During the construction of a house, it is necessary to provide in advance all technical openings for communications. Most often, life support systems are brought into the building through lugs in the foundation. A competent developer will always leave these vents in the right places when pouring it. The construction of a concrete base is an irreversible process, so if you miss this important point, you can greatly complicate your life.

Strip foundation diagram.

After purchasing a home, homeowners often undertake a complete reconstruction of it: they supply water, gas, and install a sewer system. If the previous owner forgot to make vents in the base of the building, then the new owner, before starting to improve the house, will have to solve the question: how to make holes in the foundation? There are methods that can be used for concrete reinforced tape. With a stone base it is not much more difficult.

Installation of internal sewerage

Before starting construction and carrying out additional work on laying the sewer system, it is necessary to accurately determine its location in the interior of the building. Only after the pipes have been completely distributed throughout the rooms can you determine where the hole needs to be made. All pipes go to a riser, which is usually a pipe with a diameter of 100 millimeters. The uniform slope of the pipes ensures guaranteed drainage in the specified direction. It is important to choose the optimal hole location. There are different methods and tools and for a builder there is an excellent choice than to punch a hole in the foundation.

In order to effectively break through the foundation for the sewer system, it is important to take into account the load that the building will (or is already exerting) on this section of the foundation. It is necessary to strive for minimal pressure on the base at the selected point.

Making a hole in the foundation for sewerage is not as difficult as it might seem at first glance. It is possible to complete a complex of works independently if you follow some basic rules and constantly monitor every step of the work.

Conclusion

As we found out, in some cases it is quite possible to make a hole in concrete yourself. In order for this operation to take place efficiently and without much effort, you should use a suitable tool for this and follow the drilling technology.

You can get more information on this topic from the video in this article.

A leak in a well can seriously affect the quality of drinking water. Through a seemingly small hole in the concrete shaft, household wastewater and technical fluids spilled on the ground will begin to penetrate. Sand will fall off from the horizons lying above the aquifer, which will negatively affect transparency. It's unpleasant, isn't it?

To restore the integrity of the well shaft, a quickly hardening composition will be required, which will allow you to quickly eliminate the defect in the concrete structure. A hydraulic seal for a well will eliminate leaks, large and small cracks forever. We will tell you how to choose it correctly.

We describe in detail the process of applying the repair composition. We offer recipes for making fillings yourself. The information is supplemented by useful diagrams, photos and video tutorials.

How to make a hole in a finished foundation for sewerage yourself

So, let's try to figure out how to make a hole in the foundation for sewerage.

A hole in the foundation for the sewer can be made with a simple hammer drill, which has an output power of 2-3 kW. Also, to complete the work you will need a special set of long spikes for punching holes.

Before drilling a hole in the foundation, it is recommended to carry out minimal preparations. To do this, you need to use a diamond disc and a pre-prepared grinder. With these tools, small notches are cut in the place where the hole will be made. This makes it easier for the pike to grip the surface in the future and avoids slipping on a smooth concrete surface.

After this, it is enough to accurately place the hammer drill at the selected point and begin work. A professional can explain how to drill a hole in the foundation for sewerage in different types of foundations, but in each of them you need to be precise and careful, which becomes a guarantee of the quality of the work.

Making a sewer passage through the foundation

To make a sewer system in your own home, you need to solve many related problems.

The biggest difficulty is getting the pipeline out of the house. The reason is quite simple. The house always stands on a strong foundation. It is poured to different depths, so there are several methods for removing the pipe:

- Laying a pipeline under the foundation;

- Installation through walls.

Sewer pipes are mainly laid under floors. This is due to technological necessity. Therefore, the installation of such a pipeline has to be done across the entire foundation area.

Options for punching holes in the foundation

Before breaking through the foundation for the sewer, you should choose a method for performing the work. There are two most popular ways to do this job:

- Manual method.

- Automated using special drilling rigs.

With the right choice of technology, work is performed accurately and efficiently. For a non-specialist, it is important to know the optimal method of how to punch a hole in the foundation for a sewer with your own hands, and only after that can you proceed to work.

Tool for punching a hole in the foundation

When making a hole in the foundation for sewerage manually, you should use technology to work with thin walls of semi-basements with a thickness of up to 400 millimeters.

If the thickness is greater, then there will most likely be a massive mesh of reinforcement inside, which significantly limits the use of manual drilling - special installations should be used for working with concrete surfaces.

The standard design of this type of device consists of the following elements: a massive frame, special folding stops, a rotor, an electric motor of the required power, a rod with a bit for drilling material. Using this technique, any hole can be created within 5 minutes.

A set of crowns allows you to choose the optimal type for a specific type of hole. Geometrically correct holes of a given diameter and characteristics are created. Dragging the pipe into such a hole is extremely simple and does not cause mechanical damage.

Ready-made waterproofing seals

Ready-made hydraulic seals for concrete wells are very convenient: to use such a seal, it is enough to dilute the solution with water according to the manufacturer’s instructions. Let's look at the most popular waterproofing sealing mixtures.

Option #1: water plug. This mixture contains fine-grained quartz sand, aluminum cement, and active chemical additives that give the composition plasticity and allow it to quickly harden. Using this type of seal, you can quickly eliminate a leak within 2 minutes.

The waterplug can be used at temperatures from +5 to +35 degrees. It is used in waterproofing swimming pools, underwater bridges and similar structures. Among the disadvantages of this hydroseal is the need for dilution with warm water +20-25 degrees, which in some cases is not entirely convenient.

Option #2: peneplug. Available in the form of a dry powder that must be diluted in water. This mixture is intended for waterproofing concrete wells, as well as wells paved with brick, natural or artificial stone. The hydroseal is based on high-quality cement, quartz sand and polymer additives.

This mixture is capable of stopping a leak with a pressure of more than 5 atmospheres. Hardening time 40 seconds.

Option #3: powder ex

A fast-acting waterproofing seal that sets within 10 seconds after application. This filling has excellent characteristics: frost resistance, resistance to aggressive environments, ease of use.

The disadvantages of this mixture include high cost and the inability to work at temperatures below +5 degrees.

After using any chemicals to perform repair operations, well water should be submitted for analysis to the SES or a laboratory accredited to conduct this type of research. Studying the composition of the water will help to find out whether there are any sources of pollution left in the mine, or whether the repair material has affected the quality characteristics.

What sewer pipes are used when drilling a foundation?

Specialists install sewerage in the foundation only from durable and highly acid-resistant materials. Most often used:

- Steel pipelines. The advantages are strength, but the main disadvantage is the strong susceptibility of this material to corrosion,

- Cast iron samples are used much more often. They, unlike steel pipes, are protected from corrosion, but are more expensive.

- Plastic sewerage is most often installed inside the house. Conventional medium-density models cannot support the weight of a concrete foundation base.

Stages of drilling holes for sewerage in the foundation

If the owner decided to make a sewer system not under the foundation of the house, then now he will have to think about making holes into which the sewer pipes will be laid.

One of the necessary tools is a hammer drill

To do this you will need the following tool:

- An impact drill with a diamond tip (an impact drill will allow you to quickly drill the required hole);

- Hammer (with a nozzle for concrete products for quick drilling);

- Special installation for drilling in the foundation;

- Any model of punch.

When drilling, it is possible for the drill to get into the reinforced concrete base, so it is often worth immediately stocking up on a small grinder, which will be used when cutting the reinforcement. When the entire tool is ready for use, you can get to work.

Undermining under a concrete foundation

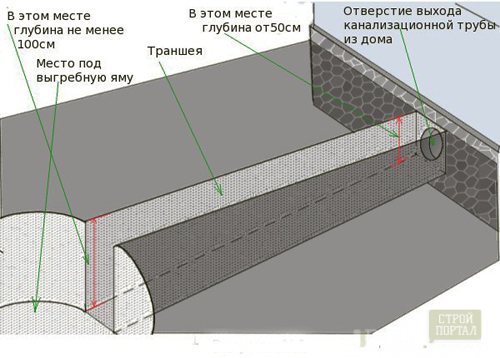

If the septic tank is located close to the house (within five meters), and the thickness of the foundation does not exceed one meter, the simplest option for installing a sewer system is to create a tunnel in the place where the pipeline intersects with the base of the house.

The trench is not very deep, which reduces the complexity of such an operation.

Before starting to lay under the foundation, marking work is carried out. The point where the pipe coincides with the future sewer passage is marked.

When performing such work, the thickness of the walls, which is the reference point, must be taken into account. If this rule is not followed, the trenches may not line up. Their connection will not occur in a specific place. We'll have to start all over again. This will cause additional financial costs.

When the trench is ready, a sewer pipe is laid in it, maintaining the required slope.

If the pipeline is shallow, the sewer passage must be insulated to prevent freezing of the channel and the formation of ice. It can cause blockage of the entire space.

Backfilling of the trench is carried out carefully , using small portions of soil. Thus, the removed pipe is not allowed to move, and its slope is not allowed to change.

An additional pipe is passed directly under the foundation, the diameter of which is much larger than the sewer pipe. The length of this segment is made equal to the width of the foundation of the house. It plays the role of a sleeve in which the main pipeline is laid.

This device protects the sewer system in case of unexpected subsidence of the foundation. When repair work is carried out, it is much easier to replace the damaged area.

Stages of foundation drilling work

First of all, it is necessary to make marks in the foundation itself at the location of the future pipeline. Here you need to draw a circle whose diameter will be slightly larger than the size of the sewer pipe.

The next step is to use a hammer drill to drill into the designated area of the concrete base. Here you try to penetrate as deep as you can with your hands. In this case, the reinforcement can be easily cut with a grinder. In the video you will see which drill should be used to cut concrete.

If you need to drill a large hole to service the sewer system of a house of 3 or more floors, you must use a drilling rig. Here, in order to break through the finished channel, you must first lay a special sleeve, and only then insert the pipeline. All gaps that appear are sealed with polyurethane foam, which will also serve as a universal heat-insulating pad.

If you managed to successfully drill a hole in the foundations, all that remains is to insert a pipe there and think about connecting it to the internal sewerage system. Here you need to make a butt joint on the pipe using nozzles or a set of fittings. On the territory of a suburban area, also do not forget to make a small pit where all sewer water will flow.

How to remove a pipe directly from the house

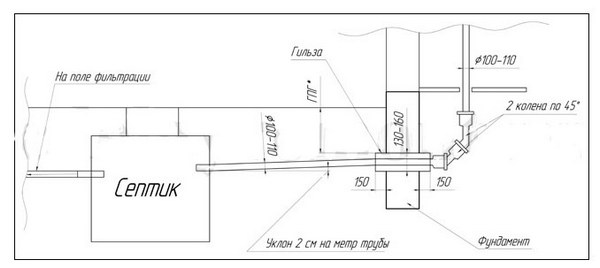

Having a finished house, the question immediately arises: how to remove the sewerage through the foundation? To remove the sewer pipeline from your own home, it is necessary to install a boundary system that connects the septic tank to the outgoing pipes.

The pipe outlet passes through the foundation. Moreover, the installation depth must exceed the freezing value of the soil. The work is performed in the following sequence.

Stage 1. A trench is dug in which the external and internal systems will be joined.

Stage 2. A hole is made in the foundation for the sewerage system. To work you will need:

- Hammer;

- Metal punch;

- Electric drill;

- Set of drills.

If it is not possible to make a hole with such tools, a special diamond installation is used.

The drilling process is always quite complicated, because you have to drill through a concrete foundation. If a reinforcing mesh was made, you will have to use a grinder. It is easy to handle the fittings. Sometimes you have to work for several days to get the hole you want.

First, the location where the pipeline will be installed is determined on the surface of the foundation. A circle is drawn in this place, and its diameter must exceed the size of the sewer pipe, together with the sleeve.

A hammer drill drills concrete to maximum depth. Any reinforcement bars encountered are cut off with a grinder.

To make a hole in a concrete foundation, builders use several methods:

- Diamond drilling. It is considered the best option. The foundation material does not receive damage during such work. This technology is one of the most expensive, even if you rent such a machine;

- Hammer. Percussion drilling is in progress. The negative side is considered to be chiselling, which causes the appearance of microcracks. Concrete begins to peel off from the reinforcing mesh;

- Impactless drilling. One of the safest methods, which requires a lot of time. A large number of smaller ones are drilled around the entire perimeter of the desired large hole. The concrete plug is knocked out with a sledgehammer, and the reinforcement is cut off with metal scissors.

Stage 3. First, a sleeve is placed in the made channel, then a pipeline is laid. The resulting cracks are closed with polyurethane foam. It also becomes a good heat insulator.

Definition of levels

The distance to the sewer pit from the base of the house, of course, plays an important role. But the main thing in such an event is still determining the level of the sewer pit to the upper receiver. This is due to the fact that waste water that enters the sewer system must move through it by gravity. This is exactly how the standard system works. Many houses have concrete screed floors. When installing an additional unit, this further complicates the installation work. Since you will have to not only break through the foundation, but also lay pipes inside the concrete floor. When performing this work, the clone must be at least 2 cm per meter of sewer pipe. This will allow the system to work flawlessly and not cause any trouble. Experts recommend that before starting construction, determine all the values and only then begin to implement your plan.

Slab foundation and laying of communications

This type of foundation requires very precise calculations at the very beginning of the project.

After pouring such a foundation with errors, it will be impossible to lay the necessary communications. Therefore, a trench is dug first. All communications and sewer pipes are laid in it, dressed in special protective sleeves.

In a slab foundation, the sleeve plays a very important role. It protects the monolithic slab from high pressure and also facilitates the process of replacing a damaged section of pipe. If the sleeve is missing, it is simply impossible to replace the pipe in such a foundation. The pipe can also be damaged when the foundation is being poured.