Moisture negatively affects many materials, leading to their destruction or loss of attractive appearance. Therefore, special materials are used that will block the impact of the liquid medium on elements sensitive to it. Liquid glass for waterproofing is a fairly common material, as it has good properties and is inexpensive. Even a beginner can work with this type of insulation, because the essence of the process is simple and understandable for everyone.

Features of application

The feasibility of its use is explained by the following characteristics:

- The ability to apply complex configurations to structures and penetrate into any hard-to-reach places.

- The ability to form a seamless seamless coating , which guarantees 100% protection against moisture infiltration.

- High resistance to constantly damp environments compared to bituminous materials.

- A thin, light layer of liquid glass can replace several layers of heavy roll waterproofing.

- Liquid glass is safe, non-toxic, non-flammable, and does not melt at high temperatures.

All of the above properties allow the use of this waterproofing material in specific conditions. For example, in regions with a humid tropical climate, when it is necessary to protect the foundation from the effects of systematic groundwater and prevent the appearance of fungus and mold , or to prepare premises for use in a humid environment: in a bathhouse, in a swimming pool. And the concrete pool bed itself is treated with liquid glass.

It should also be noted that waterproofing concrete with liquid glass has a positive effect on concrete grades . And the injection of this waterproofing material, coupled with cement, strengthens the foundation for the future building and protects the entire building structure from subsidence.

Let's figure it out, what is the peculiarity of this material?

Advantages and disadvantages

Liquid glass, used as waterproofing, is a thick, viscous and sticky mixture of an aqueous solution of silicates.

Concrete has a porous and loose structure, and when this solution is applied to its surface, all concrete cavities are filled.

There, in the capillaries, the liquid glass dries and turns into crystals.

Thus, a solid waterproof film is created, which, in addition to all that has been said, also creates antiseptic protection .

But is this process good for all situations? Let's look at the waterproofing of concrete with liquid glass from the other side and see that there are also negative aspects to this:

- A material that forms a film on the surface identical to glass, that is, fragile and delicate. This film must be protected with other waterproofing materials.

- The main composition of this building material is a silicate solution of potassium and sodium, which has good adhesive properties, that is, rapid penetration and adhesion. This property requires speed and skill during application.

- When working with this material, it is necessary to take into account some subtleties when preparing the working solution and understand the dosage of the components . Failure to comply with these requirements may result in surface defects.

- Short service life - no more than 5 years. This means that every year the insulating layer of this material decreases by 1 mm. To prevent complete destruction of the layer, additional protection is required , for example, coating with paint.

Scope of application of concrete with liquid glass

The demand for ZhS is explained by the versatility of its application. There are several recipes for mastics made from this material, used as:

- Coating materials;

- Penetrating liquids;

- Adhesives;

- Additives to cement mortars.

Coating waterproofing is recommended to be used when effective waterproofing is required; a dense layer up to 3 cm thick is formed. As an adhesive composition, ZhS is necessary for the installation of roll roofing, poured roofs, and decorative coatings for concrete.

Coating waterproofing is recommended to be used when effective waterproofing is required.

The scope of application of LC is quite extensive; the composition is used for interior and exterior finishing work, impregnation of walls, and strengthening of facades. Waterproofing the basement of the housing construction will protect you from melt and ground water, and rain runoff. The protective layer withstands high pressure and maintains integrity. A fairly plastic waterproofing material does not collapse during seasonal soil movement or moderate seismic activity.

Waterproofing the foundation with liquid glass is an important condition for trouble-free operation of buildings. Moisture is dangerous in autumn and spring, when the soil freezes and small cracks filled with water increase. When access to water is blocked, concrete retains its integrity. After treatment, the foundation does not absorb moisture.

Waterproofing walls is necessary in rooms where condensation often forms due to temperature contrast or high air humidity. For hydraulic structures, HS is an ideal option. The protective layer is chemically neutral and absolutely harmless. The mixtures are used in the construction of drinking wells and septic tanks. When applied to a poured floor, the LC retains its integrity when using detergents.

Waterproofing walls is necessary in rooms where condensation often forms due to temperature contrast or high air humidity.

Areas of use

There are several ways to use this material:

- coating;

- penetrating;

- additive to a monolithic foundation.

Coating waterproofing is used in cases where it is necessary to create particularly effective protection. When waterproofing a foundation, liquid glass is usually used as a preliminary layer before roll insulation. It is enough to apply 2 layers of liquid glass to the concrete surface with a brush, and sealing will be ensured.

The penetrating method is used when it is difficult to reach the surface being treated.

Required Tools

It is recommended to apply waterproofing in a layer of several millimeters to 1 cm. It is permissible to use various tools, the choice of which depends on the area and quality of the concrete, and the type of surface being treated. Precast concrete products produced by vibration pressing are denser and are processed with a fur roller or a wide brush with synthetic bristles. Poured foundations and walls are more porous; it is advisable to cover them with a thick layer using a spatula.

To apply GS use:

- Painting gun;

- Spray gun;

- Construction spatula;

- With a brush.

For work you will need special clothing.

It is recommended to apply waterproofing in a layer of several millimeters to 1 cm.

Proportions

- Prepare a small portion of a mixture of liquid glass and water in a ratio of 1: 1 ;

- Add a little dry construction mixture there and mix thoroughly. In this case, one must take into account the fact that this composition hardens quickly , so it must be prepared in small volumes and used promptly.

- Before using liquid glass for waterproofing, it is necessary to clean the surface to be treated from dirt and, if necessary, expand the working area.

- Apply the prepared mixture with a spatula.

- To prevent cracks from appearing when drying, it is recommended to cover the treated area with a damp cloth.

Attention! Under no circumstances should the prepared mixture be further diluted with water. Adding silicate mortars to the concrete mixture to create a monolithic foundation ensures enhanced waterproofing throughout its entire thickness.

Adding liquid glass to concrete - operating rules

Particular attention is paid to the technology of preparing waterproofing. Add colloid to prepare the working mixture according to the instructions, observing the ratio with water, in order to ensure the necessary permeability, the structures must be well saturated. In the process of impregnating concrete with liquid glass, even microscopic voids and capillaries must be filled. The composition dries quite quickly, so prepare the working mixture in small portions, as required for an hour of work.

It is necessary to thoroughly mix the mixture and apply quickly, the hardening interval is from 30 minutes to an hour, depending on the concentration.

The composition dries quite quickly, so prepare the working mixture in small portions, as required for an hour of work.

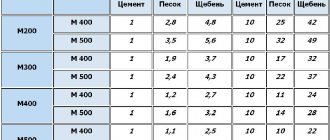

Recommended proportions

Treatment of concrete with liquid glass is a multiple process. First, the concrete is primed. To prepare primers, the following proportion is recommended: add 4 parts of water to 1 part of factory-made ZhS. The composition has good hiding power and penetrates deeply into concrete.

To remove dust from self-leveling floors, add 2 liters of water to 0.2 kg of liquid glass. The floor is covered 2-3 times. To treat the plaster layer, silicate is diluted with water in a ratio of 1 to 9.

For better adhesion of reinforced concrete to concrete, it is practiced to add no more than 1/10 of the volume of dry cement to the mixture.

For better adhesion of reinforced concrete to concrete, it is practiced to add no more than 1/10 of the volume of dry cement to the mixture.

Instructions

- Prepare the object in advance for pouring a monolithic foundation:

- perform marking;

- assemble formwork;

- prepare materials for reinforcement.

- Prepare the concrete and gradually, in small portions, pour in liquid glass.

Important to remember! Liquid glass should be no more than 5% of the total mass of the solution. Otherwise, this threatens the loss of strength and reliability of the structure.

- Pour the prepared concrete mixture into the formwork without mixing and level it horizontally.

How to choose the right liquid glass

The component composition is indicated on the packaging. Potassium silicate is resistant to acids, has good adhesive properties, and the coating does not have the shine characteristic of ordinary glass. Sodium silicate is comparable in properties, only it has better resistance to acids and ammonia compounds. Lithium LC can withstand high temperatures and is more often used in production. Mixed formulations include only sodium and potassium components. Ready-made mixtures are mostly liquid or colloidal and differ in the concentration of silicates. Granular ironclad is less common, is slowly diluted with water, and is used as a concrete plasticizer.

Potassium silicate is resistant to acids, has good adhesive properties, and the coating does not have the shine characteristic of ordinary glass.

When choosing mixtures, preference is given to trusted manufacturers. Manufacturers produce several types of liquid glass in concrete. Handmade colloids should be treated with caution.

Basement waterproofing

- Prepare the workplace by clearing it of dirt and construction debris.

- Go over the surface with sandblasting or other mechanical equipment to open the capillaries of the concrete. Then wipe this surface with hydrogen chloride diluted with water in a ratio of 1:10. If there is mold on the walls, treat them with an antiseptic.

- Grooves and joints of building materials should be grooved to a depth of more than 25 mm and a width of 20 mm.

- Cover the utility lines running along the walls hermetically.

- Wet the concrete before applying insulation.

- Prepare the insulating mixture following the manufacturer's recommendations.

- Apply waterproofing with a spatula, spray gun or wide brush.

Read about the use of “liquid rubber” here.

Main characteristics

Since liquid glass contains crystals, when they hit the surface they begin to grow and fill the smallest pores and cracks encountered along the way; this is important when restoring the formwork of a well shaft, the rings of which are destroyed over time. The result is a surface that does not allow water and air to pass through.

- The material is environmentally friendly and can be used for buildings of any purpose;

- Liquid glass is fireproof and non-toxic;

- When frozen and thawed, it retains its beneficial properties.

Storage is carried out in containers under an airtight lid.