A pressing question for builders who plan to erect structures in the autumn, because this is the time of year that is rich in precipitation. Let’s not hide it and immediately answer the question whether it is possible to pour concrete in the rain. Yes, you can, but a number of important factors must be observed that will affect the strength and durability of the structure. This material describes in detail how to pour in rainy weather and how to protect concrete from serious damage. Also at the end of the article you can find a description of damage caused by heavy rainfall.

Do not forget that the higher the quality of concrete, the better it resists external factors. If you want to get a reliable construction at the end, choose M500 or 600. The brands differ from each other:

- Duration of hardening.

- Strength, which also depends on the clinker.

- Resistant to low temperatures.

- Grain size - this parameter determines how quickly the concrete dries.

Is it possible to pour concrete in bad weather conditions?

The main component of concrete is water. It does not cause damage to the structure being constructed, however, if there is too much liquid in the solution, then an excessive number of air bubbles are formed, for this reason the load-bearing capacity decreases. Professionals believe that concrete can be poured in the rain. The main rule is to limit the ingress of moisture above the permissible norm.

Concrete is a binding building material; its strength can only increase with wet precipitation. Therefore, it is suggested to carry out this process during light precipitation or during hot but humid weather. The rain should not be very intense, and special attention should be paid to the quality of the cement. As a rule, grades M400 and M500 are used, and, of course, it is necessary to reduce the liquid content in the concrete itself using plasticizers. These materials help to avoid voids, and the polymers contained in the composition make the resulting concrete waterproof and strong. Sediment trapped in concrete must be discharged in a layer with gravel into the soil without reducing its quality. It is important that there is no clay in the soil; it retains moisture.

Concrete grades

The quality of the solution plays an important role in the strength of the foundation. Prepare information about concrete, pay attention to the brand of cement. High grade cement is resistant to moisture. In the work, it is better to use concrete, the unifying component of which will be cement of a grade of at least 400. This composition allows for procedures that come into contact with water. Increased moisture resistance is inherent in cement grades 500, 550, 600. Concrete mixtures containing such grades harden quickly. But the cost of such material is not small.

Return to contents

Difficulties working in bad weather

In rainy weather, it must be taken into account that any failure to follow the rules for mixing and pouring the solution can lead to washing out of the concrete. It is better to take a high grade of cement, for example, M400 or M500, to increase strength. If it rains heavily while carrying out work, but half of the solution has already been filled, there is no point in stopping the progress of the plan. The specific gravity of concrete is heavier than water, it will push excess moisture out. The procedure for preparing the solution if it rains is as follows:

- If excess moisture gets in, arrange a canopy made of boards and polyethylene.

- In dry form, cement and dry quarry sand are added and mixed in a ratio of 1:1.9.

- When adding water, the weight is slightly reduced by mixing in less than 0.5 mass of binder.

- Crushed stone is added in a ratio of 3.9 shares to all materials.

For concrete to gain the necessary strength, it takes at least a month, provided it dries in fairly favorable conditions. If it is not possible to wait out the bad weather, they can build a canopy over the construction site, but this will require significant financial investments. When it rains, be sure to cover the mixture poured into the formwork with plastic wrap to prevent excess moisture from getting in and being washed out. By using vibration equipment to displace excess liquid, it will be possible to ensure that there are no air voids. Cement grades M500 and M600 are moisture resistant, their use ensures good hardening even in rain. However, their price is quite high.

The influence of rainy weather on the quality of the resulting structure

What quality the finished product will have depends on the work performed and the properties of the materials. If the concrete is waterlogged, it will begin to crumble after hardening. In addition, the mixture may wash out and the reinforcing mesh will be exposed. If, in addition to rain, the temperature drops to sub-zero levels, the water may freeze and not undergo the necessary reaction to harden. The concrete will become loose in structure, and this will affect its strength and surface quality.

Construction professionals recommend making moves to protect the bottom from mold growth. If this procedure was not completed at the beginning of construction, then cutting can be done with diamond wheels.

How can rainy weather affect the quality of the resulting concrete?

If concrete is oversaturated with liquid, it may collapse after setting. This can happen when the mixture is washed out, exposing the reinforcement mesh.

Or if water does not have time to react with cement before sub-zero ambient temperatures appear, it will freeze, and the concrete becomes loose and permeated with a network of microscopic ice floes. This phenomenon will negatively affect the strength of concrete.

What causes excess water in a concrete mixture?

It is highly not recommended to do concreting if there is a threat of water freezing. It is worth stopping the work so as not to redo it in the future. Rain can ruin the concrete surface, but if at the same time (already in a compacted concrete mixture) the adhesion processes of the concrete composition are not completed.

Tools and materials for concrete work

Concreting the foundation will require preparing a number of materials and equipment:

To carry out foundation work, materials for the solution itself are needed.

- cement, sand, crushed stone, water;

- mixing container, concrete mixer or shovel;

- construction trowel and wooden grater;

- wooden pegs;

- reinforcement grid;

- plastic film to cover the finished structure;

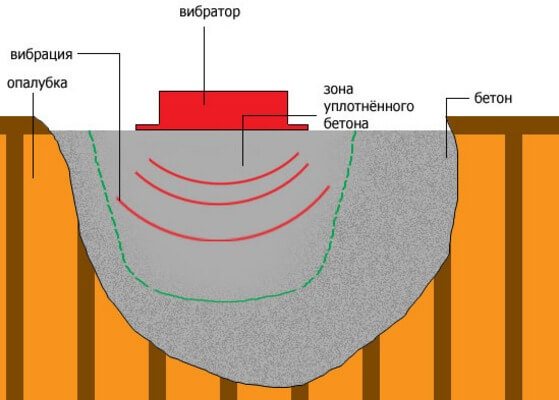

- vibration equipment for greater concrete density;

- spatula and building level.

Filling method

Preparing a high-quality solution is half the work; it is important to lay it correctly. Control of the poured material is a responsible process. The final result depends on the correct process. Concrete is a heterogeneous mass; placing and compacting it correctly is the main task in order to obtain:

- no bubbles inside the mixture;

- filled corners and transitions;

- avoid cracking.

Pour the solution in the following ways:

- manually using a concrete mixer;

- make a ready-made solution.

It is worth paying attention to the height of the foundation. If the height of the base is significant or the shape of the structure is non-standard, pouring is carried out continuously using a deep vibrator. The use of special equipment allows you to displace excess water from the solution and evenly distribute the mass throughout the structure. The quality of concrete increases after such compaction. The cost of the equipment is high, but it is justified in achieving high results. If you do not have such equipment, compact the contents manually. Create vibration waves by hitting wooden beams with a sledgehammer.

Return to contents

Pouring stages

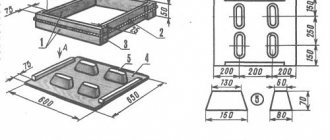

Builders divide the process into the following stages:

- Filling the base with a waterproofing coating.

- Installation of reinforcing mesh.

- Alternate pouring and covering with polyethylene.

The assembled formwork must be waterproofed and reinforced.

The area where no work is being done is covered with plastic film. After drying, the film can be removed after 1-2 days. The solution is laid out in areas one after another, when one of the elements dries, it is opened and poured on top again. After drying, the evenness of the surface and the presence of bumps are checked. If such bumps are present, they are cut off with a trowel and brought to smoothness using a wooden grater. To summarize, we can say that it is possible to pour concrete in the rain if the precipitation is not too heavy and all the conditions and stages of work are correctly fulfilled.

Cooking technology

Preparing the mixture is an important step in the process. It is necessary to take into account all the nuances of mixing the solution when working in the rain. Step-by-step technology will help you understand the features:

- at the beginning of work, prepare a covered canopy so that water does not get into the containers with the solution;

- First, one part of cement, grade no lower than 400, is poured into the solution container;

- then add 1.9-2 parts of river sand and mix the components dry;

- then add water to combine the components. Water in the mass makes up 0.5 parts of the binder. During rain, the amount of water can be reduced;

- 3.9 parts of gravel are added to the almost finished solution.

After combining all the components, the contents are thoroughly mixed for several minutes. It is these proportions that make it possible to obtain concrete that can withstand loads and have high strength.

Return to contents

Possible problems in the future

It is important to distinguish whether the foundation can be poured in the rain in the summer or in the cold season. If in warm seasons water is able to come out of it on its own, then during frosts it can remain inside. Excess liquid after heavy rainfall may be partially blocked inside the base. What happens is that the concrete is already setting, but there are still areas with watery inclusions inside.

The described case leads to a weakening of the structure; shells with liquid are formed, which subsequently remain empty. The foundation may develop cracks in these places in the future. To avoid defects, you will have to mix the concrete until the end of precipitation. But if this procedure is too long, the foundation will already acquire air pockets.

Similar problems occur when water freezes inside the foundation. It begins to expand, leading to a defective base. Voids will definitely appear in the future in a year or several years. The load capacity is significantly reduced from the calculated one.

But the answer to the question of whether it is possible to pour the foundation after rain is simple: if the formwork remains undamaged and there are no signs of its destruction, the concrete is laid perfectly. It is recommended to pay attention to the accumulation of water: there should be no puddles at the base. If the liquid is not drained, measures should be taken to change the foundation design.

Pouring process

The filling procedure is divided into the following stages:

- Laying waterproofing material in a prepared frame prevents the penetration of moisture from below.

- Installation of reinforcing mesh inside the structure at a distance of at least 5 cm from the edge. The mesh parts are fastened together with wire.

- The formwork is covered with film cut into strips. The thickness of the strips can be different, depending on the width of the foundation, plus a margin. Cover the area where no work is being done with film.

- The solution is laid in parts - one section of the structure is freed from the film and the solution is poured inside, and so on until it is completely filled.

After a period of time, the solution will set and rain will not cause damage to the concrete; after drying, the film can be removed.

Return to contents

Why does the foundation collapse?

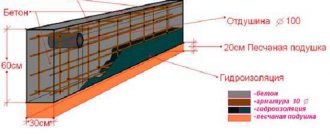

Not all developers realize that they themselves determine the service life of the foundation laid for a house. The foundation is usually a multi-layer “pie” consisting of building materials with dissimilar characteristics, which manifest themselves differently in the presence of excess moisture. Therefore, one of the main factors for the long service life of an underground structure is careful adherence to the sequence of laying the base, or cushion, consisting of several layers, each of which can have its own technology. When carrying out work, you will need to take into account weather conditions, which is important.

Preparing a pit for a slab foundation or trenches for a strip structure can be done in rainy weather. It is only important that prolonged rains do not oversaturate the soil with moisture. A layer of sand and crushed stone poured into the base of the foundation perfectly allows water to pass through, so if the soil does not contain clay that can retain moisture in large quantities, then nothing will threaten the construction site.

The well-established opinion that foundations need to be poured only in dry and warm weather is not entirely true. If we turn to the physics of the process itself, we can see that the hardening of cement, the main binder of the concrete mixture, occurs when it interacts with water at an optimal ambient temperature of 18-20 degrees. Moreover, cement, being a hydraulic binder, gains strength characteristics precisely at high air humidity - more than 80%. Therefore, pouring the foundation in light rain or damp, cool weather will not in any way affect the strength of the future structure, and the process of setting and curing of the concrete mixture will occur at the highest quality .

But on the other hand, it is the high moisture saturation of the concrete laid in the formwork that often leads to its destruction. Firstly, the solution may begin to wash out, exposing the reinforcing mesh. Secondly, water that did not have time to enter into the cement hydration reaction before the onset of negative temperatures will have a negative impact on the strength characteristics of concrete due to its possible freezing. And although the process of setting and hardening of the concrete mixture is accompanied by the release of a certain amount of heat, it is clearly not enough to warm up the water and maintain the optimal temperatures required for the monolith to acquire the necessary strength.

You should not pour the foundation if there is a risk of freezing of the concrete mixture!

Favorable humidity conditions when carrying out work on filling the underground part of the structure are ensured by the autumn period. But this time of year is always associated with the risk of early frosts, which results in a violation of the temperature regime of concrete hardening. The use of antifreeze additives prevents water from freezing. In this case, it has time to react with the cement, allowing the concrete to gain the necessary strength.