The foundation is the support of any object, the strength of which determines its operational life. Reinforcing the foundation slab with steel rods is considered the simplest and most effective option for increasing the service life of the foundation. This technology is very popular when constructing monolithic structures subject to significant bending forces, which can easily destroy simple concrete that does not have a metal frame base.

The need for reinforcement

The reinforcement cage is a necessary element of the slab. Some builders do not do this work, believing that the concrete structure can independently resist load forces. To know exactly why reinforcement of a slab foundation is required, you need to study the problematic issues solved by this element:

- the frame base gives the foundation additional strength, allowing it to withstand greater loads compared to conventional cement slabs;

- simple concrete can withstand compression, but does not withstand bending well. Steel reinforcing bars prevent the slab from bending due to uneven load, which reduces the risk of partial shrinkage of the structure;

- The reinforcement of the foundation slab does not allow it to succumb to deformation during the process of swelling and movement of the soil composition. It should be noted that the reinforced foundation is not afraid of sudden changes in temperature and the effects of ground moisture.

The reinforcement cage increases the service life of not only the foundation, but also the entire facility. The production of frames is regulated by SNIP, which specifies the basic requirements and dimensions of the rods.

Additional reinforcement of vertical structures in place

When all the rows of the frame mesh are ready, the design fastening elements of the rows themselves are mounted, as a rule, these are hooks with parallel zigzags, arranged in a checkerboard pattern. Then, all design elements reinforcing the mesh frame are installed in places of increased concentration of loads, as a rule, these are door and window openings, technological openings. They can be strengthened either with the help of additional reinforcement bars or with the help of complex beam systems using clamps. By the way, depending on the project, there may be options when the reinforcement of structures has to start being installed from these elements. Most often in elevator shafts combined with flights of stairs, where beam elements can form the main part of the reinforced frame of the structure. And such technological issues are decided individually depending on the design project.

Basic reinforcement schemes

When strengthening a slab foundation, the reinforcement scheme is drawn up in strict accordance with technology.

If necessary, this scheme may involve an uneven distribution of rods. Places where it is planned to install load-bearing interior partitions and columns (pressure zones) are subject to additional reinforcement.

The reinforcement is laid in one layer if the thickness of the slab does not exceed fifteen centimeters. In other cases, it is recommended to install a reinforcement cage.

Calculations for a slab-pile foundation are performed separately, taking into account the location of the pile supports and the material from which they are made. In each case of slab reinforcement, the drawing is drawn up according to preliminary calculation data.

Slab parameters

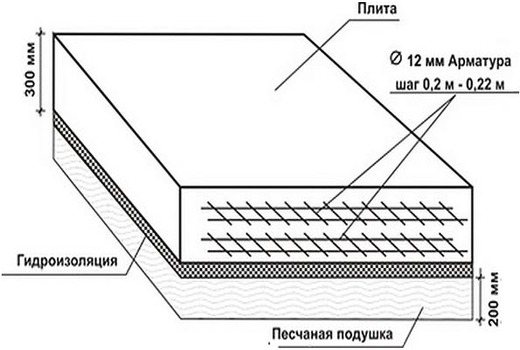

Using a specific example, we propose to consider the main components of the foundation structure. Imagine a grid with identical cells and a constant spacing between the reinforcement bars. According to the calculated load data, the interval between the rods should be from twenty to forty centimeters.

As follows from the rules of building codes, the pitch between the rods should not exceed one and a half times the thickness of the base.

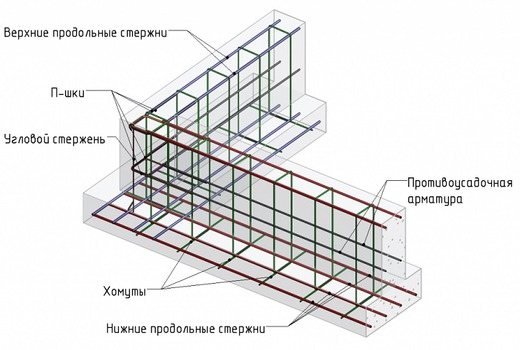

Most often, the reinforcement is laid in two rows, the joint actions of which are ensured by vertical rods. The distance between the rods should be equal to the pitch of the main metal structure. Reinforcement at the ends of the slab is performed with U-shaped clamps; their minimum length is equal to two parameters of the base thickness.

All rows must be covered with rod strapping to ensure reliable perception of torque at the edges of the foundation and to be able to anchor the ends of the longitudinal rods.

The entire frame is recessed in the concrete mixture two to three centimeters on each side. If this condition is not met, the process of metal corrosion accelerates, causing destruction of the base.

Punching zones

At the support points of vertical structures, rods are laid out with a reduced reinforcement pitch. If the rods are laid out across the entire width of the foundation slab in increments of twenty centimeters, then in places where partitions are placed it is recommended to reduce this distance to ten. This will prevent the occurrence of cracks and dents.

If the junction point is on a monolithic basement wall, the laying is carried out to a depth corresponding to the height of the room under construction. In this case, the bases are tied to the walls.

When reinforcing a monolithic foundation, the frame elements of the slabs and walls should be tied together. When concreting the base, it is necessary to leave parts of vertically placed rods, which later act as connecting links. Such ends are launched into the base, the edges are bent at the level of two dimensions of the slab height, then they are tied to the main frame.

Installation of vertical reinforcing bars

Mounting with crimp clamps

After all the preparatory work, the direct reinforcement of the structure begins with the installation of vertical reinforcement outlets on the “reed” construction layer. In areas of increased seismic hazard, any joining reinforcement in vertical structures with diameters above 20 mm must:

- Or welded onto trays (an outdated method that requires a lot of labor for welders).

- Or as a more modern and faster option for mounting on clamps with hydraulic compression.

Both options, when executed correctly, produce a joint that exceeds the tensile strength of the reinforcement bar itself.

In areas with no seismic activity and upon approval of the project, vertical rods are joined with an overlap of at least 20 diameters, that is, if the diameter of the joining rods is, for example, 12 mm, then the joint of two rods should be at least 20x12 = 480 mm.

The joint is tied with knitting wire in three places, 5 cm from the edges and in the middle. Then the reinforcement bars located in the area of the edges of the structure are secured with additional bars in a strictly vertical position using a level. This is done to avoid the rods falling out of the protective layer of concrete in areas where there is an increased risk of the rod losing its design position:

- near the corners;

- next to technological openings.

Selection of reinforcement material

Three types of reinforcement are used in construction:

- And 240 – with a smooth surface. It performs reinforcement in vertical planes. It is not used to strengthen monolithic slabs;

- And 300 - the diameter is ten to twelve millimeters. The rods have notches in the form of rings;

- A 400 – rods with a crescent-shaped profile. The working diameter is increased, excellent for reinforcing thick foundation slabs.

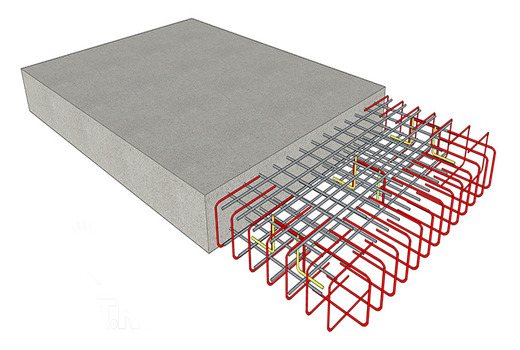

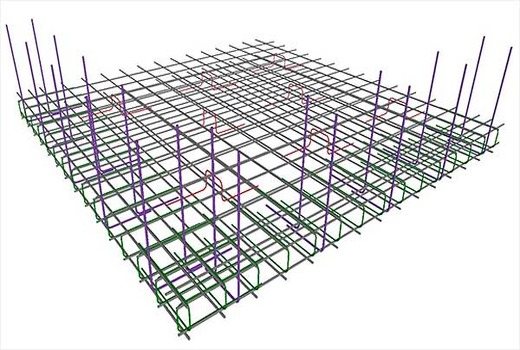

Before performing reinforcement, the optimal cross-section of metal rods should be determined. The reinforcing mesh is made up of a pair of layers, its elements are located at right angles towards each other. The bottom and top are connected with clamps.

By specifying the thickness of the concrete, you can determine the diameter of the reinforcement running in one direction. It should reach 0.3% of the total area of the slab.

If one side of the foundation is less than three meters, it is sufficient to use ten-millimeter reinforcement. Thicker slabs are reinforced with rods with a cross-section of twelve millimeters. The maximum percentage of reinforcement for large slabs reaches four centimeters.

Alternative to metal rods

You can replace metal rods with fiberglass reinforcement. Features of using composite products are as follows:

- the use of fiberglass rods is similar to steel ones, connecting with plastic ties or metal wire;

- experts do not provide a single argument that would suggest that composite reinforcement should not be used when reinforcing a monolithic slab;

- Fiberglass rods for reinforcement for strip foundations are becoming more widespread. In private construction, this type of reinforcement is also suitable for slabs;

- The advantages include durability and ease of use. Firstly, transporting fiberglass coils to the site is easier, and the weight is so low that you can handle the reinforcement alone.

Strengthening the slab base is a process that cannot be neglected. The strength and reliability of the monolith will ensure the comfort and coziness of the future home.

Vertical reinforcement of structures in place is most often carried out in elements with a large number of outlets and a large tonnage of metal in the structure. It is difficult to prepare a reinforced frame of such a design in advance in a reinforcement workshop and it has to be carried out directly at the construction site. This method is most often used to reinforce the frames of diaphragms, supporting walls, and in the realities of our construction industry and columns, when there is not even basic lifting equipment on the construction site that is capable of lifting the pre-prepared reinforced frame of the structure.

The entire reinforcement process consists of several stages:

Calculation of diameter and quantity of reinforcement

The cross-section of the reinforcing material used to construct a reinforced strip monolithic foundation is considered an important indicator, and it should be determined in advance.

There is a certain technique for this:

- the length of the slab is multiplied by its height to determine its cross-section;

- the permissible diameter of the rod is calculated, for which the cross-section of the slab should be divided by the minimum reinforcement indicator (in percent);

- the area of the rods in the row is determined;

- Having data on the length of the slab and the spacing of the reinforcing bars, their minimum cross-sectional value is determined.

Having data on the cross section of the rod. Its diameter can be specified in the current GOST 5781.

To calculate the amount of reinforcement required for reinforcement, use a simple diagram.

Knowing the parameters of the slab, they are divided by the value of the standard cell in order to clarify the number of rods. An additional rod is added to the resulting number.

To obtain a frame mesh, it will be necessary to lay transverse reinforcement material, so the resulting value is doubled.

The frame consists of two rows, so the final result is doubled again, and we get the required number of rods.

As a rule, steel rods are supplied in six-meter lengths, so it is easy to determine how many linear meters of material will be required.

Vertical connection elements are defined similarly. To clarify the parameter for the length of the connecting element, it is necessary to know the height of the slab, from which two distances separating the ends of the reinforcement from the upper and lower surfaces are subtracted. All that remains is to calculate the total length, add up all the data and get the final result.

Design features

Reinforced concrete reinforcement is used exclusively vertically downwards, and is evenly distributed throughout the site. The weight of the load itself is calculated taking into account the own weight of the building material and the weight of the structure itself, by people/objects located in the room itself. The reinforcement of the slabs helps to withstand this weight. Two reinforcing mesh are laid, placing the rods themselves inside the structure along/across the span itself.

The minimum pitch of a rod is the existing distance in the structure being built between the rods laid in parallel. On average, it is 15-20 cm. In such an indicator as the thickness of the concrete pour, the mesh is placed 20-25 mm from the surface itself. All rods must be tied with fastening wire, securely fixing each connection.

Somewhat less often, a break between connections is possible. And therefore, special vertical type clamps can be installed between the lower/upper layer of the mesh. It is they who ensure compliance with a uniform distance and integrity between the grid cells. The edges of the reinforced floor themselves are additionally reinforced during the work process. This is done with reinforcement in the form of L and U shaped elements. This is especially done at points of contact with the support.

When the floor slab itself rests along its entire floor, reinforcement must be carried out over the entire area. In this case, the upper part of the reinforcement in the structure itself will work accordingly in compression. The lower one is stretched and, accordingly, takes on the entire load. Accordingly, taking all this into account, rods of larger diameter are taken for the lower layer. For the top one - smaller in size.

Manufacturing of mesh and frame

We already know how to calculate the thickness and reinforcement of a slab foundation. Now let's figure out how to properly make a steel frame or tie a mesh.

There are two known ways to connect rods - hand knitting and welding. For tying, a wire with a diameter of two to three millimeters is used. Winding is done manually or special equipment is used to help wind around the rod. The option is difficult, but the connection is reliable.

Ready-made meshes are installed quickly and easily than with hand knitting. There is one drawback - choosing the right types and sizes sometimes causes certain difficulties.

If the connections of steel pins are made by welding, then the corner areas and places where it is planned to build massive walls are connected using knitting wire.

The welding unit is rarely used because it produces rigid and immovable connections, which has a negative impact on the quality characteristics of the monolithic foundation base. During welding, the metal melts, which reduces its strength.

Installation of horizontal rods of vertical reinforced frames

Reinforcement of horizontal bars

When the vertical rods are mounted in the design position, the reinforcement of the horizontal rods of the structure begins. If the height of the structure is above 3 meters, scaffolding or scaffolding must be used for these purposes.

The installation of horizontal rods begins with calculating the position of the outermost rod of the top of the reinforced frame. For example, if the height of the structure being poured is 4 m, then the outermost rod will be at a height of 4 m. minus the thickness of the protective layer, which is usually 2 cm, that is, in our example, 3.98 meters. Its position is marked with chalk and a tape measure on the outermost vertical rods, then the mark is transferred using a level to all other rods.

After this, the vertical and horizontal rods begin to be connected to each other. The first rod is tied at each node of the frame mesh; subsequent rods are not necessarily tied at each node, but rather one after another in a checkerboard pattern.

If the first rod is set clearly in a horizontal position, then it is not necessary to set the ones following it using a level, but simply hang special prepared hooks-templates equal to the length of the design reinforcement step, lay the next rod on them, and then tie it with a knitting wire. Then, the next one and so on until the outermost rod in the structure.

Horizontal rods must be strictly parallel

Template hooks are made either from small diameter reinforcement on a bending machine or from electrodes. The use of hooks when installing the horizon gives maximum precision in the reinforcement pitch, which is one of the main points that determines the quality of the work performed and is strictly controlled by the technical supervision engineer. If this moment is not subject to strict control, then the accuracy of the step is marked with simple chalk marks or even approximately by eye.

During the reinforcement process, it is strictly ensured that the vertical rods of the rows of the reinforced frame coincide with each other in the horizontal plane. And they were parallel.

Laying the reinforcement

How to properly reinforce a foundation slab?

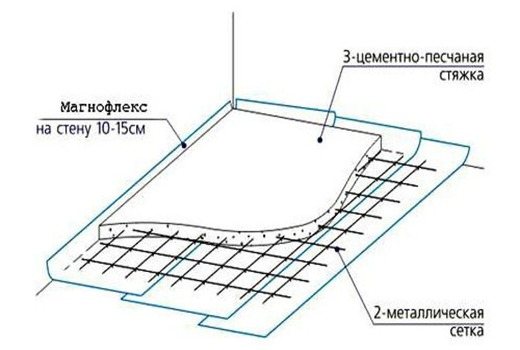

When laying the reinforcement frame into the formwork structure, it is necessary to calculate everything in such a way that each rod, after completing the pouring of concrete, is covered with a two- to three-centimeter layer of mortar. To maintain the required distances, special clamps made of plastic material or metal fasteners are used.

If the lengths of the rods are less than the foundation width, an overlap is made, the length of which should be more than forty diameters of the working rod.

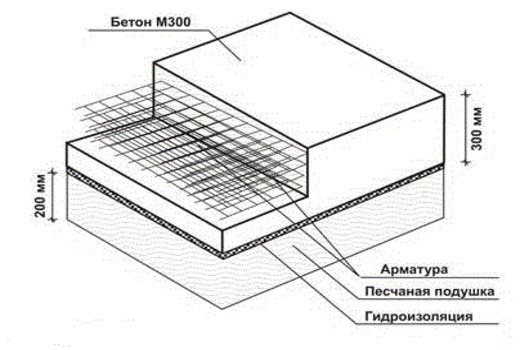

If the work on reinforcing a 300 mm slab is carried out in a pre-constructed pit, then the installation time is reduced and installation is easily carried out in the right place. True, there is a certain drawback - there is a risk of damaging the compacted cushion or waterproofing layer.

Reinforcement of a slab foundation with ribs is recommended to be performed as follows:

- the mounted bottom row is placed on supports;

- installation of transverse rods is in progress;

- The top row is assembled, connections with the posts and the bottom belt are made with knitting wire.

Requirements for openings

Often, when installing a slab base, it is necessary to arrange openings, in particular for the installation of utility networks. At this stage, you should pay attention to the following nuances:

- in the process of cutting holes in the metal frame, make sure that the ends of the cut rods are bent upward;

- if the opening is more than 300 mm, it is necessary to reinforce it. To do this, we attach rods with a diametrical cross-section of 10 – 14 mm around the perimeter of the opening;

- openings with dimensions less than 150 mm do not need to be reinforced.

Basic installation errors

To provide the foundation with the necessary properties and protect it from destruction, it is necessary to strictly adhere to the reinforcement technology. As a rule, inexperienced builders make common mistakes:

- Do not stretch polyethylene material over the poured concrete solution. The laitance leaks out and cracks appear on the surface;

- Having filled a cushion of sand and crushed stone, many neglect to compact it. The foundation shrinks and cracks form;

- on the installed formwork, the cracks through which the mortar mixture flows are not sealed, which leads to the appearance of unevenness;

- poor insulation of the slab from the soil surface will lead to premature destruction of the foundation, and restoration work will be quite expensive;

- It is a mistake to use stones as spacers;

- during installation work, reinforcing bars are fixed in the soil layer, the metal corrodes and quickly collapses;

- Before laying the foundation, a cushion of sand-crushed stone mixture is not poured, which reduces the strength of the slab. Another typical mistake is that only crushed stone is used to construct the cushion, but the minimum percentage of sand content in the cushion under the foundation slab before its reinforcement should be within forty;

- the spacing of the mesh rods exceeds the permissible maximum limit of forty centimeters, or does not at all correspond to the calculated data on load effects;

- there is no protective layer of concrete mortar on the side of the reinforcement ends, and the metal is subject to corrosion ahead of time;

- There are no vertical reinforcing bars under the installation of walls and columns, and the load forces are distributed unevenly.

These are the most serious errors that can clearly have a negative impact on the performance of the foundation. There are also more unobvious features that only experienced specialists can tell you about.

Technology

Welding of reinforcement is rarely used and only in exceptional cases during the construction of large monolithic structures.

It is important to know that welding at the connection point of the reinforcement weakens the material, makes it unstable to loads and exposes it to an additional risk of accelerated corrosion.

In private and low-rise construction, the only option left is to tie the reinforcement with wire or other mechanical fastening materials.

For tying reinforcement the following is used:

- Special baked steel wire with a diameter of 0.8 to 1.5 mm. Annealing the wire gives it toughness and softness, due to which it can be twisted and tied even by hand;

- Ready-made clamps made of unfired steel wire for cross-connecting reinforcement;

- Polymer clamps and ties.

Annealed knitting wire has become more widespread, but more as a historical fact, it is polymer clamps or ready-made spring-loaded steel wire clamps that can speed up the knitting process.

The task of tying the reinforcement frame is as follows:

- The boundaries of the future monolithic slab are marked along the prepared site, indicating all boundaries and angles. Next, bosses are laid - special clamps, supports, on which the first layer of reinforcement is laid out in order to maintain a given distance from the lower boundary of the slab being poured, so that the reinforcement is completely covered with concrete;

- The reinforcement is laid first in one direction, with obligatory overlap at the points where the reinforcement is made to cover the entire length;

- Transverse vertical elements are distributed to connect with subsequent layers of reinforcement;

- Knitting is performed at all points of triple intersection, where there are vertical transverse drains, along the entire perimeter of the reinforcement and inside in a checkerboard pattern or at each intersection;

- Next, bosses are installed for the second row of reinforcement. The entire procedure is repeated, only on the condition that the checkerboard knitting pattern in the central part of the slab will be shifted diagonally relative to the first row.

Crochet

The simplest and most accessible knitting option. A hook made of thick, strong steel wire (even a slate nail) of a special shape is used. The end of the hook is pointed, the bend of the hook itself has a turning diameter of approximately 3 cm and an end extension of 3-4 cm.

The handle of the hook is made rotary and shifted relative to the hook to the side so that they are not located on the same axis.

You can make a crochet hook yourself, but it is better to purchase a ready-made tool at any hardware store.

The purchased version will be stronger, more reliable and incredibly more convenient, since a convenient ergonomic shape of the tool and a grip option have long been found so that the hand does not get tired.

For knitting, a piece of wire about 20-25 cm is used. It is folded in half and then bent again in the middle at an angle of 90 degrees. The result is a curved hook on one side with a loop and two free ends on the other side.

The wire is hooked under the intersection or overlap of the reinforcement. The hook is inserted into the loop on the wire so that its tip catches on the second end. If you twist the hook around the axis several times, the ends of the wire twist and tighten the loop around the reinforcement.

The last step is to bend the protruding piece of wire towards the plane of the frame so that in no case does it protrude beyond the limits of the harrowing volume. If this is not done, the protruding metal will rust over time, which will affect the strength of the slab and will even show through further finishing.

As an improvement to crochet, other options are used:

- The hook is made with a straight base and is clamped in a screwdriver chuck or drill with a force limiter. By inserting the hook into the loop of the wires, you can quickly twist and tighten it, while focusing on the force on the screwdriver limiter. This will speed up the knitting process by about half;

- Semi-automatic hooks for knitting reinforcement are available for sale.

This is a hook made of steel wire, mounted on a thick cylindrical shaft, which has a special spiral thread with a large angle of inclination. The handle is designed specifically for this thread. By hooking the hook onto the loop and pulling the handle towards you, the shaft rotates around the axis, tightening the wire. It is noteworthy that the knitting is more accurate than in previous versions due to stable tension. However, users complain about the short service life of such semi-automatic hooks.

With a pistol

Wrap the intersection of the reinforcement with wire, pull the ends together and twist them; this can be done in 0.5-0.8 seconds if you use a special gun. The wire for tying is fed from the reel to special gripping claws, which rest against the crosshairs of the reinforcement. Next, just pull the trigger and in a split second the mating is completed.

The shape and repeatability of the pistol's knitting is ideal. The tension force and wire consumption are adjustable, so this approach has no disadvantages, except for the high cost of the equipment itself.

The gun will cost the contractor or owner of the house being built approximately 35-50 thousand rubles. If necessary, you can find stores or companies that can offer a pistol for rent, which will be much more economical.

All work on knitting a frame for a monolithic slab is carried out with a gun an order of magnitude faster than by hand. In fact, what a team of workers with hooks can do in 10 days, one person can do with a gun in one shift.

Wire clamps

The main task is not to firmly fasten the reinforcement, but to hold it in place without moving before pouring concrete.

Instead of burnt wire, you can use prepared clamps. They are made from springy steel wire up to 2 mm thick.

The wire is wrapped around two pipes with a diameter slightly larger than the fittings. The result should be a clamp in the form of a segment folded in half with two free edges bent around the circumference.

It is enough to hook one of the rods at the intersection with a wire and, bending it over the transverse reinforcement, hook it again to the first rod. There are ready-made forms for clamps in case of triple intersection and for overlapping reinforcement.

Plastic ties

It is not at all necessary to use steel wire and crochet it or use wire cutters. Plastic ties ranging from 50 mm to a meter in length are already widespread and available everywhere, which are easily tightened by hand and at the same time provide a reliable fixation.

It is better to wrap long ties once on each side of the reinforcement crosshairs and then tighten them, however, even a diagonal wrap is sufficient in strength. The ideal solution would be plastic ties when reinforcing a monolithic slab with polymer reinforcement.