It is permissible to install a pile-screw foundation at any time of the year, including in winter. There are also no significant temperature restrictions. The only point is the difficulty of screwing in the pile when passing through a layer of frozen soil; in some cases, a narrow hole is first drilled into which the support itself is installed. The ability to install screw piles in winter is one of the main advantages of this type of foundation. The combination of other advantages - speed and relative ease of installation, the ability to work in the most unfavorable soils, favorable cost - indicates the high competitiveness and feasibility of using screw piles in the field of low-rise housing construction.

Nuances and features of working with screw piles in winter

The pile-screw foundation is the only one that can be installed regardless of the season and weather conditions

To understand how difficult and potentially dangerous the installation of screw piles in winter can be, you need to know what the weather and nature have in store when carrying out installation work:

- Thus, under a smooth and pristine snow cover, rocky and uneven soils can be hidden, which are a potential threat to equipment. Metal, when resistance from the stone occurs, can even break.

- It is also worth remembering that too frozen ground causes difficulties in drilling. This means excessive labor costs, excessive fuel consumption for the drilling rig, and possible equipment breakdown. Steel screw piles require special attention. After all, steel becomes partially brittle in the cold. The same applies to cast iron tips on piles. It must be remembered that if cracks are detected, the foundation elements must be replaced.

- Do not forget also that working with metal at sub-zero temperatures can injure bare skin, namely, cause burns or frostbite.

- The concrete mixture for pouring piles also requires special handling, since ice crystals formed from water disrupt the hardening technology of the solution.

Important: based on the above features of work in winter, it is worth understanding that screw piles are best and more profitable to screw in in the summer or simply at above-zero temperatures.

However, there are a number of reasons why it is more advisable to drive screw piles in winter than in summer

However, there are a number of reasons why it is more advisable to drive screw piles in winter than in summer or at positive temperatures. These are:

- Lack of physical ability to perform work in summer;

- Short and limited construction time;

- Excessively flooded soils (quicksands) on the construction site;

- Swampy soil on the site.

In these cases, screwing in screw piles in winter is the only right solution. Therefore, in the material below we will consider the technology for performing the work.

Installation of screw piles: stages of installation work

Important: one of the advantages of installing screw piles in winter is the uniform growth of lawn grass in the spring. That is, one can only guess about any installation work on the site.

Preparing a construction site for installation of a pile-screw foundation

Snow drifts on a flat construction site prevent deep freezing of the soil, so it is recommended to remove snow in the building area immediately before installing screw piles.

Many landowners do a study of the terrain of the site, taking into account the difference in elevation, as well as test screwing at the site of future construction, in the warm season. The main advantage of carrying out this work before the onset of frost and heavy snow cover is that a test drilling specialist can, without extra effort, determine the depth of the dense layer of soil into which the screw piles will subsequently be buried, and the absence of snow cover makes it possible to assess the presence of elevation changes in the area and take them into account when planning a pile field.

Technology and principles of work execution

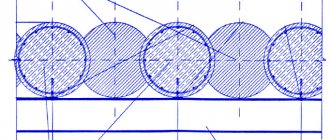

When screwing in support pillars, the most difficult section is 1.5-2 meters of soil

In order for the foundation on screw piles to be installed correctly in winter and have the optimal load-bearing capacity for construction, it is advisable to carry out all design work in the summer. It is during this period that it is possible to fully analyze the properties of the soil on the site, and therefore calculate its behavior in contact with the piles. In addition, it is in the warm season that it is advisable to make markings for support pillars. Since in winter it is more difficult to lay out the foundation axes due to the snow crust.

Important: if it was not possible to do the marking in the summer, then it can be done in the winter. The main thing for this is to clear the area of snow. But don’t be too zealous, since snow is a natural heat insulator that reduces the depth of soil freezing.

Otherwise, the technology for screwing in piles will look like this:

- First of all, screw the supports. Due to the fact that the ground is frozen, screw piles will be very difficult to screw in, and therefore it is not recommended to do the work manually. It is better to use a motor drill for soil development. But it is worth remembering that it is first advisable to warm the ground with fires at the site where the support is installed. This process is quite long and labor-intensive, but it will prevent damage to the metal of the pile or drilling rig. And as a preliminary preparation of the ground for drilling, you can make special pits - sample the soil to the level of its freezing. When performing this installation stage, you should remember safety precautions and work only in protective gloves to avoid frostbite or thermal burns.

Important: when screwing in support pillars, the most difficult section is 1.5-2 meters of soil. After passing this mark, drilling will be easier, comparable to drilling in the warm season.

- After the screw piles are installed in the intended places, it is necessary to fill the voids of the pile with concrete mixture. This is necessary so that the pipe does not deform during seasonal changes in the soil (freezing/freezing). Otherwise, the support will not have its load-bearing capacity.

Important: pouring the solution at sub-zero temperatures can cause difficulties, since the main binding component, water, can crystallize. And this interferes with the quality of the solution’s hardening. The problem can be solved.

Features of winter foundation laying. Possible difficulties and ways to eliminate them.

The most popular foundation remains the strip foundation. In this case, there should be no freezing of the foundation with groundwater during the excavation process. It is also necessary to add substances to the solution to reduce the degree of concrete freezing. It will be possible to avoid rapid hardening of the solution when pouring. For this purpose, timely heating of the filling is also provided. This method violates the norms and current standards, but is also indicated in the regulatory documentation. Although severe frost will not allow heating or various additives to help avoid freezing, a truly high-quality laying is not always possible.

Working in subzero temperatures results in less productivity, more regular rest is required, and more time is needed for certain tasks. For some “wet” jobs, you can reduce the volume or even reduce their number. Accordingly, you need to use ready-made blocks produced directly at the factory. They are placed in the finished foundation pit. This foundation requires relatively little mortar, so it is possible to reduce the necessary wet work.

The foundation can be made on ready-made piles of similar concrete. When building a not very large house, it can be recommended to abandon the strip foundation for the sake of pile technology

. Often this choice is made for the construction of wooden houses. If all the rules for constructing a pile foundation are followed, it is possible to ensure strength and reliability.

Concrete piles can be bored or bored. In the first case, ready-made piles are driven into the ground, in the second, the drilled holes are filled with concrete. In winter, the first option is more preferable, because in this case you will not need to prepare and pour the solution yourself. But the disadvantages include not only the high cost, but also the high noise level during the work process.

Pouring concrete

It is necessary to add special impurities and additives to the finished concrete solution, which will contribute to better hardening of the solution

The solution to the problem of pouring mortar into a pile can be solved in several ways:

Bored piles: device technology and calculation

- Performing work at positive temperatures. But this method is not suitable for us, since we are considering the technology of installing a pile foundation in winter.

- Heating of all supports around the perimeter during the entire period of solidification of the solution. But this method is associated with certain difficulties, since the pipe pile goes into the ground, blocking access to the perimeter of the column. But heating the solution from the inside is technically difficult and expensive.

- Complete disregard for the technology of filling pipe voids with solution. This cannot be done, since the pipe may lose its geometry in the ground, which will reduce the strength of the supports.

- Adding special impurities and additives to the finished concrete solution, which will promote better hardening of the solution, reducing the possible freezing temperature of water to -20-30 degrees Celsius. This method is considered the most optimal, especially considering the large range of construction additives on the modern market.

It is worth remembering that at sub-zero temperatures it is strictly forbidden to pour solution without additives into screw piles. In this case, ice crystals in the concrete mixture are quite capable of rupturing a pipe underground. Such supports are considered defective and require mandatory replacement.

Important: the price of such drugs is quite significant. But given that you don’t need a particularly large amount of mortar mixture, you can get a high-quality and reliable foundation at low cost.

Price list

Screw piles with welded tip

Ø 57 Ø 76 Ø 89 Ø 108 Ø 133

| Name | Standard | Premium | Cold zinc + Premium | Hot zinc (Galvanized) | Installation |

| SVSN-57/200/1500 | 700 rub. | 750 rub. | 9 00 rub. | 1,200 rub. | 700 rub. |

| SVSN-57/200/2000 | 800 rub. | 950 rub. | 1,000 rub. | 1,400 rub. | 750 rub. |

| SVSN-57/200/2500 | 900 rub. | 1,050 rub. | 1,100 rub. | 1,600 rub. | 800 rub. |

| SVSN-57/200/3000 | 1,000 rub. | 1,150 rub. | 1,200 rub. | 1,700 rub. | 850 rub. |

| SVSN-57/200/3500 | 1,200 rub. | 1,250 rub. | 1,400 rub. | 1,900 rub. | 900 rub. |

| SVSN-57/200/4000 | 1,300 rub. | RUB 1,350 | 1,500 rub. | 2,200 rub. | 920 rub. |

| SVSN-57/200/4500 | 1,500 rub. | RUB 1,550 | 1,700 rub. | 2,400 rub. | 1,050 rub. |

| SVSN-57/200/5000 | 1,600 rub. | 1,650 rub. | 1,800 rub. | 2,500 rub. | 1,150 rub. |

| SVSN-57/200/5500 | 1,700 rub. | 1,850 rub. | 2,000 rub. | 2,800 rub. | 1,250 rub. |

| SVSN-57/200/6000 | 1,900 rub. | 1,950 rub. | 2,100 rub. | 3,000 rub. | 1,400 rub. |

| Name | Standard | Premium | Cold zinc + Premium | Hot zinc (Galvanized) | Installation |

| SVSN-76/250/1500 | 900 rub. | 1,050 rub. | 1,200 rub. | 1,600 rub. | 800 rub. |

| SVSN-76/250/2000 | 1,000 rub. | 1,250 rub. | 1,400 rub. | 1,800 rub. | 850 rub. |

| SVSN-76/250/2500 | 1,200 rub. | 1,450 rub. | 1,500 rub. | 2,100 rub. | 920 rub. |

| SVSN-76/250/3000 | 1,300 rub. | 1,650 rub. | 1,700 rub. | 2,400 rub. | 960 rub. |

| SVSN-76/250/3500 | 1,500 rub. | 1,850 rub. | 1,900 rub. | 2,600 rub. | RUB 1,020 |

| SVSN-76/250/4000 | 1,600 rub. | RUB 2,050 | 2,100 rub. | 2,900 rub. | 1,050 rub. |

| SVSN-76/250/4500 | 1,800 rub. | RUB 2,150 | 2,300 rub. | 3,200 rub. | 1,150 rub. |

| SVSN-76/250/5000 | 2,000 rub. | RUB 2,350 | 2,500 rub. | 3,500 rub. | 1,300 rub. |

| SVSN-76/250/5500 | 2,100 rub. | RUB 2,550 | 2,700 rub. | RUB 3,800 | RUB 1,380 |

| SVSN-76/250/6000 | 2,200 rub. | RUB 2,750 | 2,900 rub. | 4,100 rub. | RUB 1,480 |

| Name | Standard | Premium | Cold zinc + Premium | Hot zinc (Galvanized) | Installation |

| SVSN-89/250/1500 | 1,100 rub. | 1,150 rub. | 1,300 rub. | 1,600 rub. | 850 rub. |

| SVSN-89/250/2000 | 1,200 rub. | 1,250 rub. | 1,400 rub. | 1,800 rub. | 900 rub. |

| SVSN-89/250/2500 | 1,300 rub. | 1,450 rub. | 1,600 rub. | 2,300 rub. | 950 rub. |

| SVSN-89/250/3000 | 1,500 rub. | 1,650 rub. | 1,800 rub. | 2,400 rub. | 1,100 rub. |

| SVSN-89/250/3500 | 1,800 rub. | 1,850 rub. | 2,000 rub. | 2,700 rub. | 1,150 rub. |

| SVSN-89/250/4000 | 2,000 rub. | RUB 2,050 | 2,200 rub. | 3,000 rub. | 1,200 rub. |

| SVSN-89/250/4500 | 2,200 rub. | RUB 2,250 | 2,400 rub. | 3,300 rub. | 1,300 rub. |

| SVSN-89/250/5000 | 2,300 rub. | RUB 2,450 | 2,600 rub. | 3,600 rub. | 1,400 rub. |

| SVSN-89/250/5500 | 2,500 rub. | RUB 2,650 | 2,800 rub. | RUB 3,800 | 1,500 rub. |

| SVSN-89/250/6000 | 2,700 rub. | RUB 2,850 | 3,000 rub. | 4,100 rub. | 1,600 rub. |

| Name | Standard | Premium | Cold zinc + Premium | Hot zinc (Galvanized) | Installation |

| SVSN-108/300/1500 | 1,300 rub. | RUB 1,350 | 1,500 rub. | 2,200 rub. | 900 rub. |

| SVSN-108/300/2000 | 1,500 rub. | 1,650 rub. | 1,800 rub. | 2,600 rub. | 950 rub. |

| SVSN-108/300/2500 | 1,700 rub. | 1,850 rub. | 2,100 rub. | 2,900 rub. | 1,000 rub. |

| SVSN-108/300/3000 | 2,000 rub. | RUB 2,150 | 2,400 rub. | 3,400 rub. | 1,200 rub. |

| SVSN-108/300/3500 | 2,300 rub. | RUB 2,450 | 2,700 rub. | RUB 3,800 | 1,250 rub. |

| SVSN-108/300/4000 | 2,500 rub. | RUB 2,750 | 3,000 rub. | 4,300 rub. | 1,300 rub. |

| SVSN-108/300/4500 | 2,700 rub. | RUB 2,950 | 3,200 rub. | 4,700 rub. | 1,400 rub. |

| SVSN-108/300/5000 | 3,100 rub. | RUB 3,250 | 3,500 rub. | 5,200 rub. | 1,500 rub. |

| SVSN-108/300/5500 | 3,400 rub. | RUB 3,550 | RUB 3,800 | 5,600 rub. | 1,600 rub. |

| SVSN-108/300/6000 | 3,700 rub. | RUB 3,750 | 4,100 rub. | 6,000 rub. | 1,700 rub. |

| Name | Standard | Premium | Cold zinc + Premium | Hot zinc (Galvanized) | Installation |

| SVSN-133/350/1500 | 1,600 rub. | RUB 1,750 | 1,900 rub. | 2,700 rub. | 1,100 rub. |

| SVSN-133/350/2000 | 1,900 rub. | RUB 2,050 | 2,300 rub. | 3,300 rub. | 1,150 rub. |

| SVSN-133/350/2500 | 2,200 rub. | RUB 2,450 | 2,600 rub. | 3,700 rub. | 1,250 rub. |

| SVSN-133/350/3000 | 2,600 rub. | RUB 2,850 | 3,000 rub. | 4,200 rub. | 1,300 rub. |

| SVSN-133/350/3500 | 2,900 rub. | RUB 3,050 | 3,300 rub. | 3,300 rub. | RUB 1,350 |

| SVSN-133/350/4000 | 3,200 rub. | RUB 3,450 | 3,700 rub. | 5,400 rub. | 1,400 rub. |

| SVSN-133/350/4500 | 3,600 rub. | RUB 3,750 | 4,000 rub. | RUB 5,900 | 1,450 rub. |

| SVSN-133/350/5000 | RUB 3,900 | 4,050 rub. | 4,400 rub. | 6,400 rub. | RUB 1,550 |

| SVSN-133/350/5500 | 4,200 rub. | 4,450 rub. | 4,700 rub. | 7,000 rub. | 1,600 rub. |

| SVSN-133/350/6000 | 4,500 rub. | RUB 4,750 | 5,100 rub. | 7,500 rub. | 1,700 rub. |

Screw piles with cast tip

Ø 57 Ø 76 Ø 89 Ø 108 Ø 133

| Name | Standard | Premium | Cold zinc + Premium | Hot zinc (Galvanized) | Installation |

| SVLN-57/150/1500 | 900 rub. | 950 rub. | 1,100 rub. | 1,200 rub. | 700 rub. |

| SVLN-57/150/2000 | 1,000 rub. | 1,150 rub. | 1,200 rub. | 1,400 rub. | 750 rub. |

| SVLN-57/150/2500 | 1,100 rub. | 1,250 rub. | 1,300 rub. | 1,600 rub. | 800 rub. |

| SVLN-57/150/3000 | 1,200 rub. | RUB 1,350 | 1,400 rub. | 1,800 rub. | 850 rub. |

| SVLN-57/150/3500 | 1,300 rub. | 1,450 rub. | 1,500 rub. | 1,900 rub. | 900 rub. |

| SVLN-57/150/4000 | 1,500 rub. | RUB 1,550 | 1,700 rub. | 2,100 rub. | 920 rub. |

| SVLN-57/150/4500 | 1,600 rub. | 1,650 rub. | 1,800 rub. | 2,300 rub. | 1,050 rub. |

| SVLN-57/150/5000 | 1,700 rub. | RUB 1,750 | 1,900 rub. | 2,500 rub. | 1,150 rub. |

| SVLN-57/150/5500 | 1,800 rub. | 1,950 rub. | 2,000 rub. | 2,700 rub. | 1,250 rub. |

| SVLN-57/150/6000 | 1,900 rub. | RUB 2,050 | 2,200 rub. | 2,900 rub. | 1,400 rub. |

| SVLN-57/screw/1500 | 800 rub. | 950 rub. | 1,000 rub. | 1,100 rub. | 600 rub. |

| SVLN-57/screw/2000 | 1,000 rub. | 1,050 rub. | 1,100 rub. | 1,300 rub. | 650 rub. |

| SVLN-57/screw/2500 | 1,100 rub. | 1,150 rub. | 1,200 rub. | 1,500 rub. | 700 rub. |

| SVLN-57/screw/3000 | 1,200 rub. | 1,250 rub. | 1,400 rub. | 1,700 rub. | 750 rub. |

| SVLN-57/screw/3500 | 1,300 rub. | RUB 1,350 | 1,500 rub. | 1,900 rub. | 800 rub. |

| SVLN-57/screw/4000 | 1,400 rub. | RUB 1,550 | 1,600 rub. | 2,100 rub. | 820 rub. |

| SVLN-57/screw/4500 | 1,500 rub. | 1,650 rub. | 1,700 rub. | 2,200 rub. | 950 rub. |

| SVLN-57/screw/5000 | 1,600 rub. | RUB 1,750 | 1,800 rub. | 2,400 rub. | 1,050 rub. |

| SVLN-57/screw/5500 | 1,700 rub. | 1,850 rub. | 2,000 rub. | 2,600 rub. | 1,150 rub. |

| SVLN-57/screw/6000 | 1,800 rub. | 1,950 rub. | 2,100 rub. | 2,800 rub. | 1,300 rub. |

| Name | Standard | Premium | Cold zinc + Premium | Hot zinc (Galvanized) | Installation |

| SVLN-76/150/1500 | 1,100 rub. | 1,150 rub. | 1,300 rub. | 1,500 rub. | 800 rub. |

| SVLN-76/150/2000 | 1,200 rub. | RUB 1,350 | 1,400 rub. | 1,800 rub. | 850 rub. |

| SVLN-76/150/2500 | 1,400 rub. | 1,450 rub. | 1,600 rub. | 2,000 rub. | 920 rub. |

| SVLN-76/150/3000 | 1,500 rub. | 1,650 rub. | 1,700 rub. | 2,200 rub. | 960 rub. |

| SVLN-76/150/3500 | 1,700 rub. | RUB 1,750 | 1,900 rub. | 2,500 rub. | RUB 1,020 |

| SVLN-76/150/4000 | 1,800 rub. | 1,950 rub. | 2,100 rub. | 2,700 rub. | 1,050 rub. |

| SVLN-76/150/4500 | 2,000 rub. | RUB 2,050 | 2,200 rub. | 3,000 rub. | 1,150 rub. |

| SVLN-76/150/5000 | 2,100 rub. | RUB 2,250 | 2,400 rub. | 3,200 rub. | 1,300 rub. |

| SVLN-76/150/5500 | 2,300 rub. | RUB 2,350 | 2,500 rub. | 3,500 rub. | RUB 1,380 |

| SVLN-76/150/6000 | 2,400 rub. | RUB 2,550 | 2,700 rub. | 3,700 rub. | RUB 1,480 |

| SVLN-76/screw/1500 | 1,100 rub. | 1,150 rub. | 1,200 rub. | 1,400 rub. | 700 rub. |

| SVLN-76/screw/2000 | 1,200 rub. | 1,250 rub. | 1,300 rub. | 1,600 rub. | 750 rub. |

| SVLN-76/screw/2500 | 1,300 rub. | 1,450 rub. | 1,500 rub. | 1,800 rub. | 820 rub. |

| SVLN-76/screw/3000 | 1,500 rub. | 1,650 rub. | 1,700 rub. | 2,100 rub. | 860 rub. |

| SVLN-76/screw/3500 | 1,600 rub. | RUB 1,750 | 1,800 rub. | 2,300 rub. | 920 rub. |

| SVLN-76/screw/4000 | 1,700 rub. | 1,950 rub. | 2,000 rub. | 2,500 rub. | 950 rub. |

| SVLN-76/screw/4500 | 1,900 rub. | RUB 2,050 | 2,100 rub. | 2,800 rub. | 1,050 rub. |

| SVLN-76/screw/5000 | 2,000 rub. | RUB 2,150 | 2,300 rub. | 3,000 rub. | 1,200 rub. |

| SVLN-76/screw/5500 | 2,200 rub. | RUB 2,350 | 2,400 rub. | 3,200 rub. | RUB 1,280 |

| SVLN-76/screw/6000 | 2,300 rub. | RUB 2,550 | 2,600 rub. | 3,400 rub. | RUB 1,380 |

| Name | Standard | Premium | Cold zinc + Premium | Hot zinc (Galvanized) | Installation |

| SVLN-89/250/1500 | 1,400 rub. | RUB 1,550 | 1,600 rub. | 2,000 rub. | 850 rub. |

| SVLN-89/250/2000 | 1,600 rub. | RUB 1,750 | 1,800 rub. | 2,300 rub. | 900 rub. |

| SVLN-89/250/2500 | 1,700 rub. | 1,950 rub. | 2,000 rub. | 2,600 rub. | 950 rub. |

| SVLN-89/250/3000 | 2,000 rub. | RUB 2,150 | 2,200 rub. | 2,900 rub. | 1,100 rub. |

| SVLN-89/250/3500 | 2,100 rub. | RUB 2,250 | 2,400 rub. | 3,200 rub. | 1,150 rub. |

| SVLN-89/250/4000 | 2,300 rub. | RUB 2,450 | 2,600 rub. | 3,500 rub. | 1,200 rub. |

| SVLN-89/250/4500 | 2,500 rub. | RUB 2,650 | 2,800 rub. | 3,700 rub. | 1,300 rub. |

| SVLN-89/250/5000 | 2,600 rub. | RUB 2,850 | 3,000 rub. | 4,000 rub. | 1,400 rub. |

| SVLN-89/250/5500 | 2,800 rub. | RUB 3,050 | 3,200 rub. | 4,300 rub. | 1,500 rub. |

| SVLN-89/250/6000 | 3,000 rub. | RUB 3,250 | 3,400 rub. | 4,600 rub. | 1,600 rub. |

| SVLN-89/screw/1500 | 1,200 rub. | RUB 1,350 | 1,400 rub. | 1,800 rub. | 750 rub. |

| SVLN-89/screw/2000 | 1,400 rub. | RUB 1,550 | 1,600 rub. | 2,100 rub. | 800 rub. |

| SVLN-89/screw/2500 | 1,600 rub. | RUB 1,750 | 1,800 rub. | 2,300 rub. | 850 rub. |

| SVLN-89/screw/3000 | 1,800 rub. | 1,950 rub. | 2,000 rub. | 2,600 rub. | 1,000 rub. |

| SVLN-89/screw/3500 | 1,900 rub. | RUB 2,050 | 2,200 rub. | 2,900 rub. | 1,050 rub. |

| SVLN-89/screw/4000 | 2,100 rub. | RUB 2,250 | 2,400 rub. | 3,200 rub. | 1,100 rub. |

| SVLN-89/screw/4500 | 2,300 rub. | RUB 2,450 | 2,500 rub. | 3,500 rub. | 1,200 rub. |

| SVLN-89/screw/5000 | 2,400 rub. | RUB 2,650 | 2,700 rub. | RUB 3,800 | 1,300 rub. |

| SVLN-89/screw/5500 | 2,600 rub. | RUB 2,850 | 2,900 rub. | 4,100 rub. | 1,400 rub. |

| SVLN-89/screw/6000 | 2,800 rub. | RUB 3,050 | 3,100 rub. | 4,400 rub. | 1,500 rub. |

| Name | Standard | Premium | Cold zinc + Premium | Hot zinc (Galvanized) | Installation |

| SVLN-108/300/1500 | 2,000 rub. | RUB 2,150 | 2,200 rub. | 3,000 rub. | 900 rub. |

| SVLN-108/300/2000 | 2,300 rub. | RUB 2,450 | 2,500 rub. | 3,400 rub. | 950 rub. |

| SVLN-108/300/2500 | 2,500 rub. | RUB 2,750 | 2,800 rub. | RUB 3,800 | 1,000 rub. |

| SVLN-108/300/3000 | 2,800 rub. | RUB 3,050 | 3,200 rub. | 4,400 rub. | 1,200 rub. |

| SVLN-108/300/3500 | 3,100 rub. | RUB 3,350 | 3,500 rub. | 4,800 rub. | 1,250 rub. |

| SVLN-108/300/4000 | 3,400 rub. | RUB 3,650 | RUB 3,800 | 5,300 rub. | 1,300 rub. |

| SVLN-108/300/4500 | 3,700 rub. | RUB 3,950 | 4,100 rub. | 5,800 rub. | 1,400 rub. |

| SVLN-108/300/5000 | RUB 3,900 | 4,150 rub. | 4,400 rub. | 6,200 rub. | 1,500 rub. |

| SVLN-108/300/5500 | 4,200 rub. | 4,450 rub. | 4,700 rub. | 6,700 rub. | 1,600 rub. |

| SVLN-108/300/6000 | 4,500 rub. | RUB 4,750 | 5,000 rub. | 7,200 rub. | 1,700 rub. |

| SVLN-108/screw/1500 | 1,800 rub. | 1,950 rub. | 2,000 rub. | 2,600 rub. | 800 rub. |

| SVLN-108/screw/2000 | 2,100 rub. | RUB 2,250 | 2,300 rub. | 3,000 rub. | 850 rub. |

| SVLN-108/screw/2500 | 2,400 rub. | RUB 2,550 | 2,600 rub. | 3,500 rub. | 900 rub. |

| SVLN-108/screw/3000 | 2,600 rub. | RUB 2,850 | 2,900 rub. | RUB 3,900 | 1,100 rub. |

| SVLN-108/screw/3500 | 2,900 rub. | RUB 3,150 | 3,200 rub. | 4,400 rub. | 1,150 rub. |

| SVLN-108/screw/4000 | 3,200 rub. | RUB 3,450 | 3,500 rub. | 4,800 rub. | 1,200 rub. |

| SVLN-108/screw/4500 | 3,400 rub. | RUB 3,650 | RUB 3,800 | 5,200 rub. | 1,300 rub. |

| SVLN-108/screw/5000 | 3,700 rub. | RUB 3,950 | 4,100 rub. | 5,700 rub. | 1,400 rub. |

| SVLN-108/screw/5500 | 4,000 rub. | 4,250 rub. | 4,400 rub. | 6,100 rub. | 1,500 rub. |

| SVLN-108/screw/6000 | 4,300 rub. | RUB 4,550 | 4,700 rub. | 6,600 rub. | 1,600 rub. |

| Name | Standard | Premium | Cold zinc + Premium | Hot zinc (Galvanized) | Installation |

| SVLN-133/350/1500 | 2,800 rub. | RUB 2,950 | 3,000 rub. | 4,100 rub. | 1,050 rub. |

| SVLN-133/350/2000 | 3,200 rub. | RUB 3,350 | 3,400 rub. | 4,700 rub. | 1,100 rub. |

| SVLN-133/350/2500 | 3,500 rub. | RUB 3,650 | RUB 3,800 | 5,300 rub. | 1,150 rub. |

| SVLN-133/350/3000 | RUB 3,800 | 4,050 rub. | 4,100 rub. | RUB 5,900 | 1,250 rub. |

| SVLN-133/350/3500 | 4,200 rub. | RUB 4,350 | 4,500 rub. | 6,400 rub. | 1,300 rub. |

| SVLN-133/350/4000 | 4,500 rub. | RUB 4,750 | 4,900 rub. | 7,000 rub. | RUB 1,350 |

| SVLN-133/350/4500 | 4,800 rub. | RUB 5,050 | 5,200 rub. | 7,600 rub. | 1,400 rub. |

| SVLN-133/350/5000 | 5,200 rub. | RUB 5,450 | 5,600 rub. | 8,200 rub. | 1,500 rub. |

| SVLN-133/350/5500 | 5,500 rub. | RUB 5,850 | 6,000 rub. | 8,800 rub. | RUB 1,550 |

| SVLN-133/350/6000 | 5,800 rub. | 6,150 rub. | 6,400 rub. | 9,300 rub. | 1,650 rub. |

Request the exact cost of the object Call our specialist

Cost of work

Each pile will cost approximately 14-120 USD. for one pile, and the price will depend on the length and cross-section of the pile

If you are interested in how much it will cost to install a pile-screw foundation, then you need to understand that the prices for piles do not differ from summer prices. Each pile will cost approximately 14-120 USD. for one pile. Moreover, the price will depend on the length and cross-section of the pile. The price of the anti-freeze additive will be added to the cost amount. Its cost varies between 0.8-1.6 USD. for one liter. For 100 kg of dry cement, approximately 4-5 liters of additive are used.

Important: construction and installation companies are interested in clients during the winter period, since the demand for services at this time is low. Therefore, there is a chance to slightly reduce the price of the work.

Expense part of the enterprise

And the last thing (but not least) that I would like to talk about is the cost of winter installation.

So, anti-frost additives will cost you 60-100 rubles. for 1 liter, while for a hundredweight of dry cement you will spend about 4-5 liters. All other materials are purchased regardless of the time of year.

As for work, in winter it is much more difficult and inconvenient. However, due to the seasonal decline in the number of orders, construction companies try not to increase prices or increase them slightly.

In the end, I will repeat the thought already expressed above: winter installation of piles should be resorted to only in cases of extreme necessity. And, of course, contact competent specialists with experience in this type of work.