Do you want to build a frame house? When deciding on the type of foundation, you should focus on a pile-screw foundation. It involves reducing the financial and physical costs of installing the foundation. Screw piles for a frame house have their own characteristics, and their installation requires a certain precision. What are these features? Let's try to figure it out.

Description of pile types

Let's first take a look at the definition of each type of pile.

About screw piles

Screw piles are hollow steel pipes with a sharp tip into which a blade is welded. When installed from the inside, they are filled with a cement-sand mixture, which prevents internal corrosion, and a cap is placed on top. To protect them from the effects of the external environment, they are coated with an anti-corrosion coating. As a rule, these are epoxy compounds or galvanization. Relatively recently, manufacturers have appeared on the market that use double corrosion protection. More on this below.

Installation of screw piles Source www.severecosrub.ru

About reinforced concrete piles

Reinforced concrete piles are a concrete rod with a reinforcement cage. For private housing construction, supports with a cross section of 150x150 mm or 200x200 mm are used. When choosing reinforced concrete piles, you need to pay attention to the grade of concrete from which they are cast and its frost resistance class. These characteristics determine how strong and durable the foundation will be.

Let's move on to comparing technologies. To do this, we will take “Standard-1” screw piles from the KKZM plant, screw piles with two-level protection of the HelixZINC series from the HelixPRO company and reinforced concrete driven piles from the manufacturer MONTAZHSVAY.RF. What aspects are we interested in? Firstly, a rational cost ratio for the planned construction, secondly, the convenience and possibility of installation for the site, thirdly, the price of components, labor and delivery.

Characteristics of screw piles

Their advantages

- The advantage of screw piles is the quick installation of the foundation from them.

- No preparatory excavation work is required on the site.

- The foundation construction technology does not require wet processes, which allows you to begin building a house immediately after installing the pile foundation.

- The cost of screw piles, together with the work required to install them, is less than the cost of bored piles and significantly less than the cost of a columnar or strip foundation.

- They can be used on many types of difficult soils, except rocky soils.

- Their use makes it possible to erect buildings on inaccessible areas, next to trees, on the slopes of the site, and near water.

- Using them, you can make extensions to finished houses without affecting the structure of the house.

- Ventilation of the subfloor of the house, preventing rotting of the wooden parts of the floor of the house.

- Piles can be reused in construction.

Disadvantages of screw piles

- Screw piles will last for more than 60 years, but if the anti-corrosion layer is damaged, their service life is halved.

- Piles in the foundation require additional reinforcement of the structure. The heads must be welded, the piles are additionally fastened together with bevels to increase rigidity and prevent vibrations of the house from internal and external influences.

- Screw piles can “sag” in the warm season, and in the cold season they can be pushed out by frozen soil, which leads to a violation of the rigidity of the house’s structure. Compliance with foundation installation technology eliminates such situations.

- Instability of screw piles in the foundation can occur when they are screwed in to a “specified depth”, and not all the way. For the reliability of a pile foundation, it is necessary to inspect the soil under the foundation and screw in the piles until they stop.

Value for money

To begin with, we note that on screw piles, as well as on reinforced concrete, you can build any type of wooden houses (frame-panel, half-timbered, timber, log), baths, garages, gazebos, outbuildings, etc. The main thing is to understand the relationship between price and quality. If you are planning to build a house for permanent or seasonal residence and the conditions on the site are good, then it’s all about the price. Please note that reinforced concrete piles have a greater load-bearing capacity compared to screw piles. But despite this, when designing, they have the same step, that is, it will not be possible to save on quantity.

Continuing my thoughts... If your plans include a bathhouse, garage or some small house, then it is more profitable to use screw piles. Now the question is: which ones? In appearance, most of them look the same, since they have a black coating on top (if we are not talking about galvanization). But coverage is different from coating, as they say. Today the price varies from 70 to 700 rubles per liter. You understand that not everything that is black protects metal from rust. It was not in vain that we paid attention to the proposal of the KKZM plant. “Standard-1” is a budget option for piles with a more or less high-quality protective coating. The manufacturer monitors compliance with technology, does not use used rolled metal, and purchases anticorrosive materials that have been proven over the years. Such piles will last more than 80 years if installed correctly. The main thing is to choose the required size. Typically, supports with a diameter of 108 mm are chosen for construction. The design department will be able to carry out calculations for a specific house.

Speaking about screw piles with double corrosion protection HelixZINC, we note that these supports have an increased service life. The manufacturer specifies 120 years of operation. The meaning of the technology is that the piles are coated with hot zinc, and on top - with an epoxy composition. For what? During installation, the top layer of the coating may be damaged by stones in the ground. At the site of chips and scratches, corrosion will occur first, which will have a detrimental effect on the foundation as a whole. The barrier layer provides a guarantee against premature destruction of the metal. Of course, galvanized piles differ in cost from regular ones. But when it comes to building a family nest, the difference will seem insignificant. But for simpler buildings, ordinary piles are also suitable.

If we are talking about building a huge wooden house with a large number of rooms, then it is better to give preference to reinforced concrete driven piles. One support can withstand loads from 9 to 60 tons depending on the section, while a screw pile has a load-bearing capacity of up to 10 tons depending on the diameter.

Reinforced concrete piles are a concrete rod with a reinforcement cage Source kkzm.ru

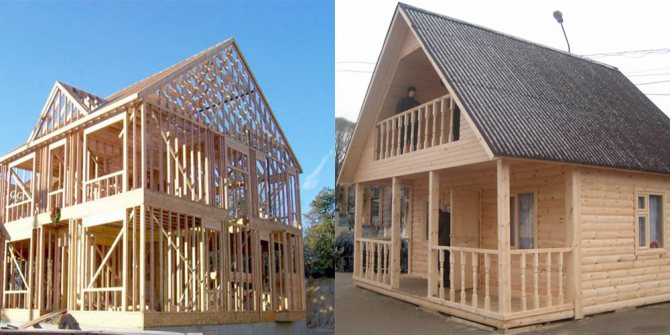

What is a frame house?

Frame houses take their name from the base of the structure - a wooden frame, which is sheathed outside and inside with special materials. For external cladding, plywood, OSB boards, lining and analogues of these materials are used. The inside walls are filled with insulation. It can be glass wool, mineral wool, polystyrene foam or polystyrene foam.

Frame houses can be built using two technologies:

Types of frame houses

- Frame-panel construction involves manual execution of all stages, including material processing and insulation. This technology is more labor-intensive, but is considered low-cost.

- Frame-panel houses are assembled from special panels, in which insulation is pre-installed. Such buildings are erected quickly, with minimal labor costs, but require large material investments.

But, like any structure, a frame house requires a reliable, good foundation. Among the huge number of options, screw piles are popular in the construction of frame houses.

Priming

Much depends on the conditions at the site. If the soil is highly acidic, then installing screw piles is dangerous, as they will quickly rot. Therefore, it is worth doing a soil test before starting construction to avoid risk.

There are areas with a large difference in ground level or water-logged soil. In this case, on the contrary, it is worth giving preference to screw piles, because during installation they can be increased until the blade reaches dense soil. In addition, due to the wide base, the screw pile will be more stable in this type of soil, where a concrete pile can simply fall deep into the ground.

How to calculate construction costs

The price of construction is determined by the density of the pile field, and this indicator depends on the operational, bearing, snow and wind load. All these parameters are determined when designing the foundation, so the work estimate is drawn up only after the completion of the project.

Moreover, the project indicates not only the number of supports, but also the depth of immersion. Based on the project data, you can select piles of the required length and diameter in the quantity required for field assembly. If we sum up the total length and multiply it by the price of a linear meter of the required diameter, we will get the approximate cost of the pipes. Add to it the price of heads and tips, and you get the cost of the material.

In addition, the estimate must take into account transportation costs, the cost of engineering and geodetic surveys and payments to workers. But even in total, these expenses do not exceed 25-30% of the cost of concrete for a strip foundation.

Delivery and installation process

Reinforced concrete piles are installed using a mini-pile driving machine. That's what they're called - driven ones. The crawler-mounted machine moves independently around the site, operates at high and low temperatures, and installs supports quite quickly. But delivering it to the site requires special equipment. However, in one shift it is possible to install about 40 reinforced concrete piles, that is, the foundation for a house.

Mini-pile driving machine drives reinforced concrete piles Source kkzm.ru

Screw piles are installed manually, electromechanically or, if absolutely necessary, using a hole drill. The best option is electromechanical installation. Today, any serious company offers it. How does this happen? Screw piles are installed using manual hydraulic machines. That is, the mounting hole is inserted into the gearbox, which creates torque. Compared to the manual method, the electromechanical method has advantages in terms of penetration and installation speed.

If the area where it is necessary to install the foundation is difficult to access for one reason or another, the only possible way is manual installation of screw piles.

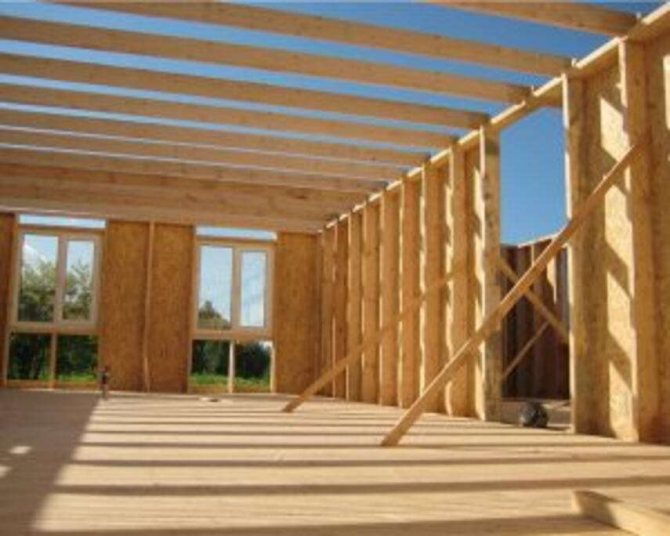

Construction of a pile foundation

The order of placement of pile supports, the depth of their immersion and the size of the section are determined by the design specifications. When designing a foundation on screw piles for a frame house, certain factors should be taken into account:

- total mass of the object;

- results of geological exploration;

- level of soil freezing;

- relief of the area allocated for construction.

Pile supports are installed in corner areas, at the intersection points of walls, along the entire perimeter and floor with interior partitions at intervals of one and a half to three meters, in places of expected loads. The piles are screwed in until they reach solid soil, but not less than the depth of freezing of the soil.

The site is preliminarily marked, and pits are installed in the places where the supports are supposed to be installed. The pile is lowered vertically, a metal rod is inserted into its hole, and levers made of steel pipes, the length of which reaches four meters, are put on.

To perform such work, at least three people will be required. Two of them will move in a circle, turning the pile support with levers, the third will have to control the vertical using a level.

Having screwed the pile supports to the required depth, their upper parts are cut to the mark of the proposed foundation. The cavities are filled with concrete mortar, which gives the supporting structure additional strength and resistance to corrosion on the internal walls of the piles.

Now comes the turn of welding the heads, the installation of which is controlled by a horizontally stretched cord or using a level. All joining areas are treated with an anti-corrosion agent.

The final working stage is associated with the arrangement of the grillage. Wooden beams or a metal corner are laid on pile heads and fixed to them with bolts. Previously, two layers of roofing felt material are laid over the heads to create waterproofing.

For frame houses, it is recommended to use timber with a cross-section of 15 by 15 cm. This size is determined by the thickness of the insulating material laid in the load-bearing walls. The wood must contain a minimum amount of moisture; before installation work begins, it should be treated with antiseptics.

Many developers do not hire construction crews to erect a frame structure, but do all the work with their own hands.

Bottom line

| Technology / Structure: | Bathhouse / Terrace / Garage | Wooden house (timber/log/frame) | Aerated concrete house (foam block, aerated concrete) | Stone house (brick, monolith) |

| Screw piles | 5 | 5 | 3 | X |

| RCC driven piles | X* | 3 | 5 | 5 |

* irrational costs

Small buildings and wooden houses made of timber or logs

Speaking about garages, bathhouses, terraces, gazebos, fences, cabins and other small and light buildings, we note that it is not rational to use reinforced concrete piles. For an ordinary timber or log house with a residential attic, screw piles are often also more preferable. But if we are talking about a large house, and you are betting on durability, then you can consider the option of a reinforced concrete driven foundation, because in the ground concrete practically does not collapse and does not deteriorate.

House made of lightweight concrete (foam blocks or aerated concrete)

For this type of building, both screw piles and reinforced reinforced concrete piles are suitable. In the first case, it is worth choosing supports of large diameter and further strengthening the foundation. In the second, it is enough to choose the right section. In addition, on reinforced concrete piles paired with a shallow grillage of 600x400 mm, you can safely build even a three-story brick house.

Brick or monolithic house

For heavy masonry structures, reinforced concrete piles are definitely recommended. Such houses weigh a lot, and the load-bearing capacity of screw piles will not be enough. Or rather, to ensure the necessary load-bearing capacity, so many of them will have to be screwed in that the cost of the foundation will be comparable to a similar concrete-driven one. In such cases, driven reinforced concrete piles should be used.

Ratings 0

Construction of a screw base for a frame house

A foundation made of screw piles can be erected with your own hands without the use of machinery. All work is performed by two or three people in several stages:

Screw base for a frame house

- To build a reliable foundation for a frame house, it is necessary to draw up a foundation project. At this stage, the required number of piles is calculated, the diameter of the products and their design are selected. The distance between the piles is also determined.

- Then the soil is examined to determine its composition and freezing depth. To obtain more accurate results, a test screwing is carried out.

- Now you need to prepare the area. The main advantage of screw piles is the ability to use them at any time of the year. Therefore, in the summer, the area is cleared of excess vegetation, and in the winter, the snow layer and broken branches are cleared off. In addition, places of possible passage of pipelines and underground cables are noted.

- According to the project, wooden pegs are placed at the locations of the piles in the prepared area. The distance between them is determined depending on the weight of the future structure. It is considered ideal to install piles at a distance of 2-2.5 meters. Instead of pegs, you can use the piles themselves, screwing them to a shallow depth.

- Before screwing the piles, depressions of up to 30 cm are made in the places where they are installed. The pile is installed in the resulting holes. For convenience, each product has a technological hole into which a piece of pipe or crowbar is inserted. They will serve as a kind of lever for screwing in the pile. It is better to use a square pipe, it is less susceptible to deformation. When screwing a pile into the ground, it is important to control the vertical position of the piles, as well as their height. Control must be carried out from the very beginning, since later leveling becomes impossible. To check the vertical, use a building level.

- When screwing piles, it is necessary to select the correct depth of depth. It all depends on the level of soil freezing. The tip of the pile should be located 30 cm below this point. It is best to immerse the piles to dense layers of soil. This can be determined by the more difficult screwing of the pile.

- After screwing in all the foundation piles for a frame house, it is necessary to carry out horizontal leveling, since it is almost impossible to maintain the same height of the piles during their screwing. Using a horizontal level, the piles are cut to the desired height using a grinder. The minimum height of piles should be 50-60 cm.

- Now it is necessary to concrete the piles. This gives them strength and also prevents corrosion of metal piles from the inside. The concrete solution should be poured in a thin stream to displace the maximum amount of air from the pipe. At the same time, you can add a solution with anti-frost properties, which will prevent the pile from breaking.

Construction of a foundation on screw piles

It is recommended to mark the area using a laser level

Before work, you will need to prepare tools for marking. If possible, it is recommended to use a laser level. This tool will ensure the greatest accuracy of the procedure.

Step-by-step instructions for arranging the foundation:

- It is necessary to mark the area and indicate the places where the piles will be located. You can use stakes for this.

- Having prepared the pits, screw in the first support. A crowbar is inserted into a special hole and a tube is put on it. This creates a lever mechanism. The pile is screwed into the soil at least 1.5 m.

- A similar procedure is performed with the remaining supports.

- When all the piles are installed, they need to be trimmed with a grinder so that they are at the same height.

- The headers are being installed. A welding machine is used for this.

Then you will need to connect the piles with a tape grillage or strapping. The most reliable design will be one that combines both of these components. The grillage is mounted similarly to a strip foundation and is a reinforced concrete strip poured into removable wooden formwork.

The strapping is used to combine supports into a common system and more evenly distribute the mass of the building. To organize it you need to stock up on quality timber. In each element I pre-saw grooves for connection. It is also important to treat the timber with compounds that protect against rotting, mold and reduce the flammability of the material. The harness can be used to lay the floor or to assemble the frame of the building.

Articles on the topic

Pros and cons of frame houses. All the pitfalls of popular technology

Materials for a frame house. What to look for and what is important to know when choosing

Do-it-yourself frame house: how to build it so that it turns out efficiently and economically

Do-it-yourself frame house: step-by-step work

Materials and fastening of cladding outside and inside frame houses

Frame and panel house designs are the most rational solution for summer cottages

Take into account the nuances when calculating a frame house: not everything is as simple as it seems