Choosing sand for concrete among the many proposals is quite difficult if you do not have an idea of the properties of this material. Several types of sand fillers are used in construction and finishing, each of which has typical characteristics. The quality of sand and the possibility of its use in the preparation of concrete mortar is influenced by several factors that are closely related to its origin.

General requirements for fine aggregate

Sand concrete (PB), which is used to make a concrete mixture, must meet the GOST standard 8736-2014. It is allowed for use when its formulation contains less than 10% of elements with a fraction of up to 0.15 mm and no more than 2.9% of dust, silt inclusions and clay. The presence of the last component in the structure has a very negative effect on the frost resistance and strength qualities of the mixture. Clay envelops the kernels, preventing them from combining with other components.

The developer, wondering what kind of raw material is needed, should know that in accordance with the standards, the presence of large-sized fractions of more than 10 mm in the bulk is not allowed, and the volume of parts measuring 5.0-10.0 mm must be within the range of 4.0-5.0%. Basic inclusions in the structure, in the form of humus or plant elements, should be absent.

A little theory

Even a person who is not too knowledgeable about the construction business and its nuances understands that for the foundation it is necessary to use only clean sand, in which no organic elements such as branches, grass and leaves are allowed. To clean sand from these elements, it is enough to sift it. The situation is more complicated with impurities of inorganic origin such as clay or lime. It is very difficult to determine their presence. But the maximum amount of clay in the sand that goes into pouring the foundation should be no more than five percent of its total mass. Exceeding the clay content will cause the entire structure to become unreliable.

You can check the purity of sand in the field using an ordinary transparent bottle made of glass or plastic. Sand is poured into it one third and half filled with water. The bottle is shaken to moisten the sand as much as possible, and left to stand quietly for five minutes. If after this the water turns out to be dirty, the sand is not suitable for building a foundation. If a five-millimeter layer of foreign matter forms on the sand, it is also not suitable for use.

Classification by factions

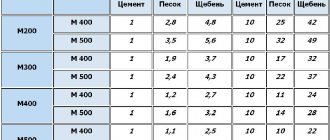

In order to find out what raw materials are needed to create a working mixture, first determine the primary selection parameter - the fractional size module. According to this indicator, it is classified in millimeters:

- very large, with fractional inclusions greater than 3.6;

- high fractionality in the region of 3.2-3.5;

- coarse: 2.6-2.9;

- average fractional size: 2.2-2.5;

- fine fraction: 1.51-2.2;

- very fine fractions: 1.2-1.45;

- fine fractions: 0.9-1.0;

- very fine compositions up to 0.71.

Definition of quality

Sand with high-quality properties is necessary for the production of long-term PB monoliths and depends on its chemical composition, occurrence zone and, partly, on fishing technology. The existing standards strictly link the requirements for the strength properties and ductility of such a solution, which depends on:

- Fractional grain size.

- Bulk density per 1 m³. The average value of this indicator is in the range of 1.31 - 2.0 t/m³.

- Configurations of grain elements influencing precipitation in the composition.

- The presence of dust and contaminating foreign matter.

Raw humidity should not exceed 5.0%. During precipitation, this value increases to 10.0%. This indicator is taken into account when water is added to the mixture.

At a construction site, the degree of humidity can be determined in the following way. If the raw material is squeezed into a lump, it must crumble. When this does not happen, the moisture is more than 4.5%. Despite the simplicity and reliability of the visual determination method, in order to choose which sand is best for concrete, it is still more reliable to check the percentage in the laboratory.

Calculation of sand for a pillow under a house

The amount of sand required to create a foundation cushion depends on the area of the base and the thickness of the cushion. We discussed this issue in more detail in an article on the topic: building a foundation on sandy soil.

You can determine the area of the base yourself, just know its parameters.

As for the thickness of the sand cushion, the following factors are taken into account:

- Location of groundwater.

- Soil freezing depth.

- Total load on the foundation.

Based on these factors, you can choose the optimal height of the sand cushion. However, the recommended parameters should be taken into account: the minimum height of the sand layer should be 10 cm, the maximum value can be 20 cm.

The final volume of sand to create a cushion is calculated by multiplying the area of the foundation base by the height of the sand layer.

Varieties

Raw materials of natural and artificial origin are used in construction. Both varieties act as a structure-forming framework. It is thanks to their presence that the formation of internal stress is uniform in the future and the strength and durability of structures is guaranteed. This filler compacts the empty spaces that appear between the crushed stone. Interacting with adhesive components in the form of a water cement mortar, it guarantees the creation of a strong mixture with a homogeneous structure.

To carry out construction and installation operations, 2 fundamental types of raw materials are used - quarry or ravine and river, which is washed up from river beds. In areas near the seas, it is mined from the seabed, but since its transportation is a very expensive undertaking, it is often used in the area of alluvium. In the center of the Russian Federation, river composite is much cheaper. Industrial granules of the lake and quarry varieties have completely different characteristics.

Differences between quarry and river sand

This material is distinguished by a particularly pronounced rounded configuration of grains, which have been treated with water for tens of thousands of years, obtaining a smooth shape. For concrete from river or lake raw materials, this quality presupposes a uniform arrangement of fractions, which means the highest plasticity and predictable density indicators.

It is precisely this feature of lake sandy loam that is highly valued in the industrial production of PB structures, arrangement of foundations and monolithic structures. The properties of the raw material mined in the foothills or ravines make it possible to use it as a filler and key composite for bricks produced on an industrial scale, for the production of screed mixtures, for the restoration of road surfaces and areas. The distinctive uneven configuration of grains and clay alloys make it possible to extract such a composite for brick laying and mixtures that have a special strength due to internal cohesion.

Which sand to choose for making concrete

To produce PB solution, river modifications of medium or large fractions are mainly used. You can add a little washed grit from the quarries to them.

The grade of building concrete carries particularly important information for selection. In the case where it is less than M300, we recommend raw materials with inclusions less than 2.6 mm. A similar mixture is usually used for arranging the foundation directly for a car garage, low-rise buildings, and home structures. For grades greater than M350, used in the construction of high-rise buildings, floor slabs or reinforced belts, it is necessary to use raw river raw material with a grain composition of 3.6 mm or more.

What is the need for an embankment?

A residential building must be built on a solid capital foundation. The monolithic structure located on a special bulk support has good strength indicators. After preparing the area (clearing debris, marking), determining the depth, and digging a pit, a cushion of sand is lined. When is the best time to build it? Sprinkling is recommended in the following cases:

- when constructing a dwelling on heaving soils. The sand layer prevents destruction and deformation of the structure during freezing and thawing;

- in the presence of uneven soil. The embankment provides distribution and leveling of the construction site;

- with increased dampness from passing groundwater. The layer acts as a barrier;

- with possible settlement of the building. The cushion resists compressive forces in the soil;

- when constructing a building of several floors. The topping is laid to cushion the structure.

Sand under the foundation is laid in even layers, to a depth of no more than 20 cm, followed by compacting and watering each layer.

Harmful impurities

One should not lose sight of the fact that sand contains various impurities that are harmful to construction safety. Their presence in raw materials is determined visually, by elutriation or using the pipette method. If it contains a high content of inclusions, the concrete will lose its strength characteristics during creation and will not become durable. Impurities can be dusty, clay or silty. The clay film that envelops the fractions is mainly harmful, causing the connection with the cement base to deteriorate.

Harmful impurities also include unstable mine inclusions, the use of which will lead to the creation of internal stress and the appearance of dark spots on the PB. Sulfur inclusions cause corrosion processes in concrete and reinforcement, mica flakes lead to the appearance of various cracks.

Foundation sand: what does it look like?

If we consider it from the point of view of geology, sand is a very fine type of sedimentary rock, represented by fragments of various minerals, mined by open pit mining or produced by industrial enterprises. At their core, they are very small pebbles of various shapes and sizes - resulting from natural or artificial processes. There are several types of sand on the market, each of which has its own unique properties and is suitable for various construction processes:

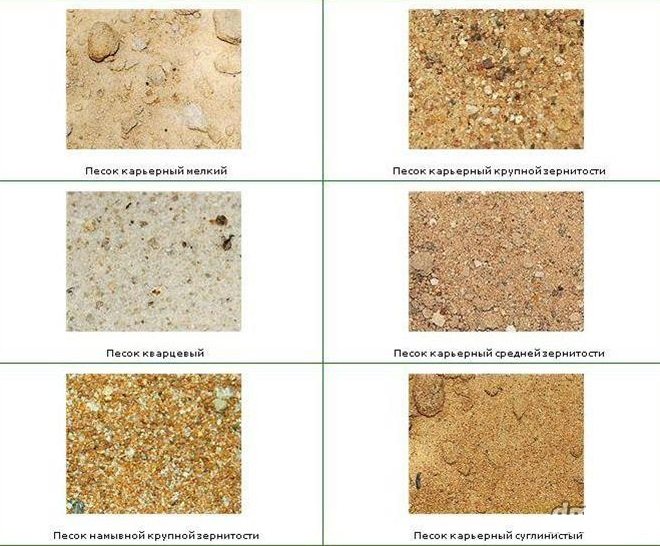

- Career is the most common and cheapest option. It is mined in open pits and contains a lot of impurities from clay, lime and earth, which must be taken into account when choosing this type of sand;

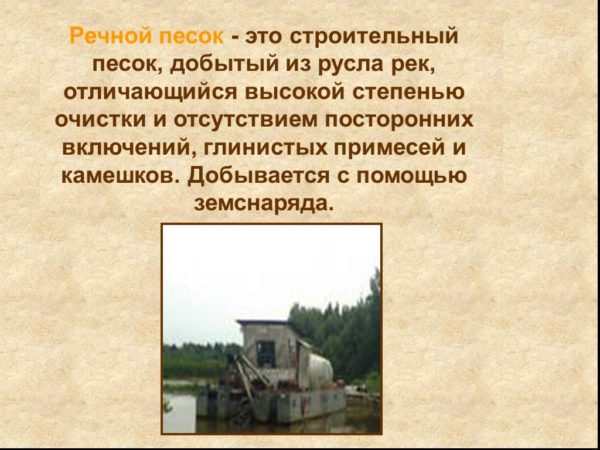

- River - a cleaner option, mined from the bottom of rivers - is most suitable for the construction of foundations and use in branded monolithic concrete. By the way, the famous skyscrapers of Dubai were built using river sand from Europe;

- Mineral - obtained by processing various rocks - that is, these are finely ground remains of granite, crushed stone, limestone, marble and other varieties. It is almost never used in concrete mixtures, as it has certain limitations on adhesion and strength - but is suitable for finishing;

- Marine - it is mined from the bottom of the seas and further purified. This sand is considered the highest quality and most expensive, is used in branded concrete and has increased strength characteristics, since it does not contain organic matter or harmful clay inclusions.

Based on the above, what sand is needed for the foundation must be determined at the design and development stage of the construction process. Our company’s professional specialists will offer several options that will optimally compare in quality and cost. Although country cottages are built for long-term use, it is not always rational to use very expensive materials, since for such small volumes the quality of different types of sand is almost identical. Moreover, if the project involves the use of ready-made concrete mixtures from the manufacturer, who himself monitors the quality of the sand used in monolithic concrete.

Is it possible to check the purity of the sand yourself?

Laboratory research provides the most accurate results of testing the qualitative composition. The user can find out not only the presence and number of inclusions, but their percentage in the total volume of building materials. In fact, expert assessment is a rather expensive procedure and takes a lot of time. It is incomparably easier to diagnose a composite for consumer qualities using the manual method.

The procedure for manually checking which sand is best for concrete:

- Take an ordinary 1.5-2 liter plastic bottle and pour the material into it to about a third of the total capacity.

- Water is poured from above to fifty percent of the volume of the bottle.

- Shake thoroughly and wait 5 minutes.

- Assess water transparency.

When foreign particles float in the water, the raw material is not suitable for use. If the liquid is unclean and cloudy, the substance contains many foreign inclusions. The transparent composition and the absence of third-party inclusions indicate that the user has in his hands high-quality raw materials suitable for use.

Crumbly building materials are divided into 2 classes based on the size of the fractions: I and II. In the volume of the best class I there are not many microscopic substances that are undesirable components for the PB mixture.

To produce a high-quality strong solution, it is better to use a large fraction, mainly with particles of 2.0-2.5 mm. At the lowest rate, the cost of the prepared composition will seriously increase, and consumer quality will decrease.

Kinds

Depending on where the raw materials are mined, construction markets sell them in three varieties - quarry, washed river and sea. Each of them has its own characteristics, advantages and disadvantages that determine the scope of application. Therefore, you should know them and take them into account so as not to make a mistake when choosing an embankment for the foundation.

Career

The most in demand and most affordable (due to the high content of clay and other impurities in the composition) raw materials extracted in quarries by breaking rocks. Humidity is the main parameter of this type; a value of 1-5% is an indicator of the stability and reliability of such sand. Read about the difference between quarry and river sand.

The moisture content of the material can be determined easily and quickly by eye. If you can’t make a lump of it, then the value of this parameter is not enough. Such a foundation will simply crumble and will not be reliable.

According to processing methods, the following types of quarry sand are distinguished:

- Sandy soil is an unrefined, impurity-rich option. Suitable for landscape work (leveling areas, sprinkling paths and filling trenches).

- Washed sand – produced in quarries filled with water using hydromechanical tools; raw materials without impurities, and therefore of higher quality. It is used in road construction, for the production of tiles for paving sidewalks and paths, bricks, reinforced concrete products, and concrete.

- Seeded sand is a variety that has been technically and mechanically cleared of large debris. Typically used for mixing construction mixtures and compositions.

Raw materials extracted from quarries are in the highest demand; their price in specialized markets is usually 300-700 rubles/cubic meter.

River

The purest, most expensive product that is extracted from the bottom of freshwater reservoirs. It contains almost no impurities, and its shape is smooth and even thanks to natural polishing with water. This option is well suited for foundations, mixing solutions for interior decoration, and forming drainages.

It, like fireclay, has a lot of advantages: in addition to environmental safety, it also has excellent sound insulation, moisture resistance, durability (the raw materials are not subject to negative environmental influences), and compliance with technical requirements important in construction. However, due to its quality, the product has a high price - 700-1000 rubles per cubic meter. Read about the sizes of concrete wall blocks here.

Sand from the bottom of the river is divided into the following groups:

- Large - produced from rocks using crushing and grinding equipment, the fraction size is about 5 mm.

- Coarse-grained - extracted from dried river beds, has a natural shade. It finds its application in decorating interiors and landscapes, as well as in finishing (external and internal) premises.

- Washed river - medium in size, grayish-yellow in color.

The finer the sand, the easier it is to compact, and therefore the more susceptible to shrinkage. Therefore, a cushion made of fine-grained river sand is suitable only for light buildings. For capital construction you need an option with a medium fraction, and for multi-storey construction - with a large fraction.

Nautical

Raw materials extracted from the seabed and coastline are also suitable for creating a foundation. It is divided into fractions by size:

- Very thin (0.7 mm) – unsuitable for construction work; It is mainly used for filling playgrounds.

- Thin (0.7-1 mm) - also not suitable for foundations, but finds its application in the preparation of thin building mixtures.

- Fine (1-2 mm) - its use increases the consumption of the building mixture.

- Medium (2-2.5 mm) – used for mixing standard concrete mixtures.

- Large (up to 3 mm) - most in demand as a component for the production of high-quality concrete and cement.

- Very large (more than 3 mm) - suitable for forming a pillow under the foundation.

Sea sand is the most expensive variety, and for good reason. It has a high percentage of organic matter (shells, algae) and foreign debris, for example, fragments of bottle glass. To make it suitable for the construction industry, cleaning and rinsing procedures are mandatory. Find out what cement is made from at home here.

Which sand is better to choose for the foundation - which one is suitable?

Considering all of the above, it is best to form a pillow under the foundation of a house from river sand. A layer of such raw materials will create a solid foundation for the entire building and will not allow cracks to form. Of course, due to its excellent quality characteristics, very coarse sea sand is also suitable, but in this case you need to remember the high cost of this material.

If the construction budget is limited and river or sea sand is too expensive a solution, then washed quarry sand would be a good choice.

Another option for creating a cushion for the foundation is a sand-gravel mixture. Gravel in the composition of ASG will improve the characteristics of the composition, making it more stable and less susceptible to fluidity.

River and sea sand

The river composite initially does not have clay in its structure. It probably contains the smallest amount of small-fraction stones. This type is very effectively used in repair and construction processes and allows you to prepare the highest quality mixture. It is distinguished by the possibility of natural sedimentation; therefore, when preparing the solution, it must be continuously stirred.

Before choosing the preparation of river or quarry concrete composition, you need to take into account that, in turn, the price of river sand is much higher than quarry sand. When making a choice, it is necessary to analyze which, in turn, is preferable - reducing the cost of producing a PB building structure or guaranteeing the required strength characteristics.

In terms of its own indicators, marine raw materials are close to lake raw materials. Additionally, it is characterized by purity and uniformity of the granulometric structure. Due to the potential for shellfish, additional cleaning may be required.

Quartz composite is obtained as a result of mechanical crushing of natural raw materials, preserving similar inclusions. It is homogeneous, pure and chemically passive and is produced artificially.

Origin of sand

Which sand is better - quarry or river, we will talk in this part.

Quarry sand

Quarry sand is extracted from a quarry by breaking down rocks. It is of lower quality than river water, but there are exceptions. When choosing quarry sand, an important factor in its reliability and strength is the moisture parameter . Its percentage should be from 1 to 5%. Humidity 5% is determined by eye because it is impossible to mold sand into a dense ball or snowball - it crumbles.

To correctly determine the humidity parameter, you can use the following method. To determine the moisture content of quarry sand, take a container and weigh it. Then, weigh 1 kg of sand in it and hold it at low heating temperature for about half an hour, and then weigh only the sand. Humidity will be calculated using the formula: the mass of sand after heating minus the mass of the container divided by 100.

Quarry sand is cheaper in price than river sand, since its extraction method is less expensive.

Return to content

river sand

River sand is ideal for laying foundations, and is also used when diluting mortars for interior decoration of a house or creating drainages. Therefore, such sand is universal and multifunctional . Its fine fraction from one and a half to two millimeters and the absence of impurities make it a desirable, but expensive building material .

In addition to river sand, there is also sea , but in modern construction it is used where it can be quickly brought from, otherwise its price exceeds even river sand . In terms of quality, it is no better than river water, and sometimes even worse due to organic impurities (shells, algae) and foreign objects.

Return to content

Quarry and ravine

In the quarry version of the feedstock, impurities of loam and pebbles are found, for this reason it can only be used in the form of bedding directly under foundations or PB screeds. When preparing PB, quarry material can be used only after thorough washing with water produced at the fishing site. When carrying out such an operation, clay and small particles are removed from the composition.

Gully raw materials differ in external and technical qualities from the parameters of river material. It is fine-grained and its grain form has angular unevenness, in comparison with the spherical and smooth geometry of the river one, which in turn makes it possible to use it in compositions of binding building materials. It also contains a significant number of mechanical fragments such as clay, silt and fine grains.

The grain size of the gully material ranges from 0.5 to 1.0 mm, however, coarse inclusions with grain sizes from 2.0 to 5.0 mm are also possible.

Features of the construction of a sand cushion

To build a reliable foundation, you must properly make an embankment and level the surface of the pit. The arrangement of the embankment implies the following indicators:

- The pillow is constructed 1/3 of the width of the foundation. The depth of the embankment layer should not exceed 20 cm.

- Before the flooring, geotextile sheets are laid on the bottom of the pit. It will provide additional drainage and protect the embankment from mixing with the soil.

- The embankment is laid in parts. After laying each layer of bulk material, it must be well moistened and compacted. It is better to compact sand using a vibrating plate.

- Compaction of sand under the foundation is carried out until then. Until there are no footprints left on the surface.

- Upon completion of filling, the surface level should be checked. It should be smooth. The correctness of the subsequent construction of the building depends on this indicator.

After filling the bottom, reinforcement is installed, formwork is laid and concrete is poured. To build a good and reliable foundation, you must first take care of the arrangement of the sand cushion. It plays an important role in the construction of the foundation, especially on heaving soils.

Article Rating

Volumetric weight and composition

The requirements for sand used in the manufacture of construction materials are specified in the relevant by-laws. Some characteristics can only be determined in laboratories; some are checked directly at the construction site. A numerical indicator reflecting the mass of 1 m³ of raw materials in their natural state weighs on average approximately 1.5 - 1.8 tons. The smallest value is considered preferable.

The composition of raw materials, as a rule, is:

- granulometric, reflecting the percentage of grains of different textures;

- mineral, from quartz to limestone materials;

- chemical, based on the elements contained in the composition, determines the potential scope of application.

Sample mineral structure:

- quartz up to 68.0%;

- granite up to 13.0%;

- feldspar up to 7.0%;

- dolomite up to 2.9%;

- limestone up to 7.9%;

- siliceous rocks up to 2%.

Other elements: quartzite, mica, sandstone, slate, gneiss, glauconite, ore iron hydroxides, accessory minerals in the total volume up to 2.0%

Thus, we can argue with those users who believe that choosing the right sand for preparing concrete is quite simple. Their judgment is completely wrong. Because there are many types of raw materials that have their own characteristic properties. Therefore, you need to know what kind of sand is used for concrete when performing certain construction and installation works.