Expansion joint

The foundation is the support of a building. All her weight rests on him. The durability of the entire structure depends on its strength and reliability. To protect the foundation from destruction due to temperature changes and soil movements, an expansion joint is specially installed in the foundation. This technological solution is used in practice mainly in seismically active areas, in areas with moving soil and in the construction of large buildings. Seams are made on tape bases to protect them from deformation.

Expansion joint in foundations - types, features, design rules

As you know, the foundation is the most important part of any structure.

It takes on loads from overlying structural elements, as well as forces acting from the soil layers. During operation, the building is subject to various deformations, depending on many factors that must be taken into account at the design stage. A professional approach allows us to minimize the risks associated with significant damage to the structure and constant repairs.

In particular, the installation of expansion joints on the foundation and other structural elements makes it possible to build houses in seismically hazardous areas or in areas with complex soil structure. Seams are also necessary when constructing long buildings and massive houses.

What is an expansion joint?

The main purpose of expansion joints is to divide the structure into separate, independent blocks. In the event of an external negative impact in the form of soil or temperature fluctuations on one of the compartments of the house, the integrity of adjacent but separated sections of the building will not be affected by deformation processes. Seams relieve stress that occurs between mating areas. Structurally, they look like cuts, but functionally they play the role of compensators, eliminating practically “no” loads that appear as a result of seasonal changes. Gaps mitigate the effects of negative phenomena as much as possible.

Expansion joints installed in the foundation are divided into five groups:

- shrinkage – control the uniformity of force distribution in a monolithic slab or concrete strip, as well as the “correctness” of deformation shrinkage;

- sedimentary - reduce the risk of structure destruction when constructing a foundation on unstable and heaving soils;

- temperature – protect structures from the influence of temperature changes. Gaps are usually made in areas elevated above the ground;

- seismic - protect structures from minor vibrations of ground layers, characteristic of earthquake-prone regions;

- combined – perform several anti-deformation functions at once.

The construction of seams requires proper placement. The distance between them is determined according to the relevant standards, depending on the material used in the construction of the foundation, the type of soil that serves as the supporting foundation, as well as the massiveness and size of the structure. The standards present tables that determine the longest length from one seam to another, accepted without calculations. In addition, they contain formulas that allow you to make more accurate calculations.

An expansion joint can be found in a foundation slab and a monolithic strip; its construction is also provided for in prefabricated foundations.

The seam design can be made using various profiles. They are selected taking into account specific conditions, focusing on the most optimal option. Each seam is protected with insulating materials.

Shrink seams

This type of joint is intended for a monolithic foundation, during the construction of which a large amount of concrete mortar was used, and a reinforcement cage was installed. The fact is that the concrete mass, during curing, tends to lose moisture, which takes an active part in the processes of preparing the mixture and proper setting when the concrete gains strength. At the same time, the monolith somewhat decreases in size, as if shrinking, which leads to the formation of cracks in its body.

Shrinkage seams in a strip foundation and a large-area concrete slab eliminate the appearance of ruptures and fractures in the body of the hardening concrete mass. The pitch of the seams is determined by calculations taking into account the design features of the underground and above-ground parts of the building.

Sedimentary seam

Foundation settlement can occur for various reasons, the main ones being:

- soil layers that are dissimilar in composition and lie on the construction site;

- different number of storeys within the same building or other features that affect the uniform distribution of loads.

Areas with a homogeneous soil structure are quite rare. This is especially true in cases where the structure occupies a large area. In this situation, only a sedimentary joint can save the building from vertical displacements resulting in cracks and fractures on the facades. The construction of expansion joints prevents settlement of the stable block of the building together with the problem section located next door. Therefore, there are no distortions.

The arrangement of a sedimentary joint is required in the area where multi-story buildings meet, for example, a two-level house and a garage or terrace. The foundations, in this case, will not be rigidly connected to each other, therefore they may have different levels of foundation and even design differences. The loads for each compartment will be distributed according to their own patterns.

Features of expansion joint

In regions with a significant temperature difference between summer and winter, deformations occur inside the enclosing structures. Frosty air cools the outer surface of the walls while the interior is heated. Or vice versa. The hot sun outside heats up the walls, and the air conditioner inside keeps the house cool. In both cases, the fence is subjected to the destructive effects of internal stress, which can grow to a critical level. As a result, the walls will begin to collapse.

The construction of an expansion joint solves the problem with temperature changes, but it is used only for ground structures and the base.

A foundation located in the ground is not subject to significant fluctuations in temperature conditions, but only if its calculation is made correctly. Special cases concern heated basements in combination with a deep level of soil freezing, although foundation walls in any case will be subject to lower temperature loads compared to ground-based enclosing structures.

Shrinkage seams are often combined with temperature seams. This solution for constructing combined seams increases the efficiency of structural protection of separated sections of the building.

Features of a seismic expansion joint

Foundations erected in regions where even minor seismic loads are possible are cut into separate blocks using special expansion joints. Protection is provided on all sides of each compartment. Such seams prevent the destruction of buildings in the event of displacement of soil layers as a result of the impact of waves resulting from earthquakes.

Basic rules for constructing compensation gaps

For foundations, it is important how this or that seam will be made. There are some nuances that should be taken into account when designing it.

- Firstly, the height of the vertical gap must be equal to the height of the foundation, otherwise the whole point of carrying out the work is lost. Often the base is included in the linear dimension.

- Secondly, the distance between the structural gaps is taken depending on the material of construction of the ground part of the structure. For a wooden house, the optimal step is sixty meters, and for a brick house - fifteen meters. The soil heaving index is also taken into account. The higher it is, the smaller the distance between expansion joints.

- Thirdly, the expansion joint is made about 10cm wide for ease of insulation and waterproofing.

- Fourthly, a gap should always be provided at the boundary of extensions, even if the nearest seam is nearby.

- Fifthly, after insulation and waterproofing work, the gap must be sealed with an elastic and weather-resistant compound.

Materials for arranging seams

Materials intended for arranging seams (regardless of type and size) are subject to the same requirements. They must be resilient, elastic, easily compressible and quickly recover their shape after compression.

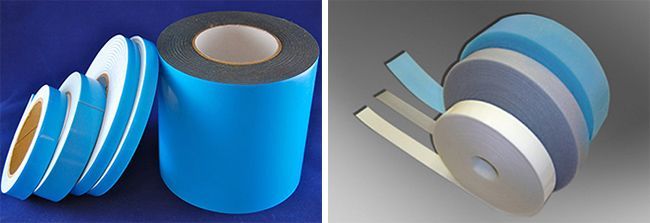

Damper tape

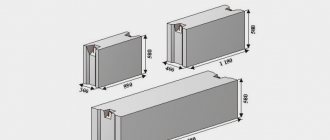

It is designed to prevent cracking of the screed during its drying process and compensate for loads from building structures (walls, columns, etc.). A wide selection of sizes (thickness: 3÷35 mm; width: 27÷250 mm) of this material allows you to equip almost any screed and concrete floors.

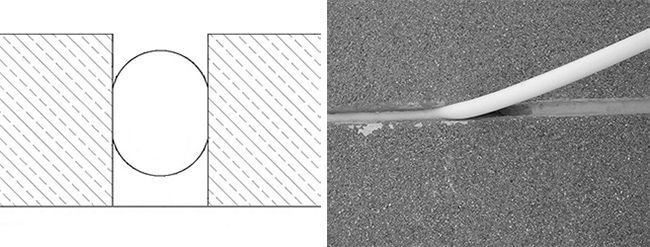

Sealing cord

A popular and easy-to-use material for filling deformation gaps is a cord made of foamed polyethylene. There are two types of it on the construction market:

- solid sealing cord Ø=6÷80 mm,

- in the form of a tube Ø=30÷120 mm.

The diameter of the cord must exceed the width of the seam by ¼÷½. The cord is installed in the groove in a compressed state and filled with ⅔÷¾ of the free volume. For example, to seal 4 mm wide grooves cut in a screed, a Ø=6 mm cord is suitable.

Sealants and mastics

Various sealants are used to seal seams:

- polyurethane;

- acrylic;

- silicone.

They come in either one-component (ready-to-use) or two-component (they are prepared by mixing the two components immediately before use). If the seam is of small width, then it is enough to fill it with sealant; if the gap width is significant, then this material is applied on top of the laid cord made of foamed polyethylene (or other damping material).

A variety of mastics (bitumen, bitumen-polymer, compositions based on raw rubber or epoxy with additives to impart elasticity) are used mainly for sealing external deformation gaps. They are applied on top of the damping material placed in the groove.

Special profiles

In modern construction, expansion joints in concrete are successfully sealed using special compensation profiles. These products come in a variety of configurations (depending on application and joint width). For their manufacture, metal, plastic, rubber are used, or several materials are combined in one device. Some models in this category must be installed during the process of pouring the solution. Others can be installed in the groove after the base has completely hardened. Manufacturers (both foreign and domestic) have developed a wide range of such devices, both for outdoor use and for indoor installation. The high price of the profiles is compensated by the fact that this method of sealing gaps does not require their subsequent waterproofing.

Expansion joint in the foundation: types and their structure

The foundation laid under a building of any size is the main load-bearing structure; it is on it that the majority of loads are placed. In this regard, special attention was paid to the high-quality implementation of such a design. When arranging the foundation, an element such as an expansion joint in the foundation deserves special consideration. It is a specially made place, the main task of which is to protect the foundation from various ground movements, as well as from sudden temperature changes.

The arrangement of elements such as expansion joints is most relevant to buildings erected in seismically hazardous areas. It is also worth noting that the component in question is usually equipped with a strip foundation. Currently, various varieties of this kind of seams are used. These include temperature-type seams, sedimentary subspecies, as well as shrinkage seams. These also include a seismic seam.

It is important to note that their arrangement completely depends on the quality of the soil on which the building will be erected, as well as on the temperature background of a particular area.

Next, we will consider what an expansion joint is, the main types of expansion joints, as well as some features of their arrangement.

Sedimentary and seismic

Seams belonging to the seismic group are installed in areas exposed to the threat of earthquakes. This is a seismically dangerous zone. The use of seams of this type is carried out to make it possible to prevent the negative effects of various types of earth vibrations. Thus, this element simply will not allow the base and walls of the building to crack.

To properly arrange them, you should, first, divide the base into several cubes that have the same side. It is important to note that seams will be made along all these edges of such cubes. They should be designed in such a way that they look like small compartments in appearance. For reliable protection from the harmful effects of temperature and excess moisture, waterproofing materials are used.

If we consider the sedimentary expansion joint of the foundation, then its arrangement should be carried out for the foundations of such buildings, which in the future will be characterized by a variable number of storeys. This is explained by the fact that usually a part of a building with fewer floors will have less impact on the foundation when compared with a larger number of floors. Seams, on the other hand, have the ability to redistribute this kind of load. Among other things, their arrangement largely prevents the occurrence of problems that may arise in cases where soil settlement occurs.

The principle of its arrangement is to divide the foundation into several units. In most cases, this also applies to the building itself. It is important that each of these seams is protected by a knot. They should also be installed on the slab of the structure being built. In fact, this can lead to increased costs for raw materials, and also require a lot of time. But it’s worth it, since a high-quality expansion joint between foundations allows you to minimize the likelihood of cracks appearing on the walls.

Protecting the blind area

So, to make expansion joints in the blind area, you need to:

- Dig a trench along the petimeter of the building. Its depth should be 15 cm. The width of the trench should be greater than the roof canopy;

- Fill the bottom of the trench with a cushion of crushed stone, and lay roofing material on top along the entire perimeter;

- Install the frame based on the reinforcement.

Before moving on to concrete work on the blind area, we will make a protective seam. It should be done on the line where the walls and the blind area connect. To organize a groove, it is enough to install boards of small thickness between the blind area and the wall. These grooves are also necessary across. This is done using the same method. You need to maintain a distance of 1.5 m.

After pouring, the concrete mixture will go where it is needed, but there will be grooves where the boards are installed. After the solution has sufficiently hardened, the wood can be pulled out. The cracks can be sealed with sealant or other means. The most important thing is that the cuts are not empty, otherwise there will be zero protection.

Expansion and shrinkage joints

As for expansion joints, which belong to the temperature class, their arrangement is relevant in those places where the climate is highly variable. Thus, in this case, temperature conditions often greatly influence the quality of the building. This condition applies to both places with extremely hot and severely cold climates.

According to the technology for arranging temperature-type joints, the entire building should be divided into several square compartments with a square shape. As for their sizes, this parameter is calculated separately using calculations. It is very convenient to carry out these actions on the stove, since in this case all the measurements obtained will become much clearer. At the same time, a number of different factors should be taken into account. This includes the seismic conditions of the area, as well as the geographical location. An important role is played by the planned parameters of the building, as well as the depth of the soil freezing level. This kind of seams is not very often installed on foundations, but many experts still recommend performing this operation. This is also explained by the fact that at different periods of time the level of soil freezing can have different depths.

The shrinkage expansion joint of a strip foundation should be used in cases where large volumes of concrete are used in the construction of foundations and the buildings themselves. This is especially true in situations where construction involves the use of a large amount of concrete poured over the monolith frame.

The above requirements are quite understandable. So, over time, concrete tends to release moisture. Thus, it is somewhat reduced in size. Often the decreases are small, but even a minor change leads to more serious deformation processes. As a result, some cracks may appear on the walls and foundation. In this regard, the arrangement of a shrinkage joint is simply mandatory in cases where a large amount of concrete is used.

Waterproofing concrete joints

There are several types of waterproofing concrete joints:

Impregnation.

The surface is treated with products containing petroleum refining substances:

- epoxy resin;

- tar;

- polymers;

- universal impregnation.

This impregnation is applied only to a well-dried surface.

Polymer waterproofing.

Surface treatment is performed with a polymer composition. Mainly used:

- acrylic dispersion;

- antiseptics;

- plasticizers.

Liquid waterproofing.

This method is somewhat different from impregnation. The amount of penetrating composition is minimal. With this method, the composition penetrates into the smallest pores of concrete. This method can be called capillary processing. As a result, the quality of the surface improves and it becomes more elastic.

Coating waterproofing.

Dry mixtures are distributed on the construction site. Since such compositions tend to harden quickly, they are diluted in minimal quantities. This technology is used only in independent residential developments.

How to arrange expansion joints

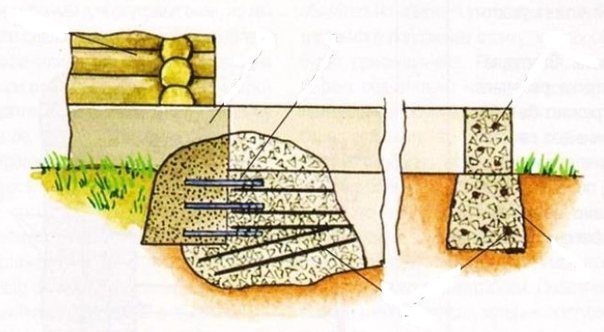

Construction of an expansion joint

To begin with, let's look at the basic rules for making each type of seam. First, you should make preliminary geodetic calculations, and based on their results, you will be able to determine what specific number is required for the construction of the foundation of your building. After this, you can begin to install expansion joints in the foundations.

At the same time, do not forget to observe some nuances:

- As for the height of each of the seams, it must be commensurate with the corresponding parameter of the foundation base. Inadmissible are those cases when the height of the resulting seams is less than the height of the foundation.

- The distance between the seams depends on what the building is planned to be built from. So, for example, if a wooden structure is built, then the best option would be a sixty-meter distance between the seams. A brick building requires a fifteen-meter distance.

Let’s define other important nuances and design features:

- If you plan to build a large building that will have at least one extension, then the corner boundaries must be provided with additional seams. So, take into account the structure of the building too.

- Seams should be made not only in the foundation strip, but in the slab itself (depending on the type of foundation). The best option for a tiled base would be tarred tow, which will successfully cope with the functions of insulation and waterproofing material. If you have a strip-type foundation, then in this case you will need to purchase separate insulation and separate waterproofing.

- Also, the construction of an expansion joint in the foundation requires a joint width of about ten centimeters. Most often this is a constant value.

- An important role is played by the blind area, which should be equipped with a wooden batten, which is filled with bitumen.

The above recommendations apply to the arrangement of seams of various types. Thus, they can be considered universal. In the process of carrying out work, you should adhere to the basic technology, and we also recommend that you do not neglect the tips given.

Expansion joints for foundations

Expansion joints for foundations

The foundation of any building of any size is the main supporting structure, which bears the entire weight of the building. That is why its quality has always been considered one of the most important features in construction. When constructing a foundation, the concept of expansion joints deserves special attention. These are specially constructed places that protect the foundation from movements of the earth’s crust and from temperature fluctuations. They are most commonly used for buildings that are being built in seismically hazardous areas. As for the type of foundation, an expansion joint is most often used with the strip type. Today, there are several types of such seams: temperature, sedimentary, seismic and shrinkage. The specific type of device directly depends on the quality of the soil on which the house stands and on the temperature conditions of the external environment.

Seismic joints between foundations are usually installed in potentially seismically hazardous areas. Their presence can prevent, to some extent, the vibration of the earth’s crust and prevent the foundation and walls of the house from cracking. To arrange them correctly, first of all it is necessary to divide the foundation into several cubes with identical sides. It is along all the edges of these conditional cubes that the seams should be made. Moreover, they should look like small compartments, reliably protected by waterproofing materials from moisture and temperature. It is advisable to install sedimentary joints for the foundations of buildings that will have a variable number of storeys. Indeed, in this case, the part of the building with fewer floors will put less pressure on the foundation than the part with more floors. And the seams are able to even out such a load. In addition, their installation can compensate for problems that arise in the event of soil settlement. The principle of the device is that both the foundation and the building itself are divided into certain units. In this case, each node must be protected by a seam. Accordingly, they need to be installed on the slab of the building. Although this will take more materials and time, in the future a high-quality expansion joint will greatly reduce the likelihood of wall cracking.

Temperature expansion joints between the foundation are best installed in areas that have a very changeable climate. That is, temperature will have a strong impact on the quality of the structure. This applies to both cold and hot climates. Based on the technology for installing expansion joints, the entire building is divided into certain square compartments, the size of which is determined by calculations. It is most convenient to do this on a stove, where the measurements will be clearer. This takes into account the geographical location, seismic conditions of the area, the dimensions of the building and the depth of soil freezing. And although such seams are usually not made on foundations, experienced builders believe that it is better to do them anyway, since the depth of freezing can vary significantly in different periods. But as for shrinkage joints, it is advisable to use them for foundations and buildings in the construction of which there is a large amount of concrete, especially if it is poured over a monolithic foundation frame.

Do-it-yourself construction of a blind area around a country house

Installing a blind area around a country house or outbuildings is a common process for a builder who equips his country house correctly. But for an ordinary summer resident who is constantly engaged in gardening and horticultural activities, this process may seem complicated.

Once we already touched on the topic of the blind area when we talked about repairing the basement, but then we only mentioned this process, practically without going into details. Today, DachaDecor specialists.

ru we decided to conduct a real excursion on the topic, and therefore we present an article from which you will learn everything about the installation of a blind area, its types, structure and even insulation and finishing.

Where in the country you may need a blind area

A blind area is needed near every major and even small building to protect its foundation and create a special slope for water drainage.

Its purpose is not at all exaggerated, since this layer, created from bulk materials and concrete, and sometimes additional compounds, shows a high degree of protection for the foundation of the building. Thanks to this, the soil does not get wet or freeze, and the foundation remains intact for many years.

Accordingly, you do not spend money on repairing the basement and do not worry that over time the walls of the house will begin to burst due to constant exposure to moisture.

Purpose of the blind area

The functions of the blind area and its tasks are obvious, but we decided to remind you of them:

- The decorative task of the blind area is to give the area, or more precisely, the narrow strip around the house, a more aesthetic and complete look. To decorate this area, concrete, stone, pebbles, paving slabs, and other materials are used;

- The protective function of the blind area is to limit the destructive effects of surface water, melt and rain, which can cause significant damage to the foundation of any building;

- The thermal insulation task of the blind area is to prevent freezing of the soil near the foundation of the building. Thanks to this, the impact on the foundation is minimized, as is the heat loss of the building, into which a large amount of cold typically penetrates through the floor;

- The blind area also prevents soil swelling, which is possible due to interaction with frost. Thus, there will be no shifts in the soil layers, and therefore no pressure on certain areas of the foundation.

It is recommended to install a blind area immediately after building a house, but it happens that its installation occurs much later. This fact is very important, although, as they say, better late than never.

Necessary characteristics of the blind area near the house

It often happens that the master seriously saves on materials and free time, due to which the blind area is only 40-50 cm wide. This is very wrong, because the minimum recommended width of the blind area is 60 cm. You can make it much larger, 90-100 cm, then the protection will be effective, and the blind area itself can additionally be used as a pedestrian path around the building.

It is also very important to take into account how much the eaves and ebbs recede from the house. They are often made wide enough to prevent water from the roof from pouring down the walls. But this means only one thing - the width of the blind area will definitely need to be increased, because according to the instructions it should be at least 20-25 cm wider than the cornices.

At this stage, I would like to remember about drainage systems that protect not only the walls, but also the blind area of the house. Consider installing a system for properly removing water from the roof, and thereby you will be able to protect the blind area that we are building today for a longer period.

Finishing the area around the building along the entire perimeter is also considered a mandatory requirement, preferably with expansion joints, expansion joints, up to 20-30 cm thick, and a slope for drainage of surface water.

Remember that in addition to the blind area, you also need to think about waterproofing the foundation, which is very important for its protection!!!

Construction of a blind area around a country house

Each stage of this process must be fully observed, because only strict adherence to the instructions and technology for laying the blind area can give the desired result. Standard savings on the process, performing work irresponsibly or ineptly, can lead to a reduction in the role of the blind area and a significant minimization of its main protective functions.

You can make many types of blind areas around a country house, as we discussed above, but today we decided to talk about the simplest type - a concrete blind area. We'll save the stone, tiles and pebbles for more expensive projects.

Territory marking

Be sure to make markings - use threads and flags to mark the height above the ground, the width of the blind area, and its uniform distance from the walls of the house, so that you don’t end up with a crooked fill. This is especially necessary if the blind area will serve as a pedestrian path.

Preparing the soil for the blind area

A very important process that can be started even after the completion of the zero cycle of building a house. But it often happens that the blind area is poured at a time when the main dacha building is already a couple of decades old, and therefore we will talk about preparing the soil in such conditions.

It is imperative to remove the plant layer, at least 20-25 cm, so that the blind area turns out to be of really high quality. So, the depth is 25 cm and the width is 90 cm, maximum cutting down of roots and high-quality soil removal evenly in this area.

It is very advisable to compact the soil well and let it settle for at least a day or two so that there is a minimum of looseness in it before installing the blind area.

A layer of sand for the blind area

It is necessary to pour a 10 cm thick layer of sand into the recess and compact it thoroughly with a special machine. If there is none, you can organize several people and have a long smoke break, for example, 30-40 minutes, while people just monotonously wander around the perimeter and trample down the sand. This is very important for the quality of the process.

For faster and more correct compaction, the layer of sand can be slightly moistened, but try to do this so that a mud porridge does not form in the recess under the formation of the blind area.

Formwork for the blind area of a country house

The formwork should be made of boards and correctly, strictly in size, secured around the perimeter. You can make stops directly into the foundation of the building and the wall around the perimeter of the recess. The main thing is that the formwork can withstand the pressure of the materials and not crumble.

For its production, you can even take construction waste (old boards and beams), but it is advisable to use high-quality formwork, which will increase operational reliability.

The formwork will also help create expansion joints along the coating if, after its installation, the perpendicular parts are left inside. This will make it possible to prevent cracking of the coating in the future. In addition, such seams every 3-6 meters will remove the load from the concrete slabs that we decided to pour, and they will not crack due to the movement of soil layers or drainage.