For the construction of private cottages intended for permanent residence or country houses, such a convenient and easy-to-install material as building blocks is often used. They can also be used when arranging the foundation of a building. For these purposes, special solid foundation blocks (abbreviated as FBS) are used. Their characteristics, as well as the distinctive features of use, will be discussed in this article.

Characteristics and features of FBS foundation blocks

FBS is produced from concrete mortar with a density from 1800 to 2400 kg/m3. The specification assumes the following three mixture options: with a strength above B7.5 (grade M100), at least B12.5 (grade M15), heavy concrete with strength from B3.5 (grade M50) to B15 (grade M200).

The resistance to low temperatures demonstrated by FBS must be at least F50 (which means that the foundation block can withstand a minimum of 50 freeze/thaw cycles). The optimal level of moisture resistance is W2, the thermal conductivity of the block is quite high, but this is not a problem for the foundation.

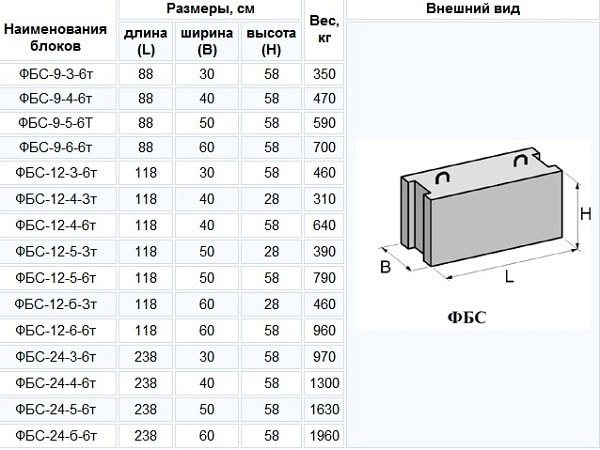

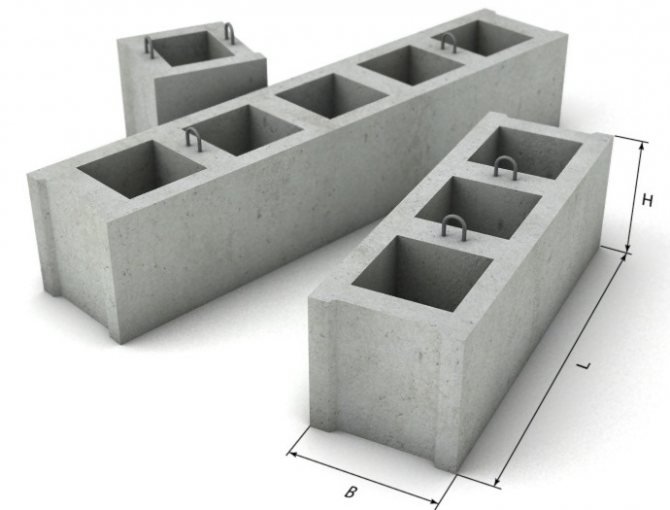

When indicating the size of the FBS, indicate its size in decimeters, rounding up. In addition to the dimensions, they also indicate the type of concrete from which the FBS is made: heavy (T), silicate (S), expanded clay (P, with a porous base).

An example of decoding the markings of the FBS-24-4-6 T block: the size of the foundation block is 240 centimeters in length, 40 and 60 centimeters on the sides, it is made of heavy concrete. Marking can be done in different ways (with periods, hyphens, spaces), but always requires the indication of basic quantities.

The weight of the FBS starts from 260 kilograms, so the construction of the foundation is carried out exclusively with the use of special equipment; the work cannot be completed with your own hands.

In the construction of residential buildings, foundation blocks of short length are usually used; multi-storey and industrial buildings - the largest ones. In the production of blocks, a certain error in dimensions is allowed.

Permissible dimensional errors in the standard:

- Height/width – deviation up to 8 millimeters.

- Length – no more than 13 millimeters.

- Along the cutout - up to 5 millimeters.

When purchasing and selecting blocks, it is important to pay attention to the size and weight of the FBS. So, if the weight is below the specified value, and the dimensions are normal, this indicates the presence of void areas in the blocks, poor compaction of the material, which negatively affects its strength. It is better not to use such blocks in the construction of a foundation.

To facilitate the installation process, the blocks are produced with special metal eyes, which are placed on top. They are made from periodic metal profiles or steel. If necessary, you can order small blocks without hinges. According to GOST, there should be no cracks or deformations on the blocks. In addition to the main types, FBP, FBV and others are also produced for the construction of residential and public buildings.

Advantages and disadvantages

When choosing the appropriate size of FBS foundation blocks and performing calculations for them, it is important to study all the features of the material, the pros and cons that need to be taken into account in construction.

The main advantages of using FBS:

- High quality of all products manufactured in strict accordance with GOST standards.

- Strict control of the entire technological process during production, which guarantees reliability and durability, compliance with the specified technical characteristics.

- Quick installation - erecting a foundation and walls from blocks takes literally a few days.

- Ease of operation - installation does not require any special knowledge or skills.

- Large selection of sizes - most often the height and width of the blocks are standard, but the length can be any. But if necessary, you can find elements with almost any width and other parameters.

- There are no complex requirements for operation - the blocks are not afraid of weather influences, aggressive environments, and can be used on wet soils.

- Long service life.

- Excellent indicators of frost resistance, resistance to moisture, fire safety.

Among the disadvantages of FBS, it is worth noting such as the need to use special equipment for installation (which increases the price of work), the importance of laying a layer of waterproofing between the joints, and the mandatory additional insulation.

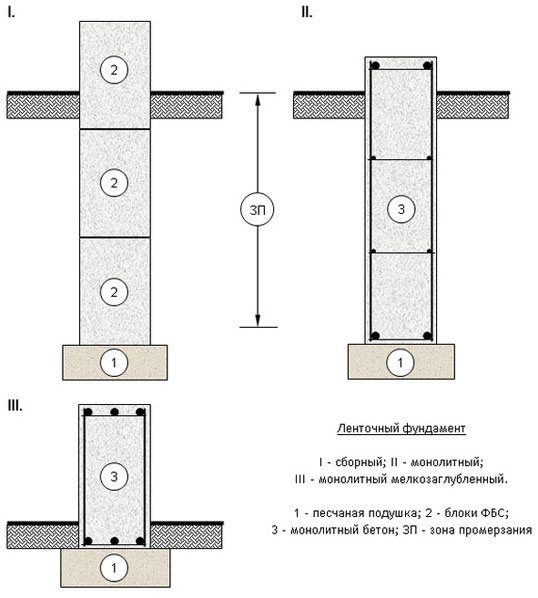

When compared with a monolithic base, it is much stronger than a prefabricated one, but for many types of structures, a prefabricated base is a more economical and suitable option.

Finishing operations

After completing the laying of the foundation strip, you need to clean the walls from any remaining concrete mortar and prime them with a primer. External surfaces must be covered with roll waterproofing in two layers. If the soil is relatively weakly saturated with water, and only surface water is present, then only capillary moisture threatens the walls. In this case, you can get by with coating waterproofing made of bitumen and SBS rubber.

A layer of insulation is glued on top of the waterproofing. Typically, sheets of extruded polystyrene foam or EPS are used, with a thickness of at least 50 mm. Previously, only the outer surfaces of foundation walls were thermally insulated; now experts recommend insulating basements and basements from the inside, especially if the house is heated. This allows you to shift the dew point inside the insulation layer, and since EPS does not absorb water vapor, such a measure makes it possible to avoid condensation on the walls inside the basement.

Any excess moisture for concrete blocks means rapid aging and destruction of the reinforcing steel frame, so any cracks or damage to the concrete material are pre-treated with waterproofing primers before laying the insulation.

The last stage of arranging a foundation strip of blocks consists of filling the spaces between the masonry and the walls of the pit with a dry mixture of clay, ground slag and sand. The top layer of soil removed when digging a pit cannot be used for backfilling the foundation. Most often, sand with loams is selected from the bottom layers of the pit or quarry sands mixed with thin, dry clay are used.

Choosing block sizes

Block sizes can be very different. That is why designing a foundation is quite simple - choosing a FBS of the required size will not be difficult. When selecting dimensions, they take into account future loads that the foundation must withstand, as well as the need to distribute them evenly over the base.

The strength and load-bearing capacity of the structure, installation technology, implementation time of the “zero cycle” and the price of the foundation depend on the size of the FBS. Also take into account soil types and soil bearing capacity. Be sure to calculate in advance the thickness of the walls, floors of the building, the weight of the structure, strength and the required area of the foundation. The greater the weight of the structure and the less stability of the soil, the larger the foundation blocks you need to choose.

Thus, for clayey soils, large elements are chosen; for coarse soils, a base is created from small FBS. The most dense installation involves the use of elements of different sizes. When choosing blocks, remember this simple rule: it is optimal to have 5 blocks per length of the wall.

Installation of foundations from monolithic structures

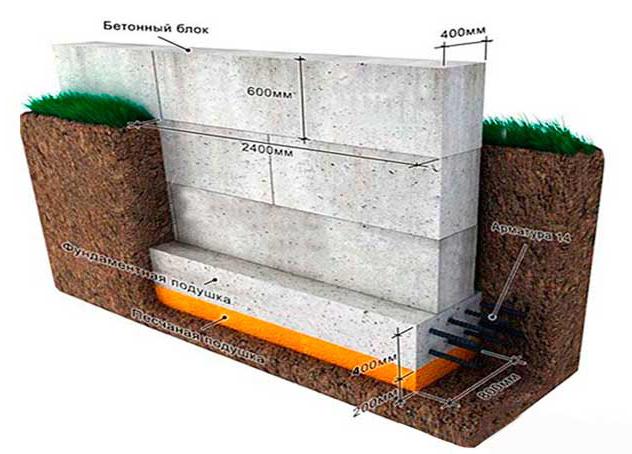

Reinforced concrete blocks are universal in use and can be used for the construction of a wide variety of types of foundations, with the exception of pile types of foundation. During operation, the installed modules transfer the mechanical load created by the mass of the building to the soil layers or a pre-prepared cushion. To form a solid foundation, it is necessary to adhere to a number of rules determined by the technology for constructing prefabricated foundations:

- before laying, it is necessary to arrange a cushion of sand or crushed stone (the final choice of material depends on the design solution and is selected according to the properties of the specific soil);

- Before forming the cushion, the soil must be compacted, the quality of which will determine the degree of strength and the presence of possible subsidence. In this regard, it is rational to use automation in the form of a vibratory rammer;

- the blocks in the first row are placed on a cushion without using cement mortars for fixation. Initially, corner modules must be accurately installed according to the markings, the installation of subsequent ones is controlled by a plumb line, excluding the slope of the edges;

- in cases where the standard dimensions of monolithic modules do not allow the formation of a foundation of the required length from solid elements, the blocks are broken using a crane;

- at the joints it is necessary to ensure the integrity of the seams using cement-sand or concrete mortar, which is used to seal and fill the seams. It is allowed to fill the resulting openings with bricks, as well as other materials;

- installation of reinforced concrete products of the second row is carried out on a solution with a layer thickness of at least 5 mm. Stones and other solid elements that could cause damage to the integrity of the base are not allowed to get into the gaps;

- During the construction of the foundation, it is necessary to constantly monitor the position of the blocks in space, adhering to the verticality of the structure and the straightness of the walls. Construction scrap can be used to move the modules slightly until the solution hardens and sets.

FBS blocks: product dimensions

Regardless of the brand used in the production of blocks, serial sizes are usually provided in standard sizes. If you need to purchase blocks of non-standard sizes, you need to order them at the factory or look for additional elements.

Standard FBS sizes:

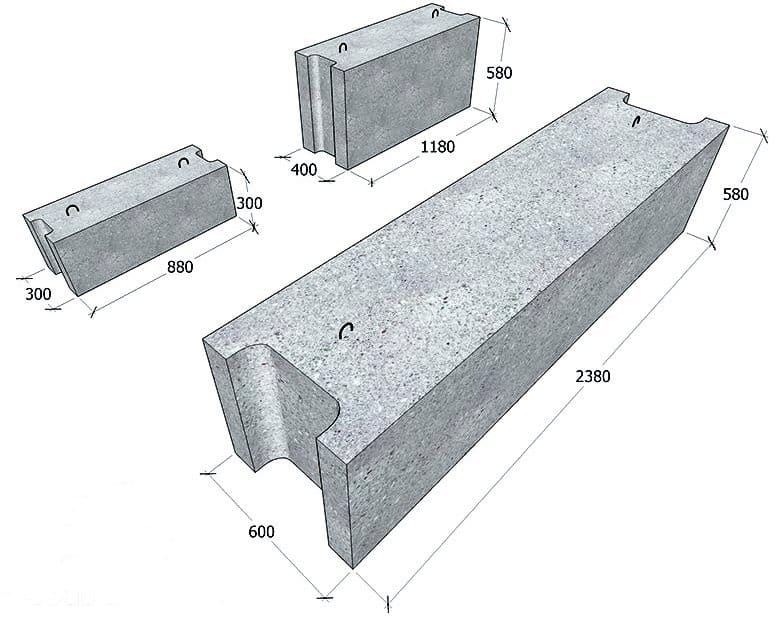

- Length – 88, 118, 238 centimeters.

- Height – 28.58 centimeters.

- Width – 30, 40, 50, 60 centimeters.

Each block must have a marking indicating the length, width/height in decimeters. These parameters must comply with GOST 13579-78. The presence of letters next to the size indicates the type of concrete from which the elements are made.

GOST suggests that FSB is produced in 15 standard sizes. The main characteristic of the dimensions is the width, which varies from 30 to 60 centimeters. The length can be in three options, the height is usually standard (with the exception of a block with a length of 118 centimeters, the height of which is always 28 centimeters). The smallest size element has 88 centimeters in length, 30 in height and 58 in width, the largest - 238/60/58.

A standard block is a solid reinforced concrete product, without any voids. When choosing blocks, it is important to request a quality certificate from the manufacturer, which will guarantee that the blocks comply with the requirements of the standards.

How to choose the right size of FBS blocks

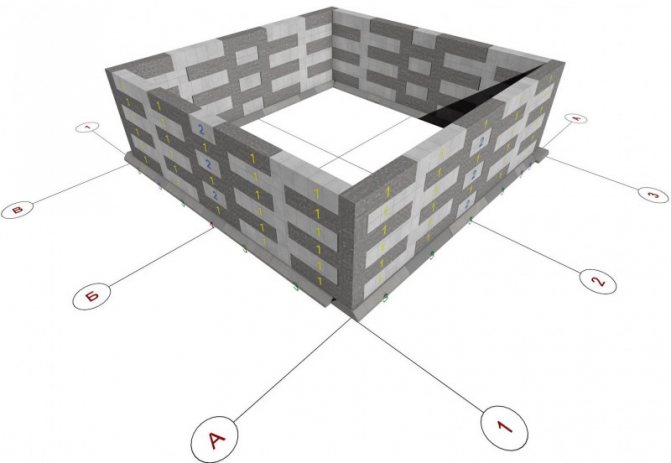

A variety of blocks are used to create foundations. In order to accurately determine the dimensions and number of elements, a sweep of the base is made: on a special drawing, a conditional layout of all elements is performed along the length/height of the basement wall of the structure. The dressing between blocks should be at least 25 centimeters.

The width of the FBS is selected in accordance with the thickness of the building walls. According to the standard, a small overhang of above-ground structures is allowed. If you plan to build brick walls, the protrusion should be no more than 4 centimeters on the sides. It is allowed to use blocks 60 centimeters wide for walls 64 centimeters wide and blocks 50 for structures 51 centimeters wide.

The length of the FBS is determined based on the development, where elements of different lengths are placed so that they are mounted smoothly, without protrusions. It is advisable to have no more than 5 elements per wall.

As for height, products with a height of 58 centimeters are usually used for the construction of foundations and walls. Blocks 28 centimeters high are used as composite (additional) elements if it is necessary to make a hole in the foundation for the input/output of networks, vents, etc.

An important indicator is the mass of the FBS, which is important when choosing special equipment used for installation work. This parameter is also important when organizing the delivery of blocks to the site and loading/unloading elements. Without the use of special equipment, it is allowed to install only small-sized FBS measuring 20x20x40 centimeters.

Stage two

At the second stage, you need to prepare the construction site. A place to install the crane is selected, a place for the foundation is cleared and work begins.

The site is marked starting from the corners. Pegs are installed at the corners of the future foundation. Next, a pit is dug for the foundation. An excavator is most often used for this.

Rules for choosing workwear for builders: an overview of all the features

Brick foundation - main applications, construction stages and tips for strengthening the foundation (105 photos and videos)

Strip foundation - step-by-step description of marking, installation of formwork and foundation filling (115 photos)

Types of blocks according to GOST: FBS, FBP, FBV, FL and BF

For the construction of technical underground premises, the construction of basement walls, the installation of strip/column foundations, as well as the construction of walls of low (often unheated) buildings, and other structures operated at temperatures ranging from +50 to -70 degrees, three types of concrete blocks are traditionally used ( according to GOST 13579-78): FBS, FBP and FBV. They are made from heavy or silicate, as well as expanded clay concrete. The density of such products should be 1800 kg/m3 and higher.

FBS is a solid foundation block with maximum strength. Small products are not reinforced, they are only equipped with metal mounting loops. Dimensional blocks are reinforced with longitudinal steel rods, which significantly increases the weight and strength of building elements.

FBV blocks assume the presence of a longitudinal dimension in the product cavity itself. This cut is needed to install various utilities. Such products are produced using the same technology as FBS, but from concrete grade no lower than M100. Such blocks are rarely used in construction; they are usually ordered at the factory. Standard dimensions: length 88 centimeters, height 58 and width 40/50/60 centimeters.

FBP are hollow lightweight blocks with open square-shaped holes located at the bottom of the element. Blocks are produced from concrete grades no lower than M150, their standard length is 238 centimeters. Linear dimensions can be very different, which determines the cost of the product. FBP is used in the construction of foundations for industrial equipment and for arranging walls inside the basement.

There are also blocks marked FL, which have a trapezoidal shape and are usually used as a base for a strip/column type foundation. The dimensions and parameters of such unique “pillows” are regulated by GOST 13580-85. The height of the elements can be 30/50 centimeters, width - from 60 to 320 centimeters, length - 78-298 centimeters.

The smallest blocks have dimensions of 118 by 60 by 30 centimeters, the largest ones have dimensions of 298 by 200 by 50 centimeters.

BF blocks are used for the construction of external/internal walls of buildings of industrial and agricultural enterprises. Reinforced concrete strip blocks are produced from heavy concrete, in accordance with GOST 28737-90. There are only 6 types of block cross-sectional sizes.

Scope of use of blocks

Solid foundation blocks are used in the construction of foundations and load-bearing walls. This is considered their main purpose. In addition, retaining walls, overpasses, bridges, and ramps are built from block stones, and they are used to construct fences. In the private residential sector you can also find cellars built from foundation blocks.

Here is a description of the main uses of this building material.

Foundation

The construction of a foundation from FBS blocks is permitted in those soil areas that are suitable for the construction of prefabricated strip foundations from FBS blocks. It is good if the soil is rocky or sandy. In weaker soil areas, having erected two next block rows, they arrange an armored belt - pouring a monolithic tape onto the FBS blocks along the reinforcement frame. In addition, the specifics of construction from foundation blocks on such lands provide for the installation of a reinforcing belt along the entire bottom of the pit before the removal of the first row. After this, a sand cushion is placed under the FBS blocks.

On low-heaving soil, it is allowed to build an intermittent foundation. This feature allows you to save material and money. In such foundations, empty spaces remain between the blocks, which are subsequently filled with soil and compacted.

This option for constructing a foundation from foundation blocks is possible only in areas with reliable load-bearing capacity. Calculations are made in advance, in which the distance between the stones should not exceed seventy centimeters.

Such foundations, as well as foundations made of blocks in one row, are erected for low-rise buildings constructed from lightweight building materials.

In addition, in an area with weak soil composition, the first row can be laid out with foundation blocks with a thrust bearing (cushion). Such blocks are wider, increasing the base area. Between them, gaps of up to 0.7 m are left, filled with earth. Solid blocks are laid on the “reinforced” row so that the seam areas fall on the material of the bottom row.

The technology of building a foundation from FBS blocks has a special feature. Experts advise buying material with the maximum length in order to minimize the number of seams, thereby giving the foundation good strength.

Manufacturers and prices

Concrete products such as FBS and other blocks are produced by many concrete plants, so finding them in Moscow and the regions is not difficult. The production volume may vary, but all serious manufacturers guarantee high quality and adherence to technology in strict accordance with current GOSTs.

One of the largest manufacturers of FBS in Russia is the Industrial Construction Parts Plant. All products are manufactured in accordance with GOST standards, they are durable and of high quality; the average price of foundation blocks starts from 1,200 rubles per piece.

specializes in the creation of various concrete elements. The product range includes more than four hundred items, including various types of foundation blocks. The cost varies, depending on the size and type, on average it starts from 1650 rubles.

The products are of high quality. The plant creates various types of concrete blocks, the cost of which depends on the position, but is at a slightly lower level in comparison with other manufacturers.

The Alexandria expanded clay plant produces various types of concrete products. Small concrete blocks used in the creation of load-bearing walls, columns, fences, and also used as supporting elements of semi-basements, basements, and basement floors are in fairly high demand. All blocks are produced in special molds, which guarantees dimensional accuracy. The cost varies, depending on the type and size of the element.

The Zlatoust plant supplies good products to the construction market - the product range includes FBS, FVP, FBP, panels, stairs, road slabs and lintels. All concrete products are sold at an affordable price; the cost of a foundation block starts from 950 rubles per piece.

Features of installation of foundation FBS blocks

Installation of foundation blocks is quite simple and does not require special qualifications, but requires the use of special equipment.

Main stages of FBS installation:

- Carrying out calculations of the number and size of foundation blocks that will be needed to create the foundation. First, the volume of the structure is determined, the value is divided by the volume of a separate block.

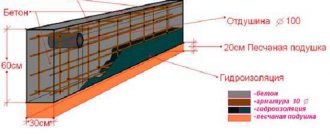

- Preparation of the base - first, a layer of sand 5-10 centimeters thick is filled with a cushion, then it is carefully leveled and compacted. The width/length of the base should be 25-30 centimeters greater than the values of the planned building.

- The correct layout of the site is carried out along the axes using construction plumbs and levels.

- Installation of FBS with a lifting mechanism. Previously, it was advisable to install beacon blocks in the corners, at lintels and intersections of the foundation. Using a level, they check the coincidence of the beacons (between which the cord is stretched) along the upper planes. The remaining elements of the first row are placed along the cord. To carry out utilities, gaps are left between the blocks (based on the design).

The correct installation of the first row directly affects the geometry of the entire base. And the accuracy of installation must be checked with a level. If necessary, all structural elements are corrected with a crowbar. Next, the row is built according to the principle of making brickwork. Between the rows it is advisable to provide a layer of concrete mortar, compacted with a bayonet shovel.

The height of a standard foundation is usually 5 rows of elements. For small structures, blocks of 40x60x20 centimeters are quite suitable.

The sizes of FBS blocks can be viewed in special tables. Provided that the calculations are carried out correctly and the installation technology is followed, thanks to the blocks you can create a reliable, strong, durable foundation.

Stage-by-stage construction of the foundation. First stage

At the first stage, it is worth preparing for the construction of a block foundation. A detailed construction project is created, in which all dimensions are indicated.

Based on the selected dimensions, you should calculate the number of blocks. To do this, you will need to know what dimensions the foundation blocks have.

You should familiarize yourself with the assortment of construction stores that carry blocks. Then a detailed quantity calculation is made.

So, after calculating the number of blocks and drawing up a plan, you can begin purchasing the blocks themselves. First, find out what types of foundation blocks there are.

Many retail outlets provide additional services for the delivery and installation of structures. This is very convenient for home craftsmen.