Coating various surfaces with bitumen, a resin-like mixture that has certain waterproofing properties, has long been considered the most effective and widely available way to protect building structures from water. Previously, to use this mixture, it was necessary to melt the bitumen at a high temperature - over a fire, and then cover the surfaces with a still hot mixture. Now everything is much simpler - it is possible to use solvents. To apply a mixture of bitumen solution with additives to the surface, no more than two workers will be needed, and bitumen mastic is quite effective and easy to use. Let's take a closer look at what types of mastics there are and their features.

Return to content

Types of mastic for waterproofing

Waterproofing mastic for foundations is popular due to its high protective properties. It does not allow moisture to pass through, and also creates a dense and reliable layer on the surface, and has good adhesion to many materials. The layer of the product is uniform and there are no flaws on it, for this reason the liquid cannot penetrate further.

The division of foundation mastic can be done for different reasons. One of them is the choice of application method: cold or hot. Most often, beginners choose the cold type for work; the hot type is more labor-intensive and dangerous, so it is usually performed by specialists.

When purchasing, pay attention to the presence of a certificate of conformity; all bitumen mastics must be produced in accordance with GOST; if there are no documents confirming this, then this product should be discarded.

Hot types can only be used in the absence of rain, otherwise the drops will spoil the uncured surface of the layer, and over time the layer will lose its properties and uniformity.

The following are distinguished by their constituent elements:

- Single-component, they are sold immediately ready for application, but it must be taken into account that they should be used in full within a short time after opening the container, otherwise the composition will harden and it can no longer be applied;

- Two-component, to use the product, you need to mix two components, which are placed in different containers, they contain a bitumen base and a thickener. Such products have a long shelf life.

Waterproofing mastic does not allow moisture to pass through, and also creates a dense and reliable layer on the surface, and has good adhesion to many materials.

Composition and production features of the substance

There is also a division into additional components that are used to obtain a variety of properties. So they distinguish:

- Polymer type - highly elastic composition, with a high degree of adhesion to the concrete base;

- Latex - positive properties include the possibility of application at low temperatures, elasticity, reliability of the layer, and low flammability. The characteristics of the mastic surface are similar to rubber;

- Rubber - rarely used as a waterproofing layer on the foundation because it is less resistant to moisture;

- Mineral - recommends using this type for buried foundations, they are able to create a particularly durable layer, while the consumption of the product is not high.

Polymer type - highly elastic composition, with a high degree of adhesion to the concrete base.

The procedure for treating the surface with mastic using the cold method

The reliability of the waterproofing layer directly depends on two factors: the quality of the product and compliance with the technology of waterproofing work. If the technology is violated, the surface may eventually begin to crack, peel, and allow groundwater to pass through.

Surface preparation

Before starting work, the base must be prepared: the surface must be leveled, dust, dirt, and old waterproofing must be removed, if it swells or peels off from the base. To apply the composition, the surface must be thoroughly dried.

Primer application

When choosing a primer, you need to focus on the type of coating waterproofing used, since not all primers and mastics are compatible with each other. The primer improves adhesion between the base and the insulation layer and reduces mastic consumption. Apply to a previously prepared surface with a short-haired roller. When processing complex elements, you can use a brush. The primer is applied in one even layer and left until completely dry.

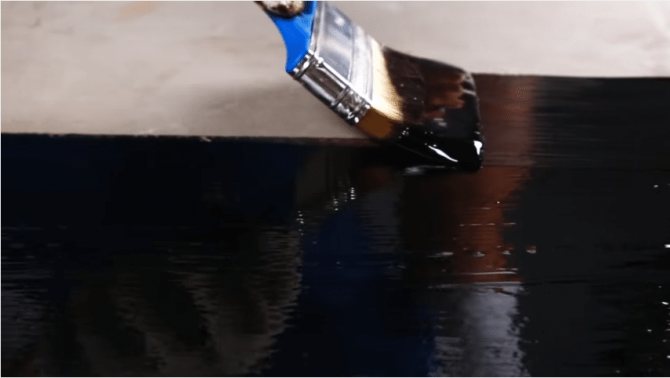

Application of bitumen mastic

The material is applied manually or by spray. The mastic is applied manually using a spatula, a folded brush with short stiff bristles or a short-haired roller. In the mechanized method, coating waterproofing is applied using airless spraying under a pressure of 150 bar. The mastic should be applied from the side exposed to water in an even layer, from top to bottom. Wait for the layer to dry completely, apply the next layer in the same way.

Waterproofing reinforcement

The waterproofing of the foundation of a new building must be reinforced to avoid damage to the waterproofing layer when the structure shrinks. For reliable protection from the negative effects of moisture, gutters, joints, corners, protrusions, joints and other complex structural elements must be reinforced with special care. Reinforcement is carried out using fiberglass or fiberglass, which is laid on the first layer of mastic waterproofing before it dries. Fiberglass fabric (fiberglass) is impregnated with mastic. After drying, the next layer is applied.

Before use, the mastic should be kept for 24 hours at a temperature of 15–30 °C. If necessary, add solvent and mix thoroughly. Two-component mastics are mixed no earlier than half an hour before application. Mixing is done with a mixer with a spiral attachment for at least 5 minutes at low speed.

How is waterproofing mastic better than roofing felt?

Bituminous foundation paint can be used to create a durable coating that will not allow moisture to reach the base. But there are other means for waterproofing work, and beginners often face a choice between roofing felt and mastic means. You should study the advantages of using mastics in order to make the best choice:

- The solution is easy to work with, the process is similar to applying paint, so you can carry out the treatment yourself;

- There is no need to create an even coating, the mastic fits well even on surfaces with flaws; for roofing felt, the base needs to be prepared more carefully;

- You can make the process easier by choosing a spray bottle for application, so the process will go faster.

The seamlessness of the layers is also noted; some delay between the application of subsequent layers is acceptable, but it should not exceed six hours.

Among the disadvantages, they note the shrinkage of the material, so the layers should be applied evenly, or use the bitumen-polymer type, which has better tensile strength. The mastic layer will protect the surface from the outside; to protect against moisture from the base, film materials are used.

Bituminous foundation paint can be used to create a durable coating that will not allow moisture to reach the base.

Criterias of choice

When choosing bitumen mastic for waterproofing the foundation, you should pay attention to:

| Manufacturer | There is no need to doubt the quality when using a product from well-known manufacturers. Among the popular brands: FARBITEX, Bitumast, AKTERM, LITOKOL, Aquamast. |

| View | Two types of protective coatings are available: bitumen and bitumen-polymer mastic. The second option combined the best properties of bitumen and polymer materials. |

| Purpose | Each product has a specific purpose: for roofing, foundations, swimming pools, bathrooms, basements. There are also universal mastics. |

| Compound | There are one-component and two-component compositions. The latter must be connected before use. |

| Application material | The insulator can be applied to different types of substrate: concrete, wooden surface, iron, brick. |

| Volume, l | Products are produced in containers of different volumes: from 1 liter and more. This allows you to rationally use material and save money when performing small-volume work. |

| Weight, kg | The weight of the mastic does not correspond to the displacement. For example, a 20 liter bucket contains 18 kg of bitumen mixture. Packaging is available in different versions, starting from 1 kg. |

How and with what to dilute bitumen mastic

To obtain different properties from the bitumen base, various additional elements are added; they often determine the characteristics of the solution. If the thickness of the mastic is not suitable for high-quality application, then you can dilute the solution with the following substances:

- Petrol;

- White Spirit;

- Gasoline galoshes.

If the thickness of the mastic is not suitable for high-quality application, then you can dilute the solution.

Main characteristics

Bitumen mastic is used for waterproofing foundations of various types due to the following characteristics:

- Excellent elasticity and flexibility of the material allow it to be used in conditions of significant temperature fluctuations. The elastic protective layer adapts to operating conditions and is able not to collapse when significant breaking loads occur. The flexibility of the material serves as an indicator of its high frost resistance and prevents cracking of the protective film.

- High adhesion rates make it possible to obtain strong adhesion between the bitumen coating material and the surface being treated, and prevent delamination of the waterproofing.

- The material does not lose its characteristics when exposed to ultraviolet radiation, and also does not lose its original appearance.

- High wettability ensures the filling of the pores of the base material, which allows them to be completely closed, creating a continuous hydro- and vapor barrier layer.

- Mastic does not create favorable conditions for the development of fungi and microorganisms and is able to withstand various biological factors.

Foundation Tools

If you decide to carry out waterproofing work yourself, then you should know what tools you will need to successfully complete the process. You will need the following tools:

- Roller, brush;

- Putty knife;

- A spray bottle may also be selected for application;

- Gloves to protect the master;

- Solvent to clean up excess mastic.

If you decide to carry out waterproofing work yourself, then you should know what tools you will need to successfully complete the process.

Preparing the foundation surface

Waterproofing technology using bitumen mastic involves a preparatory stage. Its correct implementation guarantees a high-quality result. You need to follow the steps below:

- Repairing base defects, leveling the surface;

- Corner parts require rounding, possibly cutting. To round off the internal joint areas, a fillet is used;

- They work at optimal humidity; the foundation should not release excess moisture. Check the humidity level in advance. To do this, lay a film coating on the base, after 24 hours they look at the film, when the absence of condensation is detected, waterproofing can be carried out;

- To increase the degree of adhesion, priming with a bitumen type of primer is used.

To increase the degree of adhesion, priming with a bitumen type of primer is used.

Technology of work execution

When carrying out construction work on waterproofing the foundation with bitumen mastic, the processing technology must take into account the basic requirements and rules. The preparatory stage during the operation of the structure involves the creation of a trench about 1 m wide along the entire perimeter of the structure.

Proper preparation of the work area will help enhance the insulating properties of the material:

- elimination of defects, irregularities, cracks in the foundation;

- fillets are made to eliminate sharp corners;

- if necessary, grout the surface to avoid the formation of air bubbles;

- sharp protrusions are rounded;

- The surface is cleaned from dust and soil.

It is recommended to measure the moisture level of the foundation surface using a special device. The treatment area must be dry and clean. The proximity of groundwater requires the initial construction of a drainage system.

Hot applied bitumen is heated immediately before use. The preparation of two-component mastic involves mixing bitumen and polymer additives. The bitumen-polymer material should be diluted with a solvent, bringing the composition to a uniform consistency.

The mastic is applied with a brush

The mastic is applied using a brush, working the surface of the foundation from top to bottom. The next layer is applied only after the surface has dried. There is no need to wait long periods between each application. Treatment with a special sprayer will help speed up the process.

Using a special sprayer significantly speeds up the work

A foundation waterproofing coating made with bitumen mastic will provide reliable protection of the surface from moisture. Choosing the optimal coating option will improve the performance characteristics of the building structure.

Layer thickness and consumption

The consumption of bitumen mastic per 1 m2 of foundation waterproofing differs depending on the working conditions. The average consumption is 1-1.5 kg/sq. m. It is greatly influenced by the thickness of the layer. Typically, it is required to apply the solution in 2-4 layers.

To understand how much product will be needed for waterproofing, determine the area in advance. To do this, the height from the sole to the ground is measured, and you also need to know the length of the walls.

Typically, it is required to apply the solution in 2-4 layers.

Features of applying layers

All layers of bitumen-based mastic must dry well and harden, and only then can the next layer be applied. If you rush and apply a layer without waiting for the previous one to completely dry, there is a risk of delamination. Also, failure to comply with the technology can cause disruption of the adhesion of mastic insulation to the base.

It is very easy to check the degree of dryness of floor coverings made from mastic. It is enough to determine the stickiness of its surface. If it is not sticky, the layer can be considered dry. The drying time of a layer of bitumen mastic depends on its constituent parts, the content of water vapor in the air, thermal conditions, both the environment and the temperature of the base.

Return to content

Technology for applying bitumen mastic

To get the desired result, after preparing the foundation, you should thoroughly mix the mastic; if a two-component composition is selected, then mix both components according to the manufacturer’s instructions. Then proceed as follows:

- The first layer is applied with a roller or brush, do not rush, the master must regulate the uniformity of the coating thickness;

- when the layer is completely dry, proceed to applying the next layers, while before each one they wait for it to dry and stir the composition;

- After all layers have dried, the foundation is backfilled.

It is recommended to apply the mastic solution in 3-4 layers so that the waterproofing is durable.

When the layer is completely dry, proceed to applying the next layers.

Making mastic with your own hands

To save money, it is possible to prepare the composition yourself. Since the use of cold-type mastic solutions is more popular, the manufacturing process of this particular type will be described in detail. Fillers should be prepared from crushed components from asbestos, dolomite flour or talc. You can choose green oil, diesel fuel, or kerosene as a diluent. The manufacturing process follows the steps described below:

- For four parts bitumen, use two parts filler, three parts thinner;

- Pre-mix the filler and thinner;

- The bitumen is heated in a metal container, it is constantly stirred during the process, and unnecessary impurities are removed;

- When the foam settles, remove the container from the heat and gradually add mixed filler and diluent.

To save money, it is possible to prepare the composition yourself.

Bitumen mastic is a good option to create durable protection for the foundation from moisture. The process of applying a cold look is simple, so you can do it yourself. If you wish, you can also prepare the mastic itself. It is important to adhere to the stages of work.

Don't forget about the basement!

Consider another situation in which moisture protection is a top priority. It is associated with the presence of a basement in the house. It also needs to be coated with special agents that prevent the penetration of liquids. Moreover, surface treatment in this case should be carried out both outside and inside; cases of leakage and bursting of heating and water pipes in private homes are, alas, not uncommon. And here mastic mixtures come to the rescue again.

Many people ask the question: how to waterproof a basement? In fact, the technology for preparing and applying the bitumen mass remains the same as when processing the foundation. The only difference is the need for double-sided surface treatment, which was mentioned above.