94

The foundation is the basic structure on which the entire house rests. The bookmarking process requires seriousness. You need to consult with experts, carry out calculations, perform analysis. Often people want to save money. They try to dig a pit with their own hands.

Foundation pit

Even minor mistakes lead to consequences. They cause the collapse of the house, its deformation and damage. And what’s worse, the safety of the residents depends on it.

How to make a foundation for a house with your own hands - types of structures, construction methods.

Building a house is a rather complex, labor-intensive and responsible process. The process of constructing a residential building includes several stages, at one of which the foundation for the house is installed. This stage is one of the key ones, since the quality of the laid foundation determines the durability of the building, its protection from many internal and external factors, and the degree of safety. A competent approach to foundation construction allows you to avoid many mistakes. In addition, one should take into account the fact that experts distinguish several types of foundations, each of which has its own characteristics and is suitable for a particular soil and type of structure. Depending on the design features, it is customary to distinguish strip, pile, slab and columnar foundations. And now - a little about each of them.

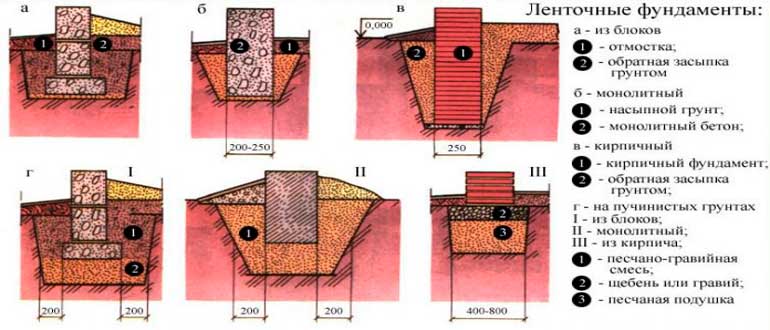

Strip foundations are ideal for the construction of residential buildings with heavy walls and floor slabs. That is why it is located along the entire perimeter of external walls and under other areas with an increased degree of load. In addition, the presence of an underground garage, cellar or basement is another argument in favor of a strip foundation. In a fairly general form, this type of foundation consists of strips buried in the ground. The entire load from the load-bearing elements of the house: columns, walls is transferred to them. The belts are supported by foundation slabs, so-called distribution pads. This design allows the existing load on the ground to be distributed evenly and over a large area. Strip foundations are divided into types according to various criteria. So, according to execution they are divided into:

- Prefabricated. They are made of reinforced concrete blocks, which are mounted directly on the construction site using a crane.

- Monolithic. Such foundations are initially laid at the construction site.

Depending on the material used, it is customary to distinguish:

- Brick strip foundations made of solid clay bricks.

- Rubble concrete. To lay them, concrete with coarse filler is used, which is used as large gravel and small boulders.

- Reinforced concrete strip foundations, which require class B15-B30 concrete and reinforcement.

Types of strip foundations for a house.

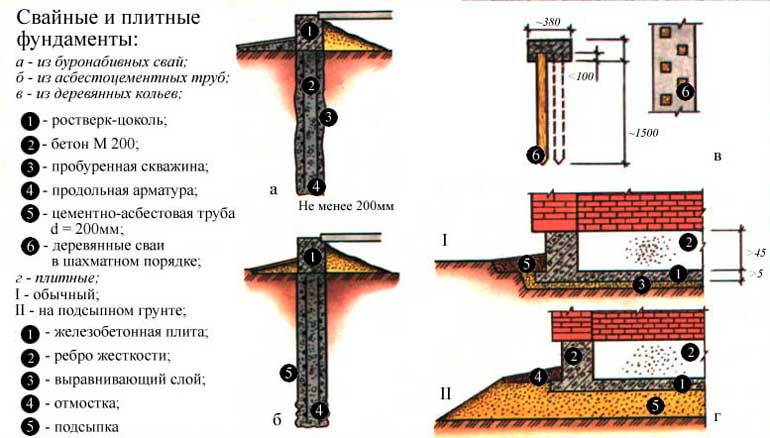

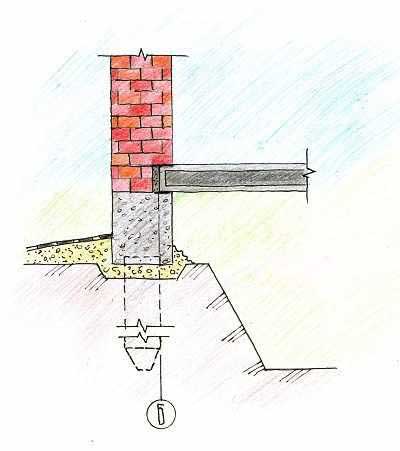

This type of foundation is suitable for soils characterized by weak bearing capacity with a fairly significant load on it of a residential building. It is worth noting that building the foundation of a house on stilts has gained wide popularity due to the low cost of materials and high performance. A pile foundation consists of groups of piles or individual piles, which are connected to each other from above using a slab or beam.

The material for making slabs and beams is concrete or reinforced concrete. This design ensures the stability and safety of the future residential building in the case when weak soil lies at a sufficiently great depth: subsidence, loose sand. Pile foundations also differ in the type of construction and the material used. By type of production we can distinguish:

- Driven foundations. They are laid using special machines on previously undeveloped territory.

- Pressed pile foundations. The piles are pressed into the ground using powerful hydraulic pumps.

- Rammed foundations. When they are laid, concrete is fed into a pre-drilled well.

Depending on the material used, pile foundations can be:

- Metal. Piles are metal pipes.

- Wooden. The piles are made from treated pine and are ideal for small wooden houses, the height of which does not exceed 2 floors.

- Reinforced concrete. This foundation is suitable for reinforced concrete structures and is made of reinforced concrete.

- Combined. For this type of foundation, both metal and concrete are used, which makes it possible to build houses in areas with difficult engineering and geological conditions.

A slab foundation most often lies on the surface of the ground or is only slightly buried into it. It is a reinforced slab made of reinforced concrete, the thickness of which can be in the range of 0.3 m - 1 m. The reinforcement of the slab is carried out using reinforcement with a diameter of 12 mm - 25 mm. Before laying the slab, the surface is prepared from low-strength concrete or sand, which allows the soil to be leveled.

A slab foundation can be used on soft soils, as it helps to effectively distribute the load from a residential building over the entire area of the laid slab. In addition, it allows the perception of horizontal and vertical deformations. Most often, this type of foundation is used for the construction of houses above two floors. It is carried out monolithically and directly on the construction site. It is worth noting that a slab foundation is also suitable for houses with a complex structure. However, in this case, the slab must have expansion joints that cut the slab into separate parts.

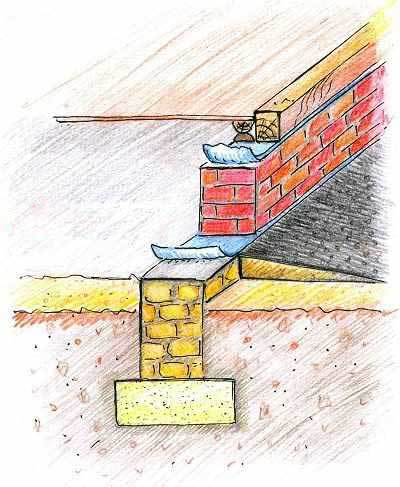

You can lay the foundation for a house with your own hands by choosing a columnar foundation. A columnar foundation is pillars immersed to a strictly defined depth in the ground, or concrete immersed in a pre-drilled well. The pillars are connected at the top using reinforced concrete beams. Columnar foundations are optimal for the construction of low houses of 1-2 floors. At the same time, the weight of the materials used for construction should not be too large. It is ideal if the walls of the house are made of wood or other lightweight analogue. A columnar foundation is also suitable for frame objects, but it is worth considering that it is used only on those soils that are not subject to heaving. Depending on the type of execution, columnar foundations can be:

- Monolithic. Made from concrete.

- Prefabricated.

The material can be:

- Stone. Suitable for the construction of residential buildings with fairly heavy structures.

- Tree. The most commonly used wood is pine or oak. Suitable for small wooden buildings.

- Clay brick.

- Concrete with reinforcing reinforcement cage. Used in the construction of heavy houses and buildings without a basement.

Types of columnar foundations.

When deciding how to lay the foundation of a house that will ensure its reliability and durability, you must first be guided by some general recommendations.

They are suitable for all types of foundations, being universal, and represent a list of factors that are recommended to be taken into account when choosing and laying a foundation.

- Soil condition, its type.

- Freezing depth.

- Load on the ground from the structures of a residential building.

- Availability of a basement or underground garage.

- Lifespan of a house under construction.

- Materials used to lay the foundation.

- Availability of underground communications.

Undoubtedly, when solving the problem of how to build a foundation for a house and avoid mistakes, you need to know the possible flaws. A common mistake can be considered laying the foundation of a future house on an uncompacted foundation (soil). In addition, it would be a mistake not to take into account the force of lateral pressure that the soil exerts on the foundation walls. Incorrect calculation of the bearing capacity of the soil can also lead to many negative consequences, as well as the lack of proper calculation of the supporting area of the foundation of the house. You should not neglect measures related to draining water from the foundation.

The question of how to make a foundation for a house correctly can be resolved by a clear sequence of actions. Thus, we can distinguish five main stages of foundation construction.

At the first stage of laying the foundation, the condition of the soil and the depth of groundwater are determined. To do this, you can dig a hole about 1 m deep and evaluate the composition of the soil and the presence of water in the hole. If it is available, then the depth of the foundation should exceed 0.5 m, and if it is absent, the depth of the foundation may not exceed 0.5 m.

Then the site is marked and the fertile layer of soil is removed. After this procedure, a trench is dug around the perimeter of the future house, the bottom of which is leveled with sand.

How to make a foundation for a house.

Structural diagram of the resulting foundation.

At the third stage, the foundation is poured directly. For this purpose, formwork is made from specially prepared boards or plywood. The pouring itself is carried out with concrete of one class or another. The density of the concrete solution is directly proportional to the strength of the foundation: the thicker the solution, the stronger the foundation of the house. In this case, the width of the foundation should be approximately 20 cm greater than the thickness of the corresponding wall.

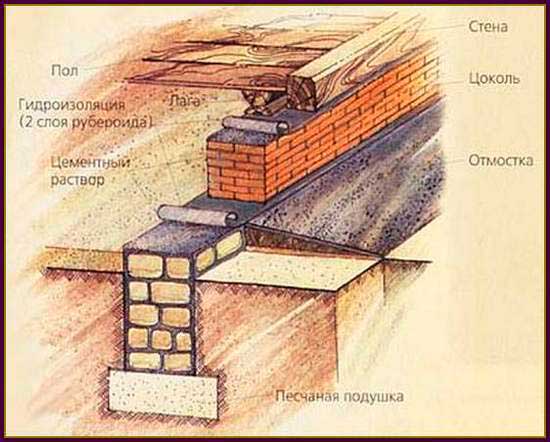

Then measures are taken to waterproof the foundation. To do this, 2 layers of roofing material are introduced into the foundation at ground level, after which its laying continues to the required height. The underground part of the foundation can be pre-coated with hot bitumen.

After the waterproofing layer, bricks or blocks are laid, and holes for ventilation are made in the opposite walls of the laid foundation, which will avoid unwanted dampness under the floor of the house.

Thus, taking into account a number of nuances, laying the foundation of a house with your own hands is not so difficult.

Pit dimensions

If everything is very clear with the shape of the pit: for a strip pit you need to dig a trench, for a slab pit you need to dig a pit, then with the dimensions the situation is much more serious.

Incorrect determination of values can lead to freezing of the foundation or filling of the space under the floor with groundwater.

Depth

The pit must be at least 0.4 m

The development of a foundation pit must be carried out by accurately determining the level of groundwater and the depth of soil freezing in the area. According to the second requirement, it is necessary to make a hole of at least 0.4 m.

The first parameter, on the contrary, limits the depth, since installing foundations on watery soil will require the construction of high-quality waterproofing, which will significantly increase the cost of the work.

Therefore, the pit level should be located between these two parameters.

| Estimated freezing depth of non-heaving soil, m | Estimated freezing depth of slightly heaving soil of solid and semi-solid consistency, m | Foundation depth, m |

| Up to 2 | Up to 1 | 0,5 |

| Until 3 | Up to 1.5 | 0,75 |

| More than 3 | From 1.5 to 2.5 | 1 |

Lenght and width

The size of the foundation should be 0.3 - 0.4 m larger than the facade of the house

Here the situation is somewhat simpler: the length and width of the trench for the strip foundation is guided by the architectural plan of the house. It will run along the entire perimeter of the load-bearing walls of the future building. The values should exceed the dimensions of the facade by 0.3 - 0.4 m, approximately 0.15 - 0.2 m on each side.

It should be taken into account that such values relate only to the base of the foundation; the upper part, located at the level of the soil surface, is made equal to the dimensions equal to the installation depth of the base. These parameters make it possible to create a 45-degree slope of the walls, which protects the soil from crumbling.

As an example, consider the following situation. If the foundation strip is 0.4 m, the width of the trench for the strip base must be at least 1 m. This value provides for the installation of formwork and a trapezoidal foundation.

Stages of self-construction of foundations for a country house.

How to make a foundation for a house with your own hands.

Preparatory work for arranging a strip foundation with your own hands.

Many private developers are constantly faced with the need to build the foundation of a country house for themselves, their friend or neighbor in the countryside. Moreover, this can be a private residential building or a commercial structure, so for each specific house the foundation structure can differ significantly.

Many existing foundations can be built by yourself in a matter of days or weeks, and if everything is done correctly, then the reliability of such a foundation is practically no different from one that was built using powerful construction equipment and teams of qualified builders.

Installation of formwork and installation of reinforcement

The metal frame of the pillars of such a foundation usually consists of 4 rods. Using knitting wire and ring-shaped clamps, they are connected into a frame. Next, blocks (or special plastic stands) 5 cm thick are placed in the pits. A frame is installed on them. This is necessary so that the metal reinforcement is subsequently completely embedded in the thickness of the concrete and subsequently does not rust.

When constructing a columnar foundation for a wooden building, the length of the frame is chosen equal to the length of the supports themselves (minus 5+5 cm at the top and bottom). If it is planned to arrange a grillage, the rods are brought out on top of the latter by 20 cm. In the future, this will make it possible to connect the reinforcement of the pillars and the grillage.

What factors does the choice of foundation depend on?

How to make a foundation for a house with your own hands.

The process of determining the type of soil for arranging the foundation of a house.

To build a foundation for a country house, it is necessary to correctly determine the type, characteristics and purpose of the future structure, as well as adhere to the step-by-step methodology for constructing the load-bearing structures of the structure. Factors influencing the choice of foundation:

- Soil type and load-bearing characteristics. It is worth taking into account the height of the groundwater, seasonal heaving of the soil, the load-bearing characteristics of the soil, as well as the terrain. It is clear that on a strong slope no one will build a monolithic foundation or prefabricated structures made of aerated concrete, because then a huge amount of work will have to be done to level the site. But a columnar base with a grillage is ideal for such purposes.

- The mass of the future building and its overall dimensions. As a rule, country houses are rarely multi-story; they are built one-story, less often two-story. Relatively lightweight aerated concrete or heavier bricks are used as building materials; concrete blocks are not used here. Therefore, a private house is distinguished by its lightness and low permissible load on the ground, and it is advisable to select the type of foundation after calculations.

- Financial component. Every builder of a private house understands perfectly well that the financial component plays an important role in the construction of the foundation. It is clear that they all want to choose the right structure for a private one-story house, but they also immediately calculate all the permissible risks and the cost of building materials. Therefore, if there is aerated concrete production nearby or deposits of natural building stone are discovered, they will use it and the foundation structure will be appropriate. In addition, the foundation for a house is often built with one’s own hands without the use of additional labor and powerful construction equipment, as this will significantly increase the cost of the financial estimate.

- Purpose of the future building. If this is a one-story or more private residential building, then the foundation is selected as strong and reliable as possible. But if this is a small outbuilding, then the type of foundation will be completely different.

You also need to remember that step-by-step instructions for laying a foundation differ significantly under different climatic conditions and the characteristics of a particular area, so it would be more correct to first decide and then build. An important role is played by the choice of building materials, from what exactly the future foundation for a country house will be built.

Pouring with lean concrete

The price of concrete preparation for the foundation is in the middle between the previous ones. At the same time, the strength of the concrete base is much higher than the crushed stone cushion.

After pouring thin concrete, the soil does not sag, and the structure is fixed as reliably as possible. The thickness of the concrete preparation for the foundation, according to SNiP, ranges from 15 to 30 cm.

This indicator is determined based on the following parameters:

- soil type,

- groundwater level,

- mass of the building being constructed.

The components of the concrete mortar are standard, but their proportions in the mortar differ from ready-mixed concrete

Lean concrete is a solution consisting of 6% cement grade M100 with strength B15 with aggregates of crushed stone and sand. The specificity of the composition and the minimum of components contribute to the rapid hydration of the mixture.

Recipe for the composition for the concrete base per 1 m3:

- cement - 275 kg,

- sand - 590 kg,

- crushed stone - 1377 kg,

- water - 165 l.

If it is necessary to enhance the frost resistance or moisture resistance of the layer, additives and plasticizers are included in the composition. The solution preparation time should be no more than 5 minutes.

The photo shows a diagram of the maximum possible set of the foundation pie of a monolithic slab with the installation of a footing

Types of foundations for a country house.

How to make a foundation for a house with your own hands.

Tape. It is easy and quick to build such a foundation for a country house, and often you can use aerated concrete or brick.

It is used in the construction of heavy one-story or more buildings, the load-bearing walls and ceilings of which will be built from heavy materials. This type of foundation is popular in suburban construction due to the ability to equip underground premises (garage, basement or technical floor).

Of course, there are several types of such bases that differ in design:

- Prefabricated. The device involves the use of ready-made factory reinforced concrete blocks, which are mounted directly on the construction site.

- Monolithic. By design, they have a single monolithic slab, load-bearing walls are erected on it. Such a slab is made from brick or rubble concrete, less often from aerated concrete. Reinforcing mesh can also be used here; such foundations are already called reinforced concrete.

- Pile foundations for weak soils. The device involves the installation of ready-made metal or reinforced concrete piles (pillars) at the construction site. They can be of considerable length, since it is necessary to reach strong layers of soil below the freezing line.

Also, such foundations are popular because of their practicality and reliability, although it will not be possible to build even a one-story, but large private building on stilts.

Piles can be different, ranging from metal and reinforced concrete to wood. The weaker the material, the less load they can withstand. Therefore, for the construction of a large private country building, it is better to immediately use reinforced concrete structures, which can be made directly on the construction site.

Just first you need to carry out the correct calculations and lay the foundation under optimal temperature conditions. It is also worth initially deciding what the foundation will be built from and creating a step-by-step methodology for its construction.

- Universal monolithic slab. The construction of such a foundation allows the construction of private houses even on soft soils, because then the load is distributed evenly over the entire area of the base.

But the foundation is expensive due to the large amount of concrete and reinforcement, and building it with weak materials at hand is prohibited by building codes. It is better to lay such a foundation for small country houses, because then there will be a minimum of financial expenses for land work, and the foundation can be shallow.

Calculation of cement mortar

The process of making concrete footings

After marking the area planned for the installation of a sub-concrete protective layer for the foundation, the work is carried out in the following order:

- A pit or trench is dug, depending on what type of foundation is planned for the device.

- Crushed stone is poured into the bottom of the prepared pit, after which the layer is compacted. The thickness of the crushed stone layer is on average about 10 cm.

- Formwork panels are being installed. The height of the shields should be at the level of the planned filling layer; this will simplify the leveling process and allow the reinforcing frame to be correctly placed.

View of the prepared site for pouring lean concrete

- Horizontal reinforcement is laid. Typically, periodic steel bars with a diameter of 8 mm are used. You can simplify the process by using special cards of construction reinforcing mesh.

- Vertical reinforcement rods are installed, protruding 20 - 30 cm beyond the edge of the formwork. These rods will allow you to connect the concrete footing to the base of the building. Sometimes vertical bars are installed in poured and compacted concrete.

- The filling composition is mixed. The cement binder used when mixing the solution is cement grade M50 or more.

- The finished solution is poured into the formwork and compacted using mechanical vibrators.

After this, the concrete footing is left alone until it sets completely. This process takes place over 4 weeks. You can learn more about the technology of constructing concrete footings with your own hands by watching the video in this article.

The main stages of laying the foundation.

How to make a foundation for a house with your own hands.

Scheme for determining the angle of inclination of the terrain for arranging the foundation of a building

As a rule, laying the foundation always begins with preparing the construction site. But in practice, everything turns out a little differently, because it is impossible to choose and build the foundation correctly without preliminary calculations. Therefore, there are several key preparatory steps that need to be done before building the foundation for a house yourself:

- First, a detailed geodetic exploration of the territory is carried out, a soil map is drawn up and the depth of groundwater is specified.

- Then a map of the soil structure is developed and the depth of solid rocks and the limiting depth of soil freezing are determined.

- The location where it is best to build the designed private building is determined.

- The angle of inclination of the terrain is determined, and minor unevenness of the construction site is eliminated.

- A calculation is made of the maximum permissible load on the foundation, taking into account building materials. Sometimes in such calculations, aerated concrete is taken as the initial parameters, which is larger in mass than brick, but smaller than concrete structures.

- The optimal type of foundation is selected.

- The type of building materials that are best suited for the construction of the designed structure is selected.

Step-by-step instructions for laying a strip foundation for a one-story country house.

How to make a foundation for a house with your own hands.

Do-it-yourself preparatory work for laying a strip foundation for a house

How to make a foundation for a house with your own hands? In practice, it is not as difficult as it seems, but still, consulting an experienced builder will not be superfluous, since the knowledge gained will help to avoid mistakes. Laying any foundation consists of the following steps using the example of a strip structure:

- The construction site is marked, the surface is leveled and the loose layer of fertile soil is removed.

- Then a trench of the estimated depth and width is dug along the perimeter of the future building, the bottom is leveled and a sand cushion is formed on it.

- Along the perimeter of the future foundation, wooden formwork is installed, inside of which a reinforcing belt is provided. The design, structure and characteristics of the reinforcement are selected individually for a specific type of foundation.

- After installing the reinforcement and connecting it, the actual filling of the trench with concrete begins. This must be done evenly; separation should not be allowed. In this case, it is possible to use prefabricated structures made of concrete or aerated concrete, only then the reinforcement must be done both horizontal and vertical with longitudinal inserts.

A layer of waterproofing is installed on the outer surface of the finished base, then you can further strengthen the structure with a vertical row of aerated concrete or brick.

Types of preparation

The most common types of preparation:

- sandy;

- gravel or crushed stone;

- concrete;

- membrane

Sand and crushed stone preparation

At the first stage, after excavation work, backfill is made from inert materials, followed by compaction with tampers. The thickness of the sand, crushed stone or gravel cushion is 20-60 cm. If the groundwater level is high, geotextiles are spread along the bottom of the pit.

Large fractions are laid first, then medium ones. They provide drainage to the base. The top layer is covered with sand. This distribution of materials by size gives the cushion under a strip or slab foundation greater rigidity and strength. The use of sand in preparation is necessary for uniform transfer of vertical load to the underlying layers.

The requirements for fine aggregate are:

- they use sand with a grain size of 2-2.5 mm, the most suitable for filling pillows - crushed gravelly sand with low specific gravity and high water throughput;

- the amount of clay particles, lime and salt contaminants should be minimal;

- organic residues lead to a rapid loss of water permeability and siltation of the sand layer, so their presence is not allowed.

The backfill for the foundation is made of gravel, granite or crushed limestone with an average strength of M800 and a fraction size of 20-70 mm. Layer-by-layer compaction with a vibrating plate or manual tampers is mandatory every 50 mm. The sand is first spilled with water.

Concrete preparation

The cushion under the slab or foundation blocks is made in two ways. The first is pouring a layer of crushed stone with liquid bitumen, the second is installing a footing made of low-grade concrete M50-M100 with a layer of up to 10 cm.

A concrete pad for the foundation is made:

- pouring into a trench or the bottom of a pit without formwork;

- installation of formwork around the perimeter of the site and subsequent spreading of the concrete base;

- First, concrete of the design grade is placed in the form for the foundation.

The solution is leveled using beacons or a rule, and compacted with a vibrator. The top of the concrete base is waterproofed with bitumen, rolled materials, and waterproof films.

Preparation with geomembrane

Polymer membranes have recently appeared on the construction market. Fiber is used to protect the foundation of a building from soil moisture, i.e. as waterproofing. What is fundamentally new is that the profile in the form of spikes simultaneously serves to strengthen the soil. Manufacturers claim that the use of geomembranes reduces the number of shrinkage cracks and redistributes forces when transferring load to the base. The cross-sectional shape prevents water from entering, and the voids between the insulation and the concrete are ventilated.

The fiber is laid using sand and crushed stone preparation; a layer of geotextile is first laid out. Membrane seams are connected by welding. The material is strong and durable, withstands high and low temperatures.

How to properly build a columnar or pile foundation with your own hands.

How to make a foundation for a house with your own hands.

Schematic representation of the procedure for laying the columnar foundation of a building with your own hands

Considering that a columnar or pile foundation is more commonly used for the construction of small private buildings for economic purposes, the financial costs of its construction are minimal.

To do this, you first need to mark the territory, set marks for future posts and drill holes to a given depth. Then sand and gravel are poured onto the bottom of the well, compacted and a vertical reinforcement belt is installed.

After all the preparatory work, the wells are filled with concrete and left to dry for several weeks. Instead of concrete, you can use aerated concrete, only in such cases it is necessary to initially provide good waterproofing of rectangular pillars.

How to choose a brand of cement

- M50 is suitable for the construction of light, auxiliary buildings (summer house on a summer cottage, garage, outbuildings).

- F-75 will be needed if the winter temperature is below minus 20 °C.

- For residential buildings, a grade of at least M200 with a water resistance level of 95% is required.

If you plan to pour the base at once, it is recommended to use the entire prepared volume of concrete in one day. If this is not possible, work is resumed at least 12 hours after the first layer has completely dried. Without this, cracks will form on the surface of the base due to the uneven distribution of uncured concrete.

Cement M400 for foundation

Strip foundation.

One of the most popular types of foundations for any individual buildings is a strip foundation. In the usual case, it is a rigid reinforced concrete frame that is poured under the load-bearing walls of the building. However, there are also such designs when the grillage serves as a frame for the supporting pillars of the foundation.

How to properly make a foundation for a house.

Arrangement of pick-up

When constructing columnar foundations, such a structure is often laid out of brick. In this case, conventional technology with ligation of sutures is used. To save money, masonry is done using the “half-brick” or “brick” method. To ventilate the pillars in such a fence, small “vents” are left in several places.

Also, sometimes the supports of such a house foundation are simply covered with boards. Of course, the wood is subsequently painted to extend its service life. In addition to boards and bricks, the siding of a house can also be made from sheet materials, for example:

- slate;

- moisture-resistant plywood;

- siding;

- corrugated sheets;

- basement siding.

Under small structures, for example, gazebos, collection is usually not collected.

Pile foundation.

When soil conditions at a construction site do not allow the use of traditional solutions, pile and columnar foundations come to the rescue. The technology for constructing such load-bearing structures is rightfully considered one of the most inexpensive and simplest.

Pile foundation for a house.

Other types of foundations.

You should not think that in each individual case you can only rely on a specific type of foundation for future construction. There is always a choice! It is likely that for your house it is more reliable and economically feasible to pour a slab foundation, and for a barn or bathhouse, a structure made from tires is quite suitable.

Types of foundations for a house.

Pillow device

Sand must first be placed under the supports of the columnar foundation. The cushion formed by this material is intended to cushion the pillars during spring heaving and movement of the building during shrinkage. The thickness of such a layer under the supports, according to the standards, should not be less than 15 cm.

Arrangement of the cushion under the columnar concrete foundation is carried out as follows:

- pour a 5 cm layer of sand onto the compacted and leveled bottom of the pit;

- thoroughly pour it with water to compact it;

- pour the next 5 cm of sand and tamp again;

- pour another 5 cm of sand and water it with water.

At the final stage, the sand cushion is covered with a piece of roofing felt. This prevents water from being drawn up from the lower layers of the support concrete.

Foundation calculation.

If you decide to save on the services of specialists involved in the calculation of load-bearing structures, then the information in the articles presented below will allow you to independently calculate the foundation. Be prepared for the fact that you will have to sit for more than one hour calculating the parameters of the future foundation!

Calculation for the foundation.

Repair and strengthening of the foundation.

Whether there were mistakes made during the construction phase, or the foundation was built a long time ago and is no longer able to cope with previous loads, you may need to carry out repairs or strengthen the foundation. You will learn how to do this from the articles below.

House foundation repair.

Insulation of the foundation.

If the design of your house involves a basement or you plan to permanently live in your own country house, then insulating the foundation will reduce heat losses and create favorable conditions for living. There are many insulation options – which one is right for you?

Foundation insulation for the foundation.

Construction of foundations on various soils.

An important role when choosing the foundation of a house is given to the characteristics of the soil at the construction site. It is often necessary to build foundations on heaving or subsiding soils, which creates certain difficulties when deciding in favor of a specific type of foundation. From the following articles you will learn about the technologies used in the construction of load-bearing structures on various types of soil.

Foundation in a swamp.

Foundation for small structures.

If you are building something with the expectation that the structure will stand for many years, then it is imperative to build a foundation for it. And it doesn’t matter whether it’s a residential building, a bathhouse, a garage, a fence or a greenhouse.

Foundation for a house.

Articles in the category dedicated to home foundations will allow you to independently begin building your own home or any other structure that requires a reliable foundation. Even if you are not a fan of doing the work yourself or you simply don’t have time, the information presented will allow you to monitor the progress of construction work carried out by hired workers.

Recommendation: The article has a general concept of how to make a foundation for a house with your own hands, but the information is not at all enough to build a foundation with your own hands. In reality, the developer will encounter a lot of problems, so before starting actual construction, it is necessary to study this topic in more detail.

Execution of work on the construction of pits

This process is divided into certain stages:

- on the site allocated for the construction of the building, a check is carried out for the passage of communication lines, the diagrams of which can be clarified with local administrative authorities. If such systems are available, you will have to obtain written approval for the procedure for performing excavation work from the organizations servicing this site;

- a site is being prepared for the construction of a private house or other structure, the fertile composition of the soil is removed to a depth of forty centimeters;

- water is pumped out and a drainage ditch is installed;

- Excavation work is being carried out. If the depth of the pit for a monolithic or other foundation exceeds 1.25 m, support beams are installed to prevent the soil from crumbling, and steps are arranged.

Under strip foundation

If you have to build a foundation pit for a strip foundation for a garage or other building, it looks like a buried trench, its dimensions allowing for the installation of formwork panels.

The dimensions are determined as follows: the length and width parameters increase by thirty to forty centimeters, the width of the trench is equal to the sum of the same value of the walls and a gap of fifty centimeters for the installation of shields.

First, the boundaries of the future foundation on the ground surface are determined, and the highest angle is determined. After this, you are allowed to dig using a shovel or tractor and periodically checking the depth with stakes.

The soil is poured nearby so that there is something to cover the backfill and drainage system.

Slab

Step-by-step instructions for installing such a foundation in a rammed pit are as follows:

with a slight recess, the dimensions correspond to the façade parameters of the object. If a slab foundation with insulation to a great depth is to be poured, sum up the dimensions of the load-bearing walls of the building and the height of the foundation;

the soil is developed gradually, in the first layers of fifty centimeters with a gradual decrease in their thickness. As a result, steps are formed on the walls. By the way, if someone doesn’t know how to dig a foundation on a slope, use this technology.

This type of foundation is convenient to pour for standard buildings - a house 8 by 8 or a house 10 by 10 m. It is an ideal solution for the construction of three-story buildings; it is a solid reinforced concrete structure that has almost no shrinkage and is not afraid of heaving of the soil composition.

Columnar

Let's look at how to dig holes for a columnar foundation. In this case, along the perimeter of the object, a half-meter trench is prepared for the foundation (as for laying a water supply system), at the bottom of which holes are made for support pillars. Note that such a supporting structure is made without formwork.