When designing a garage, the developer needs to think about a reliable foundation that would support not only the weight of the structure itself, but also of any car.

The characteristics of a slab foundation meet these requirements, and monolithic reinforced concrete guarantees the strength and durability of the building.

We will tell you in the article how to build a monolithic slab under the foundation of a garage with your own hands, and how to pour concrete correctly.

Advantages and disadvantages of a “floating” slab

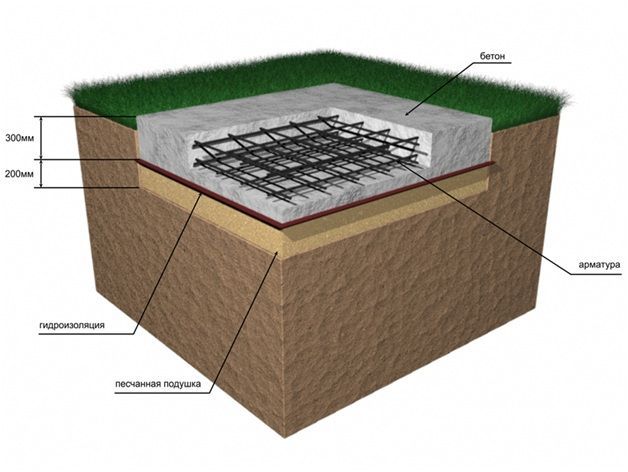

Schematic representation of a floating slab base.

A generally recognized advantage of such a base is the possibility of its construction for a two-story building made of brick or blocks. At the same time, the slabs can be installed on different types of soil, including loose and subsidence. However, good strength indicators directly depend on compliance with the norms for laying the “pie” of the base.

But, despite the significant advantages, a floating slab costs the developer much more than, say, a strip base or the use of TISE technology. Most often, a slab base is chosen due to its reliability and the absence of the need to cover the underground areas of the house.

Determining soil type

The depth of the foundation to be poured will directly depend on what kind of land is located at the construction site. Soils are rocky, sandy, clayey and loamy.

Clay tends to swell at fairly low temperatures and erode when groundwater passes close by, so the depth of foundation on such soils will be much greater than on soft sandy soils. On clay soil it is best to build a pile or slab foundation, and on sandy and loamy soil - a strip foundation.

And here is an article from which you will learn how to build a garage from corrugated sheets.

Preparation for construction

The construction of a slab foundation begins with the preparatory stage, which includes several general activities:

- resolving the issue of the composition of the “pie” under the base slab;

- determination of the reinforcement method and selection of materials for it;

- mandatory calculation of reinforcing belts;

- choice of thermal insulation method.

As for reinforcement, the need for its use should be especially emphasized. The consequences of violations can be fatal and lead to cracks in the foundation and walls of structures.

Types of foundations for garage boxes

To decide what kind of foundation is needed for the construction of your garage, personal preferences are not enough. Mandatory calculation of technical characteristics is required. You should know the load that the facility will produce and conduct georeconnaissance to determine the nature of the groundwater.

If these conditions are met, you can select the optimal foundation option.

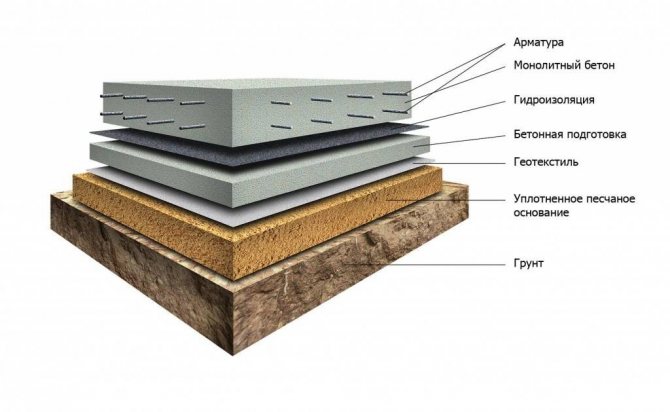

Foundation layers made of a monolithic slab.

There are several foundation options often used in garage construction:

- Strip foundation. Used as a base for one-story garages built on stable, solid soil.

- Reinforced strip foundation. Suitable for heavy or two-story structures on hard ground.

- The base is made of monolithic slabs. It is used in difficult and problematic areas where there is quicksand, loose soil or quicksand.

It is important to remember that construction must take place in accordance with all technical requirements, otherwise the structure will not cope with its functions and the owner will suffer large losses by redoing poor work.

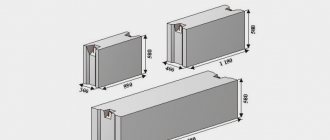

Slab parameters

The dimensions of the slab are determined based on the loads to which it will be subjected during operation. Namely, pushing and bending loads from walls and other load-bearing parts of the house, as well as frost heaving of the soil are taken into account.

When constructing a two-story frame building with reinforced concrete floors, a slab thickness of 20 cm is considered sufficient. And lighter houses can be installed on a slab whose thickness is 15 cm.

This value will increase as the weight of the building increases. For example, if the dimensions of the building are 20x20 meters, then the thickness of the slab should be about 25 cm.

In cases where the house has non-standard or complex shapes and sizes, specialists are consulted.

Soil freezing depth

As I have said more than once, in construction there is frost heaving of the soil, which warps and breaks the building. And the greater the difference between minus and plus, the more pronounced this phenomenon is.

Very roughly, you can imagine this process like this: from the rain, the earth became saturated with moisture and froze. You are heating in the garage and the moisture thaws and the soil begins to put uneven pressure on the foundation due to the fact that ice increases in volume as the temperature drops. The result is the formation of cracks in the walls, skewed openings and other pleasures.

SNiP clearly states that the reserve should be at least 20% of the maximum soil freezing depth.

However, there is another nuance - the freezing depth is different for different soils. If there is sand or coarse rock (rocky soil), then water passes through it without stopping and the freezing depth is lower. And in clayey soils (clays, loams, sandy loams) water is retained and therefore the rules must be followed more strictly.

To protect your garage from such a scourge, place the base of the garage foundation below the freezing depth. If in the Krasnodar Territory the freezing depth is 0.75 m, then the foundation depth should be below 1 m (0.75 x 1.2 = 0.9 m).

However, there is another way to solve this problem. First of all, you can remove the soil under the base of the foundation and replace it with crushed stone and sand, thus removing water from the base of the foundation. You can also make a so-called clay castle, when the backfill is made of clay with layer-by-layer compaction, also removing water from under the base of the foundation.

Well, it is also possible to insulate the side external walls of the foundations with foam plastic, which protects the ground from thawing and thereby prevents frost heaving of the soil.

All these methods are used in combination.

Thermal and waterproofing

When building a house or cottage that will be used year-round, the slab is thermally insulated. That is, the thermal insulation material is placed under and above the base. Extruded polystyrene foam is placed over the entire area of the slab, insulating its side walls.

Waterproofing is calculated taking into account the moisture level at the construction site. To determine it, a well is drilled, and if the groundwater is located at a level below one meter from the ground surface, the slab is waterproofed according to a simplified scheme.

However, in the case of a high groundwater level, the first option will not work. Here you will need qualified help.

Advantages of choosing a slab structure

A slab foundation for a garage is suitable for constructing walls made of brick, cinder block, concrete, wood, etc. According to its purpose, such a foundation structure is a universal basis for any material of external walls. A concrete monolith foundation slab has many advantages:

- Possibility of construction on soils of any complexity.

- Ease of manufacture and further finishing.

- Creates a special “dry” microclimate even with a high groundwater table.

- Ability to support the weight of a vehicle.

- Possibility of installing heating cables in the floor for the “warm floor” system.

A monolithic slab, like any other structure, has several disadvantages:

- High labor intensity of excavation work.

- The need for structural reinforcement.

- Impossibility of constructing an inspection hole.

Particular attention should be paid to the construction of a garage with a slab foundation on a site with a slope. There may be a risk of the monolithic slab sliding down the slope.

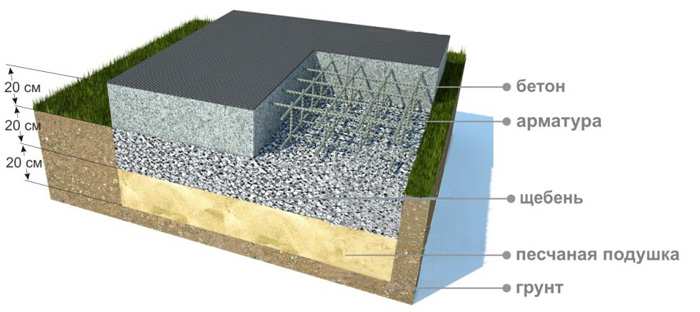

Pillow is a guarantor of reliability

The strength of a slab base is also closely related to a well-equipped cushion. The two layers of which it consists, that is, gravel and sand, work differently.

The top layer is gravel. Due to its characteristics, the material allows moisture to pass through, preventing it from collecting directly under the slab. Thus, water enters the lower layer - sand. Its tasks are to divert water to the underlying layers and evenly distribute pressure, compensating for heaving forces.

After determining the basic requirements for the arrangement of foundations, you can move on to more specific examples of laying foundations for various types of structures.

Choosing a suitable foundation

There are several types of foundation:

This is a concrete solution poured into formwork, placed in a specially dug trench along the entire perimeter of the building.

It is constructed from tightly driven or screwed piles into the soil. It is considered the most universal for any, even the most difficult soils.

It consists of a solid array of slabs under the entire structure and is not only one of the strongest, but also the most expensive of other types of foundations.

Choosing the type of foundation for the garage

Garages are classified as lightweight non-residential premises, but it should be borne in mind that the floor will be subject to additional load from the weight of the machine. Therefore, it is necessary to decide on the choice of the most suitable base option. From the experience of constructing such buildings, the following must be taken into account:

- Building design. Design features include the number of floors, dimensions, height of the walls and materials that will be used in their construction. This determines what the load on the base surface will be. This also includes the functionality of the future garage. Will it be used to repair the car, that is, will it have special performance characteristics?

- Condition of the soil under the garage. Different types of soils also require different design solutions when building the garage itself and, in particular, when laying the foundation.

- The level of water occurrence and the level of freezing, and therefore the impact of frost heaving forces.

Foundation width

The expected thickness of the garage walls will directly affect the width of the foundation being installed for the garage, which should be 30% larger than them. This also applies to the grillage, that is, to the slab connecting the foundation piles.

In the case of a strip foundation for a garage, the pouring of which involves the construction of formwork, the width of the garage foundation will also be increased by the thickness of the walls of this formwork. Let's say the width of the walls of the future garage is 12 cm (standard brick), and the wall thickness of the wooden formwork is 2.5 cm. In this case, the width of your foundation will be 12+3.6 (30% of 12)+2.5x2=20 .6 cm.

In this article, read about repairing a garage roof.

Preparatory arrangement of the slab for the garage and filling the “pie” under the slab

The slab base does not require any special complex calculations, although a number of basic requirements in the sequence of work must be met:

- The dimensions of the garage are determined in relation to the construction site. Pegs are driven into the corners of the future building;

- the plant layer is removed;

- the depth is determined by the project and can range from 0.2 to 0.5 m;

- in the presence of a blind area, the area further increases (from 0.8 to 1.5 m) from the marked foundation;

- the pit is compacted;

- When planning a drainage system, drainage ditches are prepared.

Gravel is poured into the compacted pit. The volume of material is determined from the following calculation. If the garage dimensions are 6.5x6.5 m, then about 20 tons of gravel will be required for backfilling. The thickness of the gravel layer will raise the slab from 35 to 50 cm.

So, the gravel is leveled and compacted well. Sand is poured on top of it. It is also distributed evenly, spilled with water and compacted. The thickness of the sand layer is 10 cm.

Actually, this is a “cushion” under the base slab with good reliability characteristics and a drainage system.

Preparatory period for the start of construction

Before starting to install a monolithic foundation for a garage, the site area is cleared of debris and stones, shrubs and trees are removed from the site, and a vertical layout of the building site is carried out. The top fertile layer of soil is removed to a depth of 150-300 mm and transported to the storage site. On the prepared site, you can begin linear marking of the garage configuration:

- The outer corners of the future garage building are marked according to the working diagram with wooden pegs or cuttings of reinforcing bars, which are driven 250 -300 mm into the ground.

- A construction cord or ordinary twine is stretched between the corners.

- You can check the correctness of the breakdown using the “diagonal rule”. To do this, it is enough to measure the diagonals of the marked garage configuration; if the layout is correct, the diagonals should coincide.

If there is a large discrepancy in the obtained dimensions, there may be a risk of distortion of the foundation structure, and therefore the entire garage building.

Excavation of a foundation pit for a garage using an excavator

Excavation

To install a monolithic foundation slab, a large amount of excavation work will be required. Depending on the amount of soil to be excavated, excavation work can be carried out manually or mechanized using earthmoving equipment. Typically, a pit for a garage has a depth of 300 - 500 mm.

In some cases, it is necessary to make the thickness of the monolithic slab much greater, which leads to a significant increase in the cost of the foundation. The bottom of the pit is leveled horizontally if possible and cleared of loose soil residues. The selected soil must be removed from the site.

For backfilling, it is recommended to use crumpled clay or clay soil, which will create a kind of water barrier to protect the concrete mass of the slab foundation.

Type of sand preparation of a monolithic foundation slab

sand cushion

In construction, it is recommended to lay a sand cushion at the bottom of the pit to level the earthen base and prepare concrete work. Sand is poured into the pit to a depth of 100 -150 mm and carefully leveled horizontally in an even layer. In some cases, in the presence of difficult soils, a layer of gravel of the same thickness is poured in front of the sand cushion. Laying a two-layer cushion will create a reliable shock-absorbing base that will prevent the destruction of the slab monolith.

The sand is thoroughly compacted using hand or vibrating tampers. Sometimes, when compacting, it is advisable to use water on the sand.

Waterproofing carpet

Waterproofing of a monolithic slab is a mandatory measure to protect the concrete mass from groundwater and atmospheric moisture. Most often, roll roofing materials are used for this purpose, such as roofing felt, aquaizol, technoelast, rubemast and other modern insulating coatings. Rolls of insulation are rolled out and laid directly on a sand bed or on a preparatory concrete pad. The seams are heated with gas burners and glued together. The result is a solid waterproofing “carpet” with edges curved upward by 100 - 200 mm.

There is another method of waterproofing a monolithic slab - coating, in which ready-made bitumen mastic is applied with a brush or roller to the concrete preparation. Liquid bitumen penetrates the pores of concrete and, after drying, creates a reliable waterproof coating, ready for concrete laying.

Monolithic slab in formwork

Formwork work

To prevent the concrete mixture from spreading when pouring a monolithic slab, it is necessary to install formwork from separate panels. To make formwork, you can use any suitable material: boards, metal steel sheets, types of plywood, etc. The main requirement for a material is its rigidity and strength. The panels are securely fastened around the perimeter of the pit, taking into account a distance of 200 - 300 mm from the planned walls of the garage.

To prevent the formwork from collapsing when pouring a large mass of concrete, it must be reliably connected into a single rigid system with the installation of side supports in the form of braces.

Reinforcement frame for a monolithic garage slab

Installation of reinforcement cage

At the next stage of constructing a monolithic slab, a reinforcement frame is made, which will increase the strength properties of the concrete mass. To reinforce the slab, it is recommended to use reinforcing bars with a diameter of 12 mm or more. The individual rods are connected into a frame using knitting wire. This method of fastening is considered the simplest and most accessible to any home builder. You can use electric welding to assemble the frame, but to perform such work you need to have qualifications and special welding equipment.

The dimensions of the frame cell are square with sides of 200 mm x 200 mm. The assembled spatial reinforcement frame is installed directly on the prepared sand base, previously covered with waterproofing roll material.

Concreting a monolithic slab

Concreting

It should be noted that when constructing a monolithic slab, good quality materials should be used. If, when making a concrete mixture yourself, cement of low grade and or second-rate quality is used, then such a foundation will quickly become covered with cracks and begin to collapse. The monolithic foundation slab is made of concrete not lower than class B 7.5.

Concrete is laid in a continuous manner. If for some reason it is not possible to finish concreting the foundation in one day, it is recommended to stop concrete work strictly on the metal frame. It is best to cover the laid concrete with a thick polyethylene film, and in this form the unfinished foundation can stand for several hours. The next day the concrete work can be completed.

Installation of formwork structure and reinforcement stage

Installation of formwork begins from one of the corners. First, one of the boards is attached using self-tapping screws and a corner, then the second one is added using the right angle rule, and so on. When constructing a structure, use a level to check its horizontal installation.

The final point is strengthening around the perimeter of the structure. To do this, use reinforcement, which is driven in at a distance of one meter. If the formwork box is well strengthened, the concrete will not be able to squeeze out the boards and compromise the integrity of the foundation.

The laying of reinforcing elements is carried out in two layers with a step of 20 cm. To connect the reinforcing rods, a welding machine can be used or manual dressing can be used. According to many experts, the second option is even more preferable.

Rods 30 cm long are driven into the formwork. Longitudinal sections of reinforcement are attached to them at a height of 7-10 cm with viscous wire. Transverse elements are laid on top and also tied. A second layer of reinforcement is similarly tied on top of the first mesh. The resulting structure is also checked for horizontality using a level, and any differences are eliminated.

The output is a reinforcement cage that lifts the foundation by the thickness of the slab. At the same time, the minimum slab base for a garage should be 15 - 20 cm. However, if necessary, when it comes to the further construction of a second floor, these dimensions can be much larger, and reach up to 40 cm.

Design options

The versatility of a monolithic slab as a foundation is due to the possibility of choosing between a conventional, edge-reinforced and lightweight structure.

An ordinary monolithic slab is a solid base, buried or located on the surface of the earth, 10-60 cm thick.

The structure, reinforced along the edges, can be located at any convenient depth (usually 1.5-2.5 m) and is an even layer of monolith, along the perimeter of which stiffening ribs rise above ground level.

With the help of formwork, they are also filled with concrete and can subsequently be closed at the top, forming a monolithic box that can simultaneously serve as a foundation for a garage, a basement or a ground floor. Due to its high cost and complexity, such a design is rarely .

The lightweight version of the foundation is simple to implement and allows you to save on concrete and reinforcement. It is suitable for garages made of light materials : wood, foam blocks, light frame structures. The lightweight foundation is poured on the basis of a reinforcing mesh, forming squares with walls from 1 m to 1.5 m.

It is similar to the strip one, but in the strip type the reinforcement poured with concrete is the support for the load-bearing walls. When installing a lightweight monolithic foundation, the load is distributed evenly over its entire area. A small layer of concrete can be poured on top of the lightweight foundation to form a floor, but any other floor suitable for a garage can also be laid.

The pouring stage and care of the finished slab

A concrete mixture of grade M250 and higher is prepared, with a water resistance rating of at least W6.

The pouring work is carried out continuously, so it is preferable to order ready-mix delivery.

A special tray is placed under the mixer, which supplies concrete. You need to start laying from the far edge, gradually distributing the solution and compacting it using a vibrator.

When performing manual mixing, two concrete mixers are installed on opposite sides. In this case, wooden rakes are used for leveling and distribution, and then the laid mortar is compacted with the same vibrating plate.

After 24 hours, the surface of the slab is watered. At high temperatures, for example, in hot summer, the surface is covered with a film and wetted. This care is necessary to prevent moisture from leaving the solution too quickly or unevenly.

Further work should begin only after the concrete has gained 70% of its strength. This is the minimum acceptable value that is necessary to prevent damage and cracking.

The hardening period of concrete at a temperature of +20º is at least 10 days, and at +10º up to 28 days (at average humidity).

If the developer decides to combine a garage with the construction of a second residential floor, the base can be strengthened by casting stiffeners. To do this you should:

- a trench 500 cm deep and 450 cm wide is prepared around the foundation;

- the prepared ditch is backfilled (like the pit above), compacted and reinforced, with an indispensable tie to the reinforcing frame of the slab;

- The box is being filled.

However, such stiffeners, like additional ones, are used only when a large load on the foundation is expected.

Construction material

Today, there are a large number of building materials from which you can build a garage. But the most optimal has always been and remains a brick, which can withstand loads for many years and not wear out.

Foundations come in different types:

Solid

This is a solid mass of slabs underneath the entire building and is the strongest type.

Welded

It looks like tightly driven piles into the soil. This type of foundation is suitable for any soil and is therefore a universal type.

Tape

Strip foundation for garage” width=”300″ height=”225″ />

It is a formwork into which concrete mixture is poured around the perimeter.

For each building with its own area and load, for a separate type of soil, a specific type should be selected. You need to know that the depth of the poured foundation will directly determine its strength and reliability.

For clay soils, it is preferable to choose a welded type of foundation; a tiled type will be considered quite acceptable, and for sandy soil it is best to choose a strip foundation.