Just like an old home, its foundation may need repairs. Any deformations or cracks in the foundation of the house cannot be ignored ─ if the foundation of such a house is not strengthened in time, then it is in danger of real destruction. To strengthen the foundation comprehensively, you need to understand the reasons for the formation of cracks, and then choose a method for eliminating them.

The optimal way to strengthen an old foundation is to strengthen it with any type of piles: screw, bored, pressed. To strengthen the foundation, piles are used, which make it possible to evenly distribute the load from the structure; sometimes a complete replacement of the old foundation is required.

Signs of a “weak” foundation

How to determine that something is wrong with the supporting structure:

- there was an obvious asymmetry of the facade;

- cracks and crevices appeared in window and door fillings;

- the natural slope of the roof has changed;

- During maintenance and shrinkage monitoring, uneven settlement of the structures was revealed.

Defects can occur for various reasons:

- incorrect analysis of soil characteristics or complete lack of research;

- incorrect choice of diameter and length of piles (not according to the design);

- incorrect installation of poles;

- the groundwater level was not taken into account; accordingly, the structure was undermined or the piles were corroded.

If at least one of the listed signs or causes is identified, it is necessary to immediately take measures to strengthen the unstable screw foundation in order to avoid irreversible consequences in the form of cracking of the walls.

How is foundation strengthening done?

Situations often arise when, as the foundation progresses, the condition of the foundation becomes unsatisfactory: cracks form and the integrity of the structure is compromised. The main reason influencing this development of events is the use of low-quality concrete.

Another source of problems with the foundation can be the instability of the soil, which is not able to withstand the pressure of a building erected on it for a long time.

How to properly strengthen the foundation:

- reinforce the perimeter;

- strengthen corners;

- install ebb tides;

- strengthen the foundation with piles.

How to strengthen the structure

There are several ways to solve this problem:

- build a new foundation next to the house for later relocation;

- revive an existing structure.

Raising and moving a house is possible, but there are not always the means and conditions for this. In addition, the full construction of a foundation is an expensive process that requires a lot of time.

Much more often they decide to raise the house with jacks and strengthen the screw structure:

- add screw piles;

- strengthen old supports;

- add bored piles;

- pressed piles;

- drill injection method.

Reinforcement with screw piles

The easiest way is to install additional screw piles close to the existing foundation. To do this, you will have to put the house on jacks; here it is recommended to contact specialists.

Screw piles are screwed as close as possible to the house along the perimeter and under the internal walls, and a new grillage is mounted on them - a steel channel beam or I-beam (it rests on the existing frame). Thus, the building sits on a new support. After this, the base is insulated and finished.

New piping on old piles

To strengthen the foundation on screw piles for a house raised above the ground, you can use the spatial reinforcement method:

- the house is raised;

- all piles are tied together with a profiled pipe or steel angle, which connects all piles, including internal ones;

- the house is placed on a new frame.

The advantage of the method is its relative simplicity and low cost. The most important thing is to create a spatial frame that will redistribute the load on the supports.

Bored piles

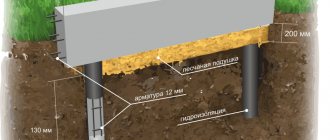

The pile foundation can be strengthened with concrete piles, which are installed directly under the house.

- for convenience, the house is raised, but you can do without this stage;

- make a preliminary calculation of strength and determine the pitch of additional supports and their location;

- holes are drilled in the ground in designated areas;

- install the reinforcement cage and pour M300-M400 concrete into the formwork.

After this, they wait for the concrete to harden (from 7 days depending on conditions), then install the grillage. By the way, you can make a monolithic reinforcement:

- bored piles are installed around the entire perimeter of the house, the previous grillage is dismantled;

- Formwork for a concrete grillage is made between the supports, the reinforcement of the piles is tied to the beam frame;

- concrete solution is poured.

The result is a new concrete pile foundation.

Indentation piles

We will not describe this method in detail, since it is similar to the arrangement of new supports, which we discussed earlier. In this case, instead of new screw piles, new concrete supports are pressed next to the foundations using special machines, onto which a new grillage is also installed.

This method is unpopular, but has a place in construction practice.

Buroinjection method

The most expensive, but also effective method of strengthening the foundation is drilling injection.

Pre-calculation of the structure is carried out. According to the new project, in specified places, a puncture is carried out on both sides with special installations at an angle of at least 30° as follows:

- the puncture is carried out on the outer and inner sides of the foundation, forming an X-shaped support;

- concrete solution is pumped under pressure;

- The reinforcement is used to tie the piles and grillage.

The drilling process is very complex and requires compliance with a number of rules and the use of equipment.

Characteristics of reinforced screw piles

If the foundation begins to collapse or it is planned to add another floor to the house, then the question arises of how to strengthen the foundation and strengthen the foundations. Reinforced screw piles 102 are ideal for these jobs. Ours has its own production and provides services for the reconstruction of foundations, due to which you can buy reinforced screw piles at a price from the manufacturer.

Reinforced piles D 102

| Pile length | Blade diameter | Price from 10 pcs. | Dealer price |

| 1500 mm | 300 mm | 2200 rub. | 2150 rub. |

| 2000 mm | 300 mm | 2400 rub. | 2350 rub. |

| 2500 mm | 300 mm | 2600 rub. | 2550 rub. |

| 3000 mm | 300 mm | 2900 rub. | 2850 rub. |

| 3500 mm | 300 mm | 3100 rub. | 3050 rub. |

| 4000 mm | 300 mm | 3400 rub. | 3350 rub. |

| 4500 mm | 300 mm | 3700 rub. | 3650 rub. |

| 5000 mm | 300 mm | 4100 rub. | 4050 rub. |

| 5500 mm | 300 mm | 4500 rub. | 4450 rub. |

| 6000 mm | 300 mm | 4900 rub. | 4850 rub. |

Price of head for screw pile ∅ 102

| Name | Size | Price from 10 pcs. | Dealer price | Installation |

| Heading | 200 mm | 200 rub. | 200 rub. | 0 rub. |

| Heading | 250 mm | 300 rub. | 300 rub. | 0 rub. |

General recommendations

There are many ways to strengthen an incorrectly calculated and constructed foundation, however, there are 3 golden rules of restoration:

- Revision and recalculation of the project is mandatory. If the piles were placed without calculation and it was not possible to guess the location of the supports and their load-bearing capacity, is it worth the risk again?

- Taking action quickly is half the battle. It is difficult to predict how quickly the deformation will develop, and this is fraught with cracking of the supporting structures, which entails the risk of destruction of the house.

- A professional approach is very important. Only experienced builders with the necessary equipment will really help restore the foundation, because in this matter accuracy is very important, from lifting the house to installing a new grillage.

Do not ignore signs of deformation and general recommendations, because the most valuable thing is at stake - your life and health.

- Foundation

Reasons for the "collapse"

The foundation of a building can collapse for several reasons:

- old age and vulnerability of the foundation from the influence of precipitation and groundwater;

- excessively increased load on the base of the building due to its reconstruction (change of facade cladding, redevelopment with the addition of massive walls, change of roofing material, completion of the attic floor, etc.);

- developer mistakes at the house design stage;

- violation of the filling process;

- a significant change in soil characteristics (waterlogging, groundwater ingress, heaving, etc.) also causes serious damage to the foundation of the building;

- carrying out excavation work in the immediate vicinity of the building;

- dynamic impacts on the building (external and internal).

What to do if there is significant foundation damage

In this case, the base as a whole should be strengthened. To consolidate soil that has exhausted its bearing capacity, methods such as cementation, resinization, silicization and roasting are provided.

Based on the type of soil, you should decide on the most optimal way to perform the work. For example, silicatization is relevant where it is necessary to strengthen large sandy or loess-like soils, resinization is good for fine sands, and cementation is good for gravelly or clayey soils.

These methods are characterized by identical technology and differ from each other only in the composition of the solution injected into the soil. Silication, for example, is characterized by the use of a sodium silicate solution, which, upon contact with the soil, “transforms” as a result of a chemical reaction into a solid, monolithic rock. By analogy, the same effect occurs during resinization, where the solution is urea resin to which hydrochloric acids are added.

To deliver the solution to the ground, special injectors are used, which are pipes driven into the ground and having perforations at the ends. Pneumatic hammers are used to drive pipes to a depth of 6 to 8 meters, and they are removed using pile drivers or hydraulic jacks.

Distinctive features are the firing technology, when a fuel mixture is placed in the soil, where it burns. Since compressed air is injected during the work, high pressure remains in the well - about 5 mPa. Injected air plays a key role in creating layers of hard rock that vary in thickness from 4 to 30 meters. It all depends on how the firing is to be carried out and in what quantity of the fuel mixture is used.

Pile installation process

To avoid the need to repair the foundation and deal with the consequences of its subsidence, it is necessary to immediately carry out installation work correctly. Fortunately, they are simple and require a minimum of effort and financial expenditure from land owners.

You should always order engineering surveys and design from professionals. Experienced professionals will be able to accurately determine the composition and characteristics of the soil, and will also select the most suitable support structures, taking into account these individual characteristics.

When the project is ready, you need to prepare places for installing piles - make shallow holes in the soil with a depth of 20 cm and a width equal to the thickness of the pipes being installed. Each pile is first immersed in a hole, and then, constantly monitoring the verticality of its location, screwed to the calculated depth into the soil.

At the next stage, the supports are cut to the same height using a grinder and concreted. After this, all that remains is to weld the heads to them and lay the grillage, that is, perform the strapping using a metal channel or wooden beam. These foundation elements also need protection from corrosion and rot.

Submit your application

PPR for installation of bored piles (BNS)

This project is intended to identify and describe the most rational solutions for constructing foundations from bored piles. Like any other organizational and technological document, the PPR for the BNS has a number of its own features that must be taken into account in the process of its development.

When calculating production methods, all fundamental conditions and factors are taken into account, which include:

- engineering and geological conditions;

- geometry of construction sites, presence of cramped conditions;

- design solutions, design conditions;

- combining work with other construction and production activities

In dry and hard soils, the “dry method” is used to install a BNS. This means that the walls of the well being drilled are stable enough to carry out concreting work without hindrance. The construction of piles in fluid-plastic soils involves the inclusion of additional measures in the PPR that make it possible to secure the soil on the inner surface of the well. To achieve these goals, as a rule, a special bentonite solution is used or casing pipes are used. For high-quality deepening of casing pipe sections, special drilling heads must be located on the surface of its cutting edge. Also, some builders use casing tables, which help immerse sections of casing pipes into the soil. For concreting a deep face after installing the reinforced frame, a vertically moved pipe (VTP) is used. In some cases, the role of the VTP is performed by the design of a special hollow screw. All these features must be taken into account as part of the development of PPR in St. Petersburg, Moscow and other regions of Russia.