The construction of a foundation is almost always accompanied by excavation work, the volume of which depends on the size of the building under construction. The excavated soil is crumbled at the construction site and is subsequently used to fill the excavation pits. This allows you to solve several problems related to the disposal of excavated earth, as well as increasing the stability of the base.

What it is?

If we consider the concept in more detail, the pit axils are the spaces formed between the slopes and the walls of the basement.

Backfilling of depressions is excavation work that directly depends on the volumetric dimensions of the building under construction , and solves the issue of recycling the earth removed from the pit.

The backfilling process is always carried out after completion of earthworks, installation of the foundation, laying and checking the functionality of communications, and with the completed completion of the preparatory stages. Backfilling should be carried out in accordance with the necessary precautions.

Despite the fact that filling gaps seems to be a rather primitive process, it must be carried out in compliance with construction standards, which are regulated by SNiP No. 3-02-01 (1987).

According to this document, backfilling should be carried out only after the concrete of the building’s foundation becomes 3/4 dense, which depends on the weather and the thickness of the pour. In this case, the waiting time can take from 2 weeks.

Filling the sinus plays an important role, since the used layers of soil support the foundation frame on all sides, which has a positive effect on the load-bearing surface and the building as a whole.

Why do you need to fill up holes?

Backfilling the pit sinuses is necessary in order to:

- ensure waterproofing of the foundation and underground communications;

- increase the durability and strength of the foundation;

- proceed freely to the next construction work (dismantling monolithic concrete formwork);

- attach waterproofing and thermal insulation materials to the external walls of the foundation (insulation occurs);

- install a drainage system around the property and prevent moisture from entering the basement.

Filling the sinuses ahead of time (before the foundation hardens) can be carried out only when the weather forecast warns of heavy rains, since bad weather can wash out the concrete from the base pouring.

How and with what to fill the foundation inside a house ⋆ Proraboff.rf

The question of how important it is to backfill the foundation from the inside confronts many home owners. In addition, they need to determine exactly what material to fill the free space with.

If the foundation is piled, additional specifics must be taken into account. It is worth figuring out what bulk materials to use for such work and how to organize it.

Before choosing any specific material and determining the thickness of the fill, you need to know the groundwater level characteristic of the site.

Also, the work on backfilling the foundation is affected by soil subsidence.

The owner must also make a choice based on what financial capabilities he has, since backfilling methods vary significantly in cost.

Be that as it may, filling the foundation from the inside is incredibly important. It determines how long the house can last without developing defects. Backfill also affects the level of thermal insulation, which affects heating costs.

What affects the depth of groundwater?

You can start backfilling the foundation yourself only after the cement has completely hardened. Spring floods can have a particularly negative impact on construction.

During this process, the soil outlets rise to the surface, which leads to heaving of the soil and the risk of squeezing out the foundation.

If the foundation is squeezed out, it will be very difficult and expensive to restore the house.

Most often, swelling occurs on clay, swampy and peat soil types.

If a house is being built on such a site, the trench for the strip foundation must be dug lower than the frost line. The inside of the trench is covered with sand by at least a third.

When the depth of groundwater is no more than 2 meters, it is enough to dig a pit to a depth of 80 cm or less.

To compact the soil, it is watered and compacted. Due to such actions, it is possible to get rid of voids that may be present in the ground.

In addition, the moisture capacity of the soil is noticeably reduced.

In cases where groundwater is located closer than 50 cm to the surface, it is very important to dig a trench for the foundation below the level where freezing occurs.

Filling the foundation is an important stage of construction

Now it should be clear how important the filling of the foundation is. But do not forget that other measures to increase its waterproofing are also important.

An owner who wants to better protect his home can additionally arrange drainage, lay waterproofing of the base, and form a blind area around the perimeter.

Then the result will be the most successful.

Source: https://xn--80ac1bcbgb9aa.xn--p1ai/kak-i-chem-zasyipat-fundament-vnutri-doma/

When can it be done?

Filling the cavities with construction soil is permitted only after the foundation of the facility has been built and filled with cement.

It is advisable to start the process immediately after the preparatory work for filling has been completed:

clearing the area of debris (large stones, old rags, polyethylene, unnecessary metal rods, etc.);- allowing the foundation to dry for 2 weeks (in some cases this period can be extended);

- moistening the intended backfill material to 20%;

- choosing a favorable day to complete the task.

Backfilling must be carried out with a homogeneous material similar to the soil on the construction site, meeting the characteristics and requirements of SNiP.

It is more economically profitable to use for backfilling the soil that remains after digging a hole . Because there will be no need to hire additional equipment for its disposal. Only the top layer, which is fertile, needs to be removed (it can be used later in landscape design).

But in practice, for some soils, for example, clayey and rocky soils, it is better to use gully sand for better drainage of the layer.

To fill the depressions, different types of soil are used (clay, sand, small crushed stone). If the land belongs to the category of swelling, then it can only be used in the area of green zones, or provided that an embankment of a non-swelling layer is made along the pit, the width of which must be indicated in the project.

In cold latitudes, the sides of the foundation are carefully insulated from frost heaving of the soil with insulated materials. This gives durability to the structure and its subsequent long-term operation.

The use of wet material for backfilling is set within the following soil compaction coefficients:

- for light soils 12-15%;

- for heavy ones up to 20%.

Light soils include sandy loam and sand, and heavy soils include loams, gravel mixtures, and clay. In professional companies providing building materials, the percentage of required humidity is established using laboratory tests.

In order to achieve moisture, not only water is used, but also a weak, light-colored water-cement solution called “milk.” It can be prepared directly at the construction site using a concrete mixer.

If the soil for work is too wet, it must be dried before use . To do this, it is loosened and turned over. At the same time, special equipment and vehicles (for example, a bulldozer) are used.

The sinuses are filled with soil mixtures according to the level height of groundwater (up to 500 mm). These tasks are carried out immediately after the foundation has been built.

What types of soils are produced?

Determination of the required soil for construction and installation work is used in accordance with GOST 25100-95.

- clay – 1.5;

- sandy loam – 1.65;

- loam – 1.6;

- fine sand – 1.7.

The work can be done with different materials, heavy or light.

Use:

- gravel-sand mixtures;

- sand;

- loams;

- clay.

It is only forbidden to use fertile layers of soil for backfilling, as they are prone to rotting and the formation of fungus.

Natural soil moisture is determined according to GOST 5180-84.

Soil that was removed during digging

This material is used most often, as it is convenient and very economical. In addition, according to the requirements of SNiP, the soil poured into the sinuses must correspond to the earth cover , which is located around the facility under construction. This method is suitable for small buildings.

Sand

According to experts, this material is considered the best for filling sinuses. The most preferred of all types is medium-grain gully sand, which is well cleaned and moistened.

It drains water well and rids the space around the foundation of excess moisture, and after compaction it does not loosen. Another advantage of this material is the fact that over time, it tends to increase the density of the grains, which will ensure reliable fixation of any building.

For clay soils, experts recommend using sand backfill. To do this, work is carried out with imported sand, not excavated on site.

Clay

This material comes in handy in cases where it is not possible to drive up to the construction site. It is allowed to use clay soil mined on site. But, if it does not compact well and is thin, it is recommended to dilute it with special clay of fatty varieties within 5%. The advantage of this soil is water resistance and good plasticity.

When backfilling, it is best to lay layers gradually, after the previous layer has hardened and dried (about 4 of them are needed in total). The thickness of one layer should not be more than 20 cm.

Loams

This type is also called sandy loam, as it is a mixture of clay and sand. Loams drain well and strengthen the walls of the pit, but are inferior to sand.

This material is most often used in regions where loam is the basis of the landscape. Loams drain well and at the same time strengthen the foundation along the edges.

The material is excellent for manual filling and compaction of small holes and pits.

Sand and gravel

It is prepared artificially. It has good density, sufficient mass and exceptional drainage properties.

The composition of the mixture is 40% medium-grain gravel and 60% sand. The mixture is delivered by dump trucks.

Plus ASG is good permeability and gradual compaction of granules due to sand.

Regardless of what kind of soil was used for backfilling, the process itself is a rather important task, since the correct implementation of it can increase the strength of the building being erected and extend the service life of the base - the foundation.

Filling the depressions with mineral soil from a quarry, tested by a laboratory and issued a special Certificate of Suitability, is preferable to independent searches for alternative mixtures. Such services are offered by many private companies that professionally deliver building materials and directly cooperate with manufacturers.

Any inorganic soil most suitable for the site according to the adopted design requires gradual and thorough compaction.

Selecting a foundation backfill material

Sand soil for backfilling

Different types of soil can be used. The main thing is that they comply with humidity and density standards. It is also very important that the filler does not change its qualities under the influence of water. To achieve the proper values of the last indicator, a special technology is used, which involves laying the material in thin layers and then compacting each of them.

Sand

Sand-gravel mixtures are well suited for laying in cavities due to their excellent drainage properties. With a properly organized blind area, this design guarantees reliable protection against heaving at low temperatures. Backfilling with sand also adds stability to the building box. It is also important that the material is easily compacted and retains its density well.

The disadvantage of sand is moisture permeability. Because of this, water accumulates in the thickness of the backfill, which creates an overload of the waterproofing layer. Wetting the sole impairs the load-bearing qualities of the soil. A properly equipped blind area can improve the situation. The correct choice of slope and installation of waterproofing will prevent the accumulation of rain moisture. It is also worth organizing drainage next to the blind area. This will allow water to be diverted for further use on the farm (for example, to water garden crops).

Gully sand is more suitable for placement in sinuses than pure river or quarry sand. This is due to the content of a large amount of salts and clay inclusions, which provide better compaction. Clean sand can be washed out by groundwater. Therefore, it is recommended to use it only in a mixture of half and half with gravel. Gully sand should not be washed as this will remove binding particles. It only needs to be cleaned of inclusions of plant origin and other organic matter.

To calculate how much sand will be needed for work, you can use an online calculator. The formula is tailored to work with different types of backfill. You can compact the sand by slightly wetting it, if this does not harm the components of the base.

Clay materials

Clay is a barrier to water

The best option is skinny clay that hardly absorbs liquid. If you have to deal with hard lumpy material, additives are added to it for plasticity, for example, sand (about 5%). The introduction of impurities does not affect the strength and shrinkage characteristics, but significantly simplifies compaction. The material is suitable for rocky soil, as well as for houses built in areas with low-lying groundwater.

Clay is good because it acts as a barrier to moisture, preventing it from reaching the sole and protecting the latter from destructive influences. The downside of this material is its tendency to heave. Under certain conditions, clay absorbs moisture. The material is laid in thin layers, subject to mandatory compaction.

What technique is used to complete the task?

Backfilling of the sinuses is carried out only after the installation of the foundation and laying work have been completed. To do this, the depressions are filled manually, with the help of a team of workers, or carried out by special equipment that delivers, unloads, compacts, and is suitable for use on large construction sites.

Significant amounts of work can be handled efficiently and quickly:

- loaders;

- excavators;

- bulldozers;

- dump trucks.

Special vehicles used in construction must meet functional characteristics, be in good working order and operate in accordance with labor protection and safety regulations.

Mechanisms and equipment must be selected according to the condition of the soil mixture - its uniformity and moisture content. Despite the assistance of transport, manual compaction of the recesses is required, since it must be done layer by layer.

Mechanical compaction is done with special machines:

- hydraulic hammer "Rummer", SP-62 and 71;

- electric rammers IE-4502A;

- vibrating plates DU-90, 91;

- rollers DU-54M, 58A.

Excavators of such models as:

- EO-3123;

- 4225, 2621В-3;

- as well as its varieties (for example, EO-3532A, UDS-114 planners).

A backhoe loader (for example, a Volvo L45B) performs tasks quickly and efficiently. For large construction sites, the work is carried out by a front loader.

Backfill mixtures developed in the quarry are delivered to the site by KamAZ-6520. This dump truck is loaded with the help of excavators and diggers.

Of the bulldozers involved in the process:

- B170M1.03VR;

- DZ-42, 190.

Rollers compact the top layers of soil.

The need for transport and its quantity is determined by the production project, and depends on the designs, scope of tasks and the planned duration of the process.

The scope of work on a construction site is always determined by the technological map. The angles of lifting and unloading, methods of distribution and compaction, distance to the delivery point, compaction depth, and height of bucket unloading are calculated.

Layer-by-layer backfilling of soil should be as follows:

- sandy loam, loam – up to 60 cm;

- clay - no more than 50 cm;

- sand – up to 70 cm.

The density coefficient is determined by the engineer and reduced to a value of K = 0.98, while the time required for compaction should be 20 s. Backfilling is carried out in the direction from the foundation to the edge of the slope. Tamping by machine or by hand always overlaps the previous mark by 20 cm.

In the area where machines are working, builders, diggers, and vehicle drivers must follow safety rules and maintain a safe distance when unloading soil (1 m from the edge of the pit). All workers must have permission to work and operate machines.

The most common method of backfilling is the mechanical method, which is carried out using a bulldozer, manual finishing and additional compaction with vibrating plates.

Stages of construction work

To carry out a construction operation, you must use working drawings and adhere to instructions and technical rules.

Constructive approaches to backfilling, according to their features, are individually decided in each specific case and determined by the contracting team:

- the scope of work is indicated;

- construction conditions and soil are considered;

- access roads are studied (if the work will be carried out using equipment), and attention is paid to weather conditions.

Next, a technological map is developed using the formula for the volume of drainage soil:

V=100 m

Construction and installation work is worked out by a technologist according to the formula:

To determine the required soil density when filling in the recesses of a hole or pit, the project specifies data on studying the soil mixture in laboratory conditions, using the standard compaction method.

This method establishes the optimal humidity and maximum density, which should be no less than 0.95.

Calculation of the volume of work for backfilling a trench is determined by the following formula:

The total volume of the pit is the volume of the foundation. Example : 1000 m3 – 800 m3 = 200 m3

Then the stages of backfilling work include the following sequence.

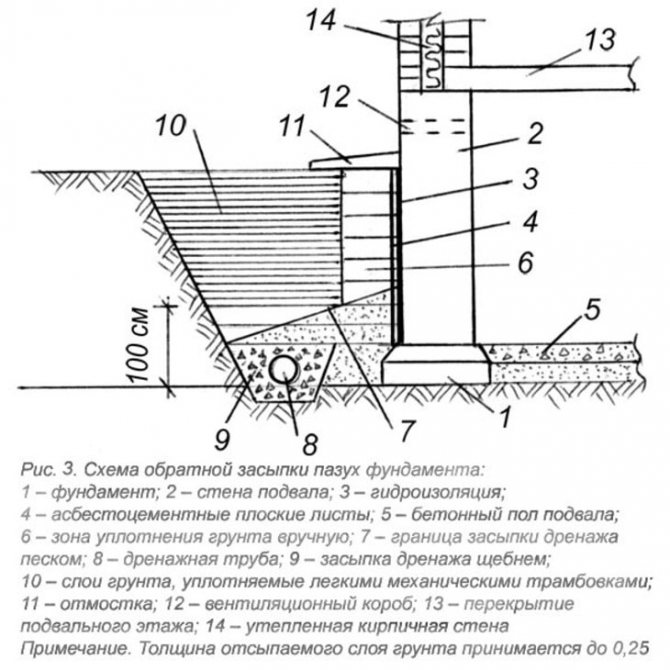

- Carrying out preparatory work:

- removal of excess moisture in the pit;

- pouring concrete into the foundation and testing it for strength;

- waterproofing the walls of the pit;

- removal of construction waste;

- completion of the scope of installation work;

- calculation of the required amount of building mixture for backfilling. The volume of soil for filling recesses in the pit is determined as the difference between the volume of the excavation and the mounted foundation blocks.

- Delivery and unloading of construction materials.

- Layer-by-layer backfilling and soil compaction.

- Filling with cement laitance (if necessary).

- Checking completed work and handing it over.

An example of an executive diagram for backfilling a pit can be downloaded here.

The general step-by-step procedure for backfilling a pit can be presented in the form of a diagram:

Carrying out work using vehicles (for example, an excavator) is specified in the TTK document 01.09.01. document.

You can download a standard map here.

Technical recommendations for production can be found here.

Filling holes requires compliance with technical conditions and sequence of actions.

It can be described in more detail as follows:

- The moistened soil material is not poured all at once, but gradually, distributing it along the entire perimeter.

- Each thin previous layer is well compacted; it should not be more than 20 cm, so it is considered thin.

- The laying of each layer is accompanied by pouring cement laitance.

- Then the next layer is poured again and compacted until the indicators (height) of backfilling the soil mixture are reached.

- The completion of compaction is carried out using a vibrating plate - a modern construction mechanism.

It is necessary to strictly adhere to the points of the project. The height of the poured soil depends on the design of the foundation, and the thickness of the layer corresponds to the characteristics of the material used. The backfill is the basis on which the subfloors are poured.

When installing ventilation, the material is poured 30 cm below the intended holes.

When performing the task of filling the sinuses, it is also important to adhere to the following rules:

- The process needs to begin only when the foundation is ready, the work on installing waterproofing and installing floor slabs has been completed.

- The manual method is used in any case, after the mechanical one.

- You need to move towards the edge of the slope from the foundation gradually, taking precautions.

- Any soil material used must be compacted.

- The vibrating plate is always used at the end of the process.

- During backfilling, to avoid damage to the waterproofing layer, it is covered with asbestos cement slabs.

- When compacting layer-by-layer, the thickness of the soil layer used should not exceed 0.25 m.

- The top layer of soil is compacted to the level of the blind area.

- Before laying communication pipes, you need to pour a 0.3 m cushion of sand or gravel mixtures under them, without using compaction. Then the selected soil layer is laid on top and compacted well.

In order to carry out these construction works as efficiently and correctly as possible, it is necessary to study in detail the requirements for building codes and follow them at every stage. Compliance with the rules guarantees the quality and integrity of the foundation - the foundation, and therefore the entire future building.

When performing the work process, it is imperative to take measures to prevent possible displacement of the foundation walls during one-sided backfilling.

How and with what to fill the foundation inside a house - The builder can do everything

How and with what to fill the foundation inside a house

The question of how important it is to backfill the foundation from the inside confronts many home owners. In addition, they need to determine exactly what material to fill the free space with.

If the foundation is piled, additional specifics must be taken into account. It is worth figuring out what bulk materials to use for such work and how to organize it.

Before choosing any specific material and determining the thickness of the fill, you need to know the groundwater level characteristic of the site.

Also, the work on backfilling the foundation is affected by soil subsidence.

The owner must also make a choice based on what financial capabilities he has, since backfilling methods vary significantly in cost.

Be that as it may, filling the foundation from the inside is incredibly important. It determines how long the house can last without developing defects. Backfill also affects the level of thermal insulation, which affects heating costs.

Prices in the estimate for GESN

In addition, in the estimate you can find prices for filling the sinuses of the pit with sand with draining properties.

The amount is from 10 m3 to 186 rubles. Filling holes manually with soil - from 662 rubles. In the Russian Federation, the cost of construction work, in addition to the proposed prices according to the estimate, may vary depending on the region.

In the Moscow, Leningrad, Krasnoyarsk regions, prices will be much higher than in the Bryansk, Belgorod, Kursk, and Irkutsk regions.

The price indicator is influenced by such factors as the type of technical transport used, mechanical or manual labor, type of soil, total volume of work tasks, material consumption rate.

You can familiarize yourself in detail with the presented prices for contracting services, in accordance with the estimate, using the table here.

Prices from private companies in 5 cities of the Russian Federation

Filling the sinuses with bulk wet material for 1 m3 in rubles is:

- Moscow – from 420;

- St. Petersburg – from 410;

- Belgorod – from 210;

- Krasnodar – from 305;

- Irkutsk – from 290.

Separate prices for backfilling with soil in the estimate include rental services for an excavator, dump truck, and loader. On average, in Russia the price of using equipment is from 1,500 rubles per 1 hour of work.

Many private companies offer to soak the backfilled soil with water before compacting . And then the cost of m3 increases by 150-200 rubles.

Common Process Problems and Errors

When performing assigned construction tasks, problems may arise if backfill calculations are made incorrectly, compliance with technical requirements according to SNiP, as well as safety, is violated.

Common mistakes made by builders include:

Poorly carried out preparatory work.- Wrong choice of soil mixture.

- Dry backfill material.

- Insufficient compaction.

- Using a backfill thickness of more than 500 mm (and should be up to this mark).

- Inconsistency between the material and the soil around the building.

- Backfilling with fertile soil, which is unacceptable, since the organic layer can contribute to the formation of fungus and mold in the sinuses.

- Improper soil storage or freezing.

- Work in unsuitable weather conditions (frost, rainstorms).

In order to avoid mistakes, it is necessary to adhere to the work plan diagram, which is accepted by the engineer and established by the relevant instructions .

For rocky soils and landscapes with low groundwater levels, it is best to use clay backfill.

How and with what to fill the foundation inside a house

Preface.

When building a house where the basement is not planned to be used, many developers ask themselves the following questions: Is it necessary to fill the foundation inside? How to fill the space inside the foundation? How to fill the pile foundation inside? We will try to answer these questions in this article, consider what bulk materials can be used for these purposes and show a video of how to fill the foundation inside under a screed.

Before making a decision on the choice of material and fill level, you should pay attention to the groundwater level in your area and the degree of subsidence of the soil on it. It's also worth thinking things through.

Calculate what will be cheaper - fill the basement of the house with your own hands from the inside with lime, sand or other material, or build a ventilated basement and make high-quality insulation of the floor in a wooden house from below.

An example of backfilling a foundation for a floor screed

After receiving permission to build a house, the administration divides the site and begins excavation work.

The issue of excavation work should be taken very seriously, since the strength of the future structure depends on the completion of this stage.

The design and depth of the foundation depends on the geology of the site: the depth of soil freezing, the groundwater level.