November 20, 2020 Stroyexpert Home page » Foundation » By construction project

Pile foundation for garage

The foundation is the supporting structure of any structure, so it is very important to choose the right type of foundation and carry out the appropriate calculations. Foundations on piles can be called a fairly popular option for the construction of light buildings, which include garages. Widespread use is explained by a number of advantages that characterize the pile foundation:

- Firstly, construction can be carried out in any weather throughout the year.

- Secondly, labor and financial costs are minimal.

- Thirdly, the pile foundation is considered one of the most reliable and durable.

- Finally, in some cases, piles are the only option, which is most often due to the properties of the soil.

However, the construction of garages on a pile foundation has its drawbacks: the inability to arrange an inspection hole or basement and the difficulty of arranging the entrance to the garage.

Garage on a pile foundation - when to use

Quite often, the beautiful appearance of the site allocated for construction upsets the owners with the instability of the soil composition. Dense layers of soil are located at a decent depth, and getting to them is quite difficult.

In addition, there may be other structures around the proposed development, and it is not possible to use special construction equipment.

In this regard, many are building a pile foundation for a garage - a reliable and inexpensive foundation that can withstand the weight of not only the structure itself, but also additional loads.

What to prefer: screw or bladed piles?

The main types of piles: bladed and multi-turn. If the former transmit most of the load through a blade located at the end of the pile, then when using multi-turn piles, the load is evenly distributed over the entire lateral surface.

Blade piles for foundation

When installed, blade piles require surgical precision: it is necessary to conduct a full geological study of the site, which, however, does not provide a 100% guarantee against unpleasant surprises if a stone or large tree root is encountered along the way of the pile. In most cases, blade piles need to be reinforced with concrete. Therefore, it is not surprising that experts prefer to use multi-turn piles for the garage foundation.

Solid-cast multi-turn piles do not deform during installation and do not require concrete pouring, and the construction of a garage can begin immediately after installing the foundation. A high-quality screw pile is not afraid of frost, humidity and can withstand loads of up to 4.5 tons. The estimated service life of pile-screw foundation elements from the best manufacturers (such as the Korean company ACG) reaches 100 years.

Multi-turn screw piles for foundation manufactured by ACG, Korea

Let us separately focus on the zinc coating of screw piles: firstly, it protects the pile from rotting and corrosion, and, secondly, it protects your wallet from buying a fake - applying a zinc coating to a pile is possible only in high-tech production conditions.

Advantages and disadvantages

The main advantages of this type of foundation include:

- simple technology for performing work;

- low labor costs;

- significant savings in money compared to other types of foundations;

- fast construction;

- the ability to carry out construction work on a newly installed pile foundation;

- pile supports are screwed into areas with problematic soil composition;

- such supports are allowed to be installed in areas with a sloping angle;

- on a pile foundation you can build a garage building from any building material;

- minimal preparatory and excavation work.

Unfortunately, there is one significant drawback. In a garage built on pile-screw supports, it is difficult, and sometimes even impossible, to build a basement or inspection pit.

Construction technology

It is possible to build a pile foundation for a garage using a team of experienced builders. As a result, you will receive a reliable foundation prepared in accordance with the requirements. But at the same time, you will have to pay not only the cost of building materials, but also the services of specialists. But if you follow all the recommendations. It is quite possible to carry out such work on your own, while incurring minimal financial costs.

Building a garage is a serious task. The fact is that the garage must provide reliable protection for your vehicle from moisture and corrosion.

Preparation

When performing any construction work, preparatory measures are carried out. First of all, you should prepare certain tools:

- shovels;

- level and plumb;

- tape measure, level and plumb line;

- pencil;

- levers necessary for screwing in pile pillars;

- grinder;

- wooden pegs and cord;

- sledgehammer

In addition, you will need screw pile supports, grillage caps, metal reinforcement, cement, crushed stone and sand.

Marking

The construction of a pile foundation does not involve preliminary leveling of the ground surface on the site, but for the convenience of performing the work, it is recommended to remove turf and debris. After this, we determine the corner areas of the object and install pegs in these places. The recommended interval between pile supports is from one and a half to two meters, while the piles are distributed evenly throughout the area.

It remains to make pits in the places designated for installation with a depth of ten to fifteen centimeters and a width slightly exceeding the diameter of the blade of the pile support.

Installation of piles

If small-sized supports are chosen for the construction of a foundation on screw piles for a garage, then they can be installed using an ordinary crowbar inserted into the technological hole of the pile and extended with pieces of steel pipes.

As a rule, piles whose length reaches five meters are used for the construction of a garage.

Installation of support elements is carried out using one of the convenient options:

- drilling - a well is manually drilled, a pile support is immersed;

- screwing - the pile column is screwed directly into the soil composition. The support is positioned vertically, twisting is performed in the direction of the clock hand until the tip of the pile reaches a dense soil layer. To install correctly, rotate the pile below the freezing point of the soil until rotation becomes difficult.

Reinforcement

Once the installation of pile supports is completed, their upper parts are leveled. Each pile is checked with a level and cut with a grinder.

To increase the strength indicator, a reinforcement cage is installed in each support. Some people neglect this condition, because the garage does not create serious loads.

Concreting

A mandatory event. Concrete poured into the support adds strength to it and creates reliable protection for the internal walls from corrosion.

The concreting process is carried out according to the standard scheme: liquid concrete is fed into the support in a thin stream and periodically pierced with a piece of reinforcement to remove air bubbles.

Installation of heads

A head is attached to each pile. It is recommended to use welded structures, placing them on the same level. The parameters of the heads are determined by the specific gravity of the garage and the cross-section of the pile supports. It is easier and more convenient to make the heads from metal plates with a thickness of 0.8 - 1 cm and a diameter that exceeds the same size of the pile by three to four millimeters.

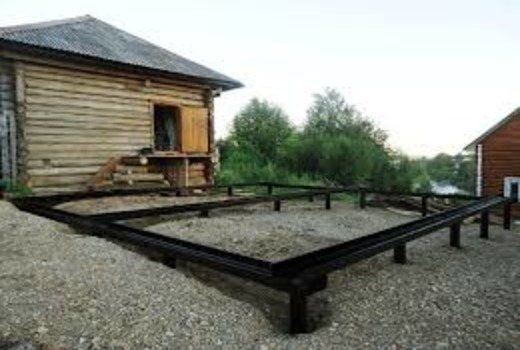

Grillage arrangement

This is the upper part of the pile-screw foundation in the form of a horizontal frame, designed to redistribute load effects and perform load-bearing functions.

Types of grillages according to materials used:

- wooden - the beams are attached to the plates with bolts or welded with metal clamps. A gap is left between such a grillage and the soil;

- concrete - a formwork structure is installed, a waterproofing layer and a reinforcing frame are installed from the inside, after which the concrete mixture is poured;

- reinforced concrete - the width of the formwork should be greater than the thickness of the proposed walls. After this, we arrange waterproofing, install the frame and fill the formwork with concrete;

- metal - the frame is made of a channel or angle.

What solutions apply in this case?

With such soil conditions, the most effective solution is to build on a pile foundation .

Foundation piles are rectangular, pyramidal, round, solid or hollow. The materials for their manufacture are reinforced concrete, concrete, wood, metal.

The pile also distinguished by a vibration protection mechanism, which is installed on top.

Existing installation options:

- retaining piles . They stand on solid ground at a great depth of burial. The technology is characterized by a complete absence of shrinkage;

- hanging piles . Used when it is impossible to reach solid ground. They are firmly driven into the moving layer and held by friction forces.

Installation methods:

- drilled and driven piles . Installed in pre-dug holes;

- piles with driven elements . Pointed piles are driven with a special installation designed for this work;

- screw piles . They are screwed into the ground like a huge screw, either automatically or manually.

What are the advantages and in what cases are they installed?

- Of all the listed methods for installing a pile foundation, the fastest is the pile-screw method.

- The use of high-quality piles from reliable manufacturers in the pile-screw method is highly valued by construction specialists.

- Such piles are used almost everywhere; they can be easily installed even in permafrost , which has made them very popular in the far north.

To carry out the work, no preparation is required before screwing the piles into the ground.

If the piles are no more than a meter long, they can be screwed in manually using a barbell or a wrench.

For example, the German one produces a large number of elements of improved shape, adapted to various foundations and soil.

Construction of a garage

Here is a classic version of a garage floor. The algorithm of actions is as follows:

- From the channel we form a system of logs laid on transverse supports. Each lag should protrude slightly beyond the frame perimeter by approximately the thickness of the wall;

- reinforcement for vehicle entry is arranged perpendicular to the log. To do this, embeds are made from the channel, laid in the wheel line;

- the entire floor plane is covered with lathing. To do this, it is recommended to use lightweight pipes, laying them in increments of forty to fifty centimeters;

- the entire floor space is covered with insulating material, a vapor barrier layer is installed, and a rough row of boards is laid.

Let's move on to arranging the walls. First of all, we install the mesh, install the frame of the entrance gate, and weld the frame structures to form a single frame.

We form a base for the roofing with one or two slopes and weld it to the overall garage structure. If there is no welding machine, you can assemble with bolts or anchors.

After this, insulation is placed in the frames, the walls are sheathed with panel material that resists moisture or steel sheets.

If it is planned to build a garage using brick or expanded clay concrete blocks on a pile foundation, a concrete grillage must be poured.

Expert advice

During the installation of a pile foundation, various problems sometimes arise. To minimize their likelihood and prevent mistakes in construction, you should follow the recommendations of experienced craftsmen:

- For the construction of the foundation, only high-quality pile supports are used, manufactured in compliance with the technology;

- when determining the location for a future garage, it is necessary to carry out a study of the soil composition so that no difficulties arise when screwing in the piles;

- each support screwed into the ground should be constantly monitored for verticality, excluding even minimal deviations;

- for ease of installation of piles, it is necessary to clear the site of debris and vegetation;

- when performing welding work, remember that the strength of the entire garage structure depends on their quality;

- if the pile being installed rests against a large stone, it is better to move the support to another place;

- welds on the piles should be treated to protect them from corrosion;

- if preliminary calculations determine that dense soil lies at great depth, it is recommended to abandon the installation of pile supports, since in this case such a foundation arrangement is irrational.

Car garage on screw piles: foundation design

A pre-designed pile field layout will help avoid mistakes when installing piles. At the beginning of the planning stage, it is necessary to determine the type of product and calculate the required quantity.

When calculating, the following factors are important:

- Type of construction of the future garage;

- Soil freezing level;

- Total weight of the structure.

For the foundation of lightweight structures, piles with a diameter of 89 or 108 millimeters are taken, and for more massive structures made of cinder block or brick, it is necessary to drive powerful piles of 133 mm.

Having drawn up a plan for the future garage, indicate the location of the piles, adhering to the basic principles:

- Supports must be installed in the corners of the structure and along its perimeter;

- A distance of at least 2 meters is maintained between them;

- They must be placed under the supports on which the garage door is hung.

Increasing their number inside the perimeter can simplify the process of making a garage floor that can withstand significant loads.