Unlike conventional piles used to create pile foundations, shell piles are hollow rods of significant diameter. Such structures have found application in the construction of large structures, for example, for laying multi-storey buildings.

Very often they are used on unstable and weak soils, since they have a sufficient area of contact of their walls with the soil layers.

Shell piles are also used in places that are regularly exposed to oscillatory processes. In particular, they are used to create supports for bridges and highways. Piles fully justify their purpose even when exposed to moisture, as well as in geologically hazardous areas.

Definition and scope

Shell piles are a hollow structure with an impressive cross-sectional diameter - depending on the type, it can reach 0.8-2 meters or more. There are wooden, metal and reinforced concrete. The ends of the piles may have a special point. The material from which the structure is made is most often reinforced concrete.

Such piles are widely used in the construction of industrial and hydraulic facilities, including the foundations of large structures, bridges and even piers. They are often used on particularly weak and unstable soils, since they are able to ensure the strength and stability of the subsequent structure due to the large area of contact of their walls with the soil.

Also, shell piles are often used in areas with increased seismic activity. In particular, it is thanks to their strength characteristics in conditions of high humidity and vibration processes that they are used to create support structures for highways and bridges.

Content

- 1 Application

- 2 Interaction of piles with soil

- 3 Types of piles

- 4 Description 4.1 Bored piles

- 4.2 Wooden piles

- 4.3 Reinforced concrete piles

- 4.4 Sheet piles

- 4.5 Tube-concrete piles

- 4.6 Fused soil piles

- 4.7 Anchor piles

- 7.1 Technical literature

Advantages and disadvantages

Like any building structures, hollow piles have their advantages and disadvantages. Let's take a closer look at them.

Advantages of use

- High quality and performance characteristics, able to withstand significant negative impacts without jeopardizing the integrity of a building or other structure.

- High load-bearing capacity of devices.

Installation Cons

- To work with sections of piles, as well as to deliver them, you will need fairly powerful cranes and other construction vehicles.

- Quite high energy consumption of vibrating devices.

Literature

Technical literature

- Mendelevich I. R.

“Carpentry and joinery work” / Ed. Syrtsova E. D. - M.: "Stroyizdat", 1950. - 320 p.

Normative literature

- GOST 19804.2-79 “Solid driven reinforced concrete piles of continuous square section with transverse shaft reinforcement with prestressed reinforcement. Design and dimensions."

- GOST 19804.5-83 “Hollow round piles and solid reinforced concrete shell piles with non-prestressing reinforcement. Design and dimensions."

- GOST 19804-91 “Reinforced concrete piles. Technical conditions".

Types and features of the use of hollow piles

Depending on the type, hollow pile structures can be open or closed. Let's look at each type in more detail.

Open piles

Such piles usually have an impressive diameter (about 0.6 - 1.5 meters). They are immersed in the ground with the open part down. To avoid damage and destruction of the pile when colliding with solid inclusions of the medium, a steel knife with longitudinal reinforcement welded to it is mounted on its lower end. Thus, when immersed in the medium, the pile cavity is filled with soil completely or partially, depending on its properties.

In the case of especially heavy loads on the piles, when their walls may not be able to cope with the soil pressure, the soil that has fallen inside the pile structure is removed and the cavity is filled with concrete. In residential and industrial construction, the soil is not completely removed, but only at the head of the device and the free space is filled with concrete.

Closed shell piles

Closed-type piles work like standard solid structures, but are equipped with a special steel or reinforced concrete shoe. As a rule, closed piles of large diameter are destroyed during immersion, which is why their diameter does not exceed 5-60 centimeters

Shell piles also differ in material and manufacturing method, and can be made of wood, steel, reinforced concrete and screw.

Wooden piles

Piles of this type are often used in the construction of foundations for temporary buildings, including road bridges and various types of scaffolding on local roads. For the construction of permanent buildings, wooden piles are used in two cases: in wooded areas remote from large transport routes and in environmental conditions that are aggressive for steel and concrete products.

Material of manufacture

The material, as a rule, is pine; spruce, larch, cedar, oak or fir are used a little less often. The assembly uses wood cut down in the cold season, as it has higher strength characteristics.

Manufacturing process

Piles are built up by using sections of steel pipes, special side plates or reinforced concrete cages. Before making piles, the logs are cleared of any growths, bark or branches. If the natural conicity of the logs does not interfere with the process of immersing the structure into the ground, then it is preserved; if not, the logs are cylindered. Shell piles that are exposed to variable humidity conditions for a long time are additionally protected from rotting using impregnation with creosote or other special solutions, or a polymer coating.

Advantages and disadvantages

The advantage of using these structures is their simple manufacture, relatively small weight, which greatly simplifies transportation and subsequent immersion. The disadvantages of wooden piles are limited length, the difficulty of immersion in a dense environment, and the possibility of rotting or damage to the device by insects.

Steel piles

Steel pile structures are used primarily in difficult geological conditions, when immersion of standard reinforced concrete shell piles into the ground is impossible. Examples of such environments: dense deposits of pebbles, boulders, and silted objects. In addition, such structures are used to strengthen the foundations of large structures.

Pros and cons of using

The advantages of use, as mentioned above, mainly lie in the ease of use of steel piles in an environment that is difficult to access for other materials.

The main and very significant disadvantage is the susceptibility of steel to corrosion under the influence of environmental conditions. To combat possible corrosion, various special coatings are used, such as bitumen, concrete, epoxy and coal tar, and paint. They are applied over the entire surface of the pile or only in potentially dangerous places. In addition, steel shell piles require special equipment for transportation and installation due to their heavy weight.

Reinforced concrete piles

Reinforced concrete shell piles are rightfully considered the most common and versatile: they are widely used both in the construction of permanent structures and various types of structures, including bridges.

Manufacturing of reinforced concrete piles

Such structures are assembled from individual links, which are connected with bolts, electric welding or using special liners. Then, at the factory, reinforcing bars are welded to the workpieces, and special steel installation circles are mounted in the middle of the link. The finished frame is subsequently concreted by centrifugation or using a vibrating table.

Advantages and disadvantages

The advantages are the following:

- Resistance to rotting and damage to the structure by insects.

- Can be used in any soil: both fresh and salty

- High speed and ease of installation.

- Quite affordable price.

Disadvantages of using reinforced concrete shell piles in the construction of structures:

- Installation in close proximity to other buildings is problematic.

- Difficulty digging into soil with a large number of large stones.

Screw piles-shells

Such structures are a special, specific type of piles that are forced into the ground by screwing. Shell screw piles are used in conditions of highly compressible soils with a substrate in the form of a dense medium without solid obstacles in the form of silted wood or large boulders. Using such devices, overpasses, hydraulic structures, bridges, and power lines are erected.

Engineering calculations

The technology of a suspended foundation is quite complex and requires careful calculations at the planning stage. These calculations differ from those for rack piles - they take into account many more direct and indirect values and parameters. This is due to the unreliability of weak subsidence soils as a load-bearing support.

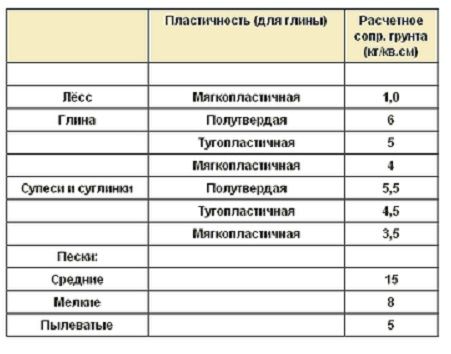

The required bearing capacity of the foundation can be determined using the formula given in section No. 2-02-03-85 of SNiP. Engineering calculations are quite complex, and they should be carried out by specialists with appropriate education. For accurate calculation you will need the following parameters:

- The outer perimeter of the pile section (u).

- Area of the lower end of the support (A).

- Length of the recessed part of the hanging support (Hi).

The formula also includes a number of tabular values:

- Soil resistance under the bottom of the support (R).

- The resistance of all layers of soil through which the pile passes (Fi).

- Conditional coefficient of work of the structure under the tip and on the side surfaces of the support. Depends on the method of deepening and is given in the corresponding SNiP tables.

The compressive load of each individual support is calculated according to the following formula.

This is the basic formula for pendant piers driven by the hammer method. There is another formula that allows you to calculate the bearing capacity of a pile. It is performed to determine the minimum pull-out load.

The parameters used in this case are similar to those previously given, with the only difference being that the operating conditions coefficient has a different meaning.

Immersion of piles into the ground

In the process of sinking shell piles, specific vibration devices are used. Pile structures are immersed in the ground to the required depth due to the vibration created by this technique. Vibration helps loosen the soil and drive the pile to the required depth. There are two ways to immerse the shell in the ground:

- With excavation. Before carrying out work on inserting a pile into the ground, it is necessary to remove excess soil from the ground using a special drilling rig.

- No excavation. This method does not require any additional excavation work.

Video of a small pile driving machine

Notes

- ↑ 12

Pile Foundations | Types of Piles | Casions. Understand Building Construction. Retrieved July 24, 2020. - Interaction of piles with the surrounding soil (processes occurring in the soil when piles operate under load). studopedia.su. Retrieved July 24, 2020.

- ↑ 1 2 M. I. Smorodinov, B. S. Fedorov, E. V. Svetinsky, A. I. Egorov and others:

“Handbook of general construction works. Foundations and foundations" - M: Stroyizdat, 1974 - ↑ 12345

"Handbook for designers of industrial, residential and public buildings and structures." Ed. M.I. Gorbunova-Posadova, L.: “Stroyizdat” (Leningrad branch), 1964, 271 p. - Encyclopedia "Technology". — M.: “Rosman”. 2006.

- Tongue (structural)

- article from the Great Soviet Encyclopedia. - Sheet piling wall

- article from the Great Soviet Encyclopedia. - Sirotyuk V.V., Arkhipov V.A.

“Technology for the production of ground-melted piles on a construction site using a low-temperature plasma generator” //

Founder of the Association “Foundation”

“Foundation, foundations and soil mechanics”: Journal. - M.: Publishing house "Economy, construction, transport", 1999. - No. 6. - P. 16-20. — ISBN UDC 624.154:624.138.9:533.9…15. — ISSN 0030-6223.

Activities on the construction site

The main stages of work on deepening pile structures look like this:

- Preparatory stage: cleaning the area, marking it.

- Transportation of piles to the work site. To transport and supply the rods, special equipment is used in the form of cranes, heavy-duty platforms, tractors, and unloading devices.

- Installation of equipment that will be used to immerse piles into the soil, installation of a guide unit.

- By means of vibration with a certain amplitude of oscillations, immersion is carried out. Important: each pile must be mounted strictly in its place according to the prepared markings.

- Shell piles are immersed to the required depth.

An important point: since the penetration of the rods into the soil is carried out through vibration, it is mandatory to obtain documented approval of the work with the relevant authorities.

Increased load-bearing capacity. Support dimensions

The load-bearing capacity of a friction pile is determined by the formula that was presented above. But if it is not enough, then the problem can be solved in several ways. The first is to increase the diameter of the support, in some cases the length also increases. Bushiness can also be increased by one unit of building base area.

Products sometimes expand in the pit area. This increases the friction area at the end. If, when determining the load-bearing capacity of friction piles, it was discovered that this value should be increased, the problem can be solved by using modern technology. For example, the discharge-pulse technique. But it is worth remembering that an increase in the size of the product can cause an increase in construction costs. The price of the foundation will be the sum of the prices for each element. The thicker the support, the more difficult it will be to dig it into the soil. The number of piles driven in for reinforcement can add weight to the structure, both literally and financially. You may not get the desired benefit.

Sometimes a suspended driven pile requires a higher load-bearing capacity. But if you use bushiness for this, the structure will shrink more than one support. The length of a standard pile is 7 m.

There is a practical observation: if the step between the supports is more than 3 diameters, then a single pile and a bush settle approximately equally. By reducing this distance, shrinkage can be increased.

Extension of pile structures

Sometimes, to achieve the required length of a pile, it needs to be increased, since a solid, standard product is only about 12 meters long. Let's consider two extension methods:

- The build-up occurs as one of the parts is buried into a certain section of soil. After building up one piece of the pile, the second one is buried in the same way. The process is repeated until the desired result is obtained. Parts of the product are connected to each other using a flange method - special metal devices are mounted at the ends of adjacent structures - flanges with holes for connecting with bolts. This type of fastening is considered quite reliable, and, importantly, fast. It ensures perfect alignment of the pile axes.

- The second method is to build up the reinforced concrete product before deepening begins. According to the calculated required depth, a monolithic structure is made, the parts of which are connected to each other by a weld. Due to the fact that the work requires special precision, it is performed on specially installed stands. The joints of welding seams must be reliably insulated by coating them with polymer mastic or bitumen.

It should be noted that this method is less expensive and material-intensive.

So, in this article we examined in detail what shell piles are, what they are needed for and where they are used, what types there are, the features of their use, and also learned the nuances of immersion and extension of products.

Description

A hanging pile differs from a stand pile in that the latter is supported by support on the soil. The length compacts the soil on the side walls. Over time, the grip only increases. Settlement occurs due to compaction of the soil under the tip of the support. There are differences between a single hanging pile and a bush pile. Under the same loads, the bush shrinks more. The settlement increases when bush piles are closely spaced.

The amount of settlement will depend on the ratio of the distances between the piles and their length. The length of the pile can be determined taking into account the characteristics of the soil. The looser the soil, the longer the pile should be. Design loads should also be taken into account. The pile will be longer, the greater the load it will have to take. When the usual length is not enough, hanging composite supports are used.

How to choose piles for various types of buildings

So, based on the above information about pile foundations, you can already decide on the type of piles used in private construction for different buildings.

Although advertising persistently advises using screw piles everywhere, you first need to decide whether there is a need to use a pile foundation in your particular case. In particular, if the soil in the designated area is normal and the houses of all the neighbors stand perfectly on traditional strip foundations, then there is no need to think about piles.

If you know for sure that the soil is mobile, heaving, or the groundwater level is high, or you have to build on a steep slope, then you should choose piles.

In the second option, you must be aware that it will not be possible to build a house with a basement or even a cellar. Which piles to choose?

Here you need to proceed from the purpose and design of the structure:

- if this is a light outbuilding or gazebo, then powerful piles will not be needed;

- if it is a frame summer house, then screw piles can be used;

- if the house is capital and heavy, then you need to choose the option that will satisfy the requirements of feasibility - that is, ensure the necessary reliability of the foundation at reasonable costs for its construction.

Thus, there is no clear recipe here. Each case must be considered separately.