The foundation is the support of any structure. Various types of foundations are used in the construction of buildings. The choice in a particular case is determined by the characteristics of the soil at the construction site, economic feasibility, dimensions and weight of the structure being erected, and the time factor. If it is necessary to quickly build a structure on soils with weak load-bearing properties, then pile foundations are often used. The supports are either ready-made, manufactured at the factory, or manufactured on site. Pile driving is carried out using various methods. The technology for carrying out the work is different in each case. The correct choice of installation method determines the construction time, money and labor costs.

Reinforced concrete supports

What methods of immersing supports exist?

Today, there are several methods for driving piles. All methods can be divided into two large groups: shock and unstressed. The first option involves various methods of driving in support elements and is the most popular because it allows you to achieve the required load-bearing capacity of the entire structure. In addition, impact technologies are recognized as the most effective by many construction companies. The use of such methods of driving piles is mainly carried out on dense and hard soils, as well as when the diameter of the support itself is large.

Impact-free methods of immersing support elements are mainly used on loose and floodable soils. Today, there are quite a lot of technologies that make it possible to install supports as firmly as possible and ensure the durability and stability of the building in accordance with the parameters of SNIP.

The impact immersion method is represented by three main technologies:

- directly percussion;

- vibration;

- vibration shock

The shockless method of driving piles, in turn, is divided into several more technologies:

- indentation;

- screwing;

- electroosmosis;

- washing

The choice of method for immersing support structures is carried out solely on the basis of data obtained during the study of the site by engineers. Experts determine the quality of the soil, its stability, hardness, strength, flowability, etc.

Advantages

Advantages of indentation pile installation technology:

- Absence of destructive deformations of structures of neighboring buildings and structures. The absence of shock loads and vibration forces ensures the safety and integrity of historical architectural monuments, nearby highways, and utility pipelines.

- Quick installation. The pressing installation is capable of performing a full cycle of work and does not require the installation of additional equipment. The machine's performance allows you to install up to 50 pile supports in one shift.

- Minimum amount of preparatory work.

- Possibility of effective work on any soil base. To overcome weak and subsiding soils and immerse the support in a dense foundation, the indentation method makes it possible to deepen the pile to a level of over 30 meters.

- Increasing the service life of foundation structures. Statistical driving technology greatly reduces the risk of dangerous microcracks forming on the pile body, which during operation can lead to a violation of the bearing capacity of the foundation.

Using computer monitoring, it is possible to adjust the pressure of each submersible support.

The method of pressing in pile supports has virtually no disadvantages.

Main characteristics of the impact method

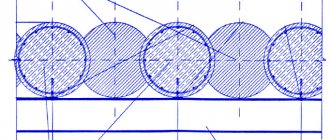

The impact method is based on the use of special equipment for driving piles. As a rule, for such purposes, special pile drivers are used, which have powerful hammers designed to drive supports into the soil. In this case, the force from the hammer blow is transmitted to the support, which acts on the layers of soil, compacting them or displacing them. This force is sufficient to ensure that the compaction is spread over an area equal in size to two or three times the diameter of the support itself.

Various types of impact rigs are used to drive support structures into the ground. Plugging units may have a rod or tubular element. Rod installations are a driving element in the form of a cylinder that moves up and down along the guides. The hammer moves downwards under the force of its gravity, and rises upwards by increasing the pressure in the combustion chamber.

The tubular installation has in its design a stationary cylindrical hammer with a guide structure called a chabot. The impact part is represented by a piston with a head, which acts on the support when fuel combustion occurs. The design is convenient in that it does not damage the upper part of the support, as often happens when using other technologies. The force imparted to the supporting structure is distributed evenly throughout the entire support.

For driving pre-prepared piles, different equipment is used, since working with ready-made supports is much easier. Driving piles using the driving method is carried out using self-propelled and rail-mounted installations, so builders first prepare the construction site, leveling it. Specially prepared piles are supports with slightly pointed ends. At the initial stage, the pace of work is chosen to be slow, since errors in the direction of the support cannot be made. After the pile is firmly immersed in the ground, the pace of driving increases.

Driving piles by screwing

This method is used only for supports that have a steel tip with blades. The rest of the structure consists of a reinforced concrete monolith. This method is used for the construction of structures that are subject to increased load (bridges, power lines). Such piles are used in soils that have a loose base or are subject to flooding. Unlike the pressing method, screwing does not require large areas; work is carried out at specific points, without creating unnecessary vibrations and noise.

The equipment necessary for driving piles using the screwing method is installed on a tractor unit and creates a torque that, with the help of a gearbox, immerses the support deeper and deeper. When entering denser soil, the possibility of reverse rotation is provided for the purpose of a slight rise. After this, the process resumes.

This technique is used for steel or reinforced concrete piles equipped with a metal tip. The procedure is carried out using mobile units that are mounted on vehicle platforms, as well as on various self-propelled vehicles. In most cases, the technique is used in the construction of foundations for masts of radio communication and power transmission networks.

The design feature of the working device makes it possible to perform the following type of operations:

- tighten the pile into the inside of the working mechanism pipe;

- maintain the required immersion angle, the limit is 0-45 degrees relative to the vertical;

- deepen the pile, applying simultaneously rotation and axial force, which can later be used to turn it out of the ground.

Having immersed the pile in the soil, the inner hole is filled with concrete mixture. The penetration time depends on the characteristics of the soil, as well as the size of the blades. It can be from 0.2 to 0.6 m/min.

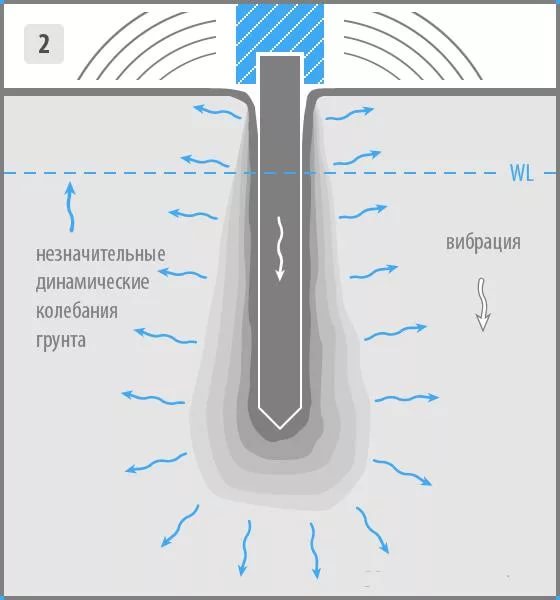

Features of the vibration method

Installation of supports with a vibratory driver involves driving the pile by imparting vibrations to it, which gradually reduce the resistance of the soil. At the same time, the soil is pushed through by the support itself. As the soil resistance decreases, the applied force also decreases. The soil compaction that occurs from driven piles can extend up to a maximum of three support diameters.

A vibratory driver is an electromechanical installation that operates on the principle of creating an imbalance of a vibrating element. The amplitude of vibrations, together with the force of gravity from the mass of the system, affects the soil, reducing its strength and resistance. In addition, such an impact leads to the destruction of soil layers, as a result of which the pile easily enters it. The frequency of vibrating vibrations is 400-450 per minute.

Installations with vibrating hammers, according to SNIP parameters, are best used on soil that is highly saturated with moisture. As a rule, they are used on wet sandy soils. If the soil is poorly saturated with water, a drilling rig may also be required.

How does impact driving happen?

Impact diving is carried out in the following order:

- Marks are made on the pile with dye every meter. They determine the depth of the dive.

- The pile driver delivers the pole to the installation site.

- The pile is fixed and raised to a vertical position, connected to the hammer.

- The position of the pile and its coincidence with the axis of the striker are controlled.

- Hammer strikes with 50% power until immersion of 2 meters. Then the force increases and the pile is driven to failure.

If during the driving process a deviation from the vertical is detected, the post is leveled using the side stops or winches.

Characteristics of the vibration-impact technique

Vibration-impact technology for driving piles simultaneously combines the effects of vibration and hammer blows. The strength of the statistical load is also added. During installation, the pile is installed using a unit in the right place and at the right angle so that the direction of support is clear. From above, using a cap, the pile is fixed to the vibrating element. The pile is then lifted and driven into the ground by its own weight and vibration. At the same time, the impact of the impact element occurs.

The vibration impact method can only be used with piles no longer than six meters, otherwise the support may be damaged due to increased impact.

Features of the vibration-impact method of immersion

This technique combines vibration and shock effects on the support. When carrying out construction work, the pile is simultaneously exposed to two methods, due to which the support quickly and relatively easily enters the soil. This method is used on construction sites with fairly dense soil, where another method may be ineffective.

|

|

|

|

Technique for screwing supports

The technology of screwing supports is used only in cases where screw piles are used. Their special design, containing blades, allows them to be screwed into the ground by communicating rotational movements. The convenience of the technology lies in the fact that when screwing, you do not need to use additional weights or impact.

The screwing method is mainly used in the construction of low-rise structures or installation of power lines. Introduction is carried out on loose or flooded soils. Screw supports are most often made of metal or reinforced concrete. Thanks to the positioned blades, the lower part of the support is wider, which provides the support with additional stability. The screwing method can be used even in fairly dense buildings; it does not lead to negative consequences for nearby structures.

Piling technology and its characteristics

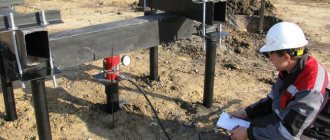

Pressing in piles requires the company to carry out labor-intensive work. It is logical that special equipment should be productive and reliable. In construction work of this type, it is advisable to use special equipment for driving piles. These are pile-pressing machines – they are usually called VCA/hydraulic pile drivers. During the operation of the installations, there is no need to use other equipment (which is also a plus). The Variator company uses STARKE YZY-320 pile driving units:

Pile driving activities are carried out according to the following simple algorithm:

- The equipment is delivered disassembled to the construction site.

- The IED is being assembled at the construction site.

- Points are being marked for the start of work and the start of using the VED.

Static immersion units have a number of objective advantages:

Useful fact: the use of IEDs makes it possible to carry out night work near residential buildings without causing inconvenience to residents.

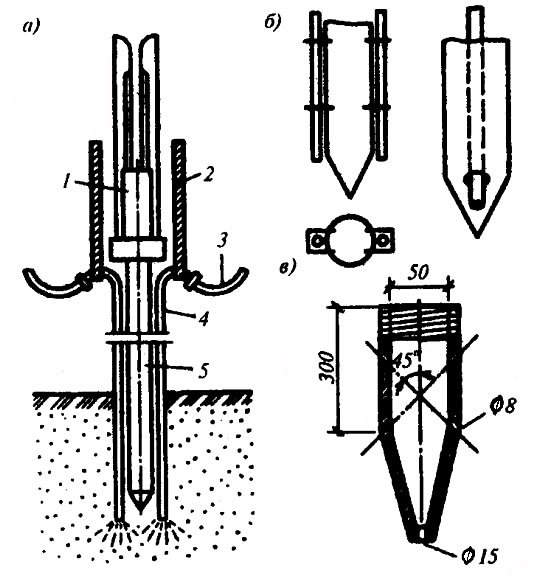

Soil washing technique

According to SNIP, in areas with loose or loose soils, installation of piles should be carried out using the soil washing technique. As a rule, in such cases, supports with a larger diameter or length are used for more reliable fastening. The essence of the technology is to erode the soil with water under high pressure. Water is supplied through large pipes in the direction of deepening the support. As a result, under the influence of the liquid, the soil is loosened, and the pile easily sinks deeper and deeper.

Pipes for supplying water are located on the sides of the support or in its very center. The tubes are attached so that they are located just above the pile itself. Water is supplied under pressure of at least 500 kPa.

According to the rules of SNIP, this method of introducing piles cannot be used in situations where, as a result of research by engineers, it was found that there are buildings or structures nearby that could be destroyed as a result of soil erosion, or if there are subsiding layers of soil on the territory.

SVU - Pile pressing installation

A hydrostatic pile driver is most often used to press piles.

This installation allows installation in the most inaccessible places and near emergency facilities. The presence of four hydraulic cylinders, divided into pairs, ensures alternate pressing of the piles, which creates a constant rotation of power and, as a result, significant energy savings. The greatest point pressure exerted on the top of the pile can reach up to one thousand two hundred tons. The operator's cabin provides a wide overview and, therefore, increases the accuracy of connecting and driving the pile.

Key priorities of a hydrostatic pile driver:

- The presence of a multi-point clamping mechanism that allows you to evenly distribute stress throughout the entire pile shaft. Allows the use of even thin tubular piles, which are easily damaged during the impact installation method.

- Eight-cylinder pile clamping box with both round and square attachments, which increases the reliability of holding the pile shaft.

- Economical energy consumption thanks to quasi-constant power.

- Accuracy of pile driving according to engineering calculations.

- Comfortable driver's cabin with wide visibility and remote control system.

Hydraulic walking chassis that performs a number of functions :

- Automatic return to the starting position if necessary;

- Uniform load distribution;

- Increases the mannerism of installation, thereby reducing labor intensity;

- Simple and quick installation, allowing you to quickly move the unit to another location.

The pile pressing installation also has the following advantages :

- Efficient and precise installation of corner and side piles.

- Providing the ability to control the vertical position of the pile and, if necessary, adjust it.

- An effective safety system that allows you to prevent an emergency when lifting a pile.

Important! The SUNWARD ZYJ320 hydrostatic pile driver has a high pile driving speed. For example, such an installation can immerse a pile twelve meters long to a depth of eleven meters in just nine seconds.

Electroosmosis technique

Electroosmosis technology involves immersing two piles at the same time. An electric current with a negative charge is connected to one, and to the other with a positive charge. Under the influence of current, moisture accumulates near the negatively charged pile, which greatly facilitates its immersion. Sometimes, to more quickly insert a pile into the ground, downhole installations are additionally used. After a power outage, the distribution of moisture in the soil is restored, as well as its resistance.

Step-by-step technology

The immersion of pile supports using the indentation method is carried out in several stages:

- Installation of pressing units at the construction site with subsequent loading of counterweights in blocks.

- Marking the installation sites for pile supports and placing pile equipment at these points.

- Lifting the support and feeding it into the clamping device of the hydrostatic pile driver.

- The process of pressing a pile into a soil mass.

At this stage, a static load is applied to the pile structure, followed by compaction of the soil around the sharp part of the submerged element.

Indentation technique

Sometimes in construction the technology of driving piles by indentation is used. As a rule, this technique is used mainly for small supports, from 3 to 5 meters long. The piles are driven using the method of static indentation. This means that the installed supports are subject to a static load, which reduces the soil resistance.

First, the push-in supports are installed in the right place and at the right angle, ensuring the correct direction. This is done using the boom of a special unit. Next, the piles are immersed by pressing, which is carried out by attaching the support to the head of the base unit. Simultaneously with the indentation method, a vibration installation can be used.

When and why is it necessary to press in piles?

The pile pressing method is especially rational to use for large volumes of piling work. If the number of supports is designed on a significant scale, then this technology will serve as an excellent solution to the installation issue. Indentation can significantly reduce the time required to carry out work, as well as the financial costs of creating the entire pile field.

Pile pressing technology

The advantages of the technology described below determine the range of construction sites where it is most readily used. In urban construction, pile driving is especially useful in the following cases:

- Construction in close proximity to old buildings and structures.

- Carrying out work in recreation areas.

- With the existing ban on impact work.

- In the proximity of neighboring existing buildings.

- In areas where landslides are possible.

- If the site has a significant terrain slope.

- Construction in historical centers.

Inspection of piles before work

The technology of vibratory driving of piles involves checking the conformity of the brand of rods and the actual dimensions of the support. The drawings indicate the modification of the element, dimensions and mark of penetration into the ground. Static and dynamic tests of racks are carried out under construction site conditions in case of doubt about design decisions.

Failures are measured on control specimens - at the end of the dive, a stopping point is set when its value approaches the calculated value, and the plunge is stopped. A collateral control of the dive is carried out, the results are recorded in the inspection log. At least 10% of the supports on site are checked and inspected this way.