Construction conditions in most regions prevent the use of traditional types of foundation. The hydrogeological conditions of the site often place increased demands on the strength and depth of the supporting structure. The optimal solution in all such situations is considered to be a pile-slab foundation (SPF), which combines all the advantages of piles and a slab foundation.

Features of SPF

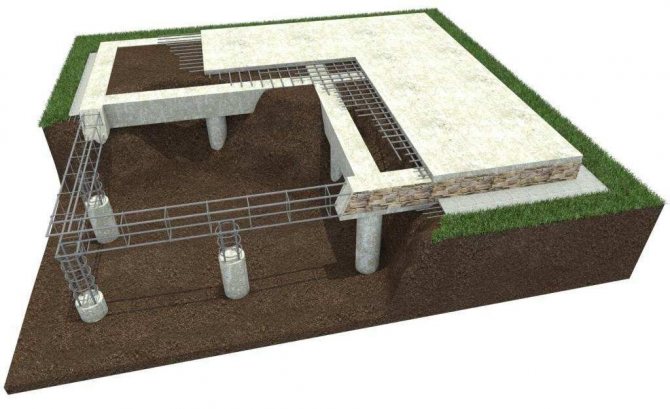

Both a pile-slab foundation and a combined pile-grillage-slab (PCS) foundation can be installed. The cost and scheme of work are almost the same in both cases. The difference between the designs is that in the first case the slab rests completely on the ground. When using a grillage, it does not come into contact with the soil; the slab is isolated from the grillage. Pile supports can be installed on a foundation or using the “suspended installation” technology. The diameter of piles for rigid installation can be much smaller than for hanging piles - in the second case, thick supports gain stability due to dense burial.

The use of a pile-slab foundation is determined by the need to achieve high rigidity and reliability of the structure, making the building resistant to translational and torsional loads. Piles can be either driven or screwed. By the way, on our website there is an excellent article about pile-screw foundations: a review of pile-screw foundations.

High pile-slab foundation.

If the base is slightly buried in the ground, it is recommended to introduce all necessary communications before the reinforcement procedure. If deep slab technology is used to arrange a basement, communications are carried out in pre-installed sleeves in the side walls.

Types of monolithic slabs with grillage

The foundation slab can be erected with two types of grillage; there are two design options, each of which has certain advantages and disadvantages:

Foundation pad with a lower grillage - when choosing this type of foundation, the surface of the slab simultaneously serves as the base of the floor for the premises of the first floor, while in such buildings it is impossible to arrange basements, and also represents the ceiling. Existing communications (water and sewer networks, distribution of heating networks and gas pipelines) have to be located in adapted premises, since there is no technical underground.

Foundation slab with an upper grillage - with this grillage arrangement option, it becomes possible to construct a basement and locate utility pipes in it. The grillage is located upward from the slab base, its height will be equal to the height of the technical underground.

Advantages and disadvantages of pile-slab foundations

The main advantage of SPF technology is the ability to install the most reliable and durable foundations for structures in seismic zones, for structures that are susceptible to vibration loads. This is also the best option for the so-called “deferred solution” - when soils, groundwater levels and other characteristics are not sufficiently studied. Thanks to special technology, significant soil removal is not required, and at the end of the work, a minimal amount of debris and waste remains.

Typical pile-slab foundation.

Disadvantages include cost and labor intensity. Compared to the pile-screw solution in low-rise construction, this option is inferior in price and ease of installation. To install the stove you will need to use special equipment. It is necessary to involve specialists in the work or to have your own significant skills in performing such work.

Read about all the pros and cons of pile foundations in a separate article:

Pros and cons of pile foundations.

Materials used

The grillage is classified according to the source material. Highlight:

- lungs (wood);

- heavy (metal, concrete).

Diagram of all elements of the foundation slab

Wood species are used to create lightweight structures. The woody type requires mandatory measures to protect against various pests and moisture.

Serious structures require the use of reliable materials such as reinforced concrete or reinforced concrete. This is the most justified grillage option. It is durable and is made directly during the main construction, which helps reduce its cost.

The use of the metal type is extremely rare. The popularity of this option is fading due to its high cost, low practicality and complex installation. Its use requires special processing, which increases the cost several times.

Scope of use of SPF

The pile-slab foundation is universal in the geography of use; it is successfully used both in permafrost conditions and in the southern regions. Often this is a more profitable solution compared to analogues - prefabricated strip and monolithic foundations.

It is advisable to use SPF in the following cases:

- When construction is carried out in an earthquake-prone area .

- On problematic soils : with significant freezing depth, on heaving soils, high level of groundwater layers. In these cases, piles are often the only reliable solution, but they can also be used subject to limitations. For massive structures with the prospect of further addition of floors, it is necessary to strengthen the piles, in particular, by tying them with slab foundations.

- In buildings sensitive to vibration loads - for example, for frame houses or walls made of foam concrete.

- When constructing extensions to existing buildings.

- In the absence of accurate data on soil characteristics, groundwater occurrence and other parameters. Construction is not an area where experimentation can be allowed, therefore it is advisable to use a reliable pile-slab foundation whenever there is doubt.

Application of SPF in onshore construction.

In the future, the use of pile-slab foundations will expand; the demand for them is already growing year by year. The unique technology allows the construction of buildings in both low- and multi-story construction quite quickly and with minimal waste.

general information

A slab foundation for individual houses and various buildings is a durable monolith made of reinforced concrete or concrete . Walls are built on these structures.

Its main advantages include the following:

- intended to create a solid foundation in areas with problematic soil , which is characterized by fairly high mobility;

- the entire load is distributed evenly , therefore, as a result, a small specific pressure is created when calculated per square meter;

- has a long service life ;

- monolith with reinforcement has high strength ;

- the surface of a slab foundation can be used as a base for the floor of a building;

- With such a foundation, houses can be built in areas where the groundwater level is too close to the ground surface. In addition, it is preferred in wetlands and places with heaving soils;

- helps prevent possible deformation of the base of the building.

The design of the slab foundation is simple and reliable . To create it you need to perform the following steps:

- Carry out calculations of the planned load on the foundation, taking into account the features of the structure design and the natural conditions of the territory.

- Take into account the freezing depth of the soil layer .

- After receiving the calculation results, select the most suitable type of slab foundation .

- Use concrete and special reinforcement that comply with all requirements and construction standards - SNiP and GOST.

- Calculate the depth of the base.

- Determine whether it is necessary to use additional reinforcing elements .

- Create a project and then a drainage system .

- Take care to create a strong cushion between the soil layer and the slab.

To build the foundation, you can use step-by-step instructions for building a slab foundation with your own hands.

Installation of pile-slab foundation

This type of foundation involves the use of two technologies - pile and slab foundations. The preparatory stage is the same for all types - cleaning the area, marking and planning the structure. Soil compaction is required to install the piles. The issues of preparing the territory for laying communications are being resolved, and a drainage system is being created.

Further stages of work:

- Excavation.

- Installation of piles.

- Slab installation.

Marking the foundation and arrangement of the pit

The marking is carried out along the axes of the pile field. The cast-offs are mounted at a distance of 1-2 m from the corners of the excavation. Cords are stretched along the axes. Lime mortar is used for contouring on each side of the pit.

Example of poured SPF

If a foundation with a grillage is used, excavation will not be necessary. With the deep slab technology, the pit is taken to a depth of 2-2.5 m, taking into account the depth of soil freezing. A shallow slab can be installed to a depth of 0.7-1 m; with a low ground or underground grillage, the excavation of the pit is carried out to a depth of 0.5 and 0.7 m, respectively.

In all cases, except for a hanging grillage, you will need to install a crushed stone or sand cushion and an insulated blind area.

Pile field manufacturing technology

The greater the number of supports, the higher the cost of the foundation. Piles should be under load-bearing walls, in corners and at the junction of adjacent walls. Supports are also installed under verandas and other extensions.

The distance between piles is calculated separately in each specific case, taking into account many parameters. As an average value, the minimum step is taken to be three diameters of the pile, the maximum is six diameters. But these are relative values; the importance of optimally calculating the number of piles cannot be underestimated, and it is better to entrust this part of the work to professionals.

Installation of piles after excavation.

Construction of a pile field includes the following steps:

- creating holes to the designed depth;

- formwork made of roofing felt, polyethylene or asbestos-cement pipes;

- reinforcement;

- concreting with mobility P4, compaction of the mixture.

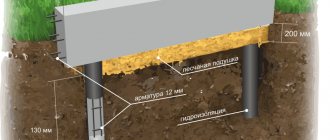

Rods with a diameter of 8-14 mm of variable cross-section are selected as reinforcement. At least 4 rods are installed on each pile of the structure. The frame is tied with clamps made of smooth reinforcement. The upper plates of the binding rods with a diameter of 6-8 mm are bent perpendicular to the surface of the earth - these ends are subsequently connected to the mesh of the grillage or slab.

Further steps can be carried out once the mixture reaches 50% strength.

Slab installation

Step-by-step model for installing a pile-slab foundation.

The plate is made in stages:

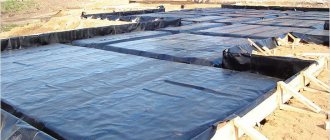

- A screed without reinforcement with a layer of up to 10 cm. Such a concrete base levels the waterproofing and protects it from tears.

- Laying a waterproofing film 0.15 cm thick.

- panel formwork is installed with a height greater than the design mark by 5-7 cm, which will allow holding the concrete mixture during the compaction process.

- Reinforcement with a variable cross-section profile with a maximum cell square of 30 cm on a side. The lower reinforcement mesh is laid on a polymer or concrete pad, its thickness is up to 4 cm. The upper part of the same configuration is laid on clamps; U-shaped ones are installed at the ends to connect the upper and lower mesh elements.

- Concrete is poured in a single direction; a rule is used for leveling. Tamping is performed using vibrators.

A separate article about slab foundations will soon be published on our website:

Review of slab foundations.

In the first week after laying and compacting the mixture, wet sand or sawdust compresses are used; it is possible to water the concrete in the hot season. In cold weather, a thermal insulator or covering film is used.

Grillage

When using a pile-grillage foundation with a slab, two types of formwork can be used:

- Fixed from loose foam. This material does not put pressure on the grillage, since it is easily compressed when the soil swells.

- Removable formwork is used only for above-ground grillage, which is installed at a height of up to 1.2 m from the ground surface. With above-ground or underground grillage, this option is not possible, since normal formwork removal will not work.

Pile-grillage foundation.

When using permanent formwork, the process is carried out similarly to concreting a monolithic reinforced slab. In this case, there is no footing; foam plastic is used instead.

If removable formwork is used, posts are used to secure the deck, serving as the basis for supporting the purlins and beams. The construction of a pile-slab foundation with a hanging grillage is the most expensive and is used extremely rarely.

Stages of construction on stilts

The construction of a pile foundation begins with marking the future foundation - the design of the pile field provided by the project is transferred to the site, after which the accuracy of the location of each support is checked. The driving places are marked with reinforcing bars, between which a string is stretched, indicating the level of the pile heads after driving.

For driving piles, special equipment is used - diesel or hydraulic piling hammers mounted on a pile driver, which is mounted on a truck chassis. Such a machine is called a pile driver; in addition to driving units, it is also equipped with a winch unit, through which the piles are moved around the site and raised to a vertical position before driving.

Rice. 1.4 : Driving construction piles

The pile driving process is performed in the following sequence:

- A coping machine is driven to the driving site.

- The installation lifts and vertically places the pile at the installation point.

- Compliance with the markings and verticality of the pile axis is checked.

- Under the influence of blows from a piling hammer, the support is driven into the ground to the designed depth or until failure occurs.

- The pile heads are aligned to the zero level.

At this point, the pile foundation can be considered ready. By additional agreement with the customer, metal plates are attached to the heads for tying with beams or channels, or the reinforcement of the piles is exposed using a pile cutter, which is necessary when tying the foundation with a reinforced concrete grillage.

Important! The performance of our equipment allows us to install up to 40 piles per work shift, which is enough to lay the foundation for a low-rise building in 2-3 working days. When working on large projects, we use several pile driving machines at once, thanks to which even large volumes of work are completed in the shortest possible time.

Cost of laying SPF

This is not the cheapest solution, but it is economically and operationally more profitable than some other traditional technologies. Without detailed calculations, no specialist will undertake to name even the approximate cost of the future structure. To roughly determine the cost, the grade of concrete, the dimensions and material of the piles, the thickness of the slab and other initial data are taken into account. It is necessary to take into account the costs of transporting building materials and operating special equipment.

House on a pile-slab foundation.

It is almost impossible to do without the services of specialists during the construction of SPF, even in private buildings; they will be needed at least at the initial (design) stage.

To at least roughly get an idea of the cost, you can add up the prices for individual parts of the structure: the average cost of a linear meter of a slab foundation is up to 5 thousand rubles, a pile foundation is 3.5-4 thousand rubles (prices are indicated at the time of publication - 2017).

Read more about the correct installation and installation of pile foundations in a separate article: Installation and installation of pile foundations.