winter.

Specifics of autumn filling

Construction in the rainy autumn is not as comfortable as in the summer, when concrete quickly gains strength. But if there is no alternative, you managed to dig a trench before frost, pour the concrete solution in early autumn, then the foundation will have time to acquire the required strength characteristics. By performing the work correctly, you can avoid subsidence of the foundation and subsequent deformation of the building walls.

Let's consider what weather factors determine the quality of work if the foundation is planned to be poured in the fall:

- Temperature regime.

The favorable temperature for setting and hardening of the concrete mixture is considered to be from 3 to 25 degrees Celsius. Elevated temperatures negatively affect strength, and at lower temperatures, hydration occurs worse. Favorable temperatures ensure slow hardening of the concrete solution in the autumn, significantly improving the strength characteristics. It is important to have time to complete the work before the soil freezes, when it swells under the influence of moisture. If a sharp drop in temperature is not expected, then get to work. - Ground water level.

If work is carried out in a swampy area or soil characterized by high humidity, pay attention to this factor. Despite the fact that in the first autumn months, when it does not rain, the level of groundwater layers is low, but the beginning of autumn rains contributes to a rise in the level. In unfavorable conditions, it is not advisable to build a foundation. We'll have to reschedule work until the spring.

If the construction process was carried out incorrectly, there is a risk of subsequent disposal of the foundation due to its unsuitability

Think through everything carefully, take advantage of the autumn period. Is it possible to pour the foundation in the fall? Naturally, remembering the main points:

- the optimal period for pouring is the beginning of autumn, when it is not hot, far from severe frosts or autumn showers;

- Focus on the long-term weather forecast, plan the start of work so that the concrete has time to gain strength within a month. During this period there should be no frosts that turn water into ice, which destroys the foundation;

- the degree of negative impact of precipitation is somewhat exaggerated. 3 days after pouring, they will not be able to cause serious harm to the hardening base, additionally moistening the surface.

While the issue of protection from autumn precipitation is easy to solve, protecting yourself from freezing temperatures is not easy. But this is possible, although the estimated cost of construction activities increases significantly. Let's consider this situation in more detail.

When pouring in the fall, there is no need for additional moisture

Foundation insulation

When building a foundation in the fall, another method can be used to protect against low temperatures. Nothing is added to the concrete, its consistency remains the same as in the summer, only the foundation is insulated. This can be done with different materials. Mainly used:

In general, you can use any available material. In severe frosts, the foundation is even covered with sawdust, which perfectly protects from sub-zero temperatures. The main thing is that the top layer is waterproof and can protect against precipitation. In addition, you need to make a slope so that the water does not remain on the material, but goes sideways from the foundation. In general, it’s worth doing everything in the form of an awning, it will be more convenient.

The question often arises about whether it is possible to fill the foundation in the fall, also because there is a lot of dampness around, in addition to frost. This can also be solved very easily: a heat gun is directed under an awning made of polyethylene, roofing felt or tarpaulin. It drives warm air inside, heating the solution and promoting the evaporation of moisture. This way you can easily dry the foundation even in January frosts.

Quite often, in places filled with concrete, greenhouses made of polyethylene are installed, inside which a heater or heat gun is placed.

Freeze protection methods

If the foundation must inevitably be poured in the fall, be sure to use one of the following methods to prevent the mortar from freezing while curing:

- The use of anti-frost additives allowing concrete to achieve the required strength at temperatures down to -20 ° C. The negative point is a significant increase in the cost of construction, which does not allow using the technique for arranging large foundations.

- The use of electrical heating of concrete with a special heat cable laid over the surface and covered with insulation. The method of passing voltage with high current is effective, but expensive, given the high cost of energy.

- Covering the base with sheets of polystyrene foam, tyrsa, mineral wool, film or any heat-insulating materials. An inexpensive, justified method of protection that allows the slowly cooling composition to retain heat throughout the week and provide a comfortable setting.

- Installation of thermal formwork. Carried out by specialized construction companies. This is an expensive but effective method that allows you to increase the temperature of the massif to + 30 ° C and maintain it throughout the setting period.

Of course, it is best to complete the work before the onset of cold weather. If you build in September, then laying the foundation will not lead to additional costs. The closer to winter, the greater the likelihood of problematic situations.

An advantage for laying a foundation in the fall compared to summer is the groundwater level, which is often significantly lower than in the summer

Do not forget that the hardening period of concrete is 28 days. If concreting is delayed, the foundation will need to be protected from negative temperatures for a whole month. Are you ready for this?

How to fill it correctly?

If you have any doubts about whether it is possible to pour a foundation in the fall, we recommend that you familiarize yourself with the requirements of building codes and regulations that regulate the algorithm for performing work at subzero temperatures:

- use hot water at a temperature of +70 °C with special fillers that prevent freezing;

- prepare the mixture using a mixer equipped with a heating system, or work in a heated room;

- increase the mixing time by 25% compared to the standard interval;

- insulate the bottom of the trench and formwork using thermal insulation materials;

- heat the reinforcement frame, preventing the formation of moisture around the reinforcement during pouring;

- extend the time of vibration compaction of the composition by a quarter compared to standard standards;

- Periodically check the condition of the concrete.

How to pour a foundation in the fall

The foundation is perhaps the main basis when building a house. Many people believe that foundations should only be poured in dry weather. Experts also disagree on this opinion, but, despite the difference in opinions, it is still possible to pour the foundation in the fall, if heavy rainfalls do not interfere with this work.

Is it possible to pour a foundation in rainy weather?

Builders claim that damp and humid weather is best for pouring the foundation, as this promotes high-quality hardening of concrete. In addition, you can use several techniques and materials, thanks to which work can be carried out throughout the year (except for days when there is heavy rain and cold). One of these methods is the use of a cement mixture of certain brands, which can increase the moisture resistance of concrete.

These cement grades include: M-600, M-500, M-450 and M-400. This mixture is often used for the construction of platforms, bridge piers and similar structures that are often exposed to heavy water during use.

- After pouring the foundation in damp and humid weather, it must be covered with plastic film to avoid erosion.

- During the construction process, when choosing the appropriate brand of concrete, it is advisable to seek help from specialists who will help you choose the best option.

Many people believe that it is better to pour the foundation when building an individual house in the fall, due to which its foundation will give a more reliable and natural settlement, which will prevent the appearance of cracks in the future.

A high-quality foundation is the main condition for the long-term operation of a building. In this case, it is necessary to take into account not only the brand of concrete, but also the method of pouring the foundation itself. If the depth and height are too great, it is recommended to pour continuously using a construction vibrator. This will avoid voids in the base, thereby facilitating the formation of a better-quality monolithic mass. If you follow the necessary technologies, you can achieve high-quality results and a long service life of the building.

In this video you can see how the process of pouring a concrete foundation using a deep vibrator takes place