Different types of piles are used in construction. They are used as a foundation for the construction of buildings on soils with weak bearing capacity. But such a type of support as sheet piles is not used for the construction of foundations. They are designed to serve as barriers that prevent movement of the soil mass. They are also used to protect pits and trenches from water penetration into them in areas where the groundwater level is high. These products, made from different materials, can withstand significant loads.

What is fencing used for?

During the construction of buildings on uneven or unstable soils, collapse of the slope or walls of the pit, soil shifts, and penetration of groundwater into the construction site may occur, which can damage neighboring buildings. To protect workers, equipment and the construction site, sheet pile fencing is used. They are indispensable in cases where it is necessary to strengthen the soil, especially near any bodies of water, in order to protect objects from the following situations:

- erosion ;

- washouts and rock collapses;

- siltation and shallowing;

- collapse of the coastal slope.

- provide protection against ground movements .

All such phenomena can be prevented in advance and various buildings can be protected using sheet piles. This technology is considered one of the best due to its simplicity and efficiency. Installation of tongues takes a minimum of time, and the fence itself is highly efficient, durable, and resistant to any type of load (tension, bending, statistics). The cost of constructing a wall is lower than using, for example, bored piles. Tongue piles are reusable, can be dismantled and used at other sites, which makes them economically viable.

Dowels are made of high-strength metal and can be used many times Source pinterest.ru

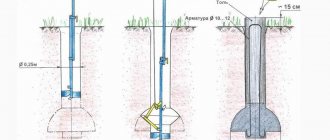

Reinforced concrete piles

The construction of reinforced concrete piles is distinguished by the presence of connections that ensure the tightness of the structure. They have the shape of trapezoidal tongues and grooves, which are inserted into one another during installation. Industrial technologies make it possible to produce elements up to 15 m in length. Increasing this parameter is almost impossible, because difficulties arise with transportation and installation. At these stages, you may encounter problems with lock damage.

Such sheet piles have significant weight and are used to strengthen coastlines and in the construction of special-purpose sites. Installation is carried out using driving technology.

Scope of application

Tongue piles are the most effective, quickly erected and economical fencing, which is why this design is used everywhere. This can be a sheet piling fencing of the pit, which allows you to create waterproof and completely airtight walls. Can be used to strengthen access roads to suburban areas, embankments, and slopes. Widely used as strengthening and arrangement of embankments and coastlines.

Often fencing is used to equip hydraulic facilities. In certain cases it is used for high-quality protection of communications. With its help, you can equip landfill fencing, wastewater collectors, and so on.

During construction work near water, there is often no alternative to sheet piles Source fens.by

See also: Catalog of companies that specialize in the construction of fences and fences.

Standards in the technological map and SNIP

The standards for fencing using the sheet piling method are specified in the technological map .

The map was developed based on experience in construction at similar sites with a repeating structure of buildings, structures with parts, as well as for buildings with unified dimensional schemes and standard designs.

It covers the basics of high-quality work performance , fire and environmental safety and other important points and issues that arise during construction work of increased complexity.

The map was developed for foremen, construction workers and engineers involved in the technical aspect of the construction of sheet piling structures.

The quality of the work carried out is assessed according to SNIP - “building norms and rules”, which can be used to guide and talk about the competence of the work and the construction of a fence in the pit.

It reflects the requirements for fire and environmental safety of work and the material and technical component, which must be aimed specifically at the norm, and not at deviation from it.

Installation of sheet pile fencing

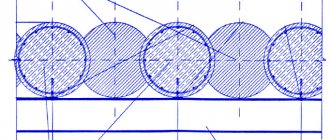

The fence consists of individual elements (sheet piles) that are assembled into one structure. There are grooves on the sides of all elements that allow them to be easily and quickly connected into one structure.

Piles can be made from various materials, which differ in durability and characteristics:

- Plastic . They are made of composites and PVC, reusable, but in most cases they are installed as permanent elements of the fence of coastal objects. They are considered inexpensive, but are not very durable.

- Reinforced concrete . Installed only once. They are distinguished by energy-consuming installation and unprofitable dismantling. Can be used as additional strengthening of the foundation.

- Wooden . Inexpensive but impractical option. They rot over time due to moisture and are used only once. Cannot be used as a reinforcing foundation frame.

Sheet piling can be made from different materials, but not all of them can be beneficial for use Source pdoshka.ru

- Metal . The most economical, durable, versatile and functional option. Manufactured from alloy or high carbon steels. Reusable, easy to install, lightweight, compact, have high static load ratings, and high strength.

In most cases, a profile tongue is used, but there is also a tubular one made of metal. It consists of thick-walled pipes with a large cross-section that are hollow inside. They have a high load-bearing capacity and are very stable. Used on unstable soils where there are heavy loads on the structure. Can be combined with profile piles for maximum reinforcement of areas.

Installation of sheet piling from pipes Source rmnt.ru

Overview of types of sheet piles

In construction, there is such a type of piles as sheet piles - they are not used to construct foundations, but have slightly different functions. Their main purpose is a fence that prevents soil movement and moisture penetration. You can read the instructions on how to make a foundation with a plinth here.

The photo shows walls made of composite sheet piling

Specifications

Sheet piles are metal or PVC piles that are used to construct sheet piling fences or rows. You can often come across the name - anti-filtration curtains. They are a continuous wall of sheet piles that fit tightly together. They are installed by driving or pressing piles into the soil or ground. Read the guide on how to add a foundation to an old house on this page.

When choosing sheet piles, you should pay attention to the following criteria:

- Durability. The longest service life for metal tongues is more than 100 years.

- Strength.

- Resistance to external influences, such as ice drift or other mechanical influences.

- Resistance to corrosion and aggressive natural phenomena.

- Quite light weight, which has a positive effect on both transportation and installation. At the same time, the load-bearing capacity is quite high.

- They have excellent decorative functions; you can choose any color you need.

The use of sheet piles has a number of advantages:

- there is no need to remove and transport the soil;

- Construction time is significantly reduced thanks to ready-to-install sheet piles, which also take up very little space;

- The sheet piles and sheet pile walls themselves take up little space after installation is completed;

- sheet piles have a high load-bearing capacity;

- after their installation, security increases;

- It is possible to reuse sheet piles; they are quite easily removed from the ground.

Kinds

The photo shows Larsen metal sheet piles. Sheet piles are divided into several types, mainly according to the type of material from which they are made:

- Steel sheet piles, also known as Larsen piles. Larsen piles are a trench with grooves on the sides of the walls. Widely used in various areas of construction, for example, to create oil terminals, bridges, various storage facilities, and also to strengthen the banks of reservoirs, helping to avoid landslides and flooding. Also, embankments and road surfaces are strengthened using steel sheet piles. In addition, steel sheet piles are actively used in residential construction. Instructions for calculating and installing foundation waterproofing are here: https://fundamentgid.ru/remont-i-obsluzhivanie/gidroizolyaciya/instrukciya-po-raschetu-i-ustrojstvu-gidroizolyacii-fundamenta.html.

- PVC sheet piles. A wall built from PVC sheet piles can withstand heavy loads and is a fairly strong wall. Piles made of this material are actively used to strengthen banks. Their great popularity is due to their ease and simplicity of installation, as well as their quite affordable price. PVC sheet piles are a fairly effective and practical solution to the problems of stabilizing coastlines.

- Composite sheet piles are a new product on the construction market. The term “ultracomposite” appeared recently, in 2012, when Russian specialists developed and patented a new series of sheet piles made from ultracomposite material. In terms of quality characteristics, composite piles are similar to PVC sheet piles, but are cheaper. The load-bearing capacity of these piles can be compared with metal sheet piles, but the cost of the former is more favorable.

Installation features

Installation of sheet piles in the picture Installation of sheet piles is quite simple to perform, but has its own characteristics that must be taken into account:

- To begin with, design calculations are carried out based on studies of soil and geological conditions. Then the location and support of the sheet piles and installation technology are calculated in accordance with the soil conditions. You should also take into account the possible permissible movements and movements of the tongues at each stage. These calculations must be carried out by professionals so that you do not have to overpay in the future. Read the guide on how to repair a crack in your foundation.

- Then preparatory work is carried out - this is the tracing of the axes of the wall on the territory, the preparation and delivery of the necessary machinery and equipment, the preparation of pits and working platforms.

- If at the preparatory stage it was not possible to determine by comparison the method of immersing the sheet piles, then it will be necessary to carry out a test immersion. Depending on the quality of immersion and the ability to insert the following tongues into the locks, the possibility of using one or another immersion method is determined.

- After identifying the method of immersing the tongues, you can proceed directly to installation. Sheet piles are installed into the ground one at a time or in pairs. First, three- or five-meter wooden guide frames are laid on the soil, the distance between them should be equal to the width of the tongue so that it can easily pass between the guides. The tongues, one or two at a time, are inserted into the lock of the corner tongue and are immersed in the soil to a depth of 2-4 meters. Then, one after another, the tongues are immersed in the ground in those areas where the guide frames are laid. To equalize the deviations of the sheet piles during immersion, upper contractions are installed and immersed in the ground along with the sheet piles.

When diving, you may encounter obstacles to the sheet piles in the form of large boulders. In this case, damage appears in the form of a rupture of the walls between the locks or a curvature of the lower edge of the tongue. In order to avoid such situations, the base of the sheet pile should be strengthened. When the sheet pile meets a boulder, you will feel a slowdown in the immersion of the pile.Read the guide to repairing the foundation of a private house.

Cost of sheet piles

The cost of sheet piles is influenced by the material from which they are made, as well as the manufacturer. The average cost of composite sheet piles is from 6,000 rubles per sq. m. m., metal sheet piles - from 10,000 rubles per sq. m., PVC sheet piles - from 5,000 rubles per sq. m.

Where to buy sheet piles?

Where to buy in Moscow:

- LLC "Trading House InMobReserve", st. Sadovaya-Kudrinskaya, 11, tel.;

- , Serebryakova proezd, 14, building 15, tel.;

- LLC "SBH COTPAHC", Ordzhonikidze st., 11, tel.: 8 (495)956-4067.

Where to buy in St. Petersburg:

- , Petrogradskaya embankment, 36, BC Linkor, office 305, tel.;

- , Afonskaya st., building 2, tel.: 8 (812)495-63-48;

- Stroitelnaya, st. Repishcheva 14, letter AD (entrance from Marshal Novikov Street), tel..

Video

Watch the video of sheet piling installation:

Sheet piles are also installed around the perimeter of the foundation when it is not possible to make slopes. Their installation is quite simple, as you can see, but it is not advisable to install it yourself, in order to avoid double costs in the future.

Fencing technology

The installation of sheet piling fencing of the pit is carried out using the same technology. The process of immersion and construction of the required wall is carried out in accordance with the calculations carried out, which are indicated in the corresponding project. The design itself specifies the method of fastening, the depth of the fence and the type of tongue and groove. Before design calculations, a hydraulic engineering assessment of the soil must be carried out.

Installation is carried out according to the following principle:

- marking and further installation of special guides is carried out

- equipment is delivered , well drilling may be required;

- elements are immersed in the ground and installed in their places;

- Fastening is carried out according to the prepared project.

Driving piles can be carried out using several methods. One option is pressing with special installations. In another case, vibratory hammers are used. A hydraulic hammer can also be used. Driving is considered the cheapest method of immersion, but it has negative sides - soil movement, damage to nearby structures. Therefore, it is not suitable for use near industrial complexes or in cities. The most delicate method is pressing; it can be used in densely built areas. Vibration driving is suitable for soft soils, can be used almost anywhere, and is characterized by productivity.

Video description

This video shows how to install sheet piling pipes using the vibration immersion method:

To install piles, specialized equipment and machinery are used, which can be used even on small objects. Minimizing the load on the soil and simplifying the driving of piles occurs using auxiliary technologies, for example, leader drilling. You can also simplify work processes by washing using hydraulic equipment. In some cases, a combined dive is used. Often, when constructing pits, a backfill of boards is used, which later acts as formwork for concreting. For scooping, an edged board or steel sheet is used; when used on soils with a large amount of groundwater, additional care must be taken for drainage.

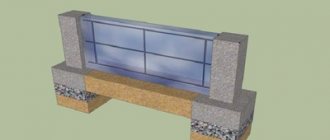

In some cases, it may be necessary to reinforce the finished wall. To do this, they can install diagonal struts that support the piles, and they themselves rest on the foundation slab or the bottom of the pit. In other cases, it is necessary to use spacers in the form of horizontal beams; they rest against the walls and prevent it from tipping over. Sometimes the optimal solution is to use a distribution belt - these are horizontal beams, attached to tongues around the entire perimeter, strengthen the wall and distribute the load.

If necessary, the sheet pile fencing is reinforced with additional beams and spacers Source pdoshka.ru

APPENDIX A (required)

Determination of the load-bearing capacity of a metal tongue-and-groove joint

The calculated load-bearing capacity of interlocking joints is determined based on the results of tensile testing of samples on a scale of 1:1, i.e., full-size cross-section, with a sample width of 100 mm.

Figure A1 shows a sample of a lock, version 1, made from hot-deformable shaped profiles produced by Severstal-METIZ (Cherepovets). Figure A2 shows a sample of a lock in version 2 - from standard hot-rolled pipes Æ 68×12 mm (female element) and from long-rolled square steel 30×30 mm (male element). Both elements are welded to strips (blanks) made of rolled sheets or strips.

Test specimens are made separately or cut from ready-made tongue and groove profiles. At least three samples are tested from each batch or order shipped. The steel for making samples must be of the same grades as for the main industrial products. Copies of certificates are attached to test reports. Acts can be drawn up in any form.

Tests of samples with a width of 100 mm are carried out on hydraulically driven tensile testing machines with a force of at least 50 tf (MUP-50). Based on the load data and the deformations corresponding to the loads, tension diagrams are constructed and from them the limiting value of the tensile force Nt is determined, at which plastic deformations begin in the connection, i.e. yield strength σt.

The design load-bearing capacity of the joint is determined by the formula Np ≥ NT/γm, where γm is the reliability coefficient for the material, the value of which is taken according to the standards [2] (see Bibliography).

The Np values obtained during testing are recommended to be used in the design and calculation of sheet piling structures with their subsequent refinement based on the results of factory testing of locks using this method.

Loads on sheet piling walls and other structures from soil pressure and other influences must be taken in accordance with current regulatory documents with a safety factor for load γf = 1.2.

1 - profile (male) A = 2059 mm2, weight 16.16 kg/m, L = 6000 mm; 2 - profile (covering) A = 2883 mm2, weight 22.63 kg/m, L = 4300 mm

Rice. A1 – Tongue and groove lock made from shaped profiles of JSC Severstal-Metiz

Version 1

Figure A2 - Lock test specimen

Version 2

Installation technology

There are practically no differences between vibration and impact immersion technologies. The only difference is the features of the functioning of the attachments. Slinging and sequencing are absolutely identical.

The fencing is installed using the following technology :

- material is delivered to the site;

- distributes the sheet pile of the construction site;

- the contour is marked , a pile driving machine is used;

- slinging and moving the sheet pile to the installation site is carried out

- the head of the loader is mounted on the tongue , the fence is placed in place of driving;

- The tongue is vertically aligned , guiding immersion is carried out;

- the sling is dismantled, the sheet pile is immersed to the depth specified in the project.

Each sheet pile is immersed in this way. The work continues until a closed fence around the perimeter of the pit is obtained.

When all the sheet piles are buried in the ground, you can start digging a pit without fear of its walls collapsing Source speccypro.ru

Calculations and cost of fencing

Calculations are required to determine the configuration, size of the wall and additional reinforcement. This will achieve the necessary strength and stability of the entire structure. In the calculation process, indicators of the overturning effect, the forces of the retaining walls, the coefficient of performance of the structure in the soil and the reliability of the wall are taken into account. The latter may have different differences depending on the type of fence and soil characteristics.

When determining the strength, the resistance of a meter of wall to loads, the resistance of the strapping, the standard resistance and the coefficient of operation of the structure in the ground are taken into account. The last indicator is the tensile strength of the locks, which takes into account horizontal loads, radial force, operating conditions coefficient and the standard tensile strength of the locks (varies depending on the type of steel).

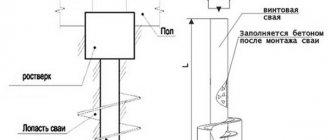

Foundation price

Some novice DIYers mistakenly believe that sheet piles form the basis of a conventional foundation. This is wrong. These products have different purposes. If you are still interested in the foundation for your future home, then you should familiarize yourself with the price of such work. If you plan to do construction yourself, you can study the prices for screw piles. They depend on the length. If this parameter is 1.5 m, then you can purchase the product for 1,250 rubles. With an increase in this value to 6 m, the price increases to 3,300 rubles.

Some companies provide foundation piling services. Products with a length of 1.5 m can be mounted for 1,750 rubles. This price also includes the headband. Manual installation costs 800 rubles. The price increases with the length of the product. If it is 6 m, then you will have to pay 1,700 rubles for manual installation. If the foundation pile is installed using machinery, you will pay 3,950 rubles for the work.

Before purchasing a support, it is important to inquire about its technical characteristics. With a barrel diameter of 57 mm, you can count on a load-bearing capacity of 1 ton. The coating affects the cost of the foundation. The weight of the barrel can reach 45 kg, while the minimum value is 10 kg. The diameter of the blade is equivalent to 200 mm, and its thickness is 4 m.

The cost of the foundation should be calculated taking into account the price of installing one pile. If you want to carry out manual installation with the help of specialists, using a pile 3.5 m long, you will have to pay 1,200 rubles.

Video description

About the rules for installing a safe sheet pile pit:

The final cost of a pit depends on a number of important factors. First of all, the type of material used is taken into account, for example, boards, pipes, metal piles, Larsen sheet piling. The cost is also affected by the type of equipment used (pile driver) that is used to drive the sheet piles. The main cost item is the volume of work performed. However, the overall cost can be increased as a result of the need to use retaining boards around the perimeter, which act as supports to strengthen the wall.

The elements of the metal tongue interlock with each other like puzzles Source pdoshka.ru

Advantages of polymer products

Recently, piles made of composite materials have become increasingly widespread. They allow you to reduce construction costs and maintain performance characteristics. For some properties, such designs are better than other varieties. They do not rot or corrode, do not require additional operating costs and do not require conservation. This makes the use of such products more profitable compared to metal ones.

They are slightly inferior in strength if special requirements are placed on the design in this regard. More often in construction, models are used whose shape is similar to trough-type metal piles. Lock connections can be presented in several options. Installation is carried out by vibration driving with preliminary erosion of the soil, and in difficult conditions the technology of digging piles is used.

Briefly about the main thing

Sheet piling is a strong and durable solution for arranging construction pits and strengthening banks near water bodies. This strengthening of the walls of the pits allows them to withstand heavy loads, and the sheet piles themselves are not afraid of the influence of moisture, high or low temperatures. It is considered one of the most economical options, since some types of tongue and groove can be reusable. There are also dowels that are installed only once. Metal, wood, plastic or reinforced concrete are used to produce sheet piles. Depending on the material used, the characteristics of the fence itself change. Before use, calculations are carried out to help achieve the best result.

Ratings 0

Main types

The described piles can be classified according to several criteria, among others - the material at the base, which is:

- steel;

- PVC;

- composite

The first type is also called Larsen piles and is a trench with grooves on the sides of the walls. These structures are used in various fields of construction, for example, in the creation of storage facilities, bridges, and oil terminals. The products are used to strengthen the banks of reservoirs and help prevent flooding and landslides. Using steel sheet piles, road surfaces or embankments are strengthened.

The structures are widespread in residential construction. If the base is PVC, then the wall will be able to withstand high loads. It has sufficient strength. Piles are used to strengthen banks and are popular due to their ease of installation and affordable cost.

PVC sheet piles are quite effective and can solve the problem of stabilizing the coastline. When the base is a composite, we are talking about products that have appeared on the construction market quite recently. They are based on ultra-composite material, and their characteristics are similar to sheet piling structures, but have a more affordable price. The load-bearing capacity is compared with metal tongues, but the price is more favorable.