For the construction of small and light buildings, such as bathhouses or cottages made of timber, rounded logs or frames, gazebos and cottages, you can use a simple columnar foundation made of wood. Its installation is quite labor-intensive, but the cost of arranging such a foundation is several times less than if you pour a concrete frame.

To install a column-type wooden foundation, you must use only those types of wood that are resistant to moisture. Teak, larch or pine are optimal, subject to high-quality pre-treatment. It is these types of wood that can serve as foundation pillars for decades. It is worth noting that to create columnar foundation supports, it is better to use exclusively the lower part of the tree trunk, which is called the butt and is characterized by increased wear-resistant characteristics.

Important: it is desirable that the diameter of the wooden support post be at least 200 mm. At the same time, it is worth deepening the columnar foundation made of wood to a depth of at least 50 cm (for the internal walls of the house), and to a depth of 75-115 cm (for load-bearing external walls of the building).

In order for wooden poles to last longer, it is necessary to treat them with an antiseptic before installation. This additional protection of wood allows you to increase the service life of columnar supports by 1.5-2 times.

Wooden foundation: options

Wood can be used to build a foundation in different ways:

- In the form of a columnar foundation, when sections of logs, the so-called “chairs”, following a number of rules, are manually dug into the ground.

- In the form of a pile foundation - the installation of wooden piles is carried out in the same way as reinforced concrete ones, using a pile driving machine.

Our company is ready to carry out driving wooden piles on your site, in accordance with all the requirements of the project, using a high-performance pile driver based on KrAZ (or Ural). Useful materials for you :

- Shallow foundation

- How much does a house foundation cost?

Antiseptic wood treatment

The wood must be sanded in advance and the upper and lower parts must be marked in accordance with the growth of the former tree

This is the most important stage in the construction of a wooden columnar foundation. It is worth knowing that harvesting logs for poles is best done in the cold months between November and January. The wood must be sanded in advance and the upper and lower parts must be marked in accordance with the growth of the former tree.

As an antiseptic method, you can choose one of the following:

- Burning wood to a strong charcoal crust;

- Chemical treatment of wood.

Each method has its own implementation features, advantages and disadvantages.

Firing method

In this case, the tree must be properly burned on all sides to a length equal to its underground part and plus 20-25 cm of the above-ground part of the pillar

In this case, the tree must be properly burned on all sides to a length equal to its underground part and plus 20-25 cm of the above-ground part of the pillar. You can burn wood either with a blowtorch or over a fire. The wood burning method requires compliance with certain rules:

- So, the wood must be burned evenly and ensure that the thickness of the crust does not exceed 2 cm;

- Before firing, the perimeter of the wood should be treated with clay, a layer of 1 cm;

- After the firing technology, the pillars should be coated with bitumen mastic or resin.

Chemical wood treatment

This type of antiseptic wood treatment is much simpler than firing, but requires certain costs for the purchase of chemicals

This type of antiseptic wood treatment is much simpler than firing, but requires certain costs for the purchase of chemicals. The following suspensions can be used as antiseptics:

- Aqueous solutions. This is the simplest type of suspension. You can prepare it from improvised means, such as table salt and boric acid at the rate of 950:50 g, respectively, per 5 liters of just boiled water. The resulting solution is used to treat the wooden support along its entire length.

Important: it is prohibited to use an aqueous solution if the groundwater level in the area is high. Under such conditions, the suspension will simply be washed off from the surface of the post, since it does not have the property of deep penetration into the structure of the tree. Here it is better to use white spirit or solvent.

- Clay paste. This type of product can also be mixed independently from sifted fatty clay and water. The resulting composition is coated with wooden pillars for the foundation.

- Ready-made chemical preparations in the form of solutions of ferrous sulfate, sodium fluoride, zinc chloride, sodium fluoride or ammonium.

- Oils - anthracene, coal, shale, creosote, etc. But such products are the most toxic of all, so you should follow all the rules specified in the instructions.

Important: the most effective antiseptic is the one that has good penetrating ability, is non-toxic, is gentle on metal fasteners without causing corrosion, and is also resistant to fungus.

Wooden foundation on “chairs”

The obvious advantages of such a foundation are its cost-effectiveness and naturalness. Flaws :

- relatively short service life

- the need for manual excavation

- the need for protective measures

- unsuitable for buildings with massive walls

Although the service life of a wooden foundation can be extended by special antiseptic treatment. To do this, you can use the following “ folk ” methods:

- charring of the outer layer 1.5 - 2 cm

- tar treatment

- liquid bitumen treatment

- wrapping with roofing felt or film, etc.

So are the modern ones :

- impregnation with antiparasitic agents

- impregnation with antiseptics

The most suitable for “chairs” is the butt part of pine or oak with a diameter of at least 20 cm. They are installed at the corners of the building at least at a depth of 125 cm. the rest - maybe 20-30 cm less.

It is better if flat stones or a piece of wooden beam 10x20x50 cm are placed under them. In heaving soils, the pillars are wrapped with film in order to minimize the buoyant forces of soil heaving.

Advantages and disadvantages of a wooden foundation

To install a column-type wooden foundation, you must use only those types of wood that are resistant to moisture.

A wooden foundation made of free-standing supports has a number of advantages, which are:

- Simplicity of building a foundation for the house;

- Low cost of work;

- Excellent thermal insulation of a house on a wooden foundation, since wood perfectly retains natural heat and does not allow cold from the ground to penetrate into the building;

- Wood has the property of elastic deformation, which makes such support pillars as wear-resistant as possible under the influence of ground movement and house pressure on them.

The disadvantages of a wooden foundation include a low service life, estimated at several tens of years.

This negative side of wood can especially manifest itself on waterlogged soils. It is worth noting that different types of wood have their own service life, different from others:

- Thus, oak supports can last on average 15 years, and if they are treated with high-quality antiseptic, the service life can be increased to 27-32 years;

- Larch will last less in total - only 7-8 years. If the wood is treated before installation, it will be possible to increase the service life of these types of wood to 11-15 years.

However, even such a minus does not prevent a wooden foundation from being in demand, especially among self-made summer residents.

Wooden foundation on stilts

Technically, installing wood piles is no different from driving reinforced concrete piles. Of course, wood piles are cheaper, but it is better not to use them without antiseptic treatment.

We work with piles with a diameter of 300 mm, which are driven to the designed depth using a pile driver. Our equipment is based on a car with a powerful engine and high cross-country ability. It allows you to carry out piling work even in places with very limited maneuverability.

Please contact our specialists with any questions:

We build reliable foundations from piles!

Contact us and we will do the work

Our company is engaged in the supply and driving of piles. We will carry out pile foundation work. We work in the Moscow region.

Contact us!

- Video of our work

- Our contact details

Our company supplies piles and piling equipment - contact us, we will help!

Selection of material

- oak;

- pine;

- larch.

The advantage of these rocks regarding foundation construction is their resistance to rotting and insect damage . In addition, pine and larch are not subject to waterlogging. They become more durable in conditions of high humidity.

The log parameters should be as follows:

- it is better to choose the butt, i.e. lower part of the trunk;

- The minimum log diameter is 20 cm.

Calculations

Considered on the example of a house with dimensions of 5x6 m, with a ground floor height of 2.7 m, a front height of 2.5 m. The roof covering is slate. The soil is loamy, Ro = 3.5 kg/sq.cm. The ground freezes to 1.3 m.

This happens as follows :

- Initially, the weight of the structure is calculated. In this case, you need to find out the mass of the walls (72 m²), it is equal to 3600 kg. (72*50=3600).

- Next, the mass of the floors is calculated, namely the base and floor between the first and second floors. They have a total area of 60 m², respectively, their mass is 6000 kg. The calculation is similar to the previous paragraph.

- The next step is to calculate the operating load, which is on the ground floor and in the attic. Total area*210 = 12600 kg.

- The weight of the roof will be equal to: total area (46 m²) * 50 = 2300 kg.

- In the case of a slope greater than 60 degrees, the snow load is taken as 0 and is not included in the calculations.

- By summing up all the resulting masses of the individual elements of the house, you get the total weight. In this case it is 31100 kg.

- To calculate the total area of all pillars, you need to use the formula: S = freezing depth (1.3) * total area (31100) / Ro (3.5) = 11550 cm².

- Next, you should calculate the area of one pillar, which is selected for the future foundation. In this case, a drill with a cross-section of 400 mm was selected, which means its area will be 1250 cm².

- The number of pillars for a structure can be found by dividing the total area of the pillars by the area of one pillar. In the above example, this is 10 pieces.

Important: when building a foundation, it is worth remembering that it is possible to install a larger number of pillars than was obtained in the calculations, but it is impossible to install fewer .

Initially, the pillars are installed in places where there is a higher level of load, and then they are distributed in other places, taking into account the symmetry of the location. If necessary, the number of pillars can be increased.

What tree species are suitable for constructing wooden piles?

To make wooden piles, coniferous wood is mainly chosen. Most often these are spruce, pine, fir, and larch. Larch has the best qualities, and therefore advantages in use. This is easy to explain: the fiber of this wood contains the largest amount of resins when compared with other coniferous trees. Resin is a natural preservative and provides wood with protection from rotting. The strength of the piles is also positively affected by the fact that they all have a cross section.

Larch is the best option for wooden piles. The photo shows a larch beam.

A little less often, oak is chosen to make piles. Bog oak could be used much more often, but harvesting it is not practical - the cost is too high. They only use what they find in nature - for example, trunks that have been lying in water for many years. However, this material has exceptional hardness, which can only be compared with a grant.

There is a popular way to protect wood from rotting - the ends of the logs should be burned. This is done three centimeters deep. Due to this, the material becomes stronger (it will be difficult to use a chainsaw, and it will not be possible to cut right away). The protective effect against rotting is guaranteed for at least 25 years.

Main menu

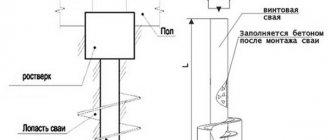

This feature is very important when building on heaving soils, when the soil, freezing, raises the foundation, and with it the structural elements of the house.

The support heel, buried below the freezing point of the soil, reliably holds the foundation, preventing it from rising. Increasing the foundation support area at its lowest point increases the load-bearing capacity of the entire structure.

This quality is especially important when building on soils with low bearing capacity. It is better to make monolithic columnar foundations in low-moisture soils when there is no water in the drilled wells. According to TISE technology, adding a sand cushion to the wells is not allowed, as this can lead to uneven precipitation when compacting the cushion. On soils with low bearing capacity, reinforcement can be done by adding cement laitance.

After this, the wells are reinforced with reinforcing bars, welding them into a frame. When installing the frame, measures should be taken to prevent it from shifting, which could lead to contact of the reinforcement with the ground. Before filling the wells with concrete, it is necessary to map out the marks of the lower edge of the strip foundation of the grillage. To do this, you can use a level or a construction hydraulic level. Concrete is laid in layers, compacted by bayonet. Having filled the spherical cavity, a roofing felt jacket is lowered into the well along the entire diameter of the cylindrical part, aligning its upper edge with the level indicator of the lower part of the grillage.

This tar paper jacket insulates the foundation from the soil, reducing the forces of the soil when it heaves. Columnar foundations are not suitable for houses with a basement or ground floor; they are not used in areas with significant differences in height, since large lateral loads can topple them.

The process of installing wooden piles.

Wooden piles are usually classified into a number of types:

- There are from one log;

- There are also spliced (that is, which are fastened along the length);

- There are also tongue-and-groove and stacked ones.

As a rule, the first two types are most often used. If we talk about the second option (joined piles), there are restrictions on the number of logs in installation - no more than two are allowed. Although, this rule is often violated and a larger number is used (but no more than four - that’s a fact). To fasten logs together (to make ties), clamps are used, and bolted linings are often also used. Cuttings of steel pipes are also often chosen for fastening - due to this, the installation becomes more reliable and durable.

Driving wooden piles in winter

It is important that solid logs have a diameter of at least 18 cm, and if we talk about packaged logs, then they are at least 16 cm. For a single pile, the length standard is in the range of 4-12 m. It is important that the logs are cleared of branches and bark. The lower end is sharpened at solid piles from one log (they give it either a quadrangular or triangular shape), then a steel shoe is stuffed here (if the foundation is built in dense soil, or the soil contains a large percentage of non-metallic materials, for example, gravel, etc.) . The upper end is called the butt. It is reinforced with a yoke so that it does not flatten with a hammer. The yoke is a steel strip, the thickness of which is 12 mm and the length is about 70 mm. The hoop is put on when it is hot - and when it cools down, the butt of the pile is grabbed very tightly, which is what builders require.

To drive piles, a steam-air hammer is used, and a vibratory hammer is also often chosen for such work. A vibratory hammer is also often used, but if necessary, you can always use a simple sledgehammer. Someone uses the press - this is normal.

Repair

How this is done in the case of a columnar structure of a wooden foundation can be found below:

- The first thing you should do is raise the structure that stands on the foundation using jacks and secure it with strong piles or logs.

- Depending on the type of breakdown, a solution to the problem . If the pillar has deviated from the vertical position, then it must be leveled and fixed in this position with the help of an additional embankment that is well compacted. If the pole needs to be replaced, then it must be removed from the soil and, having prepared a new one according to the rules, installed in its place. It should be remembered that it is necessary to remove the old sand cushion in case of replacing a wooden post.

- After the manipulations, it is necessary to check the accuracy of the height of the pillar . Level it if necessary, also check its position in the vertical plane, and then restore the grillage.

- The final touch is lowering the building to its original location.