Pouring concrete into water becomes a necessary stage of work in the construction of certain hydraulic structures, as well as sometimes in private individual construction, when groundwater lies very high. And if private construction does not welcome this option, requiring the most acceptable conditions for pouring concrete, then in the industrial sector underwater concreting is carried out without any problems, using created and tested technologies.

Concrete must be poured into the water when various breakwaters, piers, bridges and other types of structures are built. In private, such a need rarely arises - if construction work is carried out near water, if the groundwater level is very high, when there is an urgent need to implement the task in conditions of standing melt water, etc.

There are only two main technologies for industrial pouring of concrete into water: the caisson version and using piles.

Each of them has its own disadvantages and advantages. In individual construction, the capillary option and underwater concreting with bags of cement are used.

Pile method

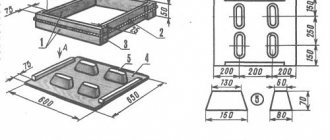

Before pouring concrete into the water, special piles are driven into the bottom of the reservoir - special reinforced concrete pillars connected to each other by means of a tongue-and-groove lock. Locks of this type are used to connect laminate floors, tongue-and-groove floorboards, etc., which is why the piles are also called tongue-and-groove piles.

The lock does not provide tightness, water passes freely into the formwork, but this does not affect the quality of concreting, since the work uses a special type of concrete that is in a semi-ready consistency.

This method is used for deep-sea concreting, as it makes it possible to pour concrete and ensure its strength at a depth of up to 50 meters.

First, a construction site is prepared above the object, where it is planned to pour concrete in water. A lift is installed on the site, and a pipe with a diameter of more than 20 centimeters is hung to it. To ensure correct and fast filling, the lifting rope must lower/raise quickly and operate with an accuracy of less than 3 centimeters.

The pipe is filled with a bag, which prevents water from entering inside and washing out the mixture. The solution is fed into the bag through a funnel - during the weighting process, the base of the pipe is lowered, thus squeezing out the water. The pipe must be filled as tightly as possible; concrete is poured in several levels. Each has an unreliable top layer (there is a risk of water getting into the mixture), so before laying the next layer, a small layer of the previous one is removed.

Large gaps are filled with solution using several large diameter pipes. The solution should be allowed to sit in the air so that it dries a little and the desired consistency is achieved. During the drying process, the concrete is covered with a tarpaulin, protecting it from rain and sun. The solution is prepared with different densities: the saturated one creates a shell 1 meter thick, its core is filled with an unsaturated mixture.

It is imperative to tamp the poured mixture - the work is carried out carefully so as not to cause active vibrations of the water.

Documenting

Concreting in water has its own documentation features. Before starting monolithic work, divers inspect the concrete pouring site and install formwork. In the process of layer-by-layer pouring, each layer is drawn up with a hidden work certificate. A passport is prepared for each cast structure, which indicates:

- concrete class;

- type of construction;

- concreting date;

- actual deviations from design parameters.

The same information is applied with indelible paint to the side face of the structure immediately after dismantling the formwork.

Return to list

Find out the cost of delivering concrete to your site

from our manager by phone or through the request form

Pouring technologies

Before pouring concrete into water, it is necessary to choose the right technology that would meet the requirements and conditions of the work and would allow achieving the required strength and reliability characteristics. In industry and private construction, different technologies are used, which is explained by differences in the scale of work and the conditions for their implementation.

Up-pipe technology

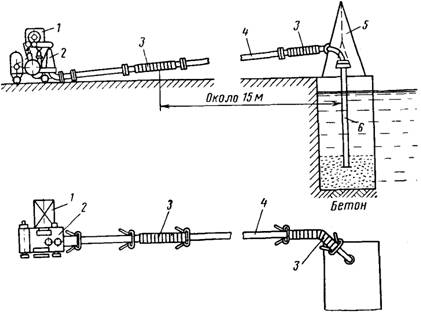

To implement this technology, you will need: two types of concrete mortar, a platform made of piles, any device for lifting a load (this could be a winch or hoist, a small floating crane, etc.), a traverse, pipes, a loading funnel, formwork (will help fence off a closed area). space of the working object from the waters of the reservoir).

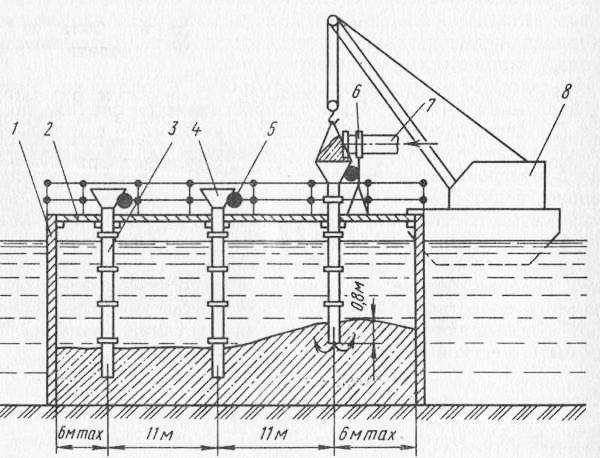

Thanks to this method, it is possible to create strong and reliable concrete structures at relatively shallow depths. A work platform is built on the surface of the reservoir directly above the structure to be poured, on piles (driven into the bottom). A traverse is installed on it, and a supply pipe with a cross-section of at least 20 centimeters is suspended from it. The pipes are raised and lowered using a winch or hoist.

It is best for the solution to be supplied using a concrete pump, and the pipe to be lowered/raised by a floating crane - this way, greater productivity and better quality can be achieved. The number of loading pipes depends on the volume of filling.

Before pouring begins, the bottom of the structure is covered with tarpaulin or canvas (any dense fabric), overlapping the formwork, then the surface is leveled with stone and crushed stone (this is done to avoid concrete leakage through differences in relief). For pouring, saturated and unsaturated concrete are used: the first is to strengthen the formwork around the perimeter, the second is to make the core of the structure. Before pouring, both solutions are kept in air.

The process of pouring concrete into water:

- The pipe (or pipes) is lowered to the bottom

- Concrete is fed into the pipe until its internal space is completely filled.

- The pipe is lifted using a lifting device, during which the solution is unloaded to the bottom

- Filling is done layer by layer until the work is completed.

The work must be done quickly - so that each lower layer does not have time to turn to stone and remains semi-liquid. The method of concreting using pipes is relevant only where there are no strong currents and no noticeable waves in reservoirs.

Caisson method

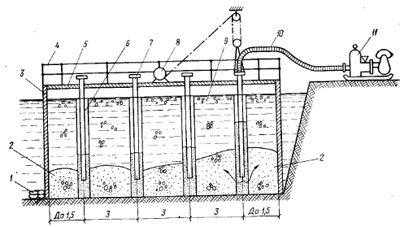

To implement this method you will need: concrete mortar in bags (to make the base), just mortar for pouring, special formwork (caisson), pouring pipes (necessarily with valves), concrete pump, small floating crane, anchors with cables. Typically, this method is chosen for deep-sea concreting at a depth of 30-50 meters, as well as where there are large waves and underwater currents.

The method requires the construction of a fairly strong formwork - if the volume of work is small, it is made of a welded metal structure, which is lowered to the bottom by a floating crane (this is a caisson).

If you plan to pour concrete on a large structure:

- Digging a pit or trench using dredging machines at the bottom of a reservoir of a size that matches the structure

- Filling the pit with bags of concrete

- Driving steel piles into the bottom clearly along the entire perimeter of the base of the structure - you need to make sure that they are with a slight slope (it turns out that the piles are standing like a fan) towards the outside of the structure (to make slopes)

- To prevent the slope from being broken, the piles are secured to the bottom with anchors and cables

- Inside, the surface between the piles is evenly covered with steel sheets with a thickness of at least 10 millimeters or boards with a thickness of at least 50 millimeters

- The outer surface between the piles is reinforced with belts constructed from metal rods, channels or corners

The solution is supplied to the pipes under the action of excess pressure - after all, there are two valves at the ends of the pipe, and the supply is carried out by a concrete pump. The remaining stages are similar to the pile concreting process.

Work options

They can be carried out in two ways:

- at shallow depths, where there are no tides and there are minor waves, the solution is lowered through a funnel into cavities fenced with special jumpers, or concrete is poured into the water;

- at quite impressive depths, in places where the waves can be very strong, caissons become a reliable assistant in concreting work. The concrete mass is moved into such caissons through shafts or pipes. It’s better not with your own hands, but with concrete pumps.

In the photo - hydraulic structures

How is pouring carried out, what is the GOST for water for concrete and mortars? Let's take a closer look at this process.

Method No. 1

- It begins with the fact that in the place where the proposed structure will be erected, rows of piles are driven (sheet piles are used). This makes it possible to avoid drainage works.

- Then concrete is thrown between them through a funnel.

Advice: if the base under the concrete solution is of insufficient density, for example, from thrown stones. In this case, it must first be densely crushed, and then covered with a cloth, the edges of which will be curved upward. Thanks to such measures, the solution will not be able to seep into the crushed stone, and concreting will be much better.

How to concrete in water using a concrete pump

Preparing concrete

After the base is ready, you need to prepare the solution. It is important to remember that it needs some time to mature. At the same time, it should not be exposed to direct sunlight or moisture.

If the solution is kept for the required period, then it will reach the desired consistency for immersion in water: it will set a little and will not erode much in water. This method of preparing a solution was first used by Kinipple, an engineer from the UK.

In this way, he managed to avoid unnecessary costs for installing a system to protect the concrete solution from erosion. Kinipple dipped the solution, which was already half-hardened, under water.

In addition, the engineer provided technology to protect it from the force of waves and underwater currents. To do this, he covered the outside of the concrete surface with thick linen fabric (canvas).

Advice: for the core of such a structure, use an unsaturated solution, while the outer part requires a saturated solution, and its thickness should be at least 1 m.

- Depending on the characteristics of the rate of hardening of the concrete mass, it is necessary to distribute the time between mixing it and moving it into water . It is important to calculate the timing in the most optimal way so that the concrete does not erode too much when immersed. Otherwise, some of the cement will be lost, which will negatively affect the quality of the structure.

- It is also important to ensure that the concrete mass does not become too hard, because in this case it will not bind tightly to the solution that was previously immersed and will not become monolithic . In those underwater areas that are subject to powerful waves and strong currents, a small portion of quick-hardening cement is added before placing the concrete in the water.

- Among other things, concrete submerged in water needs compaction. To ensure this, it is compacted. The top of the tamper is above the water level, taking the blows of the tool used for tamping. Remember that tamping must be done very carefully, because if you overdo it, then too much vibration and waves will inevitably lead to erosion of the concrete.

To obtain such concrete, you will need to mix cement with pure pitch in a ratio of 1 to 2.5.

Advice: the answer to the question - does concrete allow water to pass through can be answered - it depends on the composition, so it can be used to build water tanks.

Reinforced concrete water tanks in production

Method number 2

- Near the area where it is planned to build the necessary concrete structure, for example, a dam, it is necessary to dig two ditches at the bottom using dredging machines. Semi-hardened concrete should be poured into them, directly into the water. The result will be two shafts that will reach the low water level.

Advice: before you start laying them, evaluate the condition of the reservoir in the selected area and the quality of the cement. The price of the latter cannot be low.

- To remove these shafts, the concrete mass is lowered into water in sacks. This idea is not accidental; their value is that in the process they are able to form a monolith. After pouring cement for the shafts, iron piles are driven. Do this at an angle to create slopes.

How to properly prepare concrete mortar

Concrete mortar is prepared in two types - saturated (7 parts crushed stone and 2 parts Portland cement) and unsaturated (6 parts crushed stone and part cement). Both solutions must be kept in the fresh air so that they harden slightly, which will prevent the mixture from being washed away by water: the first solution is kept for 5 hours, the second – 3. Placed under a canopy or covered with something.

In order not to disturb the solidity of the structure, you need to monitor the consistency of the solutions. So, the next layer can only be poured onto a semi-liquid solution that has not yet hardened. Otherwise, the structure will not be strong and cracks may appear.

What determines how long concrete dries: Important Factors

Concrete countertop drying

Its future durability and quality depend on how long concrete dries. As it hardens, it not only takes the required shape, but also gains strength for further construction. Therefore, it is important to know the time frame and circumstances under which its hardening occurs.

The content of the article

What determines the drying time of concrete?

Placing concrete

Hardening concrete and turning it into a full-fledged artificial stone is a complex process, during which not only all excess moisture evaporates from it, but also the composite of components turns into calcium hydrates. This long-term action is conventionally divided into two stages, which are important to distinguish.

Grasping

This is a loss of plasticity and mobility of the mixture, without which full installation is impossible:

- Therefore, concrete is prepared in small portions and worked with very quickly, because a solution that is poorly mixed or hardened in layers will not bring anything good in the future.

- Also for this reason, the finished mixture is transported in special mixers in a state of constant mixing, and then it is promptly poured.

- Typically, setting occurs within 45 to 60 minutes. But in conditions of high temperature and humidity, this process can be halved.

- Cold weather has exactly the opposite effect on setting.

Note: In winter, concrete practically does not harden on its own. To do this, special plasticizers are added and the mixture is heated in the formwork.

Complete hardening

Hardening is the final stage of transformation of the mixture into artificial stone, its crystallization. It is characterized by a brand-name set of strength and rigidity. According to technical documentation for concrete of any type, it occurs after 28 days.

Hardened concrete sample

Attention! That is why they always focus on the results of testing samples at this particular age, and not at an earlier age. Although it was found that after two weeks the concrete gains approximately 70% of its design strength. However, exactly how this process will go in a particular case depends on many factors together.

The following factors have a direct influence on these two stages of concrete hardening, such as:

- temperature and humidity - the higher they are, the faster setting will occur;

- activity during cement steaming;

- quality of aggregates;

- homogeneity of the mixture;

- solution density;

- water cement ratio.

What are the consequences of violating the terms of exposure?

What can happen if the concrete hardening time was not maintained? There is no clear answer to this question.

But from the personal experience of many builders and laboratory workers, specific problems have been identified that can be encountered in the future if the concrete curing technology is violated:

- Cracking. Yes, it’s banal, but there’s no escape from such an unpleasant circumstance. If the cracks are not through, and after quality tests, experts recommend carrying out deep repairs and using the structure, then we can assume that the jackpot has been hit.

It is much worse when the foundation of a house that has already been built and is in use gives a serious fracture along its entire height. This also applies to other structures - for example, walls or ceilings. Hardening of foam concrete is very often accompanied by the formation of cracks in the already formed masonry.

Cracked foam concrete in masonry

- Deformations of various types: fractures, dents, chips. They can appear if the product has been demolished prematurely, and the concrete itself is still “damp”. What to do? Postpone removing the formwork for some more time. If this is not possible, carry out all operations as easily and simply as possible without sudden movements and impacts.

Cracking of fresh screed

- Damage to the finish, for example, on foam concrete walls built from uncured blocks. This leads to crumbling of the plaster. Another example is the peeling of tiles from a concrete screed, on which masonry work began to be carried out in the early stages of setting.

Peeling of tiles from the floor

To prevent such unpleasant moments from happening, you need to know exactly how long it takes for concrete to harden. You can, of course, rely on the experience of experienced builders, but it’s better to play it safe and make your own calculations.

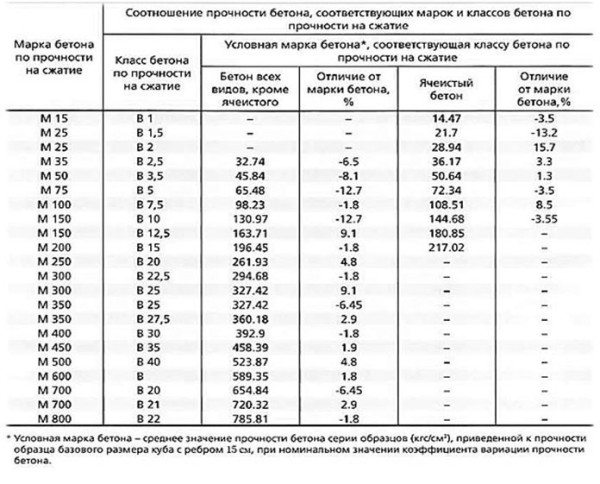

Determination of hardening time and final strength of concrete

You can find out how long concrete hardens yourself by using just one mathematical formula: Rb(n) = M*(lg(n)/lg(28)),

Where:

- M – design strength of concrete;

- n – number of days;

- Rb(n) – strength for n number of days.

Attention! The first three days of pouring are not taken into account, since it is believed that a stable strength gain can be determined starting from 3 days of age.

Approximate strength of concrete at different ages

You can check the strength of concrete and its hardening time, respectively, by testing samples using destructive and non-destructive methods. Both of these methods are GOST, however, “crushing” the cubes on the press still causes more “trust”. The result is considered correct after testing three samples of one batch of concrete.

The video in this article will tell you more clearly how to quickly and easily determine the hardening rate of concrete.

Is it possible to speed up the hardening process of concrete?

Construction is always fast, everything needs to be done “yesterday”. In many cases, “not lightning fast” concrete hardening times do not fit into the grandiose plans of developers. An exciting question immediately arises: how to speed up the hardening of concrete, and at the same time not lose in its quality.

Powdered hardening accelerator for concrete

Today there are a lot of additives and other accelerators dosed into the mixture. At the same time, such additives can still add strength and frost resistance. The main thing is to “listen” to what the instructions on the manufacturer’s packaging “say”.

You can also get quick-drying concrete by using quick-hardening cement. But, it is expensive, and in many cases the price of such a cube does not justify the investment.

Attention! For each type of concrete, developers are happy to offer a special additive. But, be careful: there are no specialized additives for cellular concrete, especially foam concrete. An alternative - yes, but no more. This is due to the fact that not every foam can withstand the action of the additive, and the collapse of its structure is inevitable. As a result: shrinkage, loss of volume, and quality.

Shrinkage of foam concrete

When construction is carried out with one’s own hands, driven by a great desire to also save money, then the use of plasticizers becomes a big question. And then inquisitiveness awakens, eager to know how quickly concrete hardens when using improvised means.

There are several options:

- using heated water, but not boiling water, to mix concrete;

- do not skimp on cement, take a good one with 1 activity group during steaming;

- wrap the formwork not only with film, but also with technical felt;

- if the pouring area is small and it is possible to arrange a “steam room”, then why not - a closed space, heated air and buckets of water.

When drying under natural conditions in summer, it is also important to create a good humidity regime. But then will concrete harden in water, because its excess is fraught with poor quality?

The answer is simple and unambiguous - yes, hardening will occur. Also, it will not crack if you constantly and abundantly water the decked concrete with water. It is even recommended and actively practiced.

Option for moistening concrete during hardening

Interesting fact! To test the strength and activity of cement at 28 days of age, standard tests are performed: beam samples are kept in a container with water all this time. Of course, they are placed there after setting under natural conditions. Only such circumstances of maintaining cement beams are considered truly true. This is due to the fact that when cement gains strength, it needs moisture, especially during the first 28 days.

So what is the difference between ordinary concrete made with the same binder?

Pouring concrete with water

Only by knowing exactly how long concrete takes to dry, and maintaining it for the required time, can you achieve high quality and be sure that the house will definitely not collapse due to the fact that once everything was done “by eye.”

beton-house.com

Work with concrete in water for private housing construction

In individual construction, other technologies for pouring concrete into water are used, which allow solving a variety of problems. After all, pouring concrete into water for a foundation, for example, is unacceptable. Therefore, you first need to make a reliable and durable concrete structure, and then build a foundation on it.

Device using bags

The technology is quite simple: a saturated solution is mixed, poured into bags, which are used to fill a pit or trench (a prepared hole above the groundwater level). They wait 30 days, then formwork (walls or foundation) is built around the structure using conventional technology.

Underwater concreting with cement bags

Bags filled with concrete mortar are used, similar to the type of base construction for caisson concreting. A saturated concrete solution is mixed and filled into pre-prepared bags. Next, a trench or pit is filled with bags of liquid solution (above the level of nearby groundwater).

The structure is maintained for at least 30 days, after which formwork is erected around the object and pouring (of the foundation or walls) is carried out using classical technology.

How long does it take for concrete to harden?

Today there is nowhere without concrete structures. That is why you should know how long concrete hardens and what factors influence this phenomenon. The main characteristic of each concrete mixture is compressive strength. It is used to determine the brand of building material. Concrete gains the required strength within a month, and this does not depend on its brand. This is what forces workers to stop construction work and wait for the concrete to dry. During the first week, the material gains more than half of its strength, and only then this process slows down. The concrete will be completely dry only on the 28th day. There are cases when builders do not wait for complete drying and continue work. Naturally, such actions lead to a deterioration in the quality of the entire structure. In order for the structure to become strong and reliable, it is necessary to withstand the necessary drying time. Only the formwork can be dismantled within a week after pouring.

Factors influencing good and rapid hardening:

1. The temperature is above zero (approximately 20 degrees).

2. Air humidity (about 80%).

But unfortunately, it is not always possible to comply with these conditions, and then wet sand, sawdust or chambers come to the rescue. This building material hardens much faster if the area in which it is located is wet. Builders insist on somehow hiding the concrete room, because if you leave it in the open air, the moisture will evaporate, and as a result, the strength of the concrete will be very low. Films are often used.

How long does it take for concrete to harden and does rapid drying affect its quality?

Cement consists of grains, each of them has a core. And they cannot react with moisture very quickly. The strength of a building material directly depends on the air temperature. If the temperature is below 17-18 degrees Celsius, it will take much longer to harden. High temperature and humidity promote rapid drying. By observing these conditions, concrete will gain its strength (75%) within two weeks. However, such premature hardening does not always have a positive effect on its quality. It may develop damage and various defects. After all, shrinkage in the internal parts of the material is much slower than in the external parts.

Are there other ways to speed up the hardening of concrete?

In addition to humidity and temperature, the type of cement also affects the speed. Various chemical additives in it also play a huge role. Practice shows that the use of cement with a high percentage of rapid hardening has a negative effect on the quality of the structure. It is for this reason that it is worth thinking, for example, not about how long it takes for a concrete foundation to dry, but whether it will turn out to be of high quality.

How long does it take for concrete to harden at a temperature of 30 degrees Celsius?

It sets almost instantly, there’s no talk of a month or more. But there is one significant drawback - the low quality of the structure. The building material intensively loses moisture from its structure, and as a result, hydration stops. At such a high temperature, concrete will dry within a couple of hours after it is poured.

How long does it take for concrete to harden at sub-zero temperatures?

In winter, it is generally not recommended to carry out construction work with concrete. Due to the cold, the hydration process is significantly reduced and strength comes with a huge delay. If we compare the drying time with a temperature of 18 degrees and minus 5, then in the second case you will have to wait 8 times longer.

dommovik.ru

What is added to concrete to make it waterproof?

Additives are the main component in a concrete mixture, increasing its waterproofing properties. Concrete becomes moisture resistant and durable. But this mixture should only be used on horizontal surfaces, since on vertical surfaces it simply slides down. Of course, this can be avoided by using a special protective film that presses the solution against the structure. But it will take a lot of time and effort.

The market puts forward a huge number of different additives, with different prices. There are several substances that are most commonly used as additives. This:

- silicate glue;

- ferric chloride;

- calcium nitrate. Perhaps the cheapest option, which has excellent resistance to moisture. It dissolves well in water, is not toxic, however, it can cause a fire;

- sodium oleate and many other additives that increase moisture-resistant quality.

You must add the component following the instructions!

There are discussions about what additives are best added to the concrete mixture: domestic or imported from abroad? A definite answer has not yet been found, since they all have good quality brands. But they still insist that domestic ones are better because they are distinguished by their low price, which means they can be used for mass use.