May 3, 2020 Stroyexpert Home page » Foundation » Installation

Waterproofing with liquid rubber

The foundation is the part on which the reliability and durability of the main structure depends. Therefore, it is important to protect this part from the negative effects of external factors. The greatest damage to the foundation is caused by soil and atmospheric moisture, such as mold, dampness, deformation and destruction of the structure. Therefore, it is necessary to create reliable protection for the foundation of the house from a damp environment. One of the modern means used for waterproofing foundations is liquid rubber.

Types of liquid waterproofing

Rubber is not a completely correct name for a protective equipment; rubber is not present in the compositions, with rare exceptions. The main component is bitumen mastic.

Rubber-based product:

There are two types:

- One-component;

A simple substance that involves bitumen mastic with the addition of polymers. The composition includes an aqueous solution of calcium chloride. When dry, a film forms. Apply with a brush or roller. It is allowed to dilute the insulation with water.

- Two-component.

Two components are used: bitumen emulsion and fixer. When the compositions are mixed, polymerization of the substance occurs - “hardening”. You cannot apply the composition manually, with a roller or brush; hardening occurs almost instantly. You need a spray bottle with two nozzles and containers. The components are supplied under pressure through nozzles, the substances are mixed immediately before application to the surface to be treated. The reaction occurs within a few seconds, after one or two minutes the substance hardens and forms a coating with rubber properties.

Characteristics of the new insulating material and its advantages

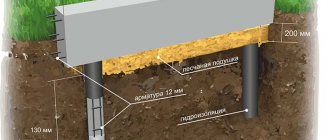

Foundation waterproofing

The traditional material that was used to seal cracks and joints on roofs, house foundations, and between blocks to ensure the tightness of structures was bitumen resin, a by-product of oil refining. The molten resin was poured into the joints, into the cracks, and after cooling it hardened, forming a dense layer through which water could not pass. The big disadvantage of this material is its fragility. The resin melts in the sun and is destroyed by temperature changes and when dried in the wind.

A new material that contains bitumen, as well as latex - artificial rubber, which is made in the form of an emulsion. When hardened, an unusually durable layer is created that is completely impermeable to water. This film has significant advantages:

- Mechanical strength, which increases over time;

- Elasticity due to the presence of latex. This property allows you to fill the smallest holes and cracks in concrete slabs, providing complete protection against water penetration;

- The flexibility of the rubber coating allows you to protect the most vulnerable areas and seal joints;

- The protective film is laid down in an even layer without blisters and bumps, that is, the service life of the coating increases;

- Resistance to environmental conditions;

- Impossibility of peeling off from the concrete surface and moisture getting under the layer of material. The insulation layer adheres equally firmly to any component used to build the foundation of the house - concrete, iron, and also adheres to the old coating;

- No harmful decomposition products, non-toxic material;

- No smell;

Coating plinth walls with liquid rubber

- Fire safety, since the solvent in this emulsion is water;

- Formation of a continuous, seamless surface providing additional strength.

- This waterproofing coating does not require reapplication and has a neat appearance.

What is liquid rubber?

Rubber is not present in the products; there is bitumen mastic with the addition of composite polymers, which give the composition “rubber” properties - this is true for most compositions.

“Liquid” rubber is used to preserve surfaces from destruction by wet environments. Application to the insulated surface is carried out in different ways:

- By hand - with brushes, spatula;

- Mechanical, spray gun.

It is applied to the surface in a “cold” way, without heat treatment. After application, it immediately gains strength and acquires working properties, resulting in a monolithic coating that is resistant to moisture, ultraviolet radiation, and mechanical stress. It has increased permeability into porous surfaces and has excellent adhesion to almost any surface, especially concrete.

Hence the name

Liquid rubber is a viscous black liquid with an odor. Characteristics:

- Shore hardness: 4 units;

- Water absorption: less than 0.7;

- 100% water permeability at a pressure of 0.1 Pa during the day;

- Flammability class G3;

- Elongation at break no less than 2.2 times;

- Maximum elongation (at break) is about 2.5 times.

- Density after hardening – 1 kg/cm².

Specifications may vary depending on the manufacturer and brand.

Advantages of cooperation with our company

If you decide to contact us about waterproofing the basement of any building, you will receive:

- free visit of a specialist to the site for a preliminary inspection;

- qualified consultation, calculation of the cost of services;

- certified high-quality materials from well-known manufacturers;

- fast and professional implementation of preparatory and waterproofing work;

- guarantees for both materials and services performed.

In our arsenal we not only have specialized equipment and materials, we have extensive experience in the field of waterproofing with liquid rubber and are ready to share it with you.

Advantages

When compared with solid analogues, they are inferior to it in a number of indicators:

- Good bonding properties (adhesion) even in the absence of a bonding primer.

- Simplicity, speed of application.

- Hygroscopic composition, solidity. No seams or cracks.

- High tensile strength. Resistant to single mechanical impacts.

- Environmentally friendly, harmless. When heated, it does not emit harmful substances.

- Possibility of repair. No dismantling required, spot repairs on site.

- Processing of complex surfaces. The only condition is increased layer thickness at the joints and the use of reinforcing tapes.

- "Cold" application. The waterproofing agent is ready for application.

- Durability – more than 20 years. During operation it does not lose properties. Technologically, ossification is acceptable with long-term use without compromising technical properties.

- Wide temperature range of use – from -60 to +90 °C.

- Most formulations have good resistance to ultraviolet radiation.

- Many samples can be applied to an untreated surface at high humidity.

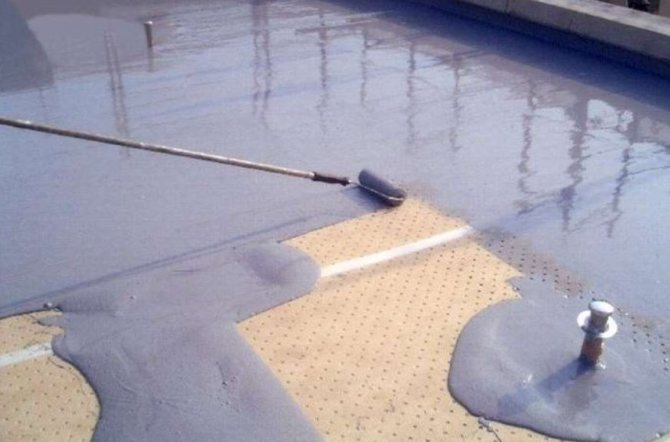

Roller application

Flaws

- Two-component compositions require equipment and significantly increase the cost of foundation waterproofing.

- Despite the resistance to mechanical stress, when applied to horizontal surfaces that are used for movement (basements, basements), they require additional protection against abrasion. The product is sensitive to the pinpoint impact of sharp objects.

- Some types of rubber, such as roofing rubber, are not resistant to UV radiation. Additional processing required: coloring.

- Not resistant to solvents.

Methods of protection against moisture

Protecting the concrete foundation of a house from moisture is possible in the following ways:

Experiment on liquid rubber

- Formation of a film on the surface of concrete using a layer of plastic reinforced with metal threads. This film is glued to concrete using a thermal method. The insulating coating retains water, but due to the smallest holes it allows air to pass through, acting as a membrane. The advantage of this method is that the film does not melt at elevated temperatures and is inexpensive. But it does not have great strength;

- Preventing leakage using roofing felt - a rolled insulating material reinforced with bitumen and special sand. Modern roll coverings have an adhesive layer that glues sheets of roofing material to the wall surface when heated with a gas burner. This method is also unreliable because the material is short-lived and you have to periodically check the condition of the structure and repeat the operation. Ruberoid sheets are heavy and difficult to bend, so laying them is a labor-intensive and time-consuming process. In addition, if groundwater gets under them, it can gradually saturate the walls, rising through the capillaries, forming dampness under the coating, and the material begins to peel off. The coating lasts for several years, then it needs to be changed. Compared to the film method, protection with roofing felt is expensive;

- There is another method that does not allow moisture penetration - using liquid glass. This method also requires periodic renewal of the insulating material;

- The latest development of construction specialists is a method using liquid rubber for waterproofing the foundation.

Features of material application

There are two types of liquid waterproofing: one-component, two-component, each requiring its own application method.

- For two-component rubber, equipment is required - sprayed waterproofing.

Lowest material consumption. The components are poured into two containers. Under pressure, the components are supplied to the output nozzles, mixed, and polymerization begins under the influence of the atmosphere. Spray nozzles are manufactured so that the component jets exit in the same plane.

- Application method: painting. The technology is no different from painting work. It is used when applying liquid rubber to relatively small areas. Number of layers: 2-3. Coloring is carried out with one-component compositions. Drying occurs naturally - it takes just over a minute to come off. The increased consumption of funds, however, is compensated by the lack of costs for equipment.

- Loading technology. Applicable for horizontal surfaces. Liquid rubber is poured onto the surface and leveled with a spatula or roller.

Preparation

Regardless of the method used to treat the surface, it must be prepared. There are times when a step can be skipped.

- The surface is cleaned of dirt and dust. It is advisable to remove oil stains. The foundation is degreased.

The surface can be cleaned with a sandblaster; all types of contaminants are removed well. When processed, a porous surface is formed on the surface, good for improved adhesion.

You can degrease the surface with a solution of hydrochloric acid; it cleans pores well of oil contaminants.

Surface cleaning

If there are small cracks, you need to widen them to 1-2 cm. The joints need to be processed and enlarged. In these places there will be a layer of waterproofing increased several times (2-3 times).

- Treating the foundation with a highly penetrating primer. Significantly increase efficiency and service life.

If you skip this step, the waterproofing will work, but the service life will be significantly reduced.

Application

Methods of application are indicated in the instructions for each composition. But the technological requirements differ little: surface preparation, priming, application of 1-3 layers of waterproofing.

Some formulations can be applied in high humidity, others in dry environments.

Methods for applying liquid waterproofing were discussed earlier: painting, pneumatic application, pouring method. Let's take a closer look at manual painting, using the example of applying Elastopaz.

Waterproofing is traditional for treating foundations. The composition allows you to obtain the required layer in one pass, which saves labor costs by at least half.

There is no need to prepare the composition additionally; the solution is completely ready for use. Apply with a brush, roller, spatula. Treating the foundation differs little from conventional painting work.

Purpose and methods of waterproofing

Simply put, the waterproofing layer is designed to “keep out” water, the main enemy of builders, from places where its presence is undesirable. However, it is worth clearly distinguishing where in the building structure water is not absolutely necessary and where its presence can be tolerated. Putting a “water barrier” where it is not needed is a thankless and pointless task.

Determining the need for an insulation device

Excessive moisture in the material that serves as insulation is always undesirable. After all, insulation saturated with moisture loses its “warm” properties and therefore protecting it from moisture is an important task for the builder.

Waterproofed foundation

But if the material fulfills its purpose without harm to itself and the building, then you can put up with its moisture. Concrete in the foundation works well under compression and in a wet state. If it is not used in a structure that serves as a wall of an inhabited space, then the moisture in it does not play a significant role for the building. Provided that this moisture does not contain aggressive substances that destroy the material.

However, the same concrete that freezes when wet can be destroyed from the inside under the influence of water frozen in its pores and expanded. This means that it is better to limit the flow of water into it than to carry out complex repairs later. And what can we say about reinforced concrete, which contains reinforcement... Water is a serious enemy for iron. That is, in each case you need to clearly understand why waterproofing is being done and how the material saturated with moisture behaves.

Types of waterproofing

Horizontal waterproofing is usually needed to create a barrier between dry and wetter materials in order to prevent capillary suction of moisture from one to the other. Waterproofing along the upper edge of the foundation is done to protect the wall from moisture from the foundation material, which picks up moisture from the ground. Vertical insulation is needed to prevent capillary moisture from entering the material and appearing on internal surfaces, for example, the foundation wall of a basement.

Water insulation methods

To put it simply, we can say that traditionally waterproofing was previously carried out using two methods: coating and pasting, or a combination of these two methods. Insulation with crumpled clay and other classical techniques were rarely used. For coating, mainly bitumens and materials based on them were used, for pasting - roll materials. The main disadvantage of coating waterproofing is the labor intensity and danger of preparing it on the construction site. Tanks with bitumen with fires built under them - this picture is probably familiar to everyone. Applying boiling bitumen resin to a surface is also not for the faint of heart.

Pasted waterproofing is much easier to work with, but its main drawback is the penetration of moisture through the joints of the rolls.

Waterproofing procedure diagram

Processing scheme:

- Providing access to the foundation surface.

- To clean the surface from dirt and oil stains, it is better to use a sandblaster.

- Treatment with deep penetration primer.

- Preparation of liquid rubber. If you need to dilute, just add a little water.

- Apply the required layer to the surface of the foundation. Use a spray gun with two independent nozzles, a hand brush, a roller, or a spatula.

- If you need to apply an additional layer, give the first one time to dry.

- Control check for waterproofing quality. They cut the insulation and check for tearing - if the layer comes off in small sections, it has been done correctly.

Preparing for foundation waterproofing

Waterproofing the foundation with any material, be it treated with liquid rubber or other coating composition, begins with preparing the base. If we are talking about a building that is already in use, then the first step is to dismantle the blind area and dig a trench around the perimeter of the building.

Further, preparatory work, before liquid waterproofing of the foundation is carried out, is carried out in the following sequence:

- all protrusions are cleaned, protruding parts of the reinforcement are cut off;

- using a stiff brush, dust and other contaminants are removed (ideally, cleaning using a sandblaster);

- solvent removes traces of paint, grease or rust;

- filling potholes, cracks and places of structural deformation with cement mortar;

- applying primer to the surface.

In addition, before applying liquid waterproofing, it is necessary to inspect the structure for the presence of mold or mildew. If traces of such are noticed, then it is imperative to treat the affected areas with an antibacterial agent. Do not forget about the places where underground utilities enter, which are hermetically sealed with polyurethane foam and only then treated with liquid rubber.

Only after completing all the above steps can the foundation be waterproofed; for this, a one-component liquid rubber or a two-component composition applied with special equipment is used.

Prepare liquid rubber yourself

With a small amount of work, you can make the insulation yourself. The properties will be identical to production analogues.

Required:

- Pack of borax;

- Water;

- Color to control the application of the insulation layer;

- PVA glue – 2 bottles.

Method of preparation: pour a pack of borax into the prepared container, add 100 ml of water, stir well. Then, combine the color and PVA glue and mix together.

Apply the homemade substance with a brush or roller. Short-term storage is allowed at a temperature not exceeding 5 °